Professional Documents

Culture Documents

1 Harman Drive 10 - Revised Calcs

Uploaded by

markomarkomarkomarkoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Harman Drive 10 - Revised Calcs

Uploaded by

markomarkomarkomarkoCopyright:

Available Formats

58 Crossway, Welwyn Garden City, Herts, AL8 7 E E

Web: www.sts-se.co.uk

Email: sia@ sts-se.co.uk

Tel: 017 0 7 695466

Fax: 017 0 7 692006

STRUCTURAL CALCULATIONS

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job Ref: 1411-857

STS Structural Engineering Ltd

Structural Engineering Project Management

Registered in England No. 02623959

REV A

London office:

Siavash Sharif BEng, Managing Director

G A Fryer BSc, CEng, FICE, FCIWEM, Consultant

Lyn Heathcote Sharif, Financial Director

lyn@sts-se.co.uk

Belgrade office:

Marko Nesovic BEng, Technical Director

marko@sts-se.co.uk

Senjacka 22 Belgrade 11000 Serbia

T: +381 11 369 2693 M: +381 63 894 1048

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Design Philosophy

1. Overview

The existing building appears to be a late Victorian or Edwardian detached house. The building is

of masonry construction with suspended timber floors and a timber framed crown roof. The

property appears to remain largely original and unextended.

A nuber of internal alterations are proposed to the existing property to improve the layout and to

accomodate the new two storey side and rear extensions. Structural openings are to be created

to facilitate the new layout. Steel beams and frames are to be installed to support the floors and

walls as required.

A new roof will be installed to replace existing. The new roof will be steel and timber framed, and

a new grillage of steel beams will be installed at loft level to support the new loft floor as well as

the stud walls and columns supporting the roof structure.

Please refer to the structural drawings for more information.

2. Loading and the Structural Model

The structure is subject to dead, imposed and wind loading. All loading is listed and also

graphically shown in the analysis.

All steel sizing was done in accordance with BS5950. The relevant load combination for sizing

was 1.4*Dead+1.6*Imposed load. The deflections were checked for unfactored combinations of

loading.

The typical loading data is listed below:

Flat or Pitched Roof:

DL, 0.80 kN/m2

LL, 0.75 kN/m2

Floors:

DL, 0.4 kN/m2

LL, 1.5 kN/m2

Stud partition:

DL, 0.40 kN/m2 (of the actual partition)

or DL, 0.50 - 1.00 kN/m2 (per m2 of the floor average for lightweight partitions)

Solid walls:

DL, 18 kN/m3 (12 kN/m3 for new lightweight concrete blockwork walls)

Page 2/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Design Philosophy

3. Preliminary risk assessment

The contractor must provide a method statement and submit it to all relevant authorities and the

designer for checking. The method statement must provide a full risk assessment, indicating all

hazards and provide adequate measures to ensure a safe construction environment.

In addition to standard H&S measures associated with steel, concrete, excavation and other

types of work, care must be taken to ensure all risks associated with a renovation project like this

must also be considered. These include:

- Working in a confined environment, and safe delivery and installation of steelwork to minimise

disruption to the existing house.

-Temporary propping of the existing roof and other structural elements must be done to a high

standard to ensure the stability of the structure at all stages of the construction. The contractor

must provide temporary works design and submit it to the engineer for approval.

-To minimise the disruption to the neighbourhood all refuse must be delicately handled. The

noise pollution must be kept to a minimum at all times, and particularly if the construction is

carried out outside of the normal working hours and at weekends.

Page 3/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Roof Beams Load Analysis

N.B. All beam selfweights assigned automatically

Made By: MN

Checked: SS

Page:

REV A

Loft Beams to be analysed as a grillage using a FE software. Only direct

loading is to be inputed. Selfweight of elements assigned automatically.

Roof Beam MKR01

Imposed:

Roof

Dead:

Roof

4.5/2*0.75 =

4.5/2*1 =

1

1.69 kN/m

1

2.25 kN/m

Roof Beam MKR02

Imposed:

Roof

Dead:

Roof

5.4/2*0.75 =

5.4/2*1 =

1

2.03 kN/m

1

2.70 kN/m

Roof Beam MKR03

Imposed:

Roof

Dead:

Roof

3.9/2*0.75 =

3.9/2*1 =

1

1.46 kN/m

1

1.95 kN/m

Roof Beams MKR04, MKR05 (similar loading)

Imposed:

Roof

Dead:

Roof

1.5/2*0.75 =

1.5/2*1 =

1

0.56 kN/m

1

0.75 kN/m

Reaction from Hip-Beams

Imposed:

Roof

Dead:

Roof

2.2/2*1.4*0.75 =

2.2/2*1.4*1 =

1

1.16 kN/m

1

1.54 kN/m

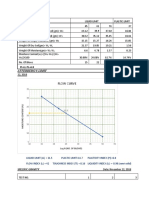

Graphical Representation of the Model

Page 4/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Roof Steels Structural Analysis Results

REV A

Page 5/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Roof Steels Structural Analysis Results

REV A

Page 6/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Beam:

Roof Beams MKR01, MKR02, MKR03 all similar

Beam sizing to BS5950:2000

REV A

Analysis

Analysis

Max. Applied Bending Moment Mx =

Max. Applied Shear, Fv =

Total length of beam (unstiffened) l =

Effective length factor Le/l =

Equivalent uniform moment factor mLT =

Member Forces (from planar frame analysis):

Table 13

Table 20

Section:

Blue book

29 kNm

21 kN

5.10 m

1.00

0.93

UC 152x152x37

Section Properties

Depth of Section (D)

Width of Section (b)

Thickness of Web (t)

Thickness of Flange (T)

Depth between fillets (d)

Second Moment of Area Axis x-x (Ix)

Radius of Gyration Axis x-x (rx)

Radius of Gyration Axis y-y (ry)

Elastic Modulus Axis x-x (Zx)

Plastic Modulus Axis x-x (Sx)

Buckling Parameter (u)

Torsional Index (x)

Area of Section (A)

161.8

154.4

8

11.5

123.6

2210

6.85

3.87

273

309

0.848

13.3

47.1

mm

mm

mm

mm

mm

cm4

cm

cm

cm3

cm3

cm2

Section Classification

Table 9

Steel is Grade:

The maximum thickness of steel:

Therefore, py =

Flange b/T =

Web d/t =

Section type:

43

11.50 mm

2

275 N/mm

6.71

15.5

UC

1

Plastic

- Class 1

=

Table 11

Cl. 4.2.3

Section is:

Shear Capacity

Max. Applied Shear, Fv =

Shear Area Av =

Shear Capacity Pv =

Efficiency Ratio

Shear Condition:

21.00 kN

2

1294 mm

213.58 kN

0.098

low

Section passes shear capacity

check

Page 7/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Beam:

Roof Beams MKR01, MKR02, MKR03 all similar

Beam sizing to BS5950:2000

REV A

Cl. 4.2.5

Moment Capacity

Low shear condition ref. cl. 4.2.6

Max. Applied Bending Moment M =

Plastic Modulus, S =

Moment Capacity, Mc =

Also check if it is less than 1.2 pyZ =

Efficiency Ratio

29.0

309

84.98

90.09

0.341

kNm

cm3

kNm

kNm

Yes

Section passes moment

capacity check

Cl 4.3

Lateral Torsional Buckling

Table 13

Effective Length Le/L ratio =

Total Length of the beam L =

Effective Length Le =

Max. Applied Bending Moment Mx =

Equivalent uniform moment factor mLT =

Slenderness =

Torsional Index x = D/t =

Slenderness factor v =

Buckling Parameter u =

Ratio W =

Equivalent Slenderness LT = uvW =

Limiting Equivalent slenderness L0 =

Robertson Constant LT =

Perry Factor LT =

Table 18

4.3.6.7

4.3.6.8

4.3.6.7

blue book

4.3.6.9

4.3.6.7

B.2.2

B.2.2

B.2.2

B.2.1

B.2.1

B.2.1

4.3.6.1

4.3.6.4

Euler Strength p =

LT =

Bending Strength pb =

Equivalent slenderness is more than Limiting eq. sl. Use pb for Lat. Tor. Buckling

Buckling Resistance moment Mb =

Efficiency Ratio

1.00

5.10 m

5.10 m

29.0 kNm

0.93

131.8

14.1

0.656

0.848

1.000

73.35

34.31

7.0

0.273

2

376 N/mm

2

377 N/mm

2

180.31 N/mm

56 kNm

0.484

Section passes lateral torsional

buckling check

Use UC 152x152x37 Section

Result:

Page 8/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Beam:

Roof Beams MKR04, MKR05

Beam sizing to BS5950:2000

REV A

Analysis

Analysis

Max. Applied Bending Moment Mx =

Max. Applied Shear, Fv =

Total length of beam (unstiffened) l =

Effective length factor Le/l =

Equivalent uniform moment factor mLT =

Member Forces (from planar frame analysis):

Table 13

Table 20

Section:

Blue book

18 kNm

11 kN

5.30 m

1.00

0.93

UC 152x152x37

Section Properties

Depth of Section (D)

Width of Section (b)

Thickness of Web (t)

Thickness of Flange (T)

Depth between fillets (d)

Second Moment of Area Axis x-x (Ix)

Radius of Gyration Axis x-x (rx)

Radius of Gyration Axis y-y (ry)

Elastic Modulus Axis x-x (Zx)

Plastic Modulus Axis x-x (Sx)

Buckling Parameter (u)

Torsional Index (x)

Area of Section (A)

161.8

154.4

8

11.5

123.6

2210

6.85

3.87

273

309

0.848

13.3

47.1

mm

mm

mm

mm

mm

cm4

cm

cm

cm3

cm3

cm2

Section Classification

Table 9

Steel is Grade:

The maximum thickness of steel:

Therefore, py =

Flange b/T =

Web d/t =

Section type:

43

11.50 mm

2

275 N/mm

6.71

15.5

UC

1

Plastic

- Class 1

=

Table 11

Cl. 4.2.3

Section is:

Shear Capacity

Max. Applied Shear, Fv =

Shear Area Av =

Shear Capacity Pv =

Efficiency Ratio

Shear Condition:

11.00 kN

2

1294 mm

213.58 kN

0.052

low

Section passes shear capacity

check

Page 9/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Beam:

Roof Beams MKR04, MKR05

Beam sizing to BS5950:2000

REV A

Cl. 4.2.5

Moment Capacity

Low shear condition ref. cl. 4.2.6

Max. Applied Bending Moment M =

Plastic Modulus, S =

Moment Capacity, Mc =

Also check if it is less than 1.2 pyZ =

Efficiency Ratio

18.0

309

84.98

90.09

0.212

kNm

cm3

kNm

kNm

Yes

Section passes moment

capacity check

Cl 4.3

Lateral Torsional Buckling

Table 13

Effective Length Le/L ratio =

Total Length of the beam L =

Effective Length Le =

Max. Applied Bending Moment Mx =

Equivalent uniform moment factor mLT =

Slenderness =

Torsional Index x = D/t =

Slenderness factor v =

Buckling Parameter u =

Ratio W =

Equivalent Slenderness LT = uvW =

Limiting Equivalent slenderness L0 =

Robertson Constant LT =

Perry Factor LT =

Table 18

4.3.6.7

4.3.6.8

4.3.6.7

blue book

4.3.6.9

4.3.6.7

B.2.2

B.2.2

B.2.2

B.2.1

B.2.1

B.2.1

4.3.6.1

4.3.6.4

Euler Strength p =

LT =

Bending Strength pb =

Equivalent slenderness is more than Limiting eq. sl. Use pb for Lat. Tor. Buckling

Buckling Resistance moment Mb =

Efficiency Ratio

1.00

5.30 m

5.30 m

18.0 kNm

0.93

137.0

14.1

0.646

0.848

1.000

75.04

34.31

7.0

0.285

2

359 N/mm

2

368 N/mm

2

176.31 N/mm

54 kNm

0.307

Section passes lateral torsional

buckling check

Use UC 152x152x37 Section

Result:

Page 10/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Roof Supporting Columns CR1-CR5

REV A

Load Analysis for CR2 most critical:

Reaction from MKR01

Imposed

Dead

Column selfweight:

Dead:

Table 13

Table 13

10.5 kN

16.5 kN

0.45 kN

Hence Maximum Axial Force (Fact.) Fc =

Nominally, assume load acting @ offset (e) from c/l:

Hence, maximum moment in a column Mx =

=R(MKR01)*e

Total Length of column =

Lex/l =

Ley/l =

Section:

Blue book

40.5 kN

0.04 m

1.60 kNm

2.8 m

1.0

1.0

SHS 80x80x8

Section Properties

Mass per metre

Depth of Section (D)

Width of Section (b)

Thickness of Web (t)

Thickness of Flange (T)

Root Radius (r)

Depth between fillets (d)

Ratios for Local Buckling Flange (b/2t)

Ratios for Local Buckling Web (d/s)

Second Moment of Area Axis x-x (Ix)

Second Moment of Area Axis y-y (Iy)

Radius of Gyration Axis x-x (rx)

Radius of Gyration Axis y-y (ry)

Elastic Modulus Axis x-x (Zx)

Elastic Modulus Axis y-y (Zy)

Plastic Modulus Axis x-x (Sx)

Plastic Modulus Axis y-y (Sy)

Buckling Parameter (u)

Torsional Index (x)

Area of Section (A)

Page 11/129

17.5

80

80

8

8

0

64

7

7

189

189

2.91

2.91

47.3

47.3

59.5

59.5

1

0

22.4

kg/m

mm

mm

mm

mm

mm

mm

cm4

cm4

cm

cm

cm3

cm3

cm3

cm3

cm2

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Roof Supporting Columns CR1-CR5

Section Classification

REV A

Steel is Grade:

The maximum thickness of steel:

Therefore,

py =

Table 9

Flange b/T =

Web d/t =

Section type:

3.5.5

43

8.00

275

5.00

8

SHS

1

=

Stress ratio r1 =

Stress ratio r2 =

0.014392

0.006579

Plastic

Table 11 Section is:

4.8.3.2

mm

N/mm2

- Class 1

Cross-section capacity

Worst combination of moments (kNm) Mx-x:

Plastic Modulus, Sx =

Moment Capacity, Mcx =

1.60

0.00

59.5

16.36

Plastic Modulus, Sy =

Moment Capacity, Mcy =

Fc/Agpy + Mx/Mcx + My/Mcy =

59.50

16.36

0.163

My-y:

kNm

kNm

cm3

kNm

cm3

kNm

1.2PyZ should be used

Section passes crosssection capacity check

4.7.4

Compression Resistances Pcx and Pcy

Total Length of the member L

Compression Pcx (x-x direction) (y-y similar)

Table 22 Effective Length Le/L ratio in x-x direction =

Effective Length Lex =

Slenderness x =

4.7.2

Limiting Slenderness L0 =

C.2

Table 23 Allocation of strut curve (x-x)

Robertson constant x =

C.2

Perry Factor x =

C.2

Euler Strength px =

C.1

x =

C.1

4.7.5, C.1 Compression Strength pcx =

Pcx = Agpc =

4.7.4

Page 12/129

2.800

1.00

2.80

96.2

17.15

a

2

0.15813

219

264

165.9

371.7

N/mm2

N/mm2

N/mm2

kN

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Roof Supporting Columns CR1-CR5

REV A

Buckling Resistance Moment Mb in x-x direction

4.3

Table 22 Effective Length Le/L ratio =

1.00

Total Length of the column L =

2.60

m

Effective Length Le =

2.60

m

Max. App. Bending Moment Mmax (MLT) =

1.6

kNm

m2 = 1,484.4, m3 = 2,114.0, m4 = 1,889.0, mmax = 2,137.4

0.93

Table 18 Equivalent uniform moment factor mLT =

4.3.6.7 Slenderness =

89.35

4.3.6.8 Torsional Index x = D/t =

10.0

4.3.6.7 Slenderness factor v =

0.669

blue book Buckling Parameter u =

1

4.3.6.9 Ratio W =

1.000

59.78

4.3.6.7 Equivalent Slenderness LT = uvW =

B.2.2 Limiting Equivalent slenderness L0 =

34.31

B.2.2 Robertson Constant LT =

7.0

Perry

Factor

=

B.2.2

0.178259

LT

2

B.2.1 Euler Strength p =

566.2475 N/mm

N/mm2

B.2.1 LT =

471

2

B.2.1 Bending Strength pb =

213.78 N/mm

4.3.6.1

4.3.6.4

4.8.3.3.4

Equivalent slenderness is more than Limiting eq.

sl. - Use pb for Lat. Tor. Buckling

Buckling Resistance moment Mb =

kNm

Equivalent uniform moment factors mx and my

Table 26 mx =

Table 26 my =

4.8.3.3.4

12.72

0.800

0.800

Member Buckling Resistance

Fc/Pc + mxMx/pyZx+myMy/pyZy =

Fc/Pcy + mLTMLT/Mb+myMy/pyZy =

0.207

0.226

Result:

Use SHS 80x80x8

Page 13/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: Flat Roof Joists R1

Made By: MN

Checked: SS

Page:

Try 150x50 timber joists at 400 mm spacing

Member Properties:

b=

d=

l=

w=

50

150

3.0

0.70

0.4*(0.75+1) =

(imp+dead)

mm breadth

mm depth

m length

kN/m udl

Grade Properties:

Timber Grade:

Bending parallel to grain:

Tension parallel to grain:

Compression parallel to grain:

Comp. perpendicular to grain:

Shear parallel to grain:

Emean:

Emin:

C16

5.3

3.2

6.8

2.2

0.67

8800

5800

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

K Factors:

Service class k1 =

Duration of loading (Table 14) k3 =

Shear of notched members k5 =

Load Shearing member k8 =

Members of several pieces (Table 17) k9 =

1

1

1

1.1

1

Maximum applied moment (at mid-span): wl2/8 =

Permissible bending stress = grade bending stress x k2xk3xk8xk9=

N/mm2

Zreqd = M/ =

135077

N/mm3

Zav.= bd2/6 =

187500

0.79 kNm

5.83 N/mm2

Member has adequate bending capacity

Deflection check:

Permissible deflection is:

0.003 xl

Permissible deflection 0.003 x l = 0.003 x 3000 =

9.00 mm

4

I = bd3/12 =

14.06E+06 mm

Use Emean because this is a load bearing member, E =

8800 N/mm2

4

Actual Bending Deflection = 5wl /384EL =

5.97 mm

Adjust deflection for shear: Tot. defl. = Defl. due to bending x (1+15.36(d/l)2)

Total Deflection =

6.20 mm

Deflection of the member is acceptable

Page 14/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: Flat Roof Joists R1

Shear Strength:

Permissible max = Shear parallel to grain x k2xk3xk5xk8xk9=

Shear at ends = wl/2 =

1.05 kN

Actual max = 1.5 F/bd =

0.21 N/mm2

Shear stress is permissible

Made By: MN

Checked: SS

Page:

0.737

Bearing Strength:

The Length of bearing is:

100 mm

The reaction at each end is:

1.05 kN

Permissible bearing stress = comp. to grain stress x k2xk3xk8xk9=

2.42 N/mm2

Actual Bearing stress is 1.05*1000/(100x50) =

0.2 N/mm2

Bearing stress is permissible

Lateral Support:

Depth to breadth ratio:

Support condition is:

Ends held in position

3.00

Page 15/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Check the side extension rafters and flat roof joists

Made By: MN

Checked: SS

Page:

Roof elements to be analysed as a frame using a FE software. Only direct

loading is to be inputed. Selfweight of elements assigned automatically.

Direct loading onto rafters and flat roof joists (per raftr/joist)

Imposed:

Roof (flat or pitched)

0.4*0.75 =

Dead:

Roof (flat or pitched)

0.4*1 =

Total:

load to be assigned as a global UDL. N.b. dead load very conservative

Loading and Analysis Results

Page 16/129

0.30 kN

0.40 kN

0.70 kN

STS Structural Engineering

Tel 0208 351 1366, Fax 0208 211 2096, www.sts-se.co.uk

20 Albany Road, Enfield EN3 5UF

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Made By: MN

L.A. Copy

Joists: Check Rafters

Check 150x50 back rafters

Member Properties:

b=

d=

l=

50

150

3.2

Max applied bending moment =

Max applied compressive force =

Max applied shear force =

mm breadth

mm depth

m length

1.45 kNm

2.20 kN

1.70 kN

Grade Properties:

Timber Grade:

Bending parallel to grain:

Tension parallel to grain:

Compression parallel to grain:

Comp. perpendicular to grain:

Shear parallel to grain:

Emean:

Emin:

C24

7.5

4.5

7.9

1.9

0.71

10800

7200

K Factors:

Service class k1 =

Duration of loading (Table 14) k3 =

Shear of notched members k5 =

Load Shearing member k8 =

Members of several pieces (Table 17) k9 =

1

1

1

1.1

1

BS5268

Table 18 Slenderness K factor, L = 3.2m, Le/L=0.7, hence Le=0.7*3.2=2.25m

i = I/A = ((bd/12) / bd) = d/12 =

0.0433 m

2.11.4 Hence Slenderness = Le/i =

52

Also, E/c,II =

1367

Table 22 Hence, K12 factor =

0.757

Page 17 of 129

N/mm

2

N/mm

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

STS Structural Engineering

Tel 0208 351 1366, Fax 0208 211 2096, www.sts-se.co.uk

20 Albany Road, Enfield EN3 5UF

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Made By: MN

L.A. Copy

Joists: Check Rafters

BS5268 Check member subject to axial compr. and bending

2.11.6 Permissible bending stress, m,adm,II = grade bending stress x k2xk3xk8xk9=

Permissible compressive stress, c,adm,II = grade compressive stress x k2xk

Euler critical stress, e = E/(Le/i) =

Applied bending stress m,a,II = M/Z =

Applied compressive stress c,a,II = N/A =

8.25 N/mm2

8.69 N/mm2

39.83 N/mm2

7.73 N/mm2

0.29 N/mm2

Hence m,a,II/(m,adm,II*(1-(1.5*c,a,II/e)*K12))+c,a,II/c,adm,II=

0.98

Section passes combined axial compression and bending stress check

Shear Strength:

Permissible max = Shear parallel to grain x k2xk3xk5xk8xk9=

Shear at ends = wl/2 =

1.12 kN

Actual max = 1.5 F/bd =

0.22 N/mm2

Shear stress is permissible

Lateral Support:

Depth to breadth ratio:

Support condition is:

Ends held in position

3.00

Page 18 of 129

1.70

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: Check flat roof joists R2

Made By: MN

Checked: SS

Page:

Try 125x50 timber joists at 400 mm spacing

Member Properties:

b=

d=

l=

50

125

3.20

mm breadth

mm depth

m length

Grade Properties:

Timber Grade:

Bending parallel to grain:

Tension parallel to grain:

Compression parallel to grain:

Comp. perpendicular to grain:

Shear parallel to grain:

Emean:

Emin:

C24

7.5

4.5

7.9

1.9

0.71

10800

7200

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

K Factors:

Service class k1 =

Duration of loading (Table 14) k3 =

Shear of notched members k5 =

Load Shearing member k8 =

Members of several pieces (Table 17) k9 =

1

1

1

1.1

1

from

2

analysis Maximum applied moment (at mid-span): wl /8 =

Permissible bending stress = grade bending stress x k2xk3xk8xk9=

N/mm2

Zreqd = M/ =

121212

N/mm3

Zav.= bd2/6 =

130208

1.00 kNm

8.25 N/mm2

Member has adequate bending capacity

Shear Strength:

Permissible max = Shear parallel to grain x k2xk3xk5xk8xk9=

from

analysis Shear at ends = wl/2 =

1.30 kN

Actual max = 1.5 F/bd =

0.31 N/mm2

Shear stress is permissible

Page 19/129

0.781

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Made By: MN

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Checked: SS

Job No. 1411-857

Page:

Joists: Check flat roof joists R2

Bearing Strength:

The Length of bearing is:

100 mm

The reaction at each end is:

1.30 kN

Permissible bearing stress = comp. to grain stress x k2xk3xk8xk9=

2.09 N/mm2

Actual Bearing stress is 1.3*1000/(100x50) =

0.3 N/mm2

Bearing stress is permissible

Lateral Support:

Depth to breadth ratio:

Support condition is:

Ends held in position

2.50

Page 20/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: Flat Roof Joists R3

Made By: MN

Checked: SS

Page:

Try 150x50 timber joists at 400 mm spacing

Member Properties:

b=

d=

l=

w=

50

150

3.3

0.70

0.4*(0.75+1) =

(imp+dead)

mm breadth

mm depth

m length

kN/m udl

Grade Properties:

Timber Grade:

Bending parallel to grain:

Tension parallel to grain:

Compression parallel to grain:

Comp. perpendicular to grain:

Shear parallel to grain:

Emean:

Emin:

C24

7.5

4.5

7.9

1.9

0.71

10800

7200

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

K Factors:

Service class k1 =

Duration of loading (Table 14) k3 =

Shear of notched members k5 =

Load Shearing member k8 =

Members of several pieces (Table 17) k9 =

1

1

1

1.1

1

Maximum applied moment (at mid-span): wl2/8 =

Permissible bending stress = grade bending stress x k2xk3xk8xk9=

N/mm2

Zreqd = M/ =

115500

N/mm3

Zav.= bd2/6 =

187500

0.95 kNm

8.25 N/mm2

Member has adequate bending capacity

Deflection check:

Permissible deflection is:

0.003 xl

Permissible deflection 0.003 x l = 0.003 x 3300 =

9.90 mm

4

I = bd3/12 =

14.06E+06 mm

Use Emean because this is a load bearing member, E =

##########

4

Actual Bending Deflection = 5wl /384EL =

7.12 mm

Adjust deflection for shear: Tot. defl. = Defl. due to bending x (1+15.36(d/l)2)

Total Deflection =

7.34 mm

Deflection of the member is acceptable

Page 21/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: Flat Roof Joists R3

Shear Strength:

Permissible max = Shear parallel to grain x k2xk3xk5xk8xk9=

Shear at ends = wl/2 =

1.16 kN

Actual max = 1.5 F/bd =

0.23 N/mm2

Shear stress is permissible

Made By: MN

Checked: SS

Page:

0.781

Bearing Strength:

The Length of bearing is:

100 mm

The reaction at each end is:

1.16 kN

Permissible bearing stress = comp. to grain stress x k2xk3xk8xk9=

2.09 N/mm2

Actual Bearing stress is 1.155*1000/(100x50) =

0.2 N/mm2

Bearing stress is permissible

Lateral Support:

Depth to breadth ratio:

Support condition is:

Ends held in position

3.00

Page 22/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: Flat Roof Joists R4

Made By: MN

Checked: SS

Page:

Try 225x50 timber joists at 400 mm spacing

Member Properties:

b=

d=

l=

w=

50

225

2.9

0.70

0.4*(0.75+1) =

(imp+dead)

mm breadth

mm depth

m length

kN/m udl

Grade Properties:

Timber Grade:

Bending parallel to grain:

Tension parallel to grain:

Compression parallel to grain:

Comp. perpendicular to grain:

Shear parallel to grain:

Emean:

Emin:

C16

5.3

3.2

6.8

2.2

0.67

8800

5800

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

K Factors:

Service class k1 =

Duration of loading (Table 14) k3 =

Shear of notched members k5 =

Load Shearing member k8 =

Members of several pieces (Table 17) k9 =

1

1

1

1.1

1

Maximum applied moment (at mid-span): wl2/8 =

Permissible bending stress = grade bending stress x k2xk3xk8xk9=

N/mm2

Zreqd = M/ =

126222

N/mm3

Zav.= bd2/6 =

421875

0.74 kNm

5.83 N/mm2

Member has adequate bending capacity

Deflection check:

Permissible deflection is:

0.003 xl

Permissible deflection 0.003 x l = 0.003 x 2900 =

8.70 mm

4

I = bd3/12 =

47.46E+06 mm

Use Emean because this is a load bearing member, E =

8800 N/mm2

4

Actual Bending Deflection = 5wl /384EL =

1.54 mm

Adjust deflection for shear: Tot. defl. = Defl. due to bending x (1+15.36(d/l)2)

Total Deflection =

1.69 mm

Deflection of the member is acceptable

Page 23/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: Flat Roof Joists R4

Shear Strength:

Permissible max = Shear parallel to grain x k2xk3xk5xk8xk9=

Shear at ends = wl/2 =

1.02 kN

Actual max = 1.5 F/bd =

0.14 N/mm2

Shear stress is permissible

Made By: MN

Checked: SS

Page:

0.737

Bearing Strength:

The Length of bearing is:

100 mm

The reaction at each end is:

1.02 kN

Permissible bearing stress = comp. to grain stress x k2xk3xk8xk9=

2.42 N/mm2

Actual Bearing stress is 1.015*1000/(100x50) =

0.2 N/mm2

Bearing stress is permissible

Lateral Support:

Depth to breadth ratio:

4.50

Support condition is:

End held in position and compression edge held in line, as by direct

connection of sheating, deck or joists

Page 24/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: Loft Floor Joists FL1

Made By: MN

Checked: SS

Page:

Try 175x50 timber joists at 400 mm spacing

Member Properties:

b=

d=

l=

w=

50

175

3.10

0.76

0.4*(1.5+0.4) =

(imp+dead)

mm breadth

mm depth

m length

kN/m udl

Grade Properties:

Timber Grade:

Bending parallel to grain:

Tension parallel to grain:

Compression parallel to grain:

Comp. perpendicular to grain:

Shear parallel to grain:

Emean:

Emin:

C24

7.5

4.5

7.9

1.9

0.71

10800

7200

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

K Factors:

Service class k1 =

Duration of loading (Table 14) k3 =

Shear of notched members k5 =

Load Shearing member k8 =

Members of several pieces (Table 17) k9 =

1

1

1

1.1

1

Maximum applied moment (at mid-span): wl2/8 =

Permissible bending stress = grade bending stress x k2xk3xk8xk9=

N/mm2

Zreqd = M/ =

110661

N/mm3

Zav.= bd2/6 =

255208

0.91 kNm

8.25 N/mm2

Member has adequate bending capacity

Deflection check:

Permissible deflection is:

0.003 xl

Permissible deflection 0.003 x l = 0.003 x 3100 =

9.30 mm

4

I = bd3/12 =

22.33E+06 mm

Use Emean because this is a load bearing member, E =

###########

4

Actual Bending Deflection = 5wl /384EL =

3.79 mm

Adjust deflection for shear: Tot. defl. = Defl. due to bending x (1+15.36(d/l)2)

Total Deflection =

3.97 mm

Deflection of the member is acceptable

Page 25/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: Loft Floor Joists FL1

Shear Strength:

Permissible max = Shear parallel to grain x k2xk3xk5xk8xk9=

Shear at ends = wl/2 =

1.18 kN

Actual max = 1.5 F/bd =

0.20 N/mm2

Shear stress is permissible

Made By: MN

Checked: SS

Page:

0.781

Bearing Strength:

The Length of bearing is:

100 mm

The reaction at each end is:

1.18 kN

Permissible bearing stress = comp. to grain stress x k2xk3xk8xk9=

2.09 N/mm2

Actual Bearing stress is 1.178*1000/(100x50) =

0.2 N/mm2

Bearing stress is permissible

Lateral Support:

Depth to breadth ratio:

3.50

Support condition is:

Ends held in position and member held in line by purlins or tie rods at centres

not more than 30 times breadth of the member

Page 26/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Joists: Loft Floor Joists FL2 (FL3 similar, shorter span)

Try 175x50 timber joists at 400 mm spacing

Grade Properties:

Timber Grade:

Bending parallel to grain:

Tension parallel to grain:

Compression parallel to grain:

Comp. perpendicular to grain:

Shear parallel to grain:

Emean:

Emin:

C24

7.5

4.5

7.9

1.9

0.71

10800

7200

Member Properties:

b=

d=

l=

50

175

2.7

Loading (per joist):

Point Load @ 1.5m approx. - Roof Reaction

Dead:

0.4*(2.7/2*1+1.5*0.5) =

Imposed:: 0.4*2.7/2*0.75 =

UDL (residential floor):

Dead:

0.4*0.4 =

Imposed:: 0.4*1.5 =

UDL (storage) :

Dead:

0.4*0.4 =

Imposed:: 0.4*0.5 =

0.840

0.405

0.160

0.600

0.160

0.200

Member Forces:

B.M. Diagram 1.6xI + 1.4xD

0

0.5

1.5

2.5

0.0

0.0

L (m)

0.5

0.8

Shear Force Diagram 1.6xI +

1.4xD

-2

0.8

1

1.3

1.5

Shear Foce (kN)

Bending Moment

(kNm)

-1.3

3

0

0.4

1.0

1

1.5

2

Page 27/129

-1.1

-1

L (m)

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Joists: Loft Floor Joists FL2 (FL3 similar, shorter span)

Deflections Diagram (unfactored)

Deformation

(mm)

0

0

0.0

0.5

1.5

2.5

0.0

3

L (m)

-2

-2.2

-2.2

-2.9

-4

Total Span/Deflection =

1/737

K Factors:

Service class k1 =

Duration of loading (Table 14) k3 =

Shear of notched members k5 =

Load Shearing member k8 =

Members of several pieces (Table 17) k9 =

1

1

1

1.1

1

Maximum applied moment Mu =

Permissible bending stress = grade bending stress x k2xk3xk8xk9=

N/mm2

Zreqd = M/ =

163515

N/mm3

Zav.= bd2/6 =

255208

Member has adequate bending capacity

Shear Strength:

Permissible max = Shear parallel to grain x k2xk3xk5xk8xk9=

Maximum Shear at ends

1.47 kN

Actual max =

0.25 N/mm2

Shear stress is permissible

Bearing Strength:

The Length of bearing is:

100 mm

The maximum reaction R =

Permissible bearing stress = comp. to grain stress x k2xk3xk8xk9=

Actual Bearing stress is 1.47*1000/(100x50) =

0.3 N/mm2

Bearing stress is permissible

Lateral Support:

Depth to breadth ratio:

3.50

Support condition is:

Ends held in position and member held in line by purlins or tie

rods at centres not more than 30 times breadth of the member

Page 28/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Joists: Loft Floor Joists FL4 (side extension)

Try 175x50 timber joists at 400 mm spacing

Grade Properties:

Timber Grade:

Bending parallel to grain:

Tension parallel to grain:

Compression parallel to grain:

Comp. perpendicular to grain:

Shear parallel to grain:

Emean:

Emin:

C24

7.5

4.5

7.9

1.9

0.71

10800

7200

Member Properties:

b=

d=

l=

50

175

2.2

Loading (per joist):

Point Load @ 1.1m approx. - Roof Reaction

Dead:

0.4*(3.7/2*1+1.5*0.5) =

Imposed:: 0.4*3.7/2*0.75 =

UDL (residential floor):

Dead:

0.4*0.4 =

Imposed:: 0.4*1.5 =

UDL (storage) :

Dead:

0.4*0.4 =

Imposed:: 0.4*0.5 =

1.040

0.555

0.160

0.600

0.160

0.200

Member Forces:

B.M. Diagram 1.6xI + 1.4xD

0

0.5

1.5

0.0

0.0

L (m)

0.5

0.7

0.7

Shear Force Diagram 1.6xI +

1.4xD

-2

2.5

1

1.2

1.5

Shear Foce (kN)

Bending Moment

(kNm)

-1.3

3

0

0.7

1.1

1.5

Page 29/129

-1.1

-1

L (m)

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Made By: MN

Checked: SS

Page:

Joists: Loft Floor Joists FL4 (side extension)

Deflections Diagram (unfactored)

Deformation

(mm)

0

0

0.0

0.5

1.5

0.0

2.5

L (m)

-1

-1.2

-1.3

-1.7

-2

Total Span/Deflection =

1/1056

K Factors:

Service class k1 =

Duration of loading (Table 14) k3 =

Shear of notched members k5 =

Load Shearing member k8 =

Members of several pieces (Table 17) k9 =

1

1

1

1.1

1

Maximum applied moment Mu =

Permissible bending stress = grade bending stress x k2xk3xk8xk9=

N/mm2

Zreqd = M/ =

147394

N/mm3

Zav.= bd2/6 =

255208

Member has adequate bending capacity

Shear Strength:

Permissible max = Shear parallel to grain x k2xk3xk5xk8xk9=

Maximum Shear at ends

1.52 kN

Actual max =

0.26 N/mm2

Shear stress is permissible

Bearing Strength:

The Length of bearing is:

100 mm

The maximum reaction R =

Permissible bearing stress = comp. to grain stress x k2xk3xk8xk9=

Actual Bearing stress is 1.52*1000/(100x50) =

0.3 N/mm2

Bearing stress is permissible

Lateral Support:

Depth to breadth ratio:

3.50

Support condition is:

Ends held in position and member held in line by purlins or tie

rods at centres not more than 30 times breadth of the member

Page 30/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: First Floor Joists FF1

Made By: MN

Checked: SS

Page:

Try 225x50 timber joists at 400 mm spacing

Member Properties:

b=

d=

l=

w=

50

225

3.50

0.76

0.4*(1.5+0.4) =

(imp+dead)

mm breadth

mm depth

m length

kN/m udl

Grade Properties:

Timber Grade:

Bending parallel to grain:

Tension parallel to grain:

Compression parallel to grain:

Comp. perpendicular to grain:

Shear parallel to grain:

Emean:

Emin:

C24

7.5

4.5

7.9

1.9

0.71

10800

7200

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

K Factors:

Service class k1 =

Duration of loading (Table 14) k3 =

Shear of notched members k5 =

Load Shearing member k8 =

Members of several pieces (Table 17) k9 =

1

1

1

1.1

1

Maximum applied moment (at mid-span): wl2/8 =

Permissible bending stress = grade bending stress x k2xk3xk8xk9=

N/mm2

Zreqd = M/ =

141061

N/mm3

Zav.= bd2/6 =

421875

1.16 kNm

8.25 N/mm2

Member has adequate bending capacity

Deflection check:

Permissible deflection is:

0.003 xl

Permissible deflection 0.003 x l = 0.003 x 3500 =

10.50 mm

4

I = bd3/12 =

47.46E+06 mm

Use Emean because this is a load bearing member, E =

###########

4

Actual Bending Deflection = 5wl /384EL =

2.90 mm

Adjust deflection for shear: Tot. defl. = Defl. due to bending x (1+15.36(d/l)2)

Total Deflection =

3.08 mm

Deflection of the member is acceptable

Page 31/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: First Floor Joists FF1

Shear Strength:

Permissible max = Shear parallel to grain x k2xk3xk5xk8xk9=

Shear at ends = wl/2 =

1.33 kN

Actual max = 1.5 F/bd =

0.18 N/mm2

Shear stress is permissible

Made By: MN

Checked: SS

Page:

0.781

Bearing Strength:

The Length of bearing is:

100 mm

The reaction at each end is:

1.33 kN

Permissible bearing stress = comp. to grain stress x k2xk3xk8xk9=

2.09 N/mm2

Actual Bearing stress is 1.33*1000/(100x50) =

0.3 N/mm2

Bearing stress is permissible

Lateral Support:

Depth to breadth ratio:

4.50

Support condition is:

End held in position and compression edge held in line, as by direct

connection of sheating, deck or joists

Page 32/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: First Floor Joists FF2

Made By: MN

Checked: SS

Page:

Try 150x50 timber joists at 400 mm spacing

Member Properties:

b=

d=

l=

w=

50

150

2.50

0.76

0.4*(1.5+0.4) =

(imp+dead)

mm breadth

mm depth

m length

kN/m udl

Grade Properties:

Timber Grade:

Bending parallel to grain:

Tension parallel to grain:

Compression parallel to grain:

Comp. perpendicular to grain:

Shear parallel to grain:

Emean:

Emin:

C24

7.5

4.5

7.9

1.9

0.71

10800

7200

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

N/mm2

K Factors:

Service class k1 =

Duration of loading (Table 14) k3 =

Shear of notched members k5 =

Load Shearing member k8 =

Members of several pieces (Table 17) k9 =

1

1

1

1.1

1

Maximum applied moment (at mid-span): wl2/8 =

Permissible bending stress = grade bending stress x k2xk3xk8xk9=

N/mm2

Zreqd = M/ =

71970

N/mm3

Zav.= bd2/6 =

187500

0.59 kNm

8.25 N/mm2

Member has adequate bending capacity

Deflection check:

Permissible deflection is:

0.003 xl

Permissible deflection 0.003 x l = 0.003 x 2500 =

7.50 mm

4

I = bd3/12 =

14.06E+06 mm

Use Emean because this is a load bearing member, E =

###########

4

Actual Bending Deflection = 5wl /384EL =

2.55 mm

Adjust deflection for shear: Tot. defl. = Defl. due to bending x (1+15.36(d/l)2)

Total Deflection =

2.69 mm

Deflection of the member is acceptable

Page 33/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

1 Harman Drive, London NW2 2EB

Job:

Side and Rear Extensions, New Roof, Extensive Remodelling

Job No. 1411-857

Joists: First Floor Joists FF2

Shear Strength:

Permissible max = Shear parallel to grain x k2xk3xk5xk8xk9=

Shear at ends = wl/2 =

0.95 kN

Actual max = 1.5 F/bd =

0.19 N/mm2

Shear stress is permissible

Made By: MN

Checked: SS

Page:

0.781

Bearing Strength:

The Length of bearing is:

100 mm

The reaction at each end is:

0.95 kN

Permissible bearing stress = comp. to grain stress x k2xk3xk8xk9=

2.09 N/mm2

Actual Bearing stress is 0.95*1000/(100x50) =

0.2 N/mm2

Bearing stress is permissible

Lateral Support:

Depth to breadth ratio:

Support condition is:

Ends held in position

3.00

Page 34/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Loft Floor Load Analysis

N.B. All beam selfweights assigned automatically

Made By: MN

Checked: SS

Page:

REV A

Loft Beams to be analysed as a grillage using a FE software. Only direct

loading is to be inputed. Selfweight of elements assigned automatically.

Beam MKL01

Imposed:

Roof

Loft Floor

Ceiling

Dead:

Roof

Loft Floor

Timber Stud Wall

Beam MKL02, MKL03 similar loading

Imposed:

Loft Floor

Dead:

Loft Floor

Beam MKL04 - OMIT

Page 35/129

2.1/2*0.75 =

2.3/2*1.5 =

1.3/2*0.25 =

0.79

1.73

0.16

2.68

kN/m1

kN/m1

kN/m1

kN/m1

2.1/2*1 =

3.6/2*0.4 =

1.5*0.5 =

1.05

0.72

0.75

2.52

kN/m1

kN/m1

kN/m1

kN/m1

5/2*1.5 =

5/2*0.4 =

1

3.75 kN/m

1

1.00 kN/m

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Loft Floor Load Analysis

Beams MKL05, MKL05a

between stairwell and MKL14

Imposed:

Roof

4.5/2*0.75 =

Loft Floor

5.8/2*1.5 =

Dead:

Roof

Loft Floor

Stud Walls (per sqm)

4.5/2*1 =

5.8/2*0.4 =

4.6/2*0.5 =

between MKL14 and PL7

Imposed:

Roof

Loft Floor

Dead:

Roof

Loft Floor

Timber Stud Wall (adj.)

Loft Floor

Stud Walls (per sqm)

1.40

1.12

0.75

3.27

2.9/2*1 =

2.5/2*0.4 =

1.4*0.5 =

Page 36/129

kN/m1

kN/m1

kN/m1

kN/m1

kN/m1

kN/m1

kN/m1

2.8/2*1 =

5.6/2*0.4 =

1.5*0.5 =

3.3/2*0.4 =

3.3/2*1 =

Roof

Loft Floor

Timber Stud Wall

1.69

4.35

6.04

2.25

1.16

1.15

4.56

1

1.05 kN/m

1

4.20 kN/m

1

5.25 kN/m

Beams MKL08, MKL09, MKL10 all similar loading

Imposed:

Roof

2.9/2*0.75 =

Loft Floor

1*1.5 =

Dead:

REV A

2.8/2*0.75 =

5.6/2*1.5 =

Part Spreaders MKL06, MKL07 similar loading

Imposed:

Loft Floor

3.3/2*1.5 =

Dead:

Made By: MN

Checked: SS

Page:

kN/m1

kN/m1

kN/m1

kN/m1

1

2.48 kN/m

1

0.66 kN/m

1

1.65 kN/m

1

2.31 kN/m

1

1.09 kN/m

1

1.50 kN/m

1

2.59 kN/m

1.45

0.50

0.70

2.65

kN/m1

kN/m1

kN/m1

kN/m1

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Loft Floor Load Analysis

Beams MKL11, MKL12, MKL14 all similar loading

Imposed:

Roof

5.6/2*0.75 =

Loft Floor

0.5*1.5 =

Dead:

Roof

Loft Floor

Timber Stud Wall

Made By: MN

Checked: SS

Page:

REV A

1

2.10 kN/m

1

0.75 kN/m

1

2.85 kN/m

kN/m1

kN/m1

kN/m1

kN/m1

5.6/2*1 =

0.5*0.4 =

1.5*0.5 =

2.80

0.20

0.75

3.75

6.5/2*0.75 =

2/2*1.5 =

1

2.44 kN/m

1

1.50 kN/m

1

3.94 kN/m

6.5/2*1 =

2/2*0.4 =

1.5*0.5 =

3.25

0.40

0.75

4.40

Beam MKLL14a

Imposed:

Loft Floor

Dead:

Loft Floor

1*1.5 =

1*0.4 =

1

1.50 kN/m

1

0.40 kN/m

Beam MKL15

Imposed:

Loft Floor / Stair

Dead:

Loft Floor / Stair

2.8/2*1.5 =

2.8/2*0.4 =

1

2.10 kN/m

1

0.56 kN/m

Beam MKL16

Imposed:

Roof

Loft Floor

3.8/2*0.75 =

0.5*1.5 =

1

1.43 kN/m

1

0.75 kN/m

1

2.18 kN/m

3.8/2*1 =

0.5*0.4 =

2.7*0.5 =

1.90

0.20

1.35

3.45

3.4/2*1.5 =

REV A

3.4/2*0.4 =

2.7*0.5 =

1

2.55 kN/m

Beams MKL13

Imposed:

Roof

Loft Floor

Dead:

Dead:

Roof

Loft Floor

Timber Stud Wall

Roof

Loft Floor

Timber Stud Wall

Beam MKL17

Imposed:

Loft Floor

Dead:

Loft Floor

Timber Stud Wall

Page 37/129

kN/m1

kN/m1

kN/m1

kN/m1

kN/m1

kN/m1

kN/m1

kN/m1

1

0.68 kN/m

1

1.35 kN/m

1

2.03 kN/m

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Loft Floor Load Analysis

Beam MKL19

Imposed:

Roof

4.7/2*0.75 =

Loft Floor

3/2*1.5 =

REV A

Dead:

Roof

Loft Floor

Timber Stud Wall

Beam MKL21

Imposed:

Roof

Loft Floor

Dead:

Roof

Loft Floor

Timber Stud Wall

Also allow for reactions from roof columns

Graphical Representation of the Model

Page 38/129

Made By: MN

Checked: SS

Page:

REV A

1

1.76 kN/m

1

2.25 kN/m

1

4.01 kN/m

kN/m1

kN/m1

kN/m1

kN/m1

4.7/2*1 =

3/2*0.4 =

2.2*0.5 =

2.35

0.60

1.10

4.05

2.4/2*0.75 =

2.4/2*1.5 =

1

0.90 kN/m

1

1.80 kN/m

1

2.70 kN/m

2.4/2*1 =

2.4*0.4 =

1/2*1.5*0.5 =

1.20

0.96

0.38

2.54

kN/m1

kN/m1

kN/m1

kN/m1

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Loft Floor Grillage Structural Analysis results

Page 39/129

Made By: MN

Checked: SS

Page:

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Loft Floor Grillage Structural Analysis results

Page 40/129

Made By: MN

Checked: SS

Page:

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Loft Floor Grillage Structural Analysis results

Page 41/129

Made By: MN

Checked: SS

Page:

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Loft Floor Grillage Structural Analysis results

Page 42/129

Made By: MN

Checked: SS

Page:

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Beam:

Beam MKL01

Beam sizing to BS5950:2000

Analysis

Analysis

Max. Applied Bending Moment Mx =

Max. Applied Shear, Fv =

Total length of beam (unstiffened) l =

Effective length factor Le/l =

Equivalent uniform moment factor mLT =

Made By: MN

Checked: SS

Page:

Member Forces (from planar frame analysis):

Table 13

Table 20

Section:

Blue book

20 kNm

18 kN

4.30 m

1.00

0.93

UC 152x152x30

Section Properties

Depth of Section (D)

Width of Section (b)

Thickness of Web (t)

Thickness of Flange (T)

Depth between fillets (d)

Second Moment of Area Axis x-x (Ix)

Radius of Gyration Axis x-x (rx)

Radius of Gyration Axis y-y (ry)

Elastic Modulus Axis x-x (Zx)

Plastic Modulus Axis x-x (Sx)

Buckling Parameter (u)

Torsional Index (x)

Area of Section (A)

157.6

152.9

6.5

9.4

123.6

1748

6.76

3.83

222

248

0.849

16

38.3

mm

mm

mm

mm

mm

cm4

cm

cm

cm3

cm3

cm2

Section Classification

Table 9

Steel is Grade:

The maximum thickness of steel:

Therefore, py =

Flange b/T =

Web d/t =

Section type:

43

9.40 mm

2

275 N/mm

8.13

19.0

UC

1

Plastic

- Class 1

=

Table 11

Cl. 4.2.3

Section is:

Shear Capacity

Max. Applied Shear, Fv =

Shear Area Av =

Shear Capacity Pv =

Efficiency Ratio

Shear Condition:

18.00 kN

2

1024 mm

169.03 kN

0.106

low

Section passes shear capacity

check

Page 43/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Beam:

Beam MKL01

Beam sizing to BS5950:2000

Cl. 4.2.5

Made By: MN

Checked: SS

Page:

Moment Capacity

Low shear condition ref. cl. 4.2.6

Max. Applied Bending Moment M =

Plastic Modulus, S =

Moment Capacity, Mc =

Also check if it is less than 1.2 pyZ =

Efficiency Ratio

20.0

248

68.20

73.26

0.293

kNm

cm3

kNm

kNm

Yes

Section passes moment

capacity check

Cl 4.3

Lateral Torsional Buckling

Table 13

Effective Length Le/L ratio =

Total Length of the beam L =

Effective Length Le =

Max. Applied Bending Moment Mx =

Equivalent uniform moment factor mLT =

Slenderness =

Torsional Index x = D/t =

Slenderness factor v =

Buckling Parameter u =

Ratio W =

Equivalent Slenderness LT = uvW =

Limiting Equivalent slenderness L0 =

Robertson Constant LT =

Perry Factor LT =

Table 18

4.3.6.7

4.3.6.8

4.3.6.7

blue book

4.3.6.9

4.3.6.7

B.2.2

B.2.2

B.2.2

B.2.1

B.2.1

B.2.1

4.3.6.1

4.3.6.4

Euler Strength p =

LT =

Bending Strength pb =

Equivalent slenderness is more than Limiting eq. sl. Use pb for Lat. Tor. Buckling

Buckling Resistance moment Mb =

Efficiency Ratio

1.00

4.30 m

4.30 m

20.0 kNm

0.93

112.3

16.8

0.745

0.849

1.000

71.03

34.31

7.0

0.257

2

401 N/mm

2

390 N/mm

2

185.90 N/mm

46 kNm

0.403

Section passes lateral torsional

buckling check

Use UC 152x152x30 Section

Result:

Page 44/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Beam:

Beam MKL02

Beam sizing to BS5950:2000

Analysis

Analysis

Max. Applied Bending Moment Mx =

Max. Applied Shear, Fv =

Total length of beam (unstiffened) l =

Effective length factor Le/l =

Equivalent uniform moment factor mLT =

Made By: MN

Checked: SS

Page:

Member Forces (from planar frame analysis):

Table 13

Table 20

Section:

Blue book

19 kNm

38 kN

1.50 m

1.00

0.93

UC 152x152x23

Section Properties

Depth of Section (D)

Width of Section (b)

Thickness of Web (t)

Thickness of Flange (T)

Depth between fillets (d)

Second Moment of Area Axis x-x (Ix)

Radius of Gyration Axis x-x (rx)

Radius of Gyration Axis y-y (ry)

Elastic Modulus Axis x-x (Zx)

Plastic Modulus Axis x-x (Sx)

Buckling Parameter (u)

Torsional Index (x)

Area of Section (A)

152.4

152.2

5.8

6.8

123.6

1250

6.54

3.7

164

182

0.84

20.7

29.2

mm

mm

mm

mm

mm

cm4

cm

cm

cm3

cm3

cm2

Section Classification

Table 9

Steel is Grade:

The maximum thickness of steel:

Therefore, py =

Flange b/T =

Web d/t =

Section type:

43

6.80 mm

2

275 N/mm

11.19

21.3

UC

1

Semi-Compact - Class 2

=

Table 11

Cl. 4.2.3

Section is:

Shear Capacity

Max. Applied Shear, Fv =

Shear Area Av =

Shear Capacity Pv =

Efficiency Ratio

Shear Condition:

38.00 kN

2

884 mm

145.85 kN

0.261

low

Section passes shear capacity

check

Page 45/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Beam:

Beam MKL02

Beam sizing to BS5950:2000

Cl. 4.2.5

Made By: MN

Checked: SS

Page:

Moment Capacity

Low shear condition ref. cl. 4.2.6

Max. Applied Bending Moment M =

Elastic Modulus, Z =

Moment Capacity, Mc =

19.0 kNm

3

164 cm

45.10 kNm

Efficiency Ratio

0.421

Section passes moment

capacity check

Cl 4.3

Lateral Torsional Buckling

Table 13

Effective Length Le/L ratio =

Total Length of the beam L =

Effective Length Le =

Max. Applied Bending Moment Mx =

Equivalent uniform moment factor mLT =

Slenderness =

Torsional Index x = D/t =

Slenderness factor v =

Buckling Parameter u =

Ratio W =

Equivalent Slenderness LT = uvW =

Limiting Equivalent slenderness L0 =

Robertson Constant LT =

Perry Factor LT =

Table 18

4.3.6.7

4.3.6.8

4.3.6.7

blue book

4.3.6.9

4.3.6.7

B.2.2

B.2.2

B.2.2

B.2.1

B.2.1

B.2.1

4.3.6.1

4.3.6.4

Euler Strength p =

LT =

Bending Strength pb =

Equivalent slenderness is less than Limiting eq. sl. Lat.

Tor. Buckling need not be considered

Buckling Resistance Moment = Mc

Efficiency Ratio

1.00

1.50 m

1.50 m

19.0 kNm

0.93

40.5

22.4

0.963

0.84

0.901

31.12

34.31

7.0

0.000

2

2089 N/mm

2

1182 N/mm

2

275.00 N/mm

45 kNm

0.392

Section passes lateral torsional

buckling check

Use UC 152x152x23 Section

Result:

Page 46/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Beam:

Beam MKL03

Beam sizing to BS5950:2000

Analysis

Analysis

Max. Applied Bending Moment Mx =

Max. Applied Shear, Fv =

Total length of beam l =

Effective length factor Le/l =

Equivalent uniform moment factor mLT =

Made By: MN

Checked: SS

Page:

Member Forces (from planar frame analysis):

Table 13

Table 20

Section:

Blue book

50 kNm

29 kN

4.5 m

1.00

0.93

UC 152x152x37

Section Properties

Depth of Section (D)

Width of Section (b)

Thickness of Web (t)

Thickness of Flange (T)

Depth between fillets (d)

Second Moment of Area Axis x-x (Ix)

Radius of Gyration Axis x-x (rx)

Radius of Gyration Axis y-y (ry)

Elastic Modulus Axis x-x (Zx)

Plastic Modulus Axis x-x (Sx)

Buckling Parameter (u)

Torsional Index (x)

Area of Section (A)

161.8

154.4

8

11.5

123.6

2210

6.85

3.87

273

309

0.848

13.3

47.1

mm

mm

mm

mm

mm

cm4

cm

cm

cm3

cm3

cm2

Section Classification

Table 9

Steel is Grade:

The maximum thickness of steel:

Therefore, py =

Flange b/T =

Web d/t =

Section type:

43

11.50 mm

2

275 N/mm

6.71

15.5

UC

1

Plastic

- Class 1

=

Table 11

Cl. 4.2.3

Section is:

Shear Capacity

Max. Applied Shear, Fv =

Shear Area Av =

Shear Capacity Pv =

Efficiency Ratio

Shear Condition:

29.00 kN

2

1294 mm

213.58 kN

0.136

low

Section passes shear capacity

check

Page 47/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Beam:

Beam MKL03

Beam sizing to BS5950:2000

Cl. 4.2.5

Made By: MN

Checked: SS

Page:

Moment Capacity

Low shear condition ref. cl. 4.2.6

Max. Applied Bending Moment M =

Plastic Modulus, S =

Moment Capacity, Mc =

Also check if it is less than 1.2 pyZ =

Efficiency Ratio

50.0

309

84.98

90.09

0.588

kNm

cm3

kNm

kNm

Yes

Section passes moment

capacity check

Cl 4.3

Lateral Torsional Buckling

Table 13

Effective Length Le/L ratio =

Total Length of the beam L =

Effective Length Le =

Max. Applied Bending Moment Mx =

Equivalent uniform moment factor mLT =

Slenderness =

Torsional Index x = D/t =

Slenderness factor v =

Buckling Parameter u =

Ratio W =

Equivalent Slenderness LT = uvW =

Limiting Equivalent slenderness L0 =

Robertson Constant LT =

Perry Factor LT =

Table 18

4.3.6.7

4.3.6.8

4.3.6.7

blue book

4.3.6.9

4.3.6.7

B.2.2

B.2.2

B.2.2

B.2.1

B.2.1

B.2.1

4.3.6.1

4.3.6.4

Euler Strength p =

LT =

Bending Strength pb =

Equivalent slenderness is more than Limiting eq. sl. Use pb for Lat. Tor. Buckling

Buckling Resistance moment Mb =

Efficiency Ratio

1.00

4.50 m

4.50 m

50.0 kNm

0.93

116.3

14.1

0.690

0.848

1.000

68.02

34.31

7.0

0.236

2

437 N/mm

2

408 N/mm

2

193.26 N/mm

60 kNm

0.779

Section passes lateral torsional

buckling check

Use UC 152x152x37 Section

Result:

Page 48/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE

Site:

Job:

Job No.

1 Harman Drive, London NW2 2EB

Side and Rear Extensions, New Roof, Extensive Remodelling

1411-857

Beam:

Beam MKL05

Beam sizing to BS5950:2000

Analysis

Analysis

Max. Applied Bending Moment Mx =

Max. Applied Shear, Fv =

Total length of beam l =

Effective length factor Le/l =

Equivalent uniform moment factor mLT =

Made By: MN

Checked: SS

Page:

Member Forces (from planar frame analysis):

Table 13

Table 20

Section:

Blue book

54 kNm

85 kN

3.4 m

1.00

0.93

UC 152x152x37

Section Properties

Depth of Section (D)

Width of Section (b)

Thickness of Web (t)

Thickness of Flange (T)

Depth between fillets (d)

Second Moment of Area Axis x-x (Ix)

Radius of Gyration Axis x-x (rx)

Radius of Gyration Axis y-y (ry)

Elastic Modulus Axis x-x (Zx)

Plastic Modulus Axis x-x (Sx)

Buckling Parameter (u)

Torsional Index (x)

Area of Section (A)

161.8

154.4

8

11.5

123.6

2210

6.85

3.87

273

309

0.848

13.3

47.1

mm

mm

mm

mm

mm

cm4

cm

cm

cm3

cm3

cm2

Section Classification

Table 9

Steel is Grade:

The maximum thickness of steel:

Therefore, py =

Flange b/T =

Web d/t =

Section type:

43

11.50 mm

2

275 N/mm

6.71

15.5

UC

1

Plastic

- Class 1

=

Table 11

Cl. 4.2.3

Section is:

Shear Capacity

Max. Applied Shear, Fv =

Shear Area Av =

Shear Capacity Pv =

Efficiency Ratio

Shear Condition:

85.00 kN

2

1294 mm

213.58 kN

0.398

low

Section passes shear capacity

check

Page 49/129

STS Structural Engineering

Tel: 01707 695466 Fax: 01707 692006, www.sts-se.co.uk, 58 Crossway, Welwyn Garden City, Herts AL8 7EE