Professional Documents

Culture Documents

m2 U4 v2

Uploaded by

2791957Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

m2 U4 v2

Uploaded by

2791957Copyright:

Available Formats

Phase

Trade of Motor Mechanic

Module 2

Unit 4

Alternator/Circuit

Produced by

In cooperation with:

Subject Matter Experts

Martin McMahon

&

CDX Global

Curriculum Revision 2.2 16-01-07

SOLAS 2013

Module 2 - Unit 4

Alternator/Circuit

Table of Contents

Introduction......................................................................................................... 1

Unit Objective...................................................................................................... 2

1.0 Hazards when Working Charging Systems.............................................. 3

1.1

Hazards when Working Charging Systems................................... 3

2.0 Electrical Loads........................................................................................ 4

2.1 Alternator Loads............................................................................ 4

3.0 Current Load Manufacturers Data........................................................... 6

4.0 Diagram of the Charging System............................................................ 6

4.1 Schematic Block Diagrams........................................................... 6

5.0 Function of the Alternator........................................................................ 8

5.1 Charging System............................................................................ 8

5.2 Alternator Principles...................................................................... 9

6.0 Faraday's Conclusion on Electromagnetic Induction............................ 11

6.1 Faradays Laws and Flemings Right Hand Rule........................ 11

7.0 Testing a Battery Using a Voltmeter.......................................................13

7.1 Checking a Charging System.......................................................13

7.2 Using a DVOM to Measure Voltages...........................................15

8.0 Circuit Continuity Testing on the Alternator Wiring..............................17

9.0 Voltage Drop Testing on the Alternator Output Lead............................17

9.1 Voltage Drop Test.........................................................................17

10.0 Alternator Brush and Voltage Regulator Examination...........................18

11.0 Servicing an Alternator Drive Belt...........................................................18

11.1 Inspecting & Adjusting an Engine Drive Belt.............................18

11.2 Replacing an Engine Drive Belt.................................................. 23

Self Assessment................................................................................................. 27

Task Sheets........................................................................................................ 30

Checking a Charging System................................................................. 30

Removing & Replacing an Alternator.................................................... 32

Inspecting & Adjusting an Engine Drive Belt....................................... 35

Replacing an Engine Drive Belt............................................................. 40

Suggested Further Reading............................................................................... 44

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Introduction

There are six Units in this Module. In Theory 1 we cover Units 1,

2 and 3 which focuses on the basics of electricity. In Theory 2 we

cover Units 4, 5 and 6 which focuses on the fundamental electrical

circuits in the vehicle.

Module 2

Body

Electrics

Unit 4

Alternator/

Circuit

Unit 5

Starter Motor/

Circuit

Unit 6

Body Wiring

Lighting Circuits

In this Unit four it describes the basic function and operation of the

alternator and related circuits. You will receive instruction on how

Locate and calculate the total current load of the primary, constant,

long time, short time consumers of a vehicle and compare these

to the manufacturer's specifications. Draw a basic schematic block

diagram of the charging system and describe the basic function of

an alternator.

With the use of a voltmeter be able to carry out a basic charging

system test underload and off load.

Carry out circuit continuity tests on the alternator wiring. Carry

out a voltage drop test on the alternator output lead. Remove and

examine for wear alternator brushes and check the voltage regulator

assembly. Check and replace the alternator belt. Be made aware of

the danger of working with running alternator pulleys, belts etc.

and the damage to vehicle electronic circuit components by arcing/

voltage peaks. Health and safety issues related to this unit will also

be covered.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Unit Objective

By the end of this unit each apprentice will be able to:

State the primary, constant, long time and short time electrical

loads in the petrol/diesel engined automobile

Locate and calculate the total current load of the primary,

constant, long time, short time consumers of a vehicle and

compare to the manufacturers alternator specification

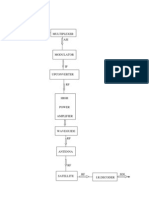

Draw a basic schematic block diagram of the charging system

(no alternator internal details)

Describe the basic function of an alternator

Describe Faradays conclusion on electromagnetic induction

Use a Voltmeter across the battery to carry out a basic charging

system voltage level underload/voltage level off load test

Carry out circuit continuity tests on the alternator wiring of

an operational vehicle

Carry out a voltage drop test on the alternator output lead of

an operational vehicle

Remove, examine for wear and replace alternator brushes and

voltage regulator assembly

Check/replace an alternator drive belt

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

1.0 Hazards when Working

Charging Systems

Key Learning Points

Danger of working with running alternator pulleys, belts

etc. Damage to vehicle electronic circuit components by

arcing/voltage peaks

1.1 Hazards when Working Charging

Systems

It is important to be aware of the potential hazards when working

an automotive charging system.Remember that the alternator is

driven by a belt and the belt rotates very quickly when the engine

is operating. Always ensure that you are aware of this when doing

any work around the alternator when the engine is running (for

instance when checking alternator output). If anything you are

wearing (including long hair gets caught in the rotating belt and other

components you could severely hurt yourself or even potentially

be killed. There is also a danger of electronic components getting

damaged from voltage peaks/arcing.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

2.0 Electrical Loads

Key Learning Points

Constant loads e.g. ignition and fuel systems; long time

loads; lights etc.; short time, starter, glow plugs etc.

2.1 Alternator Loads

Current Demand and Flow

If you have an alternator that can produce 120 amps of current

(max) and the total current demand from the electrical accessories

(including the battery) is only 20 amps, the alternator will only

produce the necessary current (20 amps) to maintain the target

voltage (which is determined by the alternator's internal voltage

regulator). Remember that the alternator monitors the electrical

system's voltage. If the voltage starts to fall below the target voltage

(approximately 13.8 volts depending on the alternator's design), the

alternator produces more current to keep the voltage up. When the

demand for current is low, the full current capacity of the alternator

is not used/produced (a 120 amp alternator does not continuously

produce 120 amps unless there is a sufficient current draw). See the

following diagram for some of examples of current demand. Refer

to automotive technical manuals for more vehicle specific data.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Short-term load

Permanent load

Per interior lamp

5W

Ignition

20W

Per flasher lamp

(indicator)

21W

Electric fuel pump

5070W

2 stop lamps

42W

Electronic petrol

injection

70100W

Per reversing lamp 21W

Long-term load

Horn

2540 W Car radio approx

10100W

Fog lamp

Rear-window

wiper

21W

Per licence-plate lamp 10W

3065W

Side lamp

Wipers.

80W

2 headlamp dip lights 110W

Cigarette lighter

100W

120W

Rear-window

heater

2 headlamp main

beams

120W

Per rear tail light

5W

5W

For diesel cars

Heater plugs for

starting (per cylinder)

100W

Power windows

150W

Electric radiator fan

200W

Starter

8003000w

Electrical Consumer Loads

Today, most systems in the average vehicle such as power windows,

power seats and power door locks are electrically powered. Typical

values for headlights would approx 10 amps and heater plugs would

be in excess of 50 amps. Initial current draw from the starter on

a diesel engine is approximately 120 amps. Refer to automotive

technical manuals for more vehicle specific data

One constant and growing challenge is the average load of the

automotive electrical system, which is increasing and is beginning

to exceed the limits of the 14-volt alternator, which typically

generates 150 amps to 180 amps. Increases the cable harness size,

power distribution box complexity, the relay and switch rating also

increases.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

3.0 Current Load Manufacturers

Data

Key Learning Points

Practical Task

Source manufacturer's data for current quantity/load value

of electrical systems

Calculation of the total current requirement of S.I. /I.C.

automotive Vehicle

This is a practical task. Please refer to your instructor for additional information,

which is available from the automotive technical manuals.

4.0 Diagram of the Charging

System

Key Learning Points

Schematic block diagram drawn to industry standard i.e.

correct terminal and component identification code/

number/symbols used.

4.1 Schematic Block Diagrams

See the following page.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Alternator/Starter Motor- Wiring Circuit

Manufacturer:

Component

G1 Alternator

H1 Alternator warning

Engine code:

lamp

AFN

31 Battery Tuned for:

30 Batter +

Model: Passat

A35 Engine control

(96-00) D TDI

Output: 81 (110) module

K270 Engine running

4150

circuits relay

Year: 1996-00

Reproduced courtesy 15 Ignition switch

- ignition ON

of Autodata

50 Ignition switch

Limited, unit

- start signal

5 priors way,

A35 Instrument panel

maidenhead,

A75 Instrumentation

England.

control module

M1 Starter motor

Volkswagen

Wiring colour Codes

bl blue

gn green

rs pink

ws white

x braided cable

br brown

gr grey

rt red

hbl light blue

y high tension

el cream

nf neutral

sw black

hgn light green

z non-cable

connection

ge yellow

og orange

vi violet

rbr maroon

Refer to Automotive technical manuals for these diagrams

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

5.0 Function of the Alternator

Key Learning Points

Alternator converting mechanical energy into electrical

energy Generating current to meet load demand

5.1 Charging System

The charging system provides electrical energy for all of the electrical

components on the vehicle.

The main parts of the charging system include, the battery, the

alternator; the voltage regulator, which is usually integral to the

alternator; a charge warning, or indicator light; and wiring that

completes the circuits.

The battery provides the electrical energy for starting. Then, once the

engine is running, the alternator supplies all electrical components

of the vehicle. It also charges the battery to replace the energy used

to start the engine. The voltage regulator prevents over-charging.

Concepts

It is important to understand that the generator creates an electric

current, but does not create electric charge, which is already present

in the conductive wire of its windings. It is somewhat analogous

to a water pump, which creates a flow of water but does not create

the water itself.

Voltage regulation is the ability of a system to provide near constant

voltage over a wide range of load conditions.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

5.2 Alternator Principles

The alternator is universally used in automotive applications. It

converts mechanical energy into electrical energy, by electromagnetic induction.

In a simple version, a bar magnet rotates in an iron yoke which

concentrates the magnetic field. A coil of wire is wound around the

stem of the yoke. As the magnet turns, voltage is induced in the

coil, producing a current flow. When the North Pole is up and South

is down, voltage is induced in the coil, producing current flow in

one direction.

As the magnet rotates and the position of the poles reverses, the

polarity of the voltage reverses too and as a result, so does the

direction of current flow.

Current that changes direction in this way is called alternating

current, or AC. The change in direction occurs once for every

complete revolution of the magnet.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Theory of Operation

Alternators generate electricity by the same principle as DC

generators. When magnetic field lines cut across a conductor, a

current is induced in the conductor. In general, an alternator has

a stationary part (stator) and a rotating part (rotor). The stator

contains windings of conductors and the rotor contains a moving

magnetic field. The field cuts across the conductors, generating an

electrical current, as the mechanical input causes the rotor to turn.

Source: Volkswagen

The rotor magnetic field may be produced by induction (in a

brushless generator), by permanent magnets, or by a rotor

winding energized with direct current through slip rings and brushes.

Automotive alternators invariably use brushes and slip rings, which

allows control of the alternator generated voltage by varying the

current in the rotor field winding. Permanent magnet machines avoid

the loss due to magnetizing current in the rotor but are restricted in

size owing to the cost of the magnet material. Since the permanent

magnet field is constant, the terminal voltage varies directly with the

speed of the generator. Brushless AC generators are usually larger

machines than those used in automotive applications.

Trade of Motor Mechanic - Phase 2 Course Notes

10

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

6.0 Faraday's Conclusion on

Electromagnetic Induction

Key Learning Points

Faraday's conclusion of EMF induction

Fleming's right-hand rule (dynamo rule)

6.1 Faradays Laws and Flemings Right

Hand Rule

Faradays Law

Any change in the magnetic environment of a coil of wire will cause

a voltage (emf - electro motive force) to be induced in the coil. No

matter how the change is produced, a voltage will be generated. The

change could be produced by changing the magnetic field strength,

moving a magnet toward or away from the coil, moving the coil

into or out of the magnetic field, rotating the coil relative to the

magnet, etc.

Electro Motive Force - EMF

The difference of potential produced by an electrical source to drive

a current through an external electrical circuit. The SI unit of emf

is the volt.

Trade of Motor Mechanic - Phase 2 Course Notes

11

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Flemings Right Hand Rule

Also known as the Generator Rule this is a way of determining the

direction of the induced emf of a conductor moving in a magnetic

field.

The thumb, the first and the second fingers on the right hand are

held so that they are at right angles to each other.

If the first finger points in the direction of the magnetic field and

the thumb in the direction of the motion of the conductor then

the second finger will point in the direction of the induced emf in

the conductor.

Trade of Motor Mechanic - Phase 2 Course Notes

12

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

7.0 Testing a Battery Using a

Voltmeter

Key Learning Points

Correct use of the multimeter

Charging system basic test; appropriate current loading used,

voltage levels compared to manufacturers specifications

7.1 Checking a Charging System

Practical Task

This is a practical task. Please refer to your instructor for additional information,

which is available from the automotive technical manuals.

Preparation and Safety

Objective

Check a charging system.

Safety Check

Make sure the bonnet stay rod is secure.

Always make sure that you wear the appropriate personal

protection equipment before starting the work. It is very easy

to hurt yourself even when the most exhaustive protection

measures are taken.

Always make sure that your work area/environment is as safe

as you can make it. Do not use damaged, broken or worn out

service department equipment.

Always follow any manufacturer's personal safety instructions

to prevent damage to the vehicle you are servicing.

Trade of Motor Mechanic - Phase 2 Course Notes

13

Revision 3.0 November 2013

Module 2 - Unit 4

Points to Note

Alternator/Circuit

Make sure that you understand and observe all legislative

and personal safety procedures when carrying out the

following tasks. If you are unsure of what these are, ask your

instructor.

DVOM stands for Digital Volt Ohm Meter.

DVOMs come in many forms. Always follow the manufacturer's

instructions in the use of the meter, or you could seriously

damage the meter or the electrical circuit.

Step-by-Step Instruction

1.

Set up the meter for a voltage check: Prepare the Digital volt ohm

meter or DVOM for testing for voltage by inserting the black

probe lead into the common input port and the red probe

lead into the Volt/Ohms input port.

2.

Check the meter function Turn the rotary dial until you have

selected the mode for Volts DC. The reading on the meter

should now be at Zero. Some meters will automatically sense

the correct voltage range when a voltage is detected. On other

meters you will have to set the voltage range before using the

meter.

3.

Check the battery voltage Place the Black probe onto the Negative

terminal of the battery, which will be marked with a Minus

sign and place the Red probe onto the Positive terminal of

the battery. This is marked with a Plus sign. Note the voltage

reading from the battery.

4.

Check the voltage after starting Start the engine. The voltage

now shown on the display should be within the 13.7 to 14.4

Volt range when the engine is running at approximately

2000RPM.

5.

Check the voltage with additional load With the engine still running,

turn the headlights of the vehicle ON and note any differences

in the reading. The meter may fluctuate a little before settling

down. Provided it retains a voltage reading within the original

specifications, the voltage regulation side of the charging

system is operating correctly.

Trade of Motor Mechanic - Phase 2 Course Notes

14

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

7.2 Using a DVOM to Measure

Voltages

Preparation and Safety

Objective

Use a DVOM to measure voltage.

Safety Check

Make sure the bonnet stay rod is secure.

Always make sure that you wear the appropriate personal

protection equipment before starting the job. It is very easy

to hurt yourself even when the most exhaustive protection

measures are taken.

Always make sure that your work area/environment is as safe

as you can make it. Do not use damaged, broken or worn out

workshop equipment.

Always follow any manufacturer's personal safety instructions

to prevent damage to the vehicle you are servicing.

Make sure that you understand and observe all legislative

and personal safety procedures when carrying out the

following tasks. If you are unsure of what these are, ask your

Instructor.

DVOM stands for Digital Volt Ohm Meter.

DVOMs come in many forms. Always follow the specific

manufacturer's instructions in the use of the meter, or serious

damage either to the meter and/or to the electrical circuit

could result.

Points to Note

Trade of Motor Mechanic - Phase 2 Course Notes

15

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Step-by-Step Instruction

1.

Set up the meter for a voltage check: Prepare the Digital Volt Ohm

Meter or DVOM for testing voltage by inserting the black

probe lead into the common input port and the red probe

lead into the Volt/Ohms input port.

2.

Check the meter function: Turn the rotary dial until you have

selected the mode for Volts DC. The reading on the meter

should now be at Zero. Some meters will automatically sense

the correct voltage range when a voltage is detected. On other

meters you will have to set the voltage range before using the

meter.

3.

Check the voltage of a battery: Place the Black probe onto the

Negative terminal of the battery, which will be marked with a

Minus sign and place the Red probe onto the Positive terminal

of the battery, which is marked with a Plus sign.

4.

Interpret the results: Note the voltage reading from this 12-volt

battery. If the battery is fully charged the meter will give a

reading that is 12.6 volts or more. If it is NOT fully charged

the reading will be less than 12.6 volts.

Trade of Motor Mechanic - Phase 2 Course Notes

16

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

8.0 Circuit Continuity Testing on

the Alternator Wiring

Key Learning Points

Practical Task

Continuity test; cables removed correctly and secured free

from shorts etc., voltage action/level compared to available

system voltage

This is a practical task. Please refer to your instructor for additional information,

which is available from the automotive technical manuals.

9.0 Voltage Drop Testing on the

Alternator Output Lead

Key Learning Points

Practical Task

Voltage drop test; voltmeter between either end of 'under

load' connector, voltage drop compared and interpreted to

manufacturer's recommended tolerances

This is a practical task. Please refer to your instructor for additional information,

which is available from the automotive technical manuals.

9.1 Voltage Drop Test

A voltage drop test is the only effective way to find excessive

resistance in high amperage circuits. It's a quick and easy test that

doesn't require any disassembly and will quickly show you whether

or not you've got a good connection or not.

To do a voltage drop test, you create a load in the circuit that's being

tested i.e. output from alternator. Then you use a digital, volt and

ohm meter (DVOM) to measure the voltage drop across the live

connection while it is under the load. Voltage always follows the

path of least resistance, so if the circuit or connection being tested

has too much resistance some of the voltage will flow through the

DVOM and create a voltage reading.

Trade of Motor Mechanic - Phase 2 Course Notes

17

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

10.0 Alternator Brush and Voltage

Regulator Examination

Key Learning Points

Practical Task

Alternator brushes examined for wear/length/spring action

etc., unit refitted/reassembled correctly, system tested for

operation

This is a practical task. Please refer to your instructor for additional information,

which is available from the automotive technical manuals.

11.0 Servicing an Alternator Drive

Belt

Key Learning Points

Practical Task

Alternator drive belt removed/examined for cracks etc.,

refitted/replaced as necessary, manual/automatic belt tension

system examined/set to manufacturer's recommendations

This is a practical task. Please refer to your instructor for additional information,

which is available from the automotive technical manuals.

11.1 Inspecting & Adjusting an Engine

Drive Belt

Preparation and Safety

Objective

Inspect and manually adjust engine accessory drive belts.

Personal Safety Whenever you perform a task in the workshop you must use personal

protective clothing and equipment that is appropriate for the task

and which conforms to your local safety regulations and policies.

Among other items, this may include:

Work clothing - such as coveralls and steel-capped footwear

Eye protection - such as safety glasses and face masks

Ear protection - such as earmuffs and earplugs

Hand protection such as rubber gloves and barrier cream

Respiratory equipment such as face masks etc.

Trade of Motor Mechanic - Phase 2 Course Notes

18

Revision 3.0 November 2013

Module 2 - Unit 4

Safety Check

Points to Note

Alternator/Circuit

Never try to inspect belts with the engine running.

Always make sure that you wear the appropriate personal

protection equipment before starting the job. It is very easy

to hurt yourself even when the most exhaustive protection

measures are taken.

Always make sure that your work area/environment is as safe

as you can make it. Do not use damaged, broken or worn out

workshop equipment.

Always follow the manufacturer's personal safety instructions

to prevent damage to the vehicle you are working on

Make sure that you understand and observe all legislative

and personal safety procedures when carrying out the

following tasks. If you are unsure of what these are, ask your

instructor.

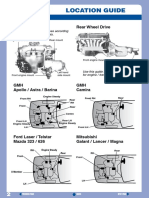

There are two types of drive belts:

V-type: A V-type belt has a profile that looks like the photo below

and sits inside a deep v-shaped groove in the pulley wheel. The sides

of the V-belt contact the sides of the groove

Serpentine: Serpentine-type belts have a flat profile with a number of

grooves running lengthwise along the belt. These grooves are the

exact reverse of the grooves in the outer edge of the pulley wheels;

they increase the contact surface area, as well as prevent the belt

from slipping off the wheel as it rotates.

Trade of Motor Mechanic - Phase 2 Course Notes

19

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Conditions to Look for on a Drive Belt

Cracked: Cracks in a belt indicate that it is getting ready to fail and

should be replaced.

Oil-soaked: A belt that has been soaked in oil will not grip properly

on the pulleys and will slip. If the oil contamination is severe enough

for this to happen, replace the belt.

Glazed: Glazing is shininess on the surface of the belt, which comes

in contact with the pulley. If the belt is worn, the glazing could be

caused by the belt "bottoming-out" (see below) and it should be

replaced. If it is not old and worn, glazing could simply indicate

that the belt is not tight enough. Tightening the belt may be all that

is necessary, depending on how bad the glazing is.

Torn: Torn or split belts are unserviceable and should be replaced

immediately.

Trade of Motor Mechanic - Phase 2 Course Notes

20

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

'Bottoming-out': When a V-type belt becomes worn, the bottom of

the V-shape may contact the bottom of the groove in the pulley,

preventing the sides of the belt from making good contact with the

sides of the pulley groove. This reduced friction causes slippage; a

belt worn enough to bottom-out should be replaced.

Manual Belt Tension versus Automatic Belt

Tension

Many vehicles require the technician to manually adjust the tension

on the belt. Other vehicles have an automatic spring tensioning

system. Depending on the system used on the particular vehicle, you

should always follow the manufacturer's service instructions.

There are a number of different types of tension gauges. Follow

the operating instructions on the tool. If you don't have a tension

gauge, you can estimate the tension by pushing the belt inwards with

your hand. If it's correctly tensioned, you should be able to deflect

the belt about 1.25 centimetres for each 30cm of belt (half an inch

for each foot).

Trade of Motor Mechanic - Phase 2 Course Notes

21

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Step-by-Step Instruction

1.

Inspect and check belt condition: Twist the belt so that you can see

the underside of the V shape or the ribs on a Serpentine belt.

Look for signs of wear and damage. You may need a flashlight

to see these clearly. A cracked or glazed or torn belt will need

to be replaced.

2.

Check tension: Check the belt tension by attaching the tension

gauge to the longest belt span and pulling it to measure the

tension. Compare your reading to the specifications in the

vehicle workshop manual.

3.

Choose the correct tools: Select the correct wrench to loosen the

tension adjustment fastener. This is usually on the Alternator

mounting or on a separate idler pulley wheel. You will also

need a pry bar, which is a metal bar you can use as a lever to

apply tension on the belt.

4.

Adjust belt tension: Loosen the adjustment fastener, then wedge

the pry bar between the alternator and a strong part of the

engine and pull in the direction that will apply tension to the

belt. Tighten the adjustment fastener.

5.

Check tension again and readjust if necessary: Check the tension

again with the gauge and if necessary loosen the fastener and

adjust the belt again until it is at the correct tension for the

vehicle.

6.

Start the engine: Start the engine and observe the belt to make

sure it is properly seated and operating correctly. Stop the

engine again and recheck the tension.

Trade of Motor Mechanic - Phase 2 Course Notes

22

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

11.2 Replacing an Engine Drive Belt

Preparation and Safety

Objective

Remove and replace an engine accessory drive belt.

Personal Safety Whenever you perform a task in the workshop you must use personal

protective clothing and equipment that is appropriate for the task

and which conforms to your local safety regulations and policies.

Among other items, this may include:

Safety Check

Work clothing - such as coveralls and steel-capped footwear

Eye protection - such as safety glasses and face masks

Ear protection - such as earmuffs and earplugs

Hand protection such as rubber gloves and barrier cream

Respiratory equipment such as face masks etc.

Never try to inspect belts with the engine running.

Always make sure that you wear the appropriate personal

protection equipment before starting the job. It is very easy

to hurt yourself even when the most exhaustive protection

measures are taken.

Always make sure that your work area/environment is as safe

as you can make it. Do not use damaged, broken or worn out

workshop equipment.

Always follow any manufacturer's instructions in relation to

personal safety and prevention of damage to the vehicle you

are working on.

Make sure that you understand and observe all legislative

and personal safety procedures when carrying out the

following tasks. If you are unsure of what these are, ask your

instructor.

Trade of Motor Mechanic - Phase 2 Course Notes

23

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

There are two types of drive belts:

V-type

A V-type belt has a profile that looks like the photo below and sits

inside a deep v-shaped groove in the pulley wheel. The sides of the

V-belt contact the sides of the groove

Serpentine

Serpentine-type belts have a flat profile with a number of grooves

running lengthwise along the belt. These grooves are the exact

reverse of the grooves in the outer edge of the pulley wheels; they

increase the contact surface area, as well as prevent the belt from

slipping off the wheel as it rotates.

Trade of Motor Mechanic - Phase 2 Course Notes

24

Revision 3.0 November 2013

Module 2 - Unit 4

'Bottomingout'

Alternator/Circuit

When a V-type belt becomes very worn, the bottom of the V-shape

may contact the bottom of the groove in the pulley, preventing the

sides of the belt from making good contact with the sides of the

pulley groove. This reduced friction causes slippage; a belt worn

enough to bottom-out should be replaced.

Many vehicles require the technician to manually adjust the tension

on the belt. Other vehicles have an automatic spring tensioning

system. Depending on the system used on the particular vehicle, you

should always follow the manufacturer's service instructions.

There are a number of different types of tension gauges. Follow

the operating instructions on the tool. If you don't have a tension

gauge, you can estimate the tension by pushing the belt inwards with

your hand. If it's correctly tensioned you should be able to deflect

the belt about 1.25 centimetres for each 30cm of belt.

Trade of Motor Mechanic - Phase 2 Course Notes

25

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Step-by-Step Instruction

1.

Loosen tension and remove belt: Locate the adjustment fastener

and loosen it. This is usually on the alternator mounting or

on a separate pulley wheel. Move the adjusting mechanism

in far enough to allow you to remove the belt. Some vehicles

use an automatic spring tension system. In that case, pull the

tensioning device back so that you can remove the belt.

2.

Inspect drive & driven pulleys: Check the drive and pulley wheels.

Look for cracks and other forms of damage. Check that

there is no sideways movement indicating worn bearings and

spin the pulley wheels by hand to check that the bearings are

rotating freely.

3.

Select correct replacement belt: Obtain the correct size and type

of replacement belt specified in the workshop manual and

compare it with the belt you have just removed. They should

be very similar, although the old belt may have stretched in

use.

4.

Install V- belt: Install the new belt, making sure that it is properly

seated in the V-shape groove, or the multiple grooves in the

pulley, depending on its construction.

5.

Install Serpentine belt: If the belt is a Serpentine type, then make

sure that it is the correct width and squarely aligned in the

pulley grooves. If it is not correctly aligned, the belt will be

thrown off the pulley wheels.

6.

Correctly tension new belt: Tension the belt using a wrench and a

pry bar and then check it with a tension gauge. With automatic

tension systems, gently allow this to apply the tension to the

belt.

7.

Start the engine: Start the engine and observe the belt to make

sure that it is properly seated and operating correctly. Stop the

engine again and recheck the tension.

Trade of Motor Mechanic - Phase 2 Course Notes

26

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Self Assessment

Q1: How many phases does a typical automotive alternator

have? (Tick one box only)

1. Three

2. Two

3. One

4. None

Q2: The main purpose of the rotor in an alternator is to:

(Tick one box only)

1. Spin very fast

2. Support end bearings

3. Produce a rotating magnetic field

4. Complete the brush circuit

Q3: The stator in an alternator is made up of:

(Tick one box only)

1. 3 phase windings and end frames

2. Laminated core and bearings

3. Laminated iron core and 3 phase windings

4. Laminated core and permanent magnets

Q4: On an alternator the main purpose of the end frames is

to: (Tick one box only)

1. Support the bearings

2. Prevent dust intrusion

3. Stop vibration

4. Insulate the alternator

Q5: How many diodes does a basic automotive alternator

rectifier have? (Tick one box only)

1. 6 positive and 6 negative

2. 1 positive and 1 negative

3. 3 positive and 3 negative

4. None

Trade of Motor Mechanic - Phase 2 Course Notes

27

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Q6: On an alternator the main purpose of the cooling fan is

to: (Tick one box only)

1. Support the pulley

2. Provide a cooling air flow

3. Support the fan belt

4. Drive the alternator

Q7: The device that converts the AC stator output to DC at

the B+ terminal on the alternator is? (Tick one box only)

1. Rectifier

2. Rotor

3. Stator

4. Regulator

Q8: What is the minimum number of diodes in the

alternator 3 phase rectifier? (Tick one box only)

1. Nine

2. Three

3. Six

4. One

Q9: The main purpose of the regulator is to:

(Tick one box only)

1. Regulate the rectifier diodes

2. Regulate alternator output by controlling field current

3. Regulate alternator speed

4. Regulate the field diodes

Q10: The maximum current output of an alternator is

regulated by? (Tick one box only)

1. The rectifier diodes

2. The regulator

3. The field diodes

4. The design of the stator winding

Trade of Motor Mechanic - Phase 2 Course Notes

28

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Q11: When the engine is not running, current to operate

electrical circuits is supplied by the: (Tick one box only)

1. Alternator

2. Battery

3. Starter

4. Light switch

Q12: The alternator converts: (Tick one box only)

1. Mechanical energy into electrical energy

2. Mechanical energy into chemical energy

3. Electrical energy into chemical energy

4. Electrical energy into mechanical energy

Q13: In a very simple alternator, what does the rotating

magnet induce in the stationary windings?

(Tick one box only)

1. A direct current flow

2. An alternating current flow

3. A variable current flow

4. A constant current flow

Trade of Motor Mechanic - Phase 2 Course Notes

29

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Task Sheets

Checking a Charging System

Preparation and Safety

Objective

Check a charging system.

Personal Safety Whenever you perform a task in the workshop you must use personal

protective clothing and equipment that is appropriate for the task

and which conforms to your local safety regulations and policies.

Among other items, this may include:

Safety Check

Work clothing - such as coveralls and steel-capped footwear

Eye protection - such as safety glasses and face masks

Ear protection - such as earmuffs and earplugs

Hand protection such as rubber gloves and barrier cream

Respiratory equipment such as face masks etc.

Make sure the bonnet rod is secure.

Always make sure that you wear the appropriate personal

protection equipment before starting the job. It is very easy

to hurt yourself even when the most exhaustive protection

measures are taken.

Always make sure that your work area/environment is as safe

as you can make it. Do not use damaged, broken or worn out

service department equipment.

Always follow any manufacturer's personal safety instructions

to prevent damage to the vehicle you are servicing.

Make sure that you understand and observe all legislative

and personal safety procedures when carrying out the

following tasks. If you are unsure of what these are, ask your

instructor.

Trade of Motor Mechanic - Phase 2 Course Notes

30

Revision 3.0 November 2013

Module 2 - Unit 4

Points to Note

Alternator/Circuit

DVOM stands for Digital Volt Ohm Meter.

DVOMs come in many forms. Always follow the manufacturer's

instructions in the use of the meter, or you could seriously

damage the meter or the electrical circuit.

Step-by-step Instruction

1.

Set up the meter for a voltage check: Prepare the Digital volt ohm

meter or DVOM for testing for voltage by inserting the black

probe lead into the common input port and the red probe

lead into the Volt/Ohms input port.

2.

Check the meter function: Turn the rotary dial until you have

selected the mode for Volts DC. The reading on the meter

should now be at Zero. Some meters will automatically sense

the correct voltage range when a voltage is detected. On other

meters you will have to set the voltage range before using the

meter.

3.

Check the battery voltage: Place the Black probe onto the Negative

terminal of the battery, which will be marked with a Minus

sign and place the Red probe onto the Positive terminal of

the battery. This is marked with a Plus sign. Note the voltage

reading from the battery.

4.

Check the voltage after starting: Start the engine. The voltage

now shown on the display should be within the 13.7 to 14.4

Volt range when the engine is running at approximately

2000RPM.

5.

Check the voltage with additional load: With the engine still

running, turn the headlights of the vehicle ON and note any

differences in the reading. The meter may fluctuate a little

before settling down. Provided it retains a voltage reading

within the original specifications, the voltage regulation side

of the charging system is operating correctly.

Trade of Motor Mechanic - Phase 2 Course Notes

31

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

6.

Carry out load test: Place an ammeter in series by clamping it

over the cable, in accordance with equipment manufacturers

instructions, between the AC generator output terminal and the

positive battery terminal and connect a carbon pile regulator

across the battery terminals. Operate the engine at about

2500 RPM and adjust the carbon pile to obtain maximum

current output. This reading should be compared against the

alternators rated output. Normally, readings more than 10

amperes out of specifications indicate a problem.

Removing & Replacing an Alternator

Preparation and Safety

Objective

Safely remove and replace a vehicles alternator.

Personal Safety Whenever you perform a task in the workshop you must use personal

protective clothing and equipment that is appropriate for the task

and which conforms to your local safety regulations and policies.

Among other items, this may include:

Safety Check

Work clothing - such as coveralls and steel-capped footwear

Eye protection - such as safety glasses and face masks

Ear protection - such as earmuffs and earplugs

Hand protection such as rubber gloves and barrier cream

Respiratory equipment such as face masks etc.

When disconnecting a battery always disconnect the negative

terminal first.

When reattaching a battery always attach the negative terminal

last.

Trade of Motor Mechanic - Phase 2 Course Notes

32

Revision 3.0 November 2013

Module 2 - Unit 4

Points to Note

Alternator/Circuit

Do not wear jewellery that may cause a short circuit with an

electrical connection.

Alternators produce heat when operating. Make sure you test

the temperature of the alternator before you handle it.

Always wear protective clothing and the appropriate safety

equipment.

Make sure that you understand and observe all legislative

and personal safety procedures when carrying out the

following tasks. If you are unsure of what these are, ask your

instructor.

Vehicle alternators are designed for use only on a negative

earth system.

The alternator must not be operated with the battery

disconnected or the terminals at the back of the alternator

disconnected.

Do not short circuit the alternator by connecting the battery

connection directly to the engine or vehicle body.

Even though most vehicle electrical systems are described as

being 12 volt, they operate at between 13.8 to 14.2 volts. If

the system is not operating at this value the alternator or the

voltage regulator are faulty

When removing electrical wires and connections make sure

you refit the securing fastener to its thread so it doesn't get

lost.

Step-by-step Instruction

1.

Disconnect the battery terminal: Locate the battery and its negative

terminal. Loosen the terminal clamp and remove the terminal

from the battery post. Store the terminal so it cannot come

in contact with the battery post while you are working on the

vehicle.

2.

Loosen the drive belt: Fit fender covers to the vehicle. Loosen the

drive belt and remove it from the alternator pulley. Check the

condition of the belt to see if it is still serviceable.

Trade of Motor Mechanic - Phase 2 Course Notes

33

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

3.

Remove electrical connections: Locate the electrical connections

at the rear of the alternator and note their positions. Loosen

any securing fasteners or covers and remove terminals one at

a time. In some cases the electrical terminals are encased in

a plug.

4.

Remove the alternator: Loosen the securing fasteners that hold

the alternator to its mounting bracket making sure that the

alternator is supported. Next remove the fasteners completely

and then remove the alternator from the engine bay.

5.

Refit the alternator: Locate the alternator in the mounting

bracket and, while still supporting the alternator, loosely fit

the securing fasteners that hold the alternator to its mounting

bracket.

6.

Attach electrical connections: Refit the electrical wires to their

correct terminals referring to the manufacturers manual to

check the connections are correct. Once all the wires are fitted

check the security of any fastening device.

7.

Refit drive belt: Fit the drive belt over the alternator drive pulley

and using the correct tools, adjust the belt to the correct

tension. The belt should not be over tightened to prevent

damage in service.

8.

8.

Refit the battery terminal: Locate the battery terminal

connection and re attach it to the negative post of the battery.

Make sure that the fastener is tight. Replace any battery post

covers.

9.

Test alternator output: Turn the ignition switch to the ON

position and make sure the charge light on the vehicle dash

panel is illuminated. Start the engine and with a DVOM set

to read DC voltage, place the positive probe onto the battery

positive and the negative probe to the battery negative. Raise

the engine speed to 2000 rpm and check that the DVOM is

reading 13.8 to 14.2 volts.

10. Clean up: Remove the fender covers and return any tools used

to their correct place.

Trade of Motor Mechanic - Phase 2 Course Notes

34

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Inspecting & Adjusting an Engine Drive

Belt

Preparation and Safety

Objective

Inspect and manually adjust engine accessory drive belts.

Personal Safety Whenever you perform a task in the workshop you must use personal

protective clothing and equipment that is appropriate for the task

and which conforms to your local safety regulations and policies.

Among other items, this may include:

Safety Check

Work clothing - such as coveralls and steel-capped footwear

Eye protection - such as safety glasses and face masks

Ear protection - such as earmuffs and earplugs

Hand protection such as rubber gloves and barrier cream

Respiratory equipment such as face masks etc.

Never try to inspect belts with the engine running.

Always make sure that you wear the appropriate personal

protection equipment before starting the job. It is very easy

to hurt yourself even when the most exhaustive protection

measures are taken.

Always make sure that your work area/environment is as safe

as you can make it. Do not use damaged, broken or worn out

workshop equipment.

Always follow the manufacturer's personal safety instructions

to prevent damage to the vehicle you are working on

Make sure that you understand and observe all legislative

and personal safety procedures when carrying out the

following tasks. If you are unsure of what these are, ask your

instructor.

Trade of Motor Mechanic - Phase 2 Course Notes

35

Revision 3.0 November 2013

Module 2 - Unit 4

Points to Note

Alternator/Circuit

There are two types of drive belts:

V-type: A V-type belt has a profile that looks like the photo below

and sits inside a deep v-shaped groove in the pulley wheel. The sides

of the V-belt contact the sides of the groove

Serpentine: Serpentine-type belts have a flat profile with a number of

grooves running lengthwise along the belt. These grooves are the

exact reverse of the grooves in the outer edge of the pulley wheels;

they increase the contact surface area, as well as prevent the belt

from slipping off the wheel as it rotates.

Trade of Motor Mechanic - Phase 2 Course Notes

36

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Conditions to Look for on a Drive Belt

Cracked: Cracks in a belt indicate that it is getting ready to fail and

should be replaced.

Oil-soaked: A belt that has been soaked in oil will not grip properly

on the pulleys and will slip. If the oil contamination is severe enough

for this to happen, replace the belt.

Glazed: Glazing is shininess on the surface of the belt, which comes

in contact with the pulley. If the belt is worn, the glazing could be

caused by the belt "bottoming-out" (see below) and it should be

replaced. If it is not old and worn, glazing could simply indicate

that the belt is not tight enough. Tightening the belt may be all that

is necessary, depending on how bad the glazing is.

Torn: Torn or split belts are unserviceable and should be replaced

immediately.

Trade of Motor Mechanic - Phase 2 Course Notes

37

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

'Bottoming-out': When a V-type belt becomes worn, the bottom of

the V-shape may contact the bottom of the groove in the pulley,

preventing the sides of the belt from making good contact with the

sides of the pulley groove. This reduced friction causes slippage; a

belt worn enough to bottom-out should be replaced.

Manual Belt Tension versus Automatic Belt

Tension

Many vehicles require the technician to manually adjust the tension

on the belt. Other vehicles have an automatic spring tensioning

system. Depending on the system used on the particular vehicle, you

should always follow the manufacturer's service instructions.

There are a number of different types of tension gauges. Follow

the operating instructions on the tool. If you don't have a tension

gauge, you can estimate the tension by pushing the belt inwards with

your hand. If it's correctly tensioned, you should be able to deflect

the belt about 1.25 centimetres for each 30cm of belt (half an inch

for each foot).

Trade of Motor Mechanic - Phase 2 Course Notes

38

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Step-by-Step Instruction

1.

Inspect and check belt condition: Twist the belt so that you can see

the underside of the V shape or the ribs on a Serpentine belt.

Look for signs of wear and damage. You may need a flashlight

to see these clearly. A cracked or glazed or torn belt will need

to be replaced.

2.

Check tension: Check the belt tension by attaching the tension

gauge to the longest belt span and pulling it to measure the

tension. Compare your reading to the specifications in the

vehicle workshop manual.

3.

Choose the correct tools: Select the correct wrench to loosen the

tension adjustment fastener. This is usually on the Alternator

mounting or on a separate idler pulley wheel. You will also

need a pry bar, which is a metal bar you can use as a lever to

apply tension on the belt.

4.

Adjust belt tension: Loosen the adjustment fastener, then wedge

the pry bar between the alternator and a strong part of the

engine and pull in the direction that will apply tension to the

belt. Tighten the adjustment fastener.

5.

Check tension again and readjust if necessary: Check the tension

again with the gauge and if necessary loosen the fastener and

adjust the belt again until it is at the correct tension for the

vehicle.

6.

Start the engine: Start the engine and observe the belt to make

sure it is properly seated and operating correctly. Stop the

engine again and recheck the tension.

Trade of Motor Mechanic - Phase 2 Course Notes

39

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Replacing an Engine Drive Belt

Preparation and Safety

Objective

Remove and replace an engine accessory drive belt.

Personal Safety Whenever you perform a task in the workshop you must use personal

protective clothing and equipment that is appropriate for the task

and which conforms to your local safety regulations and policies.

Among other items, this may include:

Safety Check

Work clothing - such as coveralls and steel-capped footwear

Eye protection - such as safety glasses and face masks

Ear protection - such as earmuffs and earplugs

Hand protection such as rubber gloves and barrier cream

Respiratory equipment such as face masks etc.

Never try to inspect belts with the engine running.

Always make sure that you wear the appropriate personal

protection equipment before starting the job. It is very easy

to hurt yourself even when the most exhaustive protection

measures are taken.

Always make sure that your work area/environment is as safe

as you can make it. Do not use damaged, broken or worn out

workshop equipment.

Always follow any manufacturer's instructions in relation to

personal safety and prevention of damage to the vehicle you

are working on.

Trade of Motor Mechanic - Phase 2 Course Notes

40

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Make sure that you understand and observe all legislative

and personal safety procedures when carrying out the

following tasks. If you are unsure of what these are, ask your

instructor.

There are two types of drive belts:

V-type

A V-type belt has a profile that looks like the photo below and sits

inside a deep v-shaped groove in the pulley wheel. The sides of the

V-belt contact the sides of the groove

Serpentine

Serpentine-type belts have a flat profile with a number of grooves

running lengthwise along the belt. These grooves are the exact

reverse of the grooves in the outer edge of the pulley wheels; they

increase the contact surface area, as well as prevent the belt from

slipping off the wheel as it rotates.

Trade of Motor Mechanic - Phase 2 Course Notes

41

Revision 3.0 November 2013

Module 2 - Unit 4

'Bottomingout'

Alternator/Circuit

When a V-type belt becomes very worn, the bottom of the V-shape

may contact the bottom of the groove in the pulley, preventing the

sides of the belt from making good contact with the sides of the

pulley groove. This reduced friction causes slippage; a belt worn

enough to bottom-out should be replaced.

Many vehicles require the technician to manually adjust the tension

on the belt. Other vehicles have an automatic spring tensioning

system. Depending on the system used on the particular vehicle, you

should always follow the manufacturer's service instructions.

There are a number of different types of tension gauges. Follow

the operating instructions on the tool. If you don't have a tension

gauge, you can estimate the tension by pushing the belt inwards with

your hand. If it's correctly tensioned you should be able to deflect

the belt about 1.25 centimetres for each 30cm of belt.

Trade of Motor Mechanic - Phase 2 Course Notes

42

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Step-by-Step Instruction

1.

Loosen tension and remove belt: Locate the adjustment fastener

and loosen it. This is usually on the alternator mounting or

on a separate pulley wheel. Move the adjusting mechanism

in far enough to allow you to remove the belt. Some vehicles

use an automatic spring tension system. In that case, pull the

tensioning device back so that you can remove the belt.

2.

Inspect drive & driven pulleys: Check the drive and pulley wheels.

Look for cracks and other forms of damage. Check that

there is no sideways movement indicating worn bearings and

spin the pulley wheels by hand to check that the bearings are

rotating freely.

3.

Select correct replacement belt: Obtain the correct size and type

of replacement belt specified in the workshop manual and

compare it with the belt you have just removed. They should

be very similar, although the old belt may have stretched in

use.

4.

Install V- belt: Install the new belt, making sure that it is properly

seated in the V-shape groove, or the multiple grooves in the

pulley, depending on its construction.

5.

Install Serpentine belt: If the belt is a Serpentine type, then make

sure that it is the correct width and squarely aligned in the

pulley grooves. If it is not correctly aligned, the belt will be

thrown off the pulley wheels.

6.

Correctly tension new belt: Tension the belt using a wrench and a

pry bar and then check it with a tension gauge. With automatic

tension systems, gently allow this to apply the tension to the

belt.

7.

Start the engine: Start the engine and observe the belt to make

sure that it is properly seated and operating correctly. Stop the

engine again and re check the tension.

Trade of Motor Mechanic - Phase 2 Course Notes

43

Revision 3.0 November 2013

Module 2 - Unit 4

Alternator/Circuit

Suggested Further Reading

Advanced Automotive Diagnosis. Tom Denton. ISBN

0340741236

Automobile Electrical and Electronic Systems (3rd Edition).

Tom Denton. ISBN 0750662190

Automotive Mechanics (10th Edition). William H. Crouse and

Donald L. Anglin. ISBN 0028009436

Bosch Automotive Electrics Automotive Electronics: Systems and

Components (4th Edition). Robert Bosch. ISBN 0837610508

Bosch Automotive Handbook (6th Edition). Robert Bosch.

ISBN 1860584748

Bosch Automotive Technology Technical Instruction booklet

series (numerous titles)

Hilliers Fundamentals of Motor Vehicle Technology: Book

One (5th Edition). V.A.W. Hillier and Peter Coombes. ISBN

0748780823

Hilliers Fundamentals of Motor Vehicle Technology: Book

Two (5th Edition). V.A.W. Hillier and Peter Coombes. ISBN

0748780998

Modern Automotive Technology. James E. Duffy. ISBN

1566376106

Motor Vehicle Craft Studies - Principles. F.K. Sully. ISBN

040800133X

National Car Test (NCT) Manual (Department of Transport,

Vehicle Testers Manual - DoT VTM). Department of

Transport

Transmission, Chassis and Related Systems (Vehicle Maintenance

and Repair Series: Level 3) (3rd Edition) John Whipp and Roy

Brooks. ISBN 186152806X

Vehicle and Engine Technology (2nd Edition). Heinz Heisler.

ISBN 0340691867

http://www.cdxglobal.com/

http://auto.howstuffworks.com/

http://www.autoshop101.com/

http://www.cdxetextbook.com/

Automotive Encyclopedia and Text Book Resource (CD version

of e-textbook), Available from your instructor.

Trade of Motor Mechanic - Phase 2 Course Notes

44

Revision 3.0 November 2013

Notes

27-33 Upper Baggot Street

Dublin 4

You might also like

- Engine troubleshooting guideDocument1 pageEngine troubleshooting guide2791957No ratings yet

- BATTERY TESTING AND CHARGING GUIDEDocument6 pagesBATTERY TESTING AND CHARGING GUIDE2791957No ratings yet

- Automotive Steering SuspensionDocument1 pageAutomotive Steering Suspension2791957No ratings yet

- IJESE 1119 Article 5808a2438fd89Document14 pagesIJESE 1119 Article 5808a2438fd892791957No ratings yet

- Sample: Diagram 1 Early Ford C-Max Wiring DiagramsDocument4 pagesSample: Diagram 1 Early Ford C-Max Wiring Diagrams2791957No ratings yet

- Battery Control System: DescriptionDocument3 pagesBattery Control System: Description2791957100% (1)

- ToolsCat 74Document58 pagesToolsCat 742791957No ratings yet

- Automotive (Small Engine)Document2 pagesAutomotive (Small Engine)2791957No ratings yet

- 9000-0020Document9 pages9000-00202791957No ratings yet

- Swift - June 09 - 03 Instrument PanelDocument56 pagesSwift - June 09 - 03 Instrument Panel2791957No ratings yet

- Determining Battery Capacity3 PDFDocument37 pagesDetermining Battery Capacity3 PDF2791957No ratings yet

- LDV 200 300 400Document108 pagesLDV 200 300 4002791957No ratings yet

- Wheel Drive and Mount Location GuideDocument107 pagesWheel Drive and Mount Location Guide27919570% (1)

- 10 Electric Power Steering GB Druck PDFDocument2 pages10 Electric Power Steering GB Druck PDF2791957No ratings yet

- A Smart Way To Drive Ecu ConsolidationDocument4 pagesA Smart Way To Drive Ecu Consolidation2791957No ratings yet

- Testing OBD interfaces and CAN busesDocument3 pagesTesting OBD interfaces and CAN buses2791957No ratings yet

- Marine Generator Set with Gasoline EngineDocument4 pagesMarine Generator Set with Gasoline Engine2791957No ratings yet

- Application Note AN06 - ELM327L and The PL-2303HX: Installing SoftwareDocument2 pagesApplication Note AN06 - ELM327L and The PL-2303HX: Installing Software2791957No ratings yet

- 5.2combustion and Combustion Chamber For SI EnginesDocument53 pages5.2combustion and Combustion Chamber For SI EnginesTamene Tesfaye100% (2)

- Module 2 Mechanics of Machining Lesson 8 Forces and Merchant's Circle DiagramDocument15 pagesModule 2 Mechanics of Machining Lesson 8 Forces and Merchant's Circle DiagramSUBHASH ANURAGNo ratings yet

- Q 117R2Document2 pagesQ 117R22791957No ratings yet

- SM-AFRGen2 User GuideDocument2 pagesSM-AFRGen2 User Guide2791957No ratings yet

- 05ivm EseriesDocument56 pages05ivm Eseries27919570% (1)

- Chap 17Document96 pagesChap 172791957No ratings yet

- Alto2011 CatalogDocument538 pagesAlto2011 CatalogIsa Restrepo Fernandez0% (1)

- Emergency Response Guide-ToyotaDocument143 pagesEmergency Response Guide-Toyota2791957100% (1)

- Focus WiresDocument816 pagesFocus Wiresionutnespus100% (2)

- Ford Wiring Diagram 1994 9404Document11 pagesFord Wiring Diagram 1994 94042791957No ratings yet

- 1GR-FE Engine Cooling System GuideDocument77 pages1GR-FE Engine Cooling System GuideMauricio Andrés Montenegro71% (7)

- Eng Trouble Diag Aug 09Document48 pagesEng Trouble Diag Aug 09279195750% (2)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- FACTORY AUTOMATION: Miniature Circuit Breakers, Residual Current Circuit Breakers, IsolatorsDocument16 pagesFACTORY AUTOMATION: Miniature Circuit Breakers, Residual Current Circuit Breakers, IsolatorsBùi Đình DuyNo ratings yet

- Wlan x86 812.3Document7 pagesWlan x86 812.3ReturnLab Recyclers Pvt. Ltd.No ratings yet

- Service Manual Ergo BikeDocument36 pagesService Manual Ergo BikeRosu EugenNo ratings yet

- MT6768 LPDDR4x Internal ProjectDocument31 pagesMT6768 LPDDR4x Internal Projectpc partnerNo ratings yet

- Model Pc100 Temperature Controller User Manual: Rev ADocument87 pagesModel Pc100 Temperature Controller User Manual: Rev AAnonymous mDLYFQuNo ratings yet

- Electrical and Electronic Installation For IACSDocument60 pagesElectrical and Electronic Installation For IACSKenneth TanNo ratings yet

- Eeswar Babu Banala: Associate Professor Vidya Jyothi Institute of Technology Hyderabad TelanganaDocument77 pagesEeswar Babu Banala: Associate Professor Vidya Jyothi Institute of Technology Hyderabad Telanganakarna_lokeshNo ratings yet

- Phu Giang Electric Co - LTDDocument54 pagesPhu Giang Electric Co - LTDBùi Thanh SơnNo ratings yet

- Siemens Electric Motor 15hp 1500rpmDocument17 pagesSiemens Electric Motor 15hp 1500rpmShamsul HaqueNo ratings yet

- Sierra GL61x0 PDFDocument96 pagesSierra GL61x0 PDFCezar CosariuNo ratings yet

- Power Harvester Design For Semi-Passive UHF RFID Tag Using A Tunable Impedance TransformationDocument5 pagesPower Harvester Design For Semi-Passive UHF RFID Tag Using A Tunable Impedance TransformationM ANo ratings yet

- ICOM RepetitorDocument22 pagesICOM Repetitorrujanac100% (1)

- Axl RTD V1 00 001Document11 pagesAxl RTD V1 00 001Centrala MetalaNo ratings yet

- Alarms of Ericsson Minilink CraftDocument43 pagesAlarms of Ericsson Minilink CraftShady Emad83% (12)

- RF-Based Multiple Device Control Using MicrocontrollerDocument7 pagesRF-Based Multiple Device Control Using Microcontrollermv mvNo ratings yet

- Catalogue TecoDocument8 pagesCatalogue TecopriyantohonggonoNo ratings yet

- Dual Active Bridge Converter Based Battery Charger in Stand-Alone Wind Power Generation System With High-Inertia Wind TurbineDocument5 pagesDual Active Bridge Converter Based Battery Charger in Stand-Alone Wind Power Generation System With High-Inertia Wind TurbinemsmegovindNo ratings yet

- 6-Pin Wire Harness Assembly Installation GuideDocument2 pages6-Pin Wire Harness Assembly Installation Guidelucian stoianofNo ratings yet

- New Step-Up and Step-Down 18-Pulse Direct Asymmetric Autotransformer Rectifier UnitsDocument7 pagesNew Step-Up and Step-Down 18-Pulse Direct Asymmetric Autotransformer Rectifier UnitsMaikPortnoyNo ratings yet

- SDI ASI Encoder MultiplexerDocument41 pagesSDI ASI Encoder MultiplexerChristie MillerNo ratings yet

- Heatcraft Condensing UnitsDocument12 pagesHeatcraft Condensing UnitsValentin LupascuNo ratings yet

- Amtech 5 Shades of YellowDocument5 pagesAmtech 5 Shades of YellowDavid WattsNo ratings yet

- Honeywell Sensing Micro Switch TP Rocker Product Sheet 005438 1 enDocument8 pagesHoneywell Sensing Micro Switch TP Rocker Product Sheet 005438 1 enDavid HughesNo ratings yet

- Low Threshold DMOS FETs for Logic Level InterfacesDocument4 pagesLow Threshold DMOS FETs for Logic Level InterfacesSaikumarNo ratings yet

- Split-Core CTs for Energy MonitoringDocument7 pagesSplit-Core CTs for Energy MonitoringJyoti ShresthaNo ratings yet

- H81MLV3 20160702Document5 pagesH81MLV3 20160702rizal hadiansyahNo ratings yet

- Mcqs cs302Document6 pagesMcqs cs302Abrish AliNo ratings yet

- Pneumatics Lab 3-Results & ObservationDocument10 pagesPneumatics Lab 3-Results & ObservationMuhd aziq FikriNo ratings yet

- Elevator Control Module User's ManualDocument44 pagesElevator Control Module User's ManualWissam RgailyNo ratings yet