Professional Documents

Culture Documents

What Is Chemical Engineering

Uploaded by

YASH0 ratings0% found this document useful (0 votes)

41 views13 pageschemical engineering guide

Original Title

What is Chemical Engineering

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentchemical engineering guide

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

41 views13 pagesWhat Is Chemical Engineering

Uploaded by

YASHchemical engineering guide

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 13

What is Chemical Engineering?

This is actually a vast question! So let me elaborate my

views about the chemical engineering profession

through a story. This tale is quite long but I hope you

will find it informative and interesting.

X is a chemical engineer. A chemical engineer par

excellence. One fine day, he is summoned by his boss

and given a new assignment. The chemists of the

company have found that if reactants A and B are

mixed, then the valuable product P will be formed. X's

boss tells him to engineer this reaction into being. And

so X sets to work.

1. Thermodynamics and Kinetics: Being a

healthy sceptic, X is not entirely convinced

about the chemists' calculations. So he first

studies the thermodynamics of the process to

understand the conditions at which it would be

feasible to carry out the

reaction. Temperature, pressure, composition, s

olvent nature ... all is variables which X can

adapt and fine-tune to the process at hand. He

also understands the factors that affect

the reaction rate to use them favourably. Apart

from the reaction being feasible and fast, he also

has to worry about side reactions, stability of all

concerned species and phase homogeneity.

These are complex calculations and so he uses

computational techniques and softwares to help

him in making decisions. He also requests the

chemists to double-check his results in some lab

experiments.

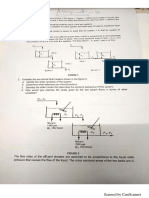

2. Targets and Material Balances: Once X is

satisfied that the reaction can be implemented,

he establishes targets and goals. The scope and

ambition of the process is decided at this step.

He identifies the sources of A and B - nearer the

better. If they're very far, he wonders if he can

make them himself. A few calculations give him

an estimate as to how much P will need to be

produced for economically viable operation,

and he deduces the quantities of A and B from

that as well. To help explain the concept of

material balances, X always likes to show the

following diagram:

3. Reactor Design: Now X turns to the heart of

the process, the reactor. He has briefly looked at

possible catalysts when studying the kinetics,

but this time he goes deeper. He plays around

with some molecular simulation tools to find

what catalyst could give the best results in terms

of conversion, yield and selectivity. He also

factors in the catalyst stability into his

calculations. Once he's done on this front, he

wonders what reactor design to use. A fixed

bed? A fluidized bed? A stirred tank? A

membrane reactor? Is it advantageous to

use multiple reactors? How large should these

reactors be? Of what material should they be

made? He pays special attention to the physical

phases and chemical natures of the participating

species while making this decision. When asked,

he shows some schematic reactor designs

labelled with typical chemical engineering

abbreviations:

4. Equipment Design: X realizes early on that just

the reactor isn't sufficient.

Unfortunately, A and B are not obtained in very

pure form and so he must do some 'preprocessing'. He considers a variety of techniques

such as washing with a solvent, selective

chemical reactions, filtration, crystallization,

distillation ... and chooses the one that is the

most suitable. These processes need special

equipment and he designs them accordingly.

There's also some 'post processing' he has to

accomplish, for P is not the sole product

obtained. So depending on the exact

requirements, he installs equipment

like absorbers, adsorbers or liquefies. To

simplify his task, he uses a computer which

returns him the design once he specifies the

layout. His distillation towers and gas

absorption scrubbers often look like what are

shown here:

5. Energy Balances: "Nothing comes for free" this is one of X's favourite lines. For effective

operation, he needs to supply energy to specific

equipment and take away energy from others.

He also learns that the reaction of interest

is exothermic and thus wants to make sure there

is no chance of hotspots forming in the reactor.

He has to decide whether he prefers fluidcarrying coils or jackets or resistive

heating or chemical heat carriers ... and also

how to ensure efficient heat transfer between

these devices and the equipment. Exchanging

heat between multiple streams is one of X's best

bets and so he develops a heat exchanger

network. He also has to consider declining

efficiency with time due to effects

like fouling or wearing out of mechanical parts.

Due to the large number of variables and

calculations, X relies on some special

computational tools, some aspects of which he

has tweaked and improved. His heat exchanger

networks are usually somewhat as shown below,

full of small symbols and fine print.

6. Piping and Instrumentation: To avoid high

levels of unconsumed reactants, X considers the

possibility of having a recycle stream for

multiple runs. A purge stream might also be

needed to avoid accumulation of inert

substances and impurities. He also explores

methods to transport the reaction mixture from

one equipment unit to another. This could be

achieved by gravity or using pumps or perhaps

even conveyor belts. He designs these as well

and optimizes the connecting pipes on the basis

of pressure drop and space considerations. He

also sets up measuring devices to monitor

important parameters like the temperature,

pressure, flow rate and composition during

operation, most of which he has designed

himself too. These are all compiled into a piping

and instrumentation diagram(P&ID), and X is

always immensely proud of these! Look at him

showing off one of his diagrams:

7. Control and Automation: It's important to

ensure that the system conditions stay within

certain limits for stable operation. This is

why X implements a large number of

sensors and actuators which enable him to

control the process. He has a large number of

options here as well, with different types and

mechanisms of controllers (PID, Adaptive,

Fuzzy logic etc.) as well as a variety

of valves with different configurations.

Also, X decides how much of this control

should be automated and how much of it should

be manually operated. During this process, he

keeps in mind his motto, "Safety first", for it's

better to be safe than sorry every time. Here's

one of X's photographs of a refinery control

room that he'd worked in:

8. Environmental Concerns: X is an

environmentally-sensitive engineer. And so he

makes sure that no potentially harmful

substances are released into the environment.

This requires special units or isolation measures

- he could employ methods like chemical

treatment, electrostatic

precipitation, combustion-dispersal or

controlled dumping. If possible, he also tries to

find a use within his own industry for any toxic

products that are produced. Here are some

images he shows to pictorially describe some

measures undertaken:

9. Alternative Energy Sources: X's boss often

tells him they will soon run out of oil. X doesn't

believe him because he is aware of the untapped

reserves of heavy oils but agrees that they pose a

threat to the environment. Hence, he too is often

on the lookout for alternative sources of energy

that can be used to run his operations. Being in a

closed environment, he can't directly take

advantage of renewable sources like wind and

water, but the prospect of biofuels excites him

for they could originate from natural sources

like sugarcane. He's trying to adapt his systems

to run using fuel cells which could be of

different types (PEM, methanol, solid-state, etc.)

and often looks at figures like the one below to

digest their variety and versatility:

10. Bioengineering Approaches: One of X's

biologist colleagues has also succeeded in

making him enthusiastic about the potential

of bioengineering. He now knows

about mutations and plasmids as well as the

advantages of using enzymes to carry out

reactions. Metabolic engineering is a new

coinage wherein he's learnt that one can change

the properties of organisms like bacteria to attain

desirable functionalities. The growing use of

computational models for cellular networks and

advancement in wet lab technologies has meant

that X also considers bioreactors whenever he is

given a task. This is why it's not uncommon to

see X poring over such cellular networks to

understand biological processes better:

11. New Materials: Another of X's colleagues

has enlightened him about new materials. He

has to come to learn of new membranes that can

filter better and improved materials that increase

adsorption efficiency. Polymers have found their

way into his dictionary and he is learning to take

advantage of their different properties. Bioinspired materials are also growing in

prominence by adapting the systems already in

existence in Nature and X keenly reads the latest

research on these, a schematic of which is

shown below:

12. Nanotechnology: X has also been alerted to

the advantages of using very fine particles for

industrial applications. Nano

emulsions and nanoparticle catalysts are hot

areas in the modern day. These particles also

have the ability to act as supports or carriers for

other chemicals as well as dispersing agents. He

carries out many simulations on these systems

using diverse types of nano systems, some of

which are shown here:

13. Scale Down: Before investing heavily in a

plant, X ponders about making aprototype to test

his analysis. He reduces the size by conserving

certaindimensionless groups across scales - the

choice of this dimensionless no. is different for

different equipment and constitutes an important

decision. Here are some basic dimensionless

numbers that X uses very often:

14. Microfluidics: Having taken a cue from

some of his chemist friends, X is now thinking

of microfluidic reactors. Using small tubes in a

controlled fashion can be advantageous in many

ways, especially for testing purposes. The

dynamics in such systems might also be very

different from that at the larger scales, so he is

actively studying the phenomenon observed

in microchannels and chips like the one shown

here.

15. Startup: One of the most important and

tense times for X is 'startup day'. Much of his

analysis has been for situations when things are

at steady state and he's had to rely

on correlations and simplifications to model

and analyze the events occurring during startup.

He ensures the feed is properly preconditioned,

the equipment are functioning properly, the

sensors are working and the controls are

responding before switching on the operation.

During this day, he monitors all readings

carefully and takes appropriate action, often

manually, to ensure things progress smoothly in

the run up to steady state.

16. Packaging and Delivery: Now the

product P is being steadily obtained but it needs

to be converted to the appropriate form and

delivered. Perhaps it needs to be made

into tablets, perhaps it needs to be packaged as

a powder, perhaps it needs to becompressed as

a gas. X calls the shots and ensures

proper formulation,handling and delivery. He

also expresses his sentiments about the product

appeal and target group to the designers and

promoters, and this picture is one of his prized

exhibits.

17. Operation and Troubleshooting: A year

after startup, the quality of product Phas

degraded. X is worried that one of the

equipment units is malfunctioning and runs

some detection tests - the product batches

obtained during this time have to be discarded.

He does not want to shut down the plant and

attempts to make somemodifications to the

existing conditions to improve performance. In

the meantime, he tries to identify and isolate the

faulty point to take necessary corrective action,

often taking the help of fault trees, event trees,

or the like.

18. Redesign: After a few more years, the

source of A has run out and a new source is

found and tapped. But X finds that the quality

and nature of this new feed material is different

from that of the earlier case. Unfortunately, it is

too expensive to dismantle the entire operation

and customize it anew so he must adapt to these

new conditions as best as he can. This might

need a change in operating conditions, or even

an add-on unit, and X has to make an

appropriate decision. Another year later, the

government issues a notice increasing the

minimum concentration of P in the product.

Some more changes and redesigning is

therefore necessitated to continue to conform to

norms without raising the price excessively. To

illustrate his point, X often shows this picture to

illustrate the different crude oil grades and the

resulting difference in properties:

19. Decommission: Many years have passed

and the process and system in place are now too

old. The system in place has to

be dismantled and it is old man X who is still in

charge. He decides which components can

be re-used, which can be modified and

adapted and which has to be sent away as scrap.

He chalks out a disposal plan and ensures that

all the raw material is consumed before

dismantling. The size and scale of this process

can be imagined when one looks at some of the

mammoth plants that X has setup and run, one

picture of which is shown here.

20. Reporting and Documentation: Through

all of this, X maintains an extensive and

exhaustive set of documents for both internal

and external use. Periodic presentations and

discussions enable him to improve the design

and efficiency of the processes that he is tasked

to 'engineer into reality'.

Moral of the Story: Chemical engineering is a

diverse field which transcends boundaries by

incorporating elements from many disciplines. A

chemical engineer could be devising or

characterizing catalysts, designing new and more

efficient plant equipment, improving control

strategies, formulating new fuels and energy sources,

engineering biological systems, innovating

novel materials, going meso or nano,

ameliorating packaging and transport, and much

more. A chemical engineer could also be attacking

fundamental questions in fluid hydrodynamics, solid

flows,chemical interaction modelling, plant startup

and shutdown, polymer theory,biosystem analysis,

and many other areas all of which have numerous

unsolved mysteries.

Hope you found this story interesting and enjoyable

You might also like

- Scaling Chemical Processes: Practical Guides in Chemical EngineeringFrom EverandScaling Chemical Processes: Practical Guides in Chemical EngineeringNo ratings yet

- Thermal Inertia in Energy Efficient Building EnvelopesFrom EverandThermal Inertia in Energy Efficient Building EnvelopesRating: 4.5 out of 5 stars4.5/5 (3)

- What Is Chemical EngineeringDocument11 pagesWhat Is Chemical EngineeringKanu Raj AnandNo ratings yet

- Equilibrium-Stage Separation Operations in Chemical EngineeringDocument384 pagesEquilibrium-Stage Separation Operations in Chemical Engineering洪意鈞100% (2)

- Introduction To Chemical Reaction Engineering ModuleDocument62 pagesIntroduction To Chemical Reaction Engineering ModuleMendoza Poma Elsner WalterNo ratings yet

- PE - IntroductionDocument6 pagesPE - IntroductionprasadparulekarNo ratings yet

- Thermodynamics and The Simulation EngineerDocument43 pagesThermodynamics and The Simulation EngineerNeagu MihaelaNo ratings yet

- Defining Engineers: How Engineers Think About The WorldDocument9 pagesDefining Engineers: How Engineers Think About The Worldranajit.gngl2542No ratings yet

- Machine Design Research PaperDocument5 pagesMachine Design Research Papercamhwq6mNo ratings yet

- Multiscale Modelling in Computational Heterogeneous CatalysisDocument40 pagesMultiscale Modelling in Computational Heterogeneous CatalysisIAMANDU COSTANo ratings yet

- English For Chemical EngineerDocument94 pagesEnglish For Chemical EngineerKresna Thufail ANo ratings yet

- FTP 200.19.144.11 Luis Books Equilibrium-Stage Separation Operations in Chemical EngineeringDocument384 pagesFTP 200.19.144.11 Luis Books Equilibrium-Stage Separation Operations in Chemical EngineeringDavid BarreraNo ratings yet

- Renewable Energy Systems DesignDocument5 pagesRenewable Energy Systems DesignAdawiyah Az-zahraNo ratings yet

- Ahmed 22Document11 pagesAhmed 22احمد كريم خلفNo ratings yet

- Thermodynamic Property Modeling For Chemical Process and Product Engineering Some PerspectivesDocument19 pagesThermodynamic Property Modeling For Chemical Process and Product Engineering Some PerspectivesindigoqweNo ratings yet

- Reactive ExtrusionDocument253 pagesReactive ExtrusionFederico ForeroNo ratings yet

- UniSim design tutorial for methanol process simulationDocument75 pagesUniSim design tutorial for methanol process simulationMurrali Raj JeyagapalNo ratings yet

- HYSYS Simulation of Chemical Process Equipments: September 2015Document8 pagesHYSYS Simulation of Chemical Process Equipments: September 2015Viet ThieuNo ratings yet

- HYSYS Simulation of Chemical Process Equipments: September 2015Document8 pagesHYSYS Simulation of Chemical Process Equipments: September 2015copiedNo ratings yet

- Lec 35Document16 pagesLec 35arjun SinghNo ratings yet

- HYSYS Methanol ProductionDocument77 pagesHYSYS Methanol ProductionGaukharAlzhanova100% (1)

- BejanDocument558 pagesBejanBala Sellamuthu89% (18)

- Design of Distillation Column Control Systems PDFDocument540 pagesDesign of Distillation Column Control Systems PDFBboubrahim BbnnNo ratings yet

- Design of Distillation Column Control SystemsDocument540 pagesDesign of Distillation Column Control SystemsAlessio Scarabelli100% (2)

- Review ProcessDocument31 pagesReview ProcessGuillermo Serralde PaezNo ratings yet

- Respect The Unstable PDFDocument14 pagesRespect The Unstable PDFMarcelo Quispe CcachucoNo ratings yet

- Part Three Protective and Preventive Methods in Hazard ControlsDocument104 pagesPart Three Protective and Preventive Methods in Hazard ControlsSeid AragawNo ratings yet

- Fundamentals of Bioreactors IIDocument33 pagesFundamentals of Bioreactors IIbettieboomNo ratings yet

- Optimization Mueller-Rochow SynthesisDocument8 pagesOptimization Mueller-Rochow Synthesissahcristine3968No ratings yet

- (Simulation Foundations, Methods and Applications) Ercan M. Dede, Jaewook Lee, Tsuyoshi Nomura (Auth.)-Multiphysics Simulation_ Electromechanical System Applications and Optimization-Springer-Verlag LDocument225 pages(Simulation Foundations, Methods and Applications) Ercan M. Dede, Jaewook Lee, Tsuyoshi Nomura (Auth.)-Multiphysics Simulation_ Electromechanical System Applications and Optimization-Springer-Verlag LTheodore Teddy JNo ratings yet

- EHD in Thermal Energy Systems A Review of The Applications Modelling and Experiments 2017 Journal of ElectrostaticsDocument14 pagesEHD in Thermal Energy Systems A Review of The Applications Modelling and Experiments 2017 Journal of ElectrostaticsomnasyNo ratings yet

- Chapter BookDocument35 pagesChapter BookmeloszNo ratings yet

- CACRE Manuscript 23112016Document230 pagesCACRE Manuscript 23112016Michele FortunatoNo ratings yet

- Bequette 1 Y2Document25 pagesBequette 1 Y2Kami JaraNo ratings yet

- Thesis DfigDocument6 pagesThesis Dfiggof1mytamev2100% (2)

- Chemical Engineering Process SimulationFrom EverandChemical Engineering Process SimulationRating: 4 out of 5 stars4/5 (13)

- Finite Element Analysis PHD ThesisDocument7 pagesFinite Element Analysis PHD Thesisnicolejonesseattle100% (2)

- Introduction to ThermodynamicsDocument24 pagesIntroduction to ThermodynamicsMitchie ZavaletaNo ratings yet

- Roles of Chemical EngineeringDocument10 pagesRoles of Chemical EngineeringIrawan Setiadi100% (1)

- Operability, Resiliency, and Flexibility: Process Design Objectives For A Changing WorldDocument83 pagesOperability, Resiliency, and Flexibility: Process Design Objectives For A Changing WorldannasitNo ratings yet

- Ver Bibliografia de La Diapositiva 3Document33 pagesVer Bibliografia de La Diapositiva 3CesarNo ratings yet

- Smart Materials Research PapersDocument5 pagesSmart Materials Research Papersyuyglccnd100% (1)

- Flowsheet SynthesisDocument27 pagesFlowsheet SynthesisPrasad Jayavant ParulekarNo ratings yet

- 23 Epilogue - Ways To Higher ReliabilityDocument7 pages23 Epilogue - Ways To Higher ReliabilityrogeriojuruaiaNo ratings yet

- Modeling Processes for Optimal DesignDocument10 pagesModeling Processes for Optimal DesignDivyanshuNo ratings yet

- InglésI EVP1 20212 - Piero HerreraDocument6 pagesInglésI EVP1 20212 - Piero HerreraPIERO MATIAS HERRERA SUAREZNo ratings yet

- Process Analysis and simulation-20180523-WA0004 PDFDocument266 pagesProcess Analysis and simulation-20180523-WA0004 PDFjackNo ratings yet

- Solar Energy Engineering: Processes and SystemsFrom EverandSolar Energy Engineering: Processes and SystemsRating: 3 out of 5 stars3/5 (1)

- Fuel Cell Modeling and Simulation: From Microscale to MacroscaleFrom EverandFuel Cell Modeling and Simulation: From Microscale to MacroscaleNo ratings yet

- Chemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignFrom EverandChemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignRating: 4 out of 5 stars4/5 (16)

- Combined Cooling, Heating and Power: Decision-Making, Design and OptimizationFrom EverandCombined Cooling, Heating and Power: Decision-Making, Design and OptimizationNo ratings yet

- Reactor and Process Design in Sustainable Energy TechnologyFrom EverandReactor and Process Design in Sustainable Energy TechnologyFan ShiRating: 3 out of 5 stars3/5 (2)

- Modeling and Simulation of Thermal Power Plants with ThermoSysPro: A Theoretical Introduction and a Practical GuideFrom EverandModeling and Simulation of Thermal Power Plants with ThermoSysPro: A Theoretical Introduction and a Practical GuideNo ratings yet

- Mathematical Models and Finite Elements for Reservoir Simulation: Single Phase, Multiphase and Multicomponent Flows through Porous MediaFrom EverandMathematical Models and Finite Elements for Reservoir Simulation: Single Phase, Multiphase and Multicomponent Flows through Porous MediaRating: 3 out of 5 stars3/5 (1)

- Algorithms ExplainedDocument35 pagesAlgorithms ExplainedUzma ChauhdryNo ratings yet

- Escalab Qxi Xps Microprobe: Quantitative Imaging and Multi-Technique Surface AnalysisDocument6 pagesEscalab Qxi Xps Microprobe: Quantitative Imaging and Multi-Technique Surface AnalysisYASHNo ratings yet

- Binary search tree data structure and algorithmsDocument40 pagesBinary search tree data structure and algorithmsYASHNo ratings yet

- NIT ROURKELA END SEMESTER EXAMINATION 2018 OPTIMIZATION AND SIMULATION TECHNIQUESDocument2 pagesNIT ROURKELA END SEMESTER EXAMINATION 2018 OPTIMIZATION AND SIMULATION TECHNIQUESYASHNo ratings yet

- Data Structure and Algorithm CS-102: Ashok K TurukDocument49 pagesData Structure and Algorithm CS-102: Ashok K TurukUzma ChauhdryNo ratings yet

- Templates PDFDocument16 pagesTemplates PDFYASHNo ratings yet

- SSM Lab 1 PpsDocument9 pagesSSM Lab 1 PpsYASHNo ratings yet

- Linked ListDocument38 pagesLinked ListYASHNo ratings yet

- 5 Inheritance PDFDocument25 pages5 Inheritance PDFYASHNo ratings yet

- Data Structure & Algorithm CS 102: Ashok K TurukDocument70 pagesData Structure & Algorithm CS 102: Ashok K TurukUzma ChauhdryNo ratings yet

- Fifth EstateDocument4 pagesFifth EstateYASHNo ratings yet

- Nitr International Model United Nations Conference 2018: Campus Ambassador Programme About The ProgramDocument2 pagesNitr International Model United Nations Conference 2018: Campus Ambassador Programme About The ProgramYASHNo ratings yet

- About NITDocument1 pageAbout NITYASHNo ratings yet

- AIR INDIA Covid19-Countrywise-TravelAdvisoriesDocument63 pagesAIR INDIA Covid19-Countrywise-TravelAdvisoriesYASHNo ratings yet

- All The Stakeholders To The Partition Agree To The Following ClausesDocument2 pagesAll The Stakeholders To The Partition Agree To The Following ClausesYASHNo ratings yet

- All The Stakeholders To The Partition Agree To The Following ClausesDocument2 pagesAll The Stakeholders To The Partition Agree To The Following ClausesYASHNo ratings yet

- Karnataka Opinion Polls 2018: Assembly Elections TimelineDocument2 pagesKarnataka Opinion Polls 2018: Assembly Elections TimelineYASHNo ratings yet

- Saudi Arabia Leads OPEC as Top Oil Producer Despite Price DropDocument8 pagesSaudi Arabia Leads OPEC as Top Oil Producer Despite Price DropYASHNo ratings yet

- CO2 ExtractionDocument35 pagesCO2 ExtractionMPChethanNo ratings yet

- Bruijn Et Al-2008-Fuel CellsDocument20 pagesBruijn Et Al-2008-Fuel CellsYASHNo ratings yet

- Sparse Matrix GuideDocument18 pagesSparse Matrix GuideYASHNo ratings yet

- Scanned document discusses properties of metallic glassDocument8 pagesScanned document discusses properties of metallic glassYASHNo ratings yet

- Scanned by CamscannerDocument8 pagesScanned by CamscannerYASHNo ratings yet

- Assignment PDC 3Document5 pagesAssignment PDC 3YASHNo ratings yet

- Scholarship Database - DAAD - Deutscher Akademischer AustauschdienstDocument4 pagesScholarship Database - DAAD - Deutscher Akademischer AustauschdienstYASHNo ratings yet

- Characterization Methods: Yash Shah, Department of Chemical Engineering, Nit Rourkela, IndiaDocument9 pagesCharacterization Methods: Yash Shah, Department of Chemical Engineering, Nit Rourkela, IndiaYASHNo ratings yet

- Beti-Bachao: "No Womenno World"Document10 pagesBeti-Bachao: "No Womenno World"YASHNo ratings yet

- Sample Paper - 2013 Class - IX Subject - Social Science: Other Educational PortalsDocument3 pagesSample Paper - 2013 Class - IX Subject - Social Science: Other Educational PortalsYASHNo ratings yet

- CPCDocument32 pagesCPCYASHNo ratings yet

- Beti-Bachao: "No Womenno World"Document10 pagesBeti-Bachao: "No Womenno World"YASHNo ratings yet

- Toaz - Info Super Coolant Af Nac PRDocument6 pagesToaz - Info Super Coolant Af Nac PRsugi yantoNo ratings yet

- Minimizing Penalty in Industrialpower Factor Correction by Engaging Apfc UnitDocument15 pagesMinimizing Penalty in Industrialpower Factor Correction by Engaging Apfc UnitabellNo ratings yet

- SynonymsDocument14 pagesSynonymsMursal IbrahimiNo ratings yet

- Tron Time Delay Fuse 500vDocument1 pageTron Time Delay Fuse 500valexjoelNo ratings yet

- Creating A 3D-Map Using Reference Points: Cfr-19-Stm-CanadasatDocument14 pagesCreating A 3D-Map Using Reference Points: Cfr-19-Stm-Canadasattuguldur bayaraaNo ratings yet

- SI 410 Weighing Indicator User ManualDocument64 pagesSI 410 Weighing Indicator User ManualShehab100% (2)

- Siehl, Caitlyn-Whatweburied Digitaledition (2015)Document64 pagesSiehl, Caitlyn-Whatweburied Digitaledition (2015)Bahar Gaser100% (1)

- Read Online Here: Bronto Skylift F32Document3 pagesRead Online Here: Bronto Skylift F32Randu WatangNo ratings yet

- Pump CommissioningDocument1 pagePump CommissioningMD SAMANNo ratings yet

- Banaba Tea Aids Weight LossDocument5 pagesBanaba Tea Aids Weight LossAveriAlonzoNo ratings yet

- Introduction To Well Completion: (Part - IV)Document36 pagesIntroduction To Well Completion: (Part - IV)Mohamed MahmoudNo ratings yet

- De-Escalation of Critical Care and Prevention of Iatrogenicity Through PICU Liberation Rounding Process and A Daily Rounding ChecklistDocument1 pageDe-Escalation of Critical Care and Prevention of Iatrogenicity Through PICU Liberation Rounding Process and A Daily Rounding ChecklistdarlingcarvajalduqueNo ratings yet

- Agile Final Exam - Answer TranscriptDocument12 pagesAgile Final Exam - Answer TranscriptMehwish GauriNo ratings yet

- Structural Modelling and Analysis using BIM ToolsDocument137 pagesStructural Modelling and Analysis using BIM ToolsManuel Solís López100% (1)

- Specifications Models 37R116, 37R118 and 43R175: Carry Capacity: 18,200 To 47,200 Lbs (8250 To 21,400 KG.)Document7 pagesSpecifications Models 37R116, 37R118 and 43R175: Carry Capacity: 18,200 To 47,200 Lbs (8250 To 21,400 KG.)Marek WyszatyckiNo ratings yet

- Step-by-Step Planning for Escalators and Moving WalksDocument21 pagesStep-by-Step Planning for Escalators and Moving WalksYusup SNo ratings yet

- ISO Standards in ProcessDocument20 pagesISO Standards in ProcessYeni OktaviaNo ratings yet

- Guidelines in The Evaluation of Comprehensive Land Use PlanDocument8 pagesGuidelines in The Evaluation of Comprehensive Land Use PlanPa Rian Rho DoraNo ratings yet

- DPS Nashik Class 12 Science SyllabusDocument18 pagesDPS Nashik Class 12 Science SyllabusSayali Morwal-KumawatNo ratings yet

- Benefits of Acupressure Health 2014Document44 pagesBenefits of Acupressure Health 2014Linh Tinh100% (1)

- Telangana Govt T-PRIDE Scheme GuidelinesDocument90 pagesTelangana Govt T-PRIDE Scheme GuidelinesitzprasuNo ratings yet

- Cambridge International Examinations Cambridge Ordinary LevelDocument7 pagesCambridge International Examinations Cambridge Ordinary LevelQuicksilverNo ratings yet

- Upper Gastro Intestinal BleedingDocument13 pagesUpper Gastro Intestinal BleedingmuniningmicanNo ratings yet

- Mintek Ar 2011Document76 pagesMintek Ar 2011Algradi MosheerNo ratings yet

- Amulets Talismans and CharmsDocument3 pagesAmulets Talismans and CharmsreikiladyNo ratings yet

- Indian MaDocument1 pageIndian MaAnass LyamaniNo ratings yet

- Eating Healthily: People's Mixed ViewsDocument2 pagesEating Healthily: People's Mixed ViewsTbb GajahMada MagetanNo ratings yet

- Astm C1396 C1396M-17Document8 pagesAstm C1396 C1396M-17Stefano CamillucciNo ratings yet

- Real-Time Reservoir Operation For Irrigation: P. P. Mujumdar and T. S. V. RameshDocument8 pagesReal-Time Reservoir Operation For Irrigation: P. P. Mujumdar and T. S. V. RameshGetachew BekeleNo ratings yet

- Water Transport Studies in Stone Masonry With Soil Cement MortarDocument10 pagesWater Transport Studies in Stone Masonry With Soil Cement MortarTJPRC PublicationsNo ratings yet