Professional Documents

Culture Documents

7,500 cbm LNG/LPG carrier design and gas handling system

Uploaded by

Kelvin XuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7,500 cbm LNG/LPG carrier design and gas handling system

Uploaded by

Kelvin XuCopyright:

Available Formats

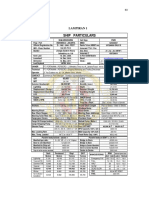

7,500 cbm LNG/LPG/Ethylene/Ammonia/VCM-Carrier

Coral Methane

for ANTHONY VEDER, The Netherlands

Project Data:

Shipyard:

Remontowa, Gdansk, Poland

Year of completion: 2009

Classification: BV

TGEs scope:

EPCS-contract, gas handling system & cargo

tanks, ship design development

Vessel:

7,500 m semi ref. LNG carrier, type 2G

Length o.a.

Beam:

Draught (LPG):

Speed:

117.8 m

18.6 m

6.8 m

15.5 kn

Characteristics of gas plant:

Capacity:

7,500 m

Number of cargo tanks:

Material of cargo tanks:

AISI 304L

Cargoes:

LNG/LPG/Ethylene/Ammonia/VCM

Design temperature / pressure:

-163C / 3.2 bar g acc. to IMO at sea

Maximum cargo density:

650 kg/m

Number of segregations:

Cargo manifolds:

3 liquid lines, 2 x 8, 1 x 6 ANSI 300 lbs flanges

3 vapour lines, 2 x 6, 1 x 4 ANSI 300 lbs flanges

Loading- / Unloadingrate:

Deepwell pump

900 m/h (with vapour return)

2 x 450 m/h at 120 m LC for LEG/LPG

2 x 450 m/h at 210 m LC for LNG

1 x 450 m/h at 120 m LC

Booster pump

Number of cargo heater / vaporizer:

1 indirect ethylene vaporiser

1 direct sea water heated LPG-heater /

vaporiser

1 indirect LNG vaporiser

Capacity:

Capacity:

Capacity:

900 m/h at 15C sea water temp.

174 t/h Propane from -42C to 0C at 15C sea water,

vapour 3 t/h

vapour 1 t/h

Reliquefaction system:

Cascade / direct cycle (not including LNG)

2 x refrigerant compressors (refrigerant R404A)

2 x cargo compressors

1 suction gas heater for fuelgas

Cargo piping system:

Stainless steel

Nitrogen generation plant:

Pressure swing adsorption

Capacity:

750 Nm/h at 0.5 vol. % O2

Deck Tank:

Capacity:

1 x 80 m3

Design Pressure / Temperature:

TGE Marine Gas Engineering GmbH

Mildred-Scheel-Strae 1

53175 Bonn, Germany

18 bar g/ -163C

Tel: +49 (228) 50218 0

Fax: +49 (228) 50218 880

www.tge-marine.com / info@tge-marine.com

Updated on 05 May 2015 / Page 28 of 80

You might also like

- LNG Carrier 10000cbmDocument1 pageLNG Carrier 10000cbmpriyoNo ratings yet

- Type Dan Jenis Kapal Tanker Gas Utk TarunaDocument25 pagesType Dan Jenis Kapal Tanker Gas Utk TarunaBebincaNo ratings yet

- Modern LNG Carriers: Design & Safety FeaturesDocument78 pagesModern LNG Carriers: Design & Safety FeaturespradeepNo ratings yet

- Economic Design Concept For Small LNG Carriers Rev 3Document26 pagesEconomic Design Concept For Small LNG Carriers Rev 3hardik5818No ratings yet

- Bulk Cargo Shipping Tankers SpecsDocument2 pagesBulk Cargo Shipping Tankers SpecsCapikah EikaNo ratings yet

- LNG Tech 2Document28 pagesLNG Tech 2genergia50% (2)

- Stena BlueGas Form C Sky - Gas Form CDocument17 pagesStena BlueGas Form C Sky - Gas Form CpoetoetNo ratings yet

- LPG/C ANNAPURNADocument2 pagesLPG/C ANNAPURNAAvinash Mudrika100% (1)

- Bali 50 MMSCFD LNG FRU F1Document1 pageBali 50 MMSCFD LNG FRU F1Ajeng NurcahyaniNo ratings yet

- Introductiontogastransportation 161222145926 PDFDocument26 pagesIntroductiontogastransportation 161222145926 PDFAl Jawad100% (1)

- 1200m Self-Propelled LNG (Type C) Barge: Main Particulars MachineryDocument2 pages1200m Self-Propelled LNG (Type C) Barge: Main Particulars MachinerysirvoltusNo ratings yet

- Gas Carrier Types ExplainedDocument29 pagesGas Carrier Types ExplainedJayant Khedkar100% (1)

- 20-Lampiran 1 Ship ParticularDocument1 page20-Lampiran 1 Ship ParticularAkun Gocar100% (1)

- TPTM CompanyDocument21 pagesTPTM CompanypiliyandalaleosNo ratings yet

- Js Insight Gas Form CDocument64 pagesJs Insight Gas Form CSomayajula SuryaramNo ratings yet

- Preparation For Receiving Nitrogen From ShoreDocument7 pagesPreparation For Receiving Nitrogen From Shoreelfantasma100% (1)

- Ship ParticularsDocument1 pageShip ParticularsEbony CarterNo ratings yet

- CARGO HANDLING PLAN (LOAD/DISCDocument4 pagesCARGO HANDLING PLAN (LOAD/DISCAbu FaiqaNo ratings yet

- LNG FuelDocument6 pagesLNG FuelKaran DoshiNo ratings yet

- Physics of Liq GasesDocument21 pagesPhysics of Liq GasesOctavianNo ratings yet

- Ship's particulars and equipment detailsDocument5 pagesShip's particulars and equipment detailsIhwan AsrulNo ratings yet

- Presentation For Gas Naturally Complete and Final Klapeidos NaftaDocument30 pagesPresentation For Gas Naturally Complete and Final Klapeidos Naftamilham09100% (1)

- LNGIndustry June 2014Document84 pagesLNGIndustry June 2014stavros7No ratings yet

- Gaztransport & TechnigazDocument4 pagesGaztransport & TechnigaziuliiulianNo ratings yet

- Product Brochure 4000m3 Self Propelled LNG Barge PDFDocument2 pagesProduct Brochure 4000m3 Self Propelled LNG Barge PDFssnisharNo ratings yet

- Rigel Schiffahrts GmbH tanker vessel specsDocument2 pagesRigel Schiffahrts GmbH tanker vessel specsJavier LNo ratings yet

- Letter of Protest for Water and SedimentsDocument2 pagesLetter of Protest for Water and SedimentsVicentiu Alexandru Grama100% (2)

- Zhejiang Hongxin Shipbuilding Co ship delivery recordDocument12 pagesZhejiang Hongxin Shipbuilding Co ship delivery recordLegend Anbu0% (1)

- BOIL-OFF UTILIZATION IN LNG CARRIERSDocument19 pagesBOIL-OFF UTILIZATION IN LNG CARRIERSPrasathAKNo ratings yet

- Adnan Ezzarhouni GTTChina (Revised Version)Document17 pagesAdnan Ezzarhouni GTTChina (Revised Version)ClemenNo ratings yet

- Panatal Factsheet CL 500 TYPEDocument2 pagesPanatal Factsheet CL 500 TYPEfrdsimNo ratings yet

- Cargo Handling Systems WartsillaDocument12 pagesCargo Handling Systems Wartsillajbloggs2007No ratings yet

- 대우의 가스추진선박에 대한 프리젠테이션Document33 pages대우의 가스추진선박에 대한 프리젠테이션Jae Sung KangNo ratings yet

- Dstenersen Pres (Full Permission)Document38 pagesDstenersen Pres (Full Permission)Salvatore BuonoNo ratings yet

- 11 000 Teu Container VesselDocument16 pages11 000 Teu Container VesselRover DmsNo ratings yet

- Gasasa Marine Fuel: Recommendations For Linked Emergency Shutdown (ESD) Arrangements For LNG BunkeringDocument14 pagesGasasa Marine Fuel: Recommendations For Linked Emergency Shutdown (ESD) Arrangements For LNG Bunkeringmhientb100% (1)

- LNG Fuel Gas SystemsDocument2 pagesLNG Fuel Gas SystemsMoanquileNo ratings yet

- Ship Particular OB - Persada 2551 PDFDocument1 pageShip Particular OB - Persada 2551 PDFMusuhan Sama CacingNo ratings yet

- Wartsila Jettyless LNG TransferDocument2 pagesWartsila Jettyless LNG TransferEka Panji SaptaprasetyaNo ratings yet

- Emsa Final Report Bunkering LNG Op 06 2012 BDocument160 pagesEmsa Final Report Bunkering LNG Op 06 2012 BEric Berger100% (2)

- Ship Education Test Liquefied Gas TankersDocument11 pagesShip Education Test Liquefied Gas TankersMahami M ProsperNo ratings yet

- Gas Tanker Cargo Operation SequenceDocument30 pagesGas Tanker Cargo Operation SequenceDon100% (2)

- LNG Recondenser Process Data SheetDocument4 pagesLNG Recondenser Process Data SheetpragatheeskNo ratings yet

- LNG - Urn 05 - 1016Document67 pagesLNG - Urn 05 - 1016kaspersky2009No ratings yet

- History of LNGDocument9 pagesHistory of LNGNick Tarr0% (1)

- Dedicated chartering management for bulk carrier Tomini UnityDocument3 pagesDedicated chartering management for bulk carrier Tomini UnityAnil SharmaNo ratings yet

- Mark V LNG TanksDocument2 pagesMark V LNG TanksEdutamNo ratings yet

- Arklow RallyDocument2 pagesArklow RallyDIEGONo ratings yet

- Oil and Gas Technology Update - 26 Oktober 2016 - P9 City Plaza - PATRIA - LNG Iso Tank DevelopmentDocument19 pagesOil and Gas Technology Update - 26 Oktober 2016 - P9 City Plaza - PATRIA - LNG Iso Tank DevelopmentagungNo ratings yet

- Gas Carrier TypesDocument34 pagesGas Carrier TypesDilli BabuNo ratings yet

- LNG CourseDocument4 pagesLNG CourseRuslan ZakirovNo ratings yet

- GTT CS1Document4 pagesGTT CS1iuliiulianNo ratings yet

- Oil Tanker FamiliarizatinDocument10 pagesOil Tanker FamiliarizatinBipin Singh100% (1)

- MergedDocument36 pagesMergedEmily BrockNo ratings yet

- Liquefied Natural Gas PDFDocument16 pagesLiquefied Natural Gas PDFwasita wadariNo ratings yet

- Fuel Equivalent Factor - Marine Services PDFDocument9 pagesFuel Equivalent Factor - Marine Services PDFMax Kolonko100% (1)

- Isabella KosanDocument1 pageIsabella KosanmariodalNo ratings yet

- Underground Gas Storage Facilities: Design and ImplementationFrom EverandUnderground Gas Storage Facilities: Design and ImplementationNo ratings yet

- Natural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryFrom EverandNatural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryNo ratings yet

- Attachment 0Document96 pagesAttachment 0Kelvin XuNo ratings yet

- Table of Contents GhsportDocument84 pagesTable of Contents GhsportKelvin XuNo ratings yet

- Me ch162Document17 pagesMe ch162Kelvin XuNo ratings yet

- Final Format IJSCT92Document11 pagesFinal Format IJSCT92Kelvin XuNo ratings yet

- Final MSC ThesisDocument81 pagesFinal MSC ThesisKelvin XuNo ratings yet

- Propeller performance analysis experimentsDocument21 pagesPropeller performance analysis experimentsKelvin XuNo ratings yet

- Cooling Product CatalogDocument51 pagesCooling Product CatalogKelvin XuNo ratings yet

- Stability AHTSDocument9 pagesStability AHTSLenin Valerio0% (1)

- Merchant Shipping (Registration of Ships) RegulatiDocument48 pagesMerchant Shipping (Registration of Ships) RegulatiKelvin XuNo ratings yet

- 6382-G405Ar0 Stability Calculation-2-71Document70 pages6382-G405Ar0 Stability Calculation-2-71Kelvin XuNo ratings yet

- Proceedings the3rdUCLOpenFOAMWorkshopreleaseDocument33 pagesProceedings the3rdUCLOpenFOAMWorkshopreleaseKelvin XuNo ratings yet

- Polyester Resin For Laminating 1Document13 pagesPolyester Resin For Laminating 1Kelvin XuNo ratings yet

- Kusuma 2021 IOP Conf. Ser. Mater. Sci. Eng. 1052 012026Document8 pagesKusuma 2021 IOP Conf. Ser. Mater. Sci. Eng. 1052 012026Kelvin XuNo ratings yet

- Of Mariive Propeller Design: Comparing FourDocument14 pagesOf Mariive Propeller Design: Comparing FourKelvin XuNo ratings yet

- Design and Performance of Bow ThrustersDocument47 pagesDesign and Performance of Bow ThrustersKelvin Xu100% (1)

- Bow Thrusters: Speeds Your PerformanceDocument16 pagesBow Thrusters: Speeds Your PerformanceKelvin XuNo ratings yet

- Tunnel Installation Guide PDFDocument16 pagesTunnel Installation Guide PDFKelvin XuNo ratings yet

- KVLCC2 Propeller Openwater Data HMRIDocument1 pageKVLCC2 Propeller Openwater Data HMRIKelvin XuNo ratings yet

- Choosing the Right Bow Thruster for Wind ConditionsDocument1 pageChoosing the Right Bow Thruster for Wind ConditionsKiky IchanafiNo ratings yet

- Contamination by Cruise Ships: Z Z Z Z ZDocument7 pagesContamination by Cruise Ships: Z Z Z Z ZKelvin XuNo ratings yet

- Maxsurf ManualDocument239 pagesMaxsurf ManualRenato Nicoli MendesNo ratings yet

- GHS Training Book OverviewDocument84 pagesGHS Training Book OverviewKelvin XuNo ratings yet

- Carbon Fibre GangwaysDocument17 pagesCarbon Fibre GangwaysKelvin XuNo ratings yet

- Turbomachinery CFD Configuration File Manual 17.02Document7 pagesTurbomachinery CFD Configuration File Manual 17.02Kelvin XuNo ratings yet

- Calmmoon Marine Provides Excellent Noise & Vibration ReductionDocument29 pagesCalmmoon Marine Provides Excellent Noise & Vibration ReductionKelvin XuNo ratings yet

- 692D Guidelines Marine DesignersDocument9 pages692D Guidelines Marine Designerspapaki2No ratings yet

- Turbomachinery CFD Configuration File Manual 17.02Document7 pagesTurbomachinery CFD Configuration File Manual 17.02Kelvin XuNo ratings yet

- Banquette Planning GuideDocument18 pagesBanquette Planning GuideKelvin XuNo ratings yet

- Ruk13 H - Guidelines For The Selection and Operations of Jack Ups in The Marine Renewable Energy Industry PDFDocument110 pagesRuk13 H - Guidelines For The Selection and Operations of Jack Ups in The Marine Renewable Energy Industry PDFKelvin XuNo ratings yet

- Bridge design loads overviewDocument30 pagesBridge design loads overviewDr. MOHAMED ALZAINNo ratings yet