Professional Documents

Culture Documents

Open Vs Enclosed Impeller

Uploaded by

Khởi NguyênOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Open Vs Enclosed Impeller

Uploaded by

Khởi NguyênCopyright:

Available Formats

Practice & Operations

The Ma

gazine

For

Open Versus

Enclosed Impellers

Pump

Users

Worldw

ide

Reprin

a PUMPS & SYSTEMS reprint

July 20

08

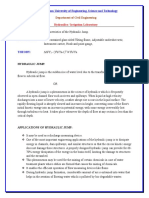

Closed vs Open Impeller Pump CR17243, 4 x 3 x 8

H e a d - C a p a c it y ( O p e n )

65

H e a d - C a p a c it y ( C lo s e d )

E f f ic ie n c y ( O p e n )

60

B H P(O pe n)

55

E f f ic ie n c y ( C lo s e d )

B H P ( C lo s e d )

50

40

35

30

25

Efficiency (%) & BHP

45

Head (FT)

o one would

80

think

about

buying a car

70

with poor gas mileage or

purchasing an inefficient

60

refrigerator.

However,

companies are purchasing

50

pumps with open-faced

impellers, which result

40

in a tremendous loss of

pump performance and

30

efficiency. The pump performance and efficiency

20

of an open-faced impeller continues to decrease

10

as the impeller and the

0

pump casing begin to

0

wear. The performance

and efficiency of an

open-faced impeller is a

function of the clearance

between the impeller face and the suction

volute or plate. A five point reduction in

performance on a pump that is operating at 50 percent efficiency will translate

into a 10 percent loss of efficiency and will

continue to decrease as the impeller and

casing housing wear.

In contrast, the performance of

shrouded or enclosed impellers is not

dependent on the gap between the impeller and the casing volute. The enclosed

impellers performance and efficiency

is simply a function of the design of the

impeller and casing volute.

Performance tests with the same

pump casing volute (Figure 1) show that

an identical impeller to the open impeller

ted fro

m

pumpzone.c

om

Two St

ep

Pump s to Longer

Life (P

art 2)1

Progre

ss

8

Pump ive Cavity

s22

Comp

ressor

s 101

Pump

24

ing Po

lymer

Air Op

s48

erat

Diaphr ed Double

agm Pu

mps6

8

John Kozel, Sims Pump Valve Company

An argument in favor of enclosed impellers

over open impellers.

July 200

8

PACK

PUMPAINGED

SYSTEMSG

20

15

10

100

200

300

400

500

600

700

Capacity (GPM)

Figure 1

En d u ran ce Te st Be fo re an d Afte r 1000 Ho u rs Ru n n in g Time o n a U.S. Nav y F ire

Pu mp with Stru ctu ral Co mp o site In te rn als

90

600

80

500

70

60

Head (ft)

400

50

300

40

30

200

20

100

10

0

0

0

210

420

630

840

1050

1200

1400

1615.4

1909.1

Capacity (GPM)

T DH(FT )

T DH(FT ) A f te r 1 00 0 Hr s

BHP

EFF ( % )

NP S h r

EF F ( % ) A f t e r 1 0 0 0 Hr s .

Figure 2

www.pump-zone.com

JULY 2008

Practice & Operations

A 4 x 3 9 chemical pump with an enclosed

impeller instead of an open impeller.

The same 4 x 3 9 chemical pump was

originally designed with an open impeller.

The chemical pump (for use with HCL acid) was performance tested with the open impeller and then again

with an enclosed impeller. The results show a substantial

improvement in efficiency and an increase in the headcapacity (H-Q) curve. The enclosed impeller would then

be trimmed to the original performance specifications.

This picture shows a comparison of two impellersone

open-faced and one enclosed. This open-faced impeller

(right) was redesigned and converted into an enclosed

impeller (left). The result was a substantial increase in

the pump performance, efficiency and reliability.

Examples

but with a shroud on the suction side of the impeller increases

the efficiency of the pump by as much as 5.3 percent. It also

increases the performance (flow) of the pump from 360-gpm

2

JULY 2008

to 400-gpm. This test was performed without any modifications to the pump and without a casing ring. If a casing ring

was installed in the casing volute, the efficiency and pump

www.pump-zone.com

a PUMPS & SYSTEMS reprint

(H-Q) curve after 1,000 hours of operation as a result of the

performance would have increased even more.

rings and impeller operating together.

Thousands of pumps operate with open impellers, and

some pump designs have even standardized on these openP&S

faced impeller pumps.

John Kozel is the president of Sims Pump Valve Company, 1314 Park

Open face impellers are popular because

Avenue, Hoboken, NJ 07030-4404, 201-792-0600, Fax: 201-792they cost less money to manufacture, so the

4803, simsite1@aol.com, www.simsite.com.

pump costs less. Unfortunately, these pumps

cost more to operate and wear more

quickly.

Fortunately, pump users have an

option today. End users can replace an

open-faced impeller with an enclosed

impeller without changing anything

else in the pump. Specialty companies

can machine a new enclosed impeller

from a patented solid block of structural

graphite composite, with the result

being a strong, lightweight, hydraulically and mechanically balanced, corrosion, erosion and cavitation resistant,

and efficient impeller.

Maintenance Reduced

Converting to an enclosed-faced impeller from open-faced eliminates the

maintenance headache and guesswork

of adjusting open-faced impellers. Since

the performance of the open-faced

impeller is totally dependant on the gap

between the housing and the front of

the impeller vanes, it must constantly

be adjusted as the impeller and/or housing wears. Finding the new setting is a

matter of trial and error. If the impeller

is set too close, the impeller vanes will

wear prematurely; if the gap is too large,

the performance will suffer and the

pump will be inefficient.

One of the many benefits of

enclosed structural composite impellers and rings is that the impeller performance will not deteriorate over time

like a metallic enclosed impeller or an

open-faced impeller. With an enclosed

composite impeller, the clearances are

permanently set between the impeller

wear ring and the pump casing ring or

the pump housing. Since the structural

composite will not gall, seize or corrode

like metallic rings, the clearances can

be controlled, as can the pump performance and efficiency. Figure 2 shows

that an enclosed structural composite

impeller will increase the head-capacity

a PUMPS & SYSTEMS reprint

www.pump-zone.com

JULY 2008

You might also like

- Free Piston Stirling 7kwDocument8 pagesFree Piston Stirling 7kwmikialeNo ratings yet

- Clutch Operati On: Roland Welter Volker Lang Bernhard WolfDocument8 pagesClutch Operati On: Roland Welter Volker Lang Bernhard WolfAshok KumarNo ratings yet

- Impeller Trim For PumpDocument9 pagesImpeller Trim For PumpkasiNo ratings yet

- 3 CsDocument14 pages3 CsRavindra PawarNo ratings yet

- Closed vs Open Impeller Design AdvantagesDocument3 pagesClosed vs Open Impeller Design Advantagesucb2_ntpcNo ratings yet

- Boiler Feed Pump Sizing CalculationDocument18 pagesBoiler Feed Pump Sizing CalculationArun Kumar Dey100% (2)

- Quick A Easy Guide: To Hydraulic Pump Technology and SelectionDocument3 pagesQuick A Easy Guide: To Hydraulic Pump Technology and SelectionGustavNo ratings yet

- 29 Life Expectancy of Piston Type Pumps and MotorsDocument2 pages29 Life Expectancy of Piston Type Pumps and Motorsbee140676No ratings yet

- Balance LineDocument0 pagesBalance Linewsjouri2510No ratings yet

- SAG Mill ComponentsDocument7 pagesSAG Mill ComponentsRodrigo GarcíaNo ratings yet

- Img 20140709 0003Document1 pageImg 20140709 0003HongKyz Jovianz X-BoyzNo ratings yet

- Thrust in Vertical Turbine PumpsDocument5 pagesThrust in Vertical Turbine PumpsKamal Arab100% (1)

- Considerations For Impeller Trimming - Empowering Pumps and EquipmentDocument8 pagesConsiderations For Impeller Trimming - Empowering Pumps and Equipment김기준No ratings yet

- GDocument34 pagesGjuanca_eduNo ratings yet

- The Power Wear RingDocument16 pagesThe Power Wear Ringpaola hernandezNo ratings yet

- Centrifugal Pump Efficiency—What Is ItDocument3 pagesCentrifugal Pump Efficiency—What Is ItAlfredo GallardoNo ratings yet

- Scotch Yoke or Rack-and-Pinion Quarter-Turn Actuator?Document2 pagesScotch Yoke or Rack-and-Pinion Quarter-Turn Actuator?Assured AutomationNo ratings yet

- Improve Pumps Performance With Composite Wear ComponentsDocument0 pagesImprove Pumps Performance With Composite Wear ComponentsDelfinshNo ratings yet

- Biffi Hydraulic ActuatorsDocument28 pagesBiffi Hydraulic ActuatorsMuthu Kumar RNo ratings yet

- Improving Reliability and Efficiency of Centrifugal PumpsDocument4 pagesImproving Reliability and Efficiency of Centrifugal PumpsHatem ShawkiNo ratings yet

- 10 OXLER VW Scotch Yoke Actuator 2Document2 pages10 OXLER VW Scotch Yoke Actuator 2DachyiNo ratings yet

- GE Reciprocating Compressor BrochureDocument13 pagesGE Reciprocating Compressor Brochurepratik banerjeeNo ratings yet

- Mb275 20-A Series Self-PrimingDocument8 pagesMb275 20-A Series Self-PrimingChristian Alberto Soto MullerNo ratings yet

- Toyo 1-55Document435 pagesToyo 1-55Yuda Satria100% (1)

- Armstrong Elec-Hsc-F43.11 HSC BrochureDocument4 pagesArmstrong Elec-Hsc-F43.11 HSC BrochureRoger AklNo ratings yet

- Flygt PumpsDocument104 pagesFlygt PumpsAchira Chanaka Peiris0% (1)

- Medium and Highspeed Diesel Engines For Marine Service 1938Document11 pagesMedium and Highspeed Diesel Engines For Marine Service 1938Merrel RossNo ratings yet

- Engineering Encyclopedia: Centrifugal PumpsDocument70 pagesEngineering Encyclopedia: Centrifugal PumpsMajdi Belguith67% (3)

- Making The Choice: Selecting and Applying Piston and Bladder AccumulatorsDocument10 pagesMaking The Choice: Selecting and Applying Piston and Bladder AccumulatorsM S GokulNo ratings yet

- Curva 4x6x9 05Document18 pagesCurva 4x6x9 05douglas marcanoNo ratings yet

- Innomag TBmag Sales GuideDocument65 pagesInnomag TBmag Sales Guideganesan 0011No ratings yet

- Single-Stage, Double Suction Vertical PumpsDocument20 pagesSingle-Stage, Double Suction Vertical Pumpsسامح الجاسمNo ratings yet

- Hydr Valve 60554Document7 pagesHydr Valve 60554errenmayNo ratings yet

- Bifrm 0023 enDocument0 pagesBifrm 0023 enMario Rivera AlonsoNo ratings yet

- Oerlikon Leybold Roots Blower Vacuum Pump CatalogDocument40 pagesOerlikon Leybold Roots Blower Vacuum Pump CatalogYasir Ali100% (1)

- Kimray Glycol PumpsDocument14 pagesKimray Glycol PumpsDiego1980bNo ratings yet

- Piston Pumps Paste-Thickened Tailings PB-PPPT-0215 LowresDocument10 pagesPiston Pumps Paste-Thickened Tailings PB-PPPT-0215 LowresMartin Lara100% (1)

- At Turbo TechDocument20 pagesAt Turbo Tech1mmahoney100% (1)

- Centrifugal Pump.......... Very ImpDocument22 pagesCentrifugal Pump.......... Very Impavi07me4uNo ratings yet

- Cameron NEWDocument64 pagesCameron NEWAnonymous fa7rg79NA250% (2)

- Skip Cycle EngineDocument8 pagesSkip Cycle Enginekumar_yogesh223881No ratings yet

- Cameron - Type U BOPDocument38 pagesCameron - Type U BOPjeinerdt100% (7)

- Mec 4Document1 pageMec 4api-3761679No ratings yet

- Look Mom No CamshaftDocument4 pagesLook Mom No CamshaftNelson Loia Jr.No ratings yet

- SOHC Head Flow Data + CarburetorsDocument62 pagesSOHC Head Flow Data + CarburetorsVincenzo SepeNo ratings yet

- The Ball Piston EngineDocument13 pagesThe Ball Piston EnginedhairyashilNo ratings yet

- Propulsion and ShaftingDocument31 pagesPropulsion and ShaftingPriscila KImNo ratings yet

- Chapter Five Jet Pumping System (JP)Document33 pagesChapter Five Jet Pumping System (JP)mghareebNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Traditional Vietnamese Folk Song "Dem Nam Mo PhoDocument4 pagesTraditional Vietnamese Folk Song "Dem Nam Mo PhoKhởi NguyênNo ratings yet

- Upstream Technology - 3rd Edition - June 2016Document76 pagesUpstream Technology - 3rd Edition - June 2016Khởi NguyênNo ratings yet

- Info 7 PDFDocument1 pageInfo 7 PDFKhởi NguyênNo ratings yet

- Bước chân lẻ loi (guitar tab)Document6 pagesBước chân lẻ loi (guitar tab)Thái SơnNo ratings yet

- Caurse of Quantily ControlDocument15 pagesCaurse of Quantily ControlKhởi NguyênNo ratings yet

- Astm Materials Specifications Cross Reference ChartDocument1 pageAstm Materials Specifications Cross Reference ChartdidikosanNo ratings yet

- Comparación B73.1 Vs ISO 5199Document2 pagesComparación B73.1 Vs ISO 5199AlvialvarezNo ratings yet

- Trouble-Shooting Chart For PUMPSDocument1 pageTrouble-Shooting Chart For PUMPSAnwar SyedNo ratings yet

- Comparicion Ansi-Iec LV CCMDocument6 pagesComparicion Ansi-Iec LV CCMRicardo MzaNo ratings yet

- Section 10 Radiographic Inspection and Other NDTDocument18 pagesSection 10 Radiographic Inspection and Other NDTAnirbanNo ratings yet

- Asme Weld Categories PierredostieDocument1 pageAsme Weld Categories PierredostieSaddam BhattiNo ratings yet

- Asme Weld Categories PierredostieDocument1 pageAsme Weld Categories PierredostieSaddam BhattiNo ratings yet

- API 685 canned pumps reduce emissionsDocument13 pagesAPI 685 canned pumps reduce emissionsKhởi NguyênNo ratings yet

- API 685 canned pumps reduce emissionsDocument13 pagesAPI 685 canned pumps reduce emissionsKhởi NguyênNo ratings yet

- Caurse of Quantily ControlDocument15 pagesCaurse of Quantily ControlKhởi NguyênNo ratings yet

- Chemical ResistanceDocument12 pagesChemical ResistancegusunNo ratings yet

- Business Lessons I Learned From Steve Jobs PDFDocument6 pagesBusiness Lessons I Learned From Steve Jobs PDFKhởi NguyênNo ratings yet

- Placa Motor ElectricoDocument21 pagesPlaca Motor ElectricoMike_ValdereyraNo ratings yet

- Absorption Single Stage Application Guide PDFDocument20 pagesAbsorption Single Stage Application Guide PDFDavid Alejandro TellezNo ratings yet

- Modeling Sfe ProcessDocument11 pagesModeling Sfe ProcessKhởi NguyênNo ratings yet

- Lab 2 Torsion Lab Instruction SpringDocument7 pagesLab 2 Torsion Lab Instruction SpringYong JinNo ratings yet

- Induction Motor Load Test AnalysisDocument6 pagesInduction Motor Load Test AnalysisCønstäh Van Der WüppertälärîanskíhNo ratings yet

- Lee's Disc Apparatus (Theory) Heat & Thermodynamics Virtual LDocument3 pagesLee's Disc Apparatus (Theory) Heat & Thermodynamics Virtual LReddyvari VenugopalNo ratings yet

- Adjusting Max Displacement HPR-02Document3 pagesAdjusting Max Displacement HPR-02ArleyTrujillo1224No ratings yet

- Trilectron DAC900 TMEverestDocument394 pagesTrilectron DAC900 TMEverestVictory GSENo ratings yet

- Wire Rope Install GuideDocument65 pagesWire Rope Install GuideChe AjeekNo ratings yet

- Characteristics of the Hydraulic Jump LabDocument10 pagesCharacteristics of the Hydraulic Jump LabnaeemNo ratings yet

- Dex39 1540 - REV 01Document1 pageDex39 1540 - REV 01Navneet RankNo ratings yet

- 14070733Document27 pages14070733layaljamal2No ratings yet

- Bearing Capacity of Rockspub101172495Document13 pagesBearing Capacity of Rockspub101172495Mehdi Mir100% (1)

- V2607-DI-T-E3B: Kubota 07 SeriesDocument2 pagesV2607-DI-T-E3B: Kubota 07 SeriesRodrigoThuLokithoPkmz0% (1)

- Volvo Ecr50D: Parts CatalogDocument469 pagesVolvo Ecr50D: Parts CataloggiselleNo ratings yet

- Renault Master BrochureDocument37 pagesRenault Master BrochureAdriano Freire SilvaNo ratings yet

- Carnot CycleDocument11 pagesCarnot CycleEngr RbNo ratings yet

- Basement Car ParkDocument10 pagesBasement Car ParkAnjali ParkheNo ratings yet

- Thermal Relief Valves: From The Automation List Department..Document1 pageThermal Relief Valves: From The Automation List Department..Sofyan HadiNo ratings yet

- CAMON C8 Rotavator PowerSafe DiagramDocument16 pagesCAMON C8 Rotavator PowerSafe DiagramDomNo ratings yet

- Sa 2696 1Document1 pageSa 2696 1siddiq alviNo ratings yet

- EASA Piston Engine Module Tutorial QuestionsDocument19 pagesEASA Piston Engine Module Tutorial QuestionsJoseph Timoney100% (5)

- Hand Operated Can CrusherDocument60 pagesHand Operated Can CrusherParen Trivedi100% (2)

- Metsec Engineering Forms the FutureDocument24 pagesMetsec Engineering Forms the Futureshashank adigaNo ratings yet

- Injectors. Adaptations. Coding - Bimmerprofs - Com - NOx Emulator NOXEM 129 - 130 - 402 Developed For BMW N43 & N53 Series EnginesDocument27 pagesInjectors. Adaptations. Coding - Bimmerprofs - Com - NOx Emulator NOXEM 129 - 130 - 402 Developed For BMW N43 & N53 Series EnginesMiguelNo ratings yet

- Rail Transportation Safety Investigation Report R21C0070Document7 pagesRail Transportation Safety Investigation Report R21C0070CTV CalgaryNo ratings yet

- Carbs 101Document5 pagesCarbs 101Ashwin KumarNo ratings yet

- Die Casting Machines Core Pins & Ejector PinsDocument1 pageDie Casting Machines Core Pins & Ejector PinsJayden BarnesNo ratings yet

- Rds No. Standard Elementary System Size Pressure (Bar (G) )Document36 pagesRds No. Standard Elementary System Size Pressure (Bar (G) )Amit SharmaNo ratings yet

- 3-Element Drum LVL ControlDocument6 pages3-Element Drum LVL ControlNAYEEM100% (1)

- Progress on Equipment OverhaulDocument4 pagesProgress on Equipment Overhaulaldy albarNo ratings yet

- Mechanical Vibration and Oscillation in Transmission LinesDocument27 pagesMechanical Vibration and Oscillation in Transmission LinesChhatrapal SinghNo ratings yet