Professional Documents

Culture Documents

Body Flange FEA

Uploaded by

Naresh KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Body Flange FEA

Uploaded by

Naresh KumarCopyright:

Available Formats

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Page

Rev

FEA-04-2013

Finite Element Analysis of

Half Body Flange and Half Blind Flange

EQUIPMENT NO

EQUIPMENT

: TEG BATH HEATER

DESIGN CODE

: ASME SEC. VIII DIV 1 ED. 2010 ADD 2011

CLIENT

: SPECIALST SERVICES

PROJECT

PROJECT NO

: FEA-04-2013

19-FEB-2014

HCA

HCA

HCA

Rev

Date

Prepared by

Checked by

Approved by

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Page

Rev

INDEX

Pages

Description

Rev.

Cover Page

Index

Reference Drawings

Record of Revisions

PART A: Stress Analysis of Half Body Flange and Half Blind Flange

1) Introduction

2) Analysis Details

3) Unit System

4) Design data

5) Material Data

6) Boundary Conditions and Loads

7) FEA Solid Model

8) Solid Element Plots

11

9) Loads & Boundary Conditions Plots

13

10) Results

14

11) Deformation Plot s

16

12) Von Misses Stress Plots

19

13) Locations of Stress Classification Lines

19

14) Conclusion

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

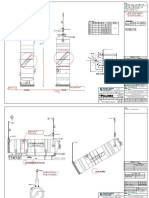

REFERENCE DRAWINGS

Sr. No. Description

Drawing. No.

General Arrangement

SS-PE-WB-T3-P-D-501

Fabrication Details

SS-PE-WB-T3-P-D-502

REFERENCE CODES

Sr. No. Description

1.

ASME Section VIII Div.1 Ed. 2010. ADD. 2011

2.

ASME Section VIII Div.2 Ed. 2010. ADD. 2011

3.

ASME Part II-D Ed. 2010 ADD. 2011

Page

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Page

RECORD OF REVISIONS

Rev. No.

0

Date

Pages

Details of Revision

19-FEB-2014

1-19

FIRST ISSUE

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Page

PART A

Finite Element Analysis of

Half Body Flange and Half Blind Flange

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Page

Rev

1) Introduction:

Configuration of this equipment includes Half Body Flange, Half Blind Flange, Shell Flange and Shell.

To check the suitability of this design, Finite Element Analysis is performed as per Part 5 of ASME

Sec. VIII Div-2. Following Clauses of the code are referred during this FEA.

Clause.

Cl. 5.2.2

Table 5.6

Figure 5.1

Annex 5.A

Title

Elastic Stress Analysis

Method

Examples Of Stress

Classification

Stress Categories and Limits

of Equivalent Stress

Linearization of Stress Results

for Stress Classification

Purpose

To check Protection Against Plastic

Collapse

For Classification of obtained stresses

To derive allowable limits in Result Table

For Linearization of Stress Results

2) Analysis Details:

Component

Half Body Flange, Half Blind Flange, Shell Flange

and Shell

Software

ANSYS 14.5

Analysis type

No. of elements

Static

Structural Solid Elements, Beam, Contact Elements

& Pretension Element

51482

No. of nodes

102964

Element type

Note:- Quarter symmetric model is considered for FE analysis due to symmetry about two planes

3) Unit System :

a) Force N

b) Pressure & Stress MPa (N/mm)

c) Length mm

4) Design data:

Design code

ASME Section VIII Div.1 Ed. 2010 ADD. 2011

Design Pressure

1.01325 barg [0.101325 MPa(g)]

Design Temperature

121 o C

Corrosion Allowance

1.5mm

Note FEA is carried for corroded condition

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Page

Rev

5) Material Data:

Component

Material

MPa

Allow. Stress at

Design Temp.

( S ) (2)

MPa

Design Temp.

o

Modulus of

Elasticity (1)

Shell

SA-516 Gr. 70N

121

196800

138

Half Body Flange

SA-516 Gr. 70N

121

196800

138

Half Blind Flange

SA-516 Gr. 70N

121

196800

138

Note:

1) The Modulus of Elasticity is obtained from Table TM1, ASME Sec. II D, Ed. 2010 ADD. 2011 for

the specified design temperature.

2) The Allowable Stress is taken from Table 1A & 3 of ASME Sec. II D, Ed.2010. ADD. 2011

6) Boundary conditions and loads:

a) Shell end is fixed in all translation direction

b) Symmetric boundary conditions are applied on plane of symmetry of equipment

c) Static Head for vessel in vertical position 0.208bar ([0.0208 MPa(g)]

d) Bolt Pretension Load of 4443778.23 N

e) Design Pressure 1.01325 bar ([0.101325 MPa(g)]

7) FEA Solid Model

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

3D Model with Blind Flange1

3D Model with Blind Flange2

3D Model Close View

Page

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

8) Solid Element Plot

Half Body Flange 1 and Blind Flange 1

Half Body Flange 2 and Blind Flange 2

Page

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Weld Model Close View

Bolt Connection Close View

Page

10

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

9) Loads & Boundary Conditions Plot

Symmetric Boundary

conditions on YZ

Plane

Contact is defined between Gasket &

Body Flange and Gasket & Blind Flange

Page

11

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Page

12

Rev

Shell face is fixed

in all translational

direction

Bolts are modeled with

Beam 188 Element and

Pretension is applied

Internal Pressure

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Page

13

Rev

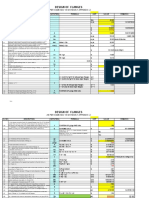

10) Results

10.1) Half Body Flange 1 & Blind Flange 1

10.1.1) Elastic Stress Analysis Results

(As per Cl.5.2.2 of ASME Sec VIII Div2 based on stress linearization)

Location of Stress Classification Line

(SCL) (1)

1) Through Weld Thickness at Body

Flange 2 to Weld Jucntion

2) Through Weld Thickness at Body

Flange 2 to Weld Jucntion

3) Through Blind Flange 2 Thickness

Type of

stress (2)

PL

PL + P b + Q

PL

PL + P b + Q

PL

PL + P b + Q

Max Induced Von

Misses stress

(MPa)

Allowable Limit

(MPa) (3)

101.9

1.5 x S = 207

136.0

3 x S = 414

69.43

1.5 x S = 207

87.18

3 x S = 414

70.79

1.5 x S = 207

171.5

3 x S = 414

Notes

1) Please refer subsequent stress plots for locations of stress classification lines as per Figure 5.A.1

(Stress Classification Lines) of ASME Sec VIII Div2.

2) Allowable limits are derived from Figure 5.1 (Stress Categories and Limits of Equivalent Stress) of

ASME Sec. VIII Div.2.

10.2) Half Body Flange 2 & Blind Flange 2

10.2.1) Elastic Stress Analysis Results

(As per Cl.5.2.2 of ASME Sec VIII Div2 based on stress linearization)

Location of Stress Classification Line

(SCL) (1)

1) Through Weld Thickness at Body

Flange 2 to Weld Jucntion

2) Through Weld Thickness at Body

Flange 2 to Weld Jucntion

3) Through Blind Flange 2 Thickness

Type of

stress (2)

PL

PL + P b + Q

PL

PL + P b + Q

PL

PL + P b + Q

Max Induced Von

Misses stress

(MPa)

Allowable Limit

(MPa) (3)

93.02

1.5 x S = 207

116.1

3 x S = 414

68.87

1.5 x S = 207

79.70

3 x S = 414

72.29

1.5 x S = 207

210.4

3 x S = 414

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

11) Deformation Plot (Unit mm)

11.1) Half Body Flange 1 & Blind Flange 1

Page

14

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

11.1) Half Body Flange 2 & Blind Flange 2

Page

15

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

12) Von Misses (Equivalent) Stress Plots (Unit MPa)

12.1) Half Body Flange 1 & Blind Flange 1

Stress Plot for Equipment

Stress Plot for Half Body Flange 1

Page

16

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Stress Plot for Half Body Blind 1

12.1) Half Body Flange 2 & Blind Flange 2

Stress Plot for Equipment

Page

17

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Stress Plot for Half Body Flange 2

Stress Plot for Half Body Blind 2

Page

18

Rev

RH TechnoSystems LLP

Client

SPECIALIST SERVICES

10, Bldg No.8, Pratiknagar, Kothrud, Pune -38, India

Tel. +91-20-65731785 Mobile: +91-9527371067

Email :hemant.abhale@rhtechno.com

Web : www.rhtechno.com

Equipment

TEG BATH HEATER

Project No

FEA-04-2013

Date

19-FEB-2014

Page

19

Rev

13) Locations of Stress Classification Lines

SCL Body Flange to Shell Flange Joint

14) Conclusion

1) From result tables (Ref. 10.1. 1 & 10.2.1) we find that stresses induced in Half Body Flange, Half

Blind Flange 1 and 2 are below the allowable limits specified in Part 5 of ASME Sec. VIII Div.2.

Therefore the designs of Half Body Flange, Half Blind Flange 1 and 2 comply with code

requirement.

You might also like

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- ASME PCC-1 - Assembly Bolt Stress & Torque DeterminationDocument11 pagesASME PCC-1 - Assembly Bolt Stress & Torque Determinationndrarly100% (1)

- Beam Splice Connection Calculation - (Bolted)Document9 pagesBeam Splice Connection Calculation - (Bolted)Naresh KumarNo ratings yet

- FEA - Flange JointDocument5 pagesFEA - Flange JointkisshokNo ratings yet

- Loads On FlangesDocument16 pagesLoads On Flangesccoollest100% (3)

- Pipe Stress AnalysisDocument19 pagesPipe Stress AnalysisJosuaNo ratings yet

- KEC plant pressure vessel training manual 4 of 5 권 PDFDocument173 pagesKEC plant pressure vessel training manual 4 of 5 권 PDFJinho Lee100% (1)

- Guides For Shoes CalculationDocument16 pagesGuides For Shoes CalculationgopaltryNo ratings yet

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarNo ratings yet

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarNo ratings yet

- PhysicsDocument234 pagesPhysicsshugufta nazneenNo ratings yet

- Materials AssignmentDocument14 pagesMaterials AssignmentRuby PanesNo ratings yet

- Fuzzy Control of Active Suspension System Based On Quarter Car ModelDocument7 pagesFuzzy Control of Active Suspension System Based On Quarter Car Modellutfil hadiNo ratings yet

- Boardwork No.1 and 2Document9 pagesBoardwork No.1 and 2John Nalog100% (1)

- Design of Flanges - 12 600# CalculationsDocument5 pagesDesign of Flanges - 12 600# CalculationsJose BijoyNo ratings yet

- 22BMJ 045 FEA 07 - Rev 0 - 23.07.05Document13 pages22BMJ 045 FEA 07 - Rev 0 - 23.07.05TEP DesignNo ratings yet

- Elastic Stress Analysis For Heat Exchanger Channel Head For Protection Against Plastic Collapse and Protection Against Local Failure (FEA)Document8 pagesElastic Stress Analysis For Heat Exchanger Channel Head For Protection Against Plastic Collapse and Protection Against Local Failure (FEA)kingstonNo ratings yet

- Pveng: Pressure Vessel Engineering LTDDocument20 pagesPveng: Pressure Vessel Engineering LTDSivateja NallamothuNo ratings yet

- ASME Section III Fatigue Calc ML093360330Document29 pagesASME Section III Fatigue Calc ML093360330Paldex100% (1)

- MP-WP-21 Gasket Selection & InstallationDocument6 pagesMP-WP-21 Gasket Selection & InstallationsaadhwNo ratings yet

- 16 Preiss Study en 13445 Asme ViiiDocument26 pages16 Preiss Study en 13445 Asme ViiiDubaiHMARNo ratings yet

- Pvp2014-28980 Analysis and Testing of A Ring-Joint FlangeDocument15 pagesPvp2014-28980 Analysis and Testing of A Ring-Joint Flangematteo_1234No ratings yet

- Pressure Vessel Engineering LTD.: Finite Element Analysis Report - VIII-2Document23 pagesPressure Vessel Engineering LTD.: Finite Element Analysis Report - VIII-2rahulNo ratings yet

- 2009 Bachelor - Stress Analysis of Riser Using Finite Element Method (FEM)Document65 pages2009 Bachelor - Stress Analysis of Riser Using Finite Element Method (FEM)Le Thanh TungNo ratings yet

- Comparison of WRC and Nozzle Pro PDFDocument36 pagesComparison of WRC and Nozzle Pro PDFPrashant Agrawal100% (1)

- Code Case 2901 - Consideration of External Loads On ASME B16.5 Standard Flanges Under ASME Code Section VIII, Division 1 & 2Document2 pagesCode Case 2901 - Consideration of External Loads On ASME B16.5 Standard Flanges Under ASME Code Section VIII, Division 1 & 2msn1981No ratings yet

- The Analysis of Piping Under PressureDocument21 pagesThe Analysis of Piping Under PressureTrungSon NguyenNo ratings yet

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocument17 pagesMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (1)

- Pressure Vessel ExampleDocument48 pagesPressure Vessel ExamplemohamedNo ratings yet

- Design of Welded Pressure EquipmentDocument67 pagesDesign of Welded Pressure EquipmentpolysourceNo ratings yet

- Sample21 SpreadsheetDocument20 pagesSample21 SpreadsheetSivateja NallamothuNo ratings yet

- Sec. VIII Div 1 Apen 1Document16 pagesSec. VIII Div 1 Apen 1ADRIANNo ratings yet

- FEA Pressure VesselDocument48 pagesFEA Pressure VesselnaimNo ratings yet

- Ansi A250 - 13Document34 pagesAnsi A250 - 13maikelc1No ratings yet

- Structural Design Calculations FOR Retensioning of ClampDocument13 pagesStructural Design Calculations FOR Retensioning of ClampFeroz Khan PatthanNo ratings yet

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument8 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeAndres Rodriguez HerreraNo ratings yet

- Understanding ASME UG-45Document3 pagesUnderstanding ASME UG-45Ahmad DanielNo ratings yet

- Expansion Bellow DesignDocument16 pagesExpansion Bellow DesignpipestressNo ratings yet

- PD 06438-1969 (1999)Document12 pagesPD 06438-1969 (1999)Sith SopanhaNo ratings yet

- Local Buckling Analysis Based On DNV-OS-F101 2000Document4 pagesLocal Buckling Analysis Based On DNV-OS-F101 2000shervinyNo ratings yet

- Flange DesignDocument6 pagesFlange DesignDinesh VaghelaNo ratings yet

- Asme Viii Div.2 PDFDocument16 pagesAsme Viii Div.2 PDFRicardo Paz SoldanNo ratings yet

- ASME B31 8 Riser CalcDocument12 pagesASME B31 8 Riser CalcEmmanuel LawrenceNo ratings yet

- Flange Leakage Checking in Caesar II Using ASME Section VIII MethodDocument7 pagesFlange Leakage Checking in Caesar II Using ASME Section VIII MethodZhiqiang Gu100% (1)

- A Comparison Study of Pressure Vessel Design Using Different Standards PDFDocument319 pagesA Comparison Study of Pressure Vessel Design Using Different Standards PDFJM100% (1)

- Design by AnalysisDocument22 pagesDesign by AnalysisJEELE77No ratings yet

- Weld Design by FEADocument11 pagesWeld Design by FEAAdarsh D. KarkiNo ratings yet

- Design of Compact Flange JointsDocument15 pagesDesign of Compact Flange JointsAkhil JoseNo ratings yet

- Finite Element Analysis of Pressure VesselDocument9 pagesFinite Element Analysis of Pressure VesselSenguttuvan RaajaahNo ratings yet

- Quickstart AutoPIPE 9.5Document51 pagesQuickstart AutoPIPE 9.5Chandra ClarkNo ratings yet

- On The Design of The Tubesheet and Tubesheet-To-Shell Junction of A Fixed Tubesheet Heat ExchangerDocument7 pagesOn The Design of The Tubesheet and Tubesheet-To-Shell Junction of A Fixed Tubesheet Heat ExchangerEdgardo Chavez BelloNo ratings yet

- Fatigue Screeing StepsDocument2 pagesFatigue Screeing StepsBashu PoudelNo ratings yet

- B31.3 Case 178Document11 pagesB31.3 Case 178fileseekerNo ratings yet

- FatigueLife FEA PDFDocument43 pagesFatigueLife FEA PDFAbigail SommersetNo ratings yet

- Fe Analysis of Rotor Assembly: Document No: Ch/Report/Drm/109/2016-17Document37 pagesFe Analysis of Rotor Assembly: Document No: Ch/Report/Drm/109/2016-17Nishit KhuntNo ratings yet

- ASME Sec VIII Div 1Document27 pagesASME Sec VIII Div 1uvarajmecheri100% (13)

- Menaa M-03 4110-002R4 (Main Stadium-Sectors A&B Precast Structural Calculations - Rev4) 2012 - 1012 PDFDocument176 pagesMenaa M-03 4110-002R4 (Main Stadium-Sectors A&B Precast Structural Calculations - Rev4) 2012 - 1012 PDFErnest NavarroNo ratings yet

- ASME BPVC Section VIII Division 2: Responsibilities and Duties ParagraphDocument3 pagesASME BPVC Section VIII Division 2: Responsibilities and Duties ParagraphSubrata PatraNo ratings yet

- Vessel FaguieDocument8 pagesVessel Faguiehgeo selimNo ratings yet

- Fatigue Analysis of 6300 Liters Pressure Vessel by Using Cyclic ServiceDocument7 pagesFatigue Analysis of 6300 Liters Pressure Vessel by Using Cyclic ServiceFisul RahumanNo ratings yet

- SYS Bolt ManualDocument64 pagesSYS Bolt ManualNoppolNorasriNo ratings yet

- 0 GRP Pipe Support Calculation Clamped Shoes Flange SupportsDocument29 pages0 GRP Pipe Support Calculation Clamped Shoes Flange SupportsmohdnazirNo ratings yet

- Weld ProeDocument14 pagesWeld ProeHenrique OliveiraNo ratings yet

- Cost Sheet For NPLDocument10 pagesCost Sheet For NPLSachin MishraNo ratings yet

- FatigueDocument11 pagesFatiguemehdi6409No ratings yet

- EXAMPLE CalculationsDocument4 pagesEXAMPLE CalculationszaheermechNo ratings yet

- Job Specific Data Tag No-PRJ0010315-5, 6,7 & 8 Quantity - 4 NosDocument6 pagesJob Specific Data Tag No-PRJ0010315-5, 6,7 & 8 Quantity - 4 NosNaresh KumarNo ratings yet

- Job Specific Data Tag No-PRJ0010315-1, 2, 3 & 4 Quantity - 4 NosDocument6 pagesJob Specific Data Tag No-PRJ0010315-1, 2, 3 & 4 Quantity - 4 NosNaresh KumarNo ratings yet

- Specialist Services: Force Resolution CalculationDocument5 pagesSpecialist Services: Force Resolution CalculationNaresh KumarNo ratings yet

- PRJ0010288 SK 001 01r0Document1 pagePRJ0010288 SK 001 01r0Naresh KumarNo ratings yet

- To Verified by Rigger.: Keppel Shipyard / BrasfelsDocument2 pagesTo Verified by Rigger.: Keppel Shipyard / BrasfelsNaresh KumarNo ratings yet

- Water Pipe Sample DGW and MaterialsDocument1 pageWater Pipe Sample DGW and MaterialsNaresh KumarNo ratings yet

- Load Calcs - Rev1Document11 pagesLoad Calcs - Rev1Naresh KumarNo ratings yet

- 26071-100-GPP-GPX-00008-001 Packing & Shipping Instruction and Marking SpecificationDocument57 pages26071-100-GPP-GPX-00008-001 Packing & Shipping Instruction and Marking SpecificationNaresh Kumar100% (2)

- Tsa ZaDocument2 pagesTsa ZaNaresh KumarNo ratings yet

- Padeye CalculationDocument2 pagesPadeye CalculationNaresh Kumar0% (1)

- Tsa YzDocument2 pagesTsa YzNaresh KumarNo ratings yet

- 91638-Tsa-Xy (Rev 1)Document2 pages91638-Tsa-Xy (Rev 1)Naresh KumarNo ratings yet

- 2014 Ford Fusion - 2.5L PDFDocument1 page2014 Ford Fusion - 2.5L PDFNaresh KumarNo ratings yet

- 91638-TP-XY: Proprietary and ConfidentialDocument1 page91638-TP-XY: Proprietary and ConfidentialNaresh KumarNo ratings yet

- 91638-TP-ZA: Transportation Drawing CONDENSER E-2-11 (91638-ZA-COND)Document1 page91638-TP-ZA: Transportation Drawing CONDENSER E-2-11 (91638-ZA-COND)Naresh KumarNo ratings yet

- 91638-TP-XY: Proprietary and ConfidentialDocument1 page91638-TP-XY: Proprietary and ConfidentialNaresh KumarNo ratings yet

- COMMENTSDocument2 pagesCOMMENTSNaresh KumarNo ratings yet

- TP XY - CMTDocument1 pageTP XY - CMTNaresh KumarNo ratings yet

- WES 1003 HC 0016 - r3Document17 pagesWES 1003 HC 0016 - r3Naresh KumarNo ratings yet

- 2014 Ford Fusion - 2.5L PDFDocument1 page2014 Ford Fusion - 2.5L PDFNaresh KumarNo ratings yet

- CP FE VT 001 - r0Document19 pagesCP FE VT 001 - r0Naresh KumarNo ratings yet

- 20191105080051256Document1 page20191105080051256Naresh KumarNo ratings yet

- (SO 10467) 14763-9 SEPARATOR STRUCTURE DETAILS FOR CALCULATION Rev.0-Sheet 1 of 1 PDFDocument1 page(SO 10467) 14763-9 SEPARATOR STRUCTURE DETAILS FOR CALCULATION Rev.0-Sheet 1 of 1 PDFNaresh KumarNo ratings yet

- Bolt Item CodesDocument1 pageBolt Item CodesNaresh KumarNo ratings yet

- 20191105080051256Document1 page20191105080051256Naresh KumarNo ratings yet

- (So 10467) 14763-9 Separator Structure Details For Calculation Rev.0-Sheet 1 of 1Document2 pages(So 10467) 14763-9 Separator Structure Details For Calculation Rev.0-Sheet 1 of 1Naresh KumarNo ratings yet

- Material Grade Comparison ChartDocument2 pagesMaterial Grade Comparison ChartNaresh KumarNo ratings yet

- KinemaTics KineticsDocument246 pagesKinemaTics KineticsAlejandro Romero MejiaNo ratings yet

- Biofluid Mechanics Chapter 1Document72 pagesBiofluid Mechanics Chapter 1AbcdNo ratings yet

- Control System: by Saurabh KorgaonkarDocument24 pagesControl System: by Saurabh Korgaonkar16 - Dimplekunwar SolankiNo ratings yet

- 10 - 1 PID ControllersDocument36 pages10 - 1 PID ControllersShilpya KurniasihNo ratings yet

- Stoke's LawDocument26 pagesStoke's Lawminglei caiNo ratings yet

- Sample ProblemsDocument36 pagesSample ProblemsLovely Joy GumbaNo ratings yet

- Chapter 3.4Document9 pagesChapter 3.4Jhon Barzola PalominoNo ratings yet

- HMT Question PaperDocument1 pageHMT Question PaperSanjay GomastaNo ratings yet

- NotesDocument40 pagesNotesnirmala_siva_1100% (1)

- 2015 Year 7 Science PhysicsaepstudentDocument3 pages2015 Year 7 Science Physicsaepstudentapi-222503660No ratings yet

- Cayley Hamilton TheoremDocument11 pagesCayley Hamilton Theoremzeren50% (6)

- Particleworks TutorialDocument105 pagesParticleworks TutorialNarongrit BaiyaiNo ratings yet

- Scitech Physics Contents CatalogueDocument12 pagesScitech Physics Contents Cataloguerajesh.v.v.kNo ratings yet

- Solutions To Habermans Book Applied Part PDFDocument420 pagesSolutions To Habermans Book Applied Part PDFSarah Suelen100% (1)

- Experiment 1 - TENSION TEST OF MILD STEEL SPECIMENDocument10 pagesExperiment 1 - TENSION TEST OF MILD STEEL SPECIMENSamiha Maysoon Nooria100% (1)

- AS Trial - 2004 Mar - P1Document14 pagesAS Trial - 2004 Mar - P1Syafiq Shazwan100% (1)

- Derivation of Van Der Waals EquationDocument6 pagesDerivation of Van Der Waals Equationnithin100% (1)

- Multi Disciplinary Optimization of An Aircraft Landing Gear PDFDocument29 pagesMulti Disciplinary Optimization of An Aircraft Landing Gear PDFRaghu B SNo ratings yet

- June 2016 QP - M1 AQADocument24 pagesJune 2016 QP - M1 AQAmark sjsieuNo ratings yet

- Penjelasan Slide PPT Liquefaction of SoilDocument14 pagesPenjelasan Slide PPT Liquefaction of Soilbasri kamaruddinNo ratings yet

- GEOL - 3003 - Lecture 3 4 Rheology PDFDocument66 pagesGEOL - 3003 - Lecture 3 4 Rheology PDFMohammed HarrasiNo ratings yet

- Grade 9 PhysicsDocument4 pagesGrade 9 PhysicsMohamed AmrNo ratings yet

- Bound ChargesDocument17 pagesBound ChargesJorge GuerreroNo ratings yet

- Text of 1st McClelland Lecture Murff PDFDocument37 pagesText of 1st McClelland Lecture Murff PDFNadya SaviraNo ratings yet

- Chemistry ch#5 MCQ Ist YearDocument2 pagesChemistry ch#5 MCQ Ist YearMohammad AshfaqNo ratings yet