Professional Documents

Culture Documents

Methanol Simulation

Uploaded by

Maria Jose TorresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Methanol Simulation

Uploaded by

Maria Jose TorresCopyright:

Available Formats

Umair Sikander and Arshad Hussain

J.Chem.Soc.Pak., Vol. 36, No. 5, 2014 798

Experimental and Simulation Analysis of Hydrogen Production by

Partial Oxidation of Methanol

1

1,2

Umair Sikander* and 2Arshad Hussain

School of Chemical and Materials Engineering (SCME), National University of Sciences and Technology

(NUST), Sector H-12, Islamabad 44000, Pakistan.

umair.sikandar@scme.nust.edu.pk*

(Received on 22nd May 2013, accepted in revised form 21st April 2014)

Summary: Partial oxidation of methanol is the only self-sustaining process for onboard production

of hydrogen. For this a fixed bed catalytic reactor is designed, based on heterogeneous catalytic

reaction. To develop an optimized process, simulation is carried out using ASPEN HYSYS v 7.1.

Reaction kinetics is developed on the basis of Langmuir Hinshelwood model. 45:55:5 of CuO: ZnO:

Al2O3 is used as a catalyst. Simulation results are studied in detail to understand the phenomenon of

partial oxidation of methanol inside the reactor. An experimental rig is developed for hydrogen

production through partial oxidation of methanol. Results obtained from process simulation and

experimental work; are compared with each other.

Keywords: Partial oxidation of methanol, Hydrogen production, Process simulation, Fixed Bed Catalytic

Reactor, Heterogeneous Catalytic Reactions.

Introduction

Nowadays extensive attention has been paid

to using hydrogen as an energy carrier for its high

efficiency and very low to zero pollution [1]. The

biggest advantage of hydrogen fuel is versatility; it

can be used in combustion engines, as a propellant,

an explosive, a source of electricity (PEM-Fuel Cells)

[2]. Major problem in using hydrogen as a fuel

source is its storage [3]. Not only it is the lightest gas

and escapes easily, it is also highly flammable and

can easily catch fire by a high friction giving it

enough temperature to reach its flash point [4]. This

work is focused on addressing the issues of

producing hydrogen economically and safely.

An alternate method of on-board production

of hydrogen by Partial Oxidation of Methanol (POM)

using a fixed Bed Catalytic Reactor (FBCR) [5] is

devised in this work. Methanol is the third

commodity chemical after ethylene and ammonia;

with a production capacity in excess of 25 million

tons, much superior to the actual overall demand [6].

It also has the leading candidate because all other

fuels require high processing temperatures and

produce unacceptable amounts of CO [7]. Hydrogen

can be produced from methanol by three different

methods [8].

Cracking [9]

CH3OH

CH3OH+(1/2)O2

2H2+CO2H=-192.2KJ/mol (3)

Among these methods partial oxidation is

the only process which is exothermic and thus selfsustaining. Also it has the advantage to use oxygen

directly from air.

For POM a ratio of 1:2 of oxygen to

methanol is fed to the reactor in vapor phase where

the reaction takes place in the presence of a catalyst.

45:55:5 of CuO: ZnO: Al2O3 is used as a catalyst

[12]. High concentrations of H2 and CO2 were

obtained with only the traces of unwanted byproducts. Perkin Elmer GC with TCD detector is

used for the product analysis. All the experimental

work and calculations are made on a pilot scale.

Reaction kinetics and process design is studied

thoroughly and an optimized process design is

developed.

This work is further extended by conducting

process simulation using Aspen HYSYS v7.1 which

is the novelty of this work. Effects of process

variables are analyzed in detail by process

simulation.

Results and discussion

2H2 + CO H = 92KJ/mol

(1)

Steam Reforming [10]

CH3OH+H2O

Partial Oxidation [11]

3H2+CO2 H = 49.4KJ/mol

(2)

To whom all correspondence should be addressed.

Simulation Results

Simulation results are helpful for the

optimization of POM process. Simulation also

provides an insight of the reactor to have a better

Umair Sikander and Arshad Hussain

J.Chem.Soc.Pak., Vol. 36, No. 5, 2014 799

understanding about the POM process. Results

obtained by HYSYS simulation are plotted by the

Aspen-HYSYS tool. These results are discussed

below:

Rate of Hydrogen Production

Fig. 1 shows that production rate of hydrogen is

increasing along the reactor length till 11cm and after

that hydrogen production rate is decreased. This

result shows that optimized reactor length is 11cm for

POM. It is also notable that the point from which

production rate of hydrogen is decreasing production

rate of methanol is increasing. This implies that if

reactor length is further increased, backward reaction

will accelerate and the product gained from such

reactor will be of much lower conversion.

Fig. 2: Reaction rate VS reactor length.

Change in Heat Capacity of the Overall System

Along the reactor, heat capacity is being

reduced as shown in Fig. 3. It means that compounds

of lower heat capacity are being produced. Since

hydrogen has a fairly low heat capacity than

methanol the plotted graph confirms that hydrogen is

being produced and methanol is being consumed

along the reactor. This plot also leads to another

discussion of efficient heat supply to the reactor. At

the end of the reactor heat capacity is low so all the

heat present at this region would be consumed by the

catalyst and it will be at higher temperature in this

region. Thus the goal of uniform temperature will not

be achieved. For this a differential model of heat

transfer should be developed to get an idea of point to

point energy requirement in the reactor.

Fig. 1: Compound Production rate VS Reactor

Length.

Rate of Reaction vs Reactor Length

Rate of reaction based on %age conversion

of methanol, increases along the reactor length as

shown in Fig. 2. When reactants are introduced in

reactor there is a pressure drop and temperature

difference which results into a slow reaction rate

which gradually increases. POM is an exothermic

reaction as the reaction proceeds there is some

increase in temperature which in turn increases the

rate of reaction. In the later part backward reaction is

taking place at a higher rate, thus there is a decrease

in rate of reaction.

Fig. 3: Heat Capacity VS Reactor Length.

Pressure Drop in the Reactor

Fig. 4 shows the pressure drop along the reactor.

From this graph pressure drop at any particular length

Umair Sikander and Arshad Hussain

can be found and incorporating these values of P/l

in Ergun Equation superficial critical velocity of any

compound at any point inside the reactor can be

calculated.

Fig. 4: Pressure VS Reactor Length.

Catalyst Characterization

Catalyst was characterized with SEM for

morphological and surface properties. JEOL JEX2300 was used under an accelerating voltage of

20kV. The magnifications used were 5000X and

50,000X. The particles were found to be micrometer

sized fine powder having spheroids and discs of 0.10.5 m. There were some aggregates present but

overall the catalyst had uniform size distribution and

was found as highly porous structure as evident from

the Figs. 5 and 6.

J.Chem.Soc.Pak., Vol. 36, No. 5, 2014 800

Table-1: Catalyst quantitative mass percentages from

EDS.

Element

Al

Cu

Zn

Composition Theoretical

(Mass %age)

3.1

43.6

53.3

Composition Actual

(Mass %age)

2.4

41.5

56.06

Fig. 6: SEM micrograph of catalyst at X50,000.

Experimental Results

From Gas chromatographic analysis,

undesirable fraction of water is also present in the

product mixture. This can only be possible by the

complete oxidation reaction of methanol in spite of

partial oxidation. Complete oxidation reaction is

given in Eq. 4.

2CH3OH + 3O2

2CO2 + 4H2O

(4)

It means that methanol being consumed not

only produces hydrogen but is also producing water

with it; as a side reaction. This side reaction

decreases the overall molar conversion of POM to

63.3%. While designing the process, care should be

taken that side reactions must be avoided as much as

possible. In the case of POM, catalyst plays this very

role. Results obtained indicate the importance of

catalyst as it is the property of catalyst only to direct

the reaction on the desired path and reduce the

chances of possible side reactions.

Process Simulation

Fig. 5: SEM micrograph of catalyst at X5000.

Jeol

JSM-6460

Energy

Dispersive

Spectroscope (EDS) was used for compositional

analysis. The compositional ratio of Cu, Zn and Al

was found concurrent with the desired mixing ratios

(Fig. 7, Table-1).

Simulation of POM is carried out using

ASPEN HYSYS v7.1. A complete dynamic model is

created using this tool and FBCR is designed along

with reaction kinetics to investigate the behavior of

the reactor under different process conditions.

Hydrogen is closest to the ideal gas in its properties;

therefore Peng Robinson fluid package is taken

which considers the gases to be ideal in nature. After

selecting the components and fluid package reaction

kinetics are defined. HYSYS has the provision to

choose a type of reaction from a list available. POM

is a heterogeneous catalytic reaction [11] so same

reaction type is taken.

Umair Sikander and Arshad Hussain

800

700

OKa

600

CuKa

CuLl

ZnLl

ZnLa CuLa

900

500

ZnKa

001

1000

Counts

J.Chem.Soc.Pak., Vol. 36, No. 5, 2014 801

200

ZnKb

AlKa

CKa

300

CuKb

400

100

0

0.00

1.00

2.00

3.00

4.00

5.00

6.00

7.00

8.00

9.00

10.00

keV

Fig. 7: EDS Compositional spectra of catalyst

Reaction Kinetics

In HYSYS heterogeneous catalytic reactions

are based on Langmuir Hinshelwood (LH) model.

For POM various mechanisms are proposed in

literature based on Langmuir Hinshelwood model.

The most promising results are however reported by

Lin et al. [13] and suggest that reaction take place

according to the following mechanism.

Rate equation in this mechanism is obtained

from an extended Langmuir Hinshelwood Hougen

Watson (LHHW) model. This model is based on the

concept that rate controlling step must be focused

while developing rate equation for any heterogeneous

catalytic reaction. The rate of reaction according to

LHHW model is calculated by Eq. 9.

(Adsorption)

O2 + 2S

2OS

(5)

(Surface reaction)

2CH3OH + OS

2CH3OS + H2O

(6)

When all the parameters in the above

equation are specified in HYSYS, heat of reaction

calculated by the software is -192 kJ/mol(as shown in

Fig. 8). Reaction is then saved in the reaction set

Rxn-1 which can now be invoked where needed.

(7)

Simulation Environment

(Desorption)

2CH3OS+H2O

CH3OH+2H2+CO2 +2S

(Overall)

2CH3OH+O2

4H2 + 2CO2

(9)

(8)

It is to be noted that methoxide is produced

on the surface reaction step (Eq. 6) which in return

produce hydrogen and carbon dioxide on the

desorption step. Formation of methoxide is of utmost

importance in POM as hydrogen is liberated on its

decomposition. This implies that rate controlling step

in this model is surface reaction where methanol is

being decomposed.

The complete process is defined in the

simulation environment after setting parameters.

Now two material streams are taken for methanol and

oxygen respectively. A mixer Mix-100 is attached

which mixes the two reactants according to the

proportion of 2:1 and provide us with a single stream

mixed reactants. This stream is then pre heated to

200oC using a heater E-100. Finally reactants are

introduced to horizontal reactor FBCR from the

bottom. Product stream is taken from the top of the

reactor. As POM is an exothermic reaction, heat is

evolved, and to maintain the temperature inside the

reactor a cooling line is attached to the reactor.

Process flow diagram is depicted in Fig. 9.

Umair Sikander and Arshad Hussain

J.Chem.Soc.Pak., Vol. 36, No. 5, 2014 802

Fig. 8: Defined heterogeneous catalytic reaction.

Fig 9: Simulation process flow diagram.

Reactor Design

Plug Flow Reactor (PFR) model is chosen

for reactor design to carry out the POM reaction. For

60% conversion FBCR volume is calculated by

equation (10) [14].

VR= (1- B)

(10)

By putting the vales

kR

B

R

T

Nf

=

=

=

=

=

=

=

19.6

(as defined in Rxn-1)

0.2

8.314 dm3.kPa/mol.K

473K

0.06mole

0.94

150 kPa

The calculated volume of the reactor is

0.0126 dm3.

Particle diameter is set to be 1mm and since

all the catalyst particles are spherical in shape;

particle sphericity is set as 1. Density of the particle

is given 5.8 kg/cm3.After setting all the reactor

parameters reaction set Rxn-1 is recalled.

Calculations are made by the HYSYS

according to design parameters on the POM reaction.

Simulation results into an 89% conversion of

methanol (set as a base component) as shown in Fig.

10.

Umair Sikander and Arshad Hussain

J.Chem.Soc.Pak., Vol. 36, No. 5, 2014 803

Fig. 10: Percentage conversion of methanol.

Pressure drop calculated on the basis of thermocouple are installed within the tank for

Ergun Equation is 3.501 kPa, which is well within the continuous monitoring of tank pressure and

allowed range. After running the simulation 0.6278 temperature. Methanol tank has a drain valve and

mole fraction of hydrogen in the product feed stream pressure relief valve for safety aspects. Methanol

is obtained. Detailed simulation process worksheet is flow rate is controlled with a needle valve.

shown in Table-2.

Single pass column of stainless steel is used

as

fixed

bed catalytic reactor. Reactor column is

Table-2: Simulation process worksheet.

filled with 45:55:5 of CuO: ZnO: Al2O3 catalyst

Component mole

Methanol

Oxygen

Mixed

Product

fraction

Stream

Stream

Reactants

Stream

(procured from Sigma-Aldrich) according to the

Methanol

1.000

0.667

0.038

required loading for maintaining the desired void

Oxygen

1.000

0.333

0.0195

fraction inside the column. Reactor is held vertically

Hydrogen

0.6278

Carbon dioxide

0.3139

and thermocouple is installed to monitor the inside.

Reactor is fully wrapped with heating tape to keep

the column at temperature (210oC) required for POM.

Experimental Setup

Experimental Rig

Synthesis of Hydrogen Gas

An experimental rig is designed and

fabricated for the production of hydrogen by POM.

Commercial grade Oxygen cylinder is used with a

dual pressure regulator. Oxygen line is then attached

with a gas flow meter of range 0.1 10 liters per

minute. By adjusting flow rate, calculated oxygen at

required pressure is fed to reactor. Methanol is kept

in a tank located at the bottom of the rig. An electric

heater is fitted inside the methanol tank for its

vaporization. Compound pressure gauge and

Methanol is heated up to 80oC by using

electric heater. When pressure inside the methanol

tank reaches 1.5bar needle valve opens and methanol

vapors are fed to the reactor. Flow rate is maintained

at 0.7 liters per minute by flow meter fitted on the

methanol line. Oxygen is then mixed with methanol

at 1.5 bar (adjusted by pressure regulator) and at flow

rate of 0.3 liters per minute (by a flow meter

attached). Mixed reactants are then introduced to the

reactor bottom which is kept at a temperature of

Umair Sikander and Arshad Hussain

J.Chem.Soc.Pak., Vol. 36, No. 5, 2014 804

210oC. At this point heating tape must be switched

off, since POM is an exothermic reaction temperature

inside the reactor is now self-maintained. Reaction

product leaving from the top of the reactor is

analyzed with Perkin Elmer GC with 5A Mol Sieve

Column and TCD detector. Argon gas is used as a

mobile phase for GC analysis. Molar concentrations

of different reaction product are calculated by the

chromatogram as shown in Table-3.

Comparison between experimental and simulation

results is carried out in the form of percentage

experimental yield. Losses are not included in the

process simulation thus theoretical yield of hydrogen

mole fraction is calculated on the basis of simulation

results from Fig. 11.

Table-3: Molar %age from GC-TCD analysis.

For experimental result mole fraction of

hydrogen is calculated from the Table-3.

Compound

Hydrogen

Oxygen

Water

Carbon dioxide

Methanol

No. of moles

1.975

0.468

0.81

1.34

0.168

Molar %age

41.48

9.8

16.67

28.14

3.52

Mole fraction of hydrogen from simulation

model=0.67

Moles of hydrogen

1.975

Total moles

4.761

Comparison between simulation and experimental

results

Mole fraction of hydrogen by experimental data

=

0.42

Both simulation and experimental designs

are identical in dimensions and process flow rates it

is advantageous to give a comparison to calculate a

deviation between the results of two processes.

%age Yield

=Actual Yield =0.42/0.67=61%

Theoretical Yield

Fig. 11: Mole Fraction Vs Reactor Length.

Umair Sikander and Arshad Hussain

J.Chem.Soc.Pak., Vol. 36, No. 5, 2014 805

Conclusion

2.

Process selectivity of POM depends

enormously on the nature of catalyst. Reaction is

sensitive to the process conditions. Optimized

process design is of high importance as number of

side reactions are likely to happen even with a

slightest change in operating conditions. Comparison

between simulation and experimental processes,

results into a yield of 61%. Thus the results discussed

here not only validate the two processes but also give

us the detail insight on the partial oxidation of

methanol process.

Design

constraints

and

assumptions are also validated by these results.

3.

4.

5.

6.

7.

Nomenclature

8.

kR

Kad

Kde

[X]

VR

B

R

Nf

T

k

P

=Reaction rate constant

=Adsorption Constant

=Desorption Constant

=concentration of X

= Volume of the reactor

=Void fraction

=Ideal gas constant

=Molar flow

=Operating temperature

=Effectiveness factor (based on reaction kinetics)

=Reaction rate constant

=Pressure

9.

10.

11.

12.

13.

References

1.

J. C. Amphlett and R. F. Mann, Canadian

Journal of Chemical Engineering, 66, 950

(1988).

14.

C. Ji and S. Wang, International Journal of

Hydrogen Energy, 34, 7823 (2009).

College of the desert, Hydrogen fuel cell

engines and related technologies. Rev 0

(2001).

A. Klerke, C. H. Christensen, J. K. Norskov

and T. Vegge, Journal of Materials

Chemistry, 18, 2304 (2008).

P. Mizsey, E. Newson, T. Truong and P.

Hottinger, Journal of Applied Catalysis,

213, 233 (2001).

L. Ajelo, R. Lago, M. R. Pena and J. L. G.

Fierro, Journal of Applied catalysis, 162,

281 (1997).

L. F. Brown, International Journal of

Hydrogen Engineeringg, 26, 381 (2001).

J. Yuanli, L. M. Sook and K. D. Hyun,

Chinese Journal of Chemical Engineering,

9, 297 (2001).

Schmidt, U.S. Patent # 3986350 (1976).

J. Agrell, H. Birgersson and M. Boutonnet,

Journalof Power Sources, 106, 249 (2002).

C. R. H. de Smet, M. H. J. M. de Croon, R.

J. Berger, G. B. Marin and J. C. Schouten,

Chemical Engineering Science, 56, 4849

(2001).

K. M. V. Bussche and G. Froment, Journal

of Catalysis, 161, 1 (1996).

Y. Lin, L. T. Fan, S. Shafie and K. L. Hohn,

Journal of Industrial and Engineering

Chemistry, 47, 2524 (2008).

Fixed Bed Catalytic Reactors. Nob Hill

Publishing (2011).

Copyright of Journal of the Chemical Society of Pakistan is the property of Asianet-Pakistan

and its content may not be copied or emailed to multiple sites or posted to a listserv without

the copyright holder's express written permission. However, users may print, download, or

email articles for individual use.

You might also like

- Recycling of NiCd Batteries by Hydrometallurgical Process On Small ScaleDocument5 pagesRecycling of NiCd Batteries by Hydrometallurgical Process On Small ScaleRaul OrtaNo ratings yet

- Kinetic of Methanol Synthesis PDFDocument12 pagesKinetic of Methanol Synthesis PDFLuisa Fernanda Carvajal RamírezNo ratings yet

- Simulation Modeling and Analysis for SystemsDocument18 pagesSimulation Modeling and Analysis for SystemstirumalayasaswiniNo ratings yet

- LaboratorymanualfordcelectricalcircuitsDocument71 pagesLaboratorymanualfordcelectricalcircuitsJisha VijayanNo ratings yet

- EDTA As Chelating Agent For Sol-Gel Synthesis of Spinel LiMn2O4 Cathode Material For Lithium BatteriesDocument35 pagesEDTA As Chelating Agent For Sol-Gel Synthesis of Spinel LiMn2O4 Cathode Material For Lithium Batteriesanhle07No ratings yet

- Dme A PDFDocument6 pagesDme A PDFcemilozanNo ratings yet

- Metals: Preparation of Battery-Grade Lithium Carbonate With Lithium-Containing Desorption SolutionDocument10 pagesMetals: Preparation of Battery-Grade Lithium Carbonate With Lithium-Containing Desorption SolutionMartin DanzeNo ratings yet

- Application of Digital Twin TechnologyDocument41 pagesApplication of Digital Twin TechnologyHemn Rafiq TofiqNo ratings yet

- Irvin Langmuir 1918, Adsorption IsothermDocument43 pagesIrvin Langmuir 1918, Adsorption IsothermJayvir100% (3)

- Nitric Acid 2000Document10 pagesNitric Acid 2000harikeshrl5477No ratings yet

- BGS Technical Report on Flake Graphite Laboratory ManualDocument35 pagesBGS Technical Report on Flake Graphite Laboratory ManualFamiloni Layo100% (1)

- CHE4162 Particle Technology: Chemical Reactions in Fluidized BedsDocument27 pagesCHE4162 Particle Technology: Chemical Reactions in Fluidized BedsPhan NeeNo ratings yet

- QB PDFDocument18 pagesQB PDFShivani0% (1)

- Ceramics International: Mahamoud S. Alkathy, Rahul Gayam, K.C. James RajuDocument10 pagesCeramics International: Mahamoud S. Alkathy, Rahul Gayam, K.C. James RajuRachna SelvamaniNo ratings yet

- Phosgene Micro Reactor A I CheDocument9 pagesPhosgene Micro Reactor A I CheJorge RamirezNo ratings yet

- Department of Mechanical Engineering Indian Institute of Technology - Kharagpur Lecture - 01Document23 pagesDepartment of Mechanical Engineering Indian Institute of Technology - Kharagpur Lecture - 01Roy BrothersNo ratings yet

- Computational Multiphase Flow ThesisDocument299 pagesComputational Multiphase Flow ThesisDeepak K NambiarNo ratings yet

- CopperGlycine PDFDocument5 pagesCopperGlycine PDFJaume HernandezNo ratings yet

- Heat Exchanger Network Design Using Pinch Analysis PDFDocument25 pagesHeat Exchanger Network Design Using Pinch Analysis PDFAhmed Mohamed KhalilNo ratings yet

- Fundamentals Mathematical Modeling GuideDocument33 pagesFundamentals Mathematical Modeling GuidedeviNo ratings yet

- Volumetric DilatometryDocument14 pagesVolumetric DilatometryNasim MalekiNo ratings yet

- 464OldTests Quizz SamplesDocument10 pages464OldTests Quizz Samplesmhrdd222No ratings yet

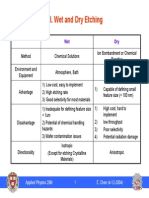

- Wet and Dry Etching Methods ComparisonDocument18 pagesWet and Dry Etching Methods ComparisonLuke D'ImperioNo ratings yet

- Richard P Feynman-Surely Youre Joking MR Feynman v5Document3 pagesRichard P Feynman-Surely Youre Joking MR Feynman v5Anonymous Nayak0% (1)

- Fundamental Quantum Mechanics For Engineers - Leon Van DommelenDocument838 pagesFundamental Quantum Mechanics For Engineers - Leon Van DommelenLucian PopescuNo ratings yet

- CAETraining (Fluid)Document129 pagesCAETraining (Fluid)andysarmientoNo ratings yet

- Chemical Engineering Analysis - CHE 411Document20 pagesChemical Engineering Analysis - CHE 411David AkomolafeNo ratings yet

- Introduction To Molecular Dynamics Simulations. Prabal MaitiDocument42 pagesIntroduction To Molecular Dynamics Simulations. Prabal MaitiCornersouthNo ratings yet

- Flow in 3D Packed Bed Reactors COMSOLDocument10 pagesFlow in 3D Packed Bed Reactors COMSOLBenedictEkowPrahNo ratings yet

- Laboratory Manual For Ac Electrical CircuitsDocument81 pagesLaboratory Manual For Ac Electrical CircuitsanupvasuNo ratings yet

- Scanning Electron MicrosDocument14 pagesScanning Electron Microszhoushengyuanly100% (1)

- Root Locus and Closed Loop Transfer Function CalculationDocument8 pagesRoot Locus and Closed Loop Transfer Function CalculationAkashNo ratings yet

- Matrix Mathematics Chemical Problems: ApplicationsDocument9 pagesMatrix Mathematics Chemical Problems: ApplicationsCarlosNo ratings yet

- Journal of The European Ceramic Society: Vincenzo Buscaglia, Clive A. Randall TDocument15 pagesJournal of The European Ceramic Society: Vincenzo Buscaglia, Clive A. Randall TAryan Singh LatherNo ratings yet

- Modeling and Simulation of Energy SystemsDocument498 pagesModeling and Simulation of Energy SystemsMiguel Angel Forero ParraNo ratings yet

- Hot Embossing Microfabrication ProcessDocument17 pagesHot Embossing Microfabrication Processliang102010No ratings yet

- Materials Science and Engineering Notes 091110Document12 pagesMaterials Science and Engineering Notes 091110Mete MetelanNo ratings yet

- Turbinas Evaporativas de GasDocument158 pagesTurbinas Evaporativas de GasluijamurNo ratings yet

- Carbon NanotubesDocument41 pagesCarbon Nanotubes2018 01403No ratings yet

- Metallurgical Physical ChemistryDocument45 pagesMetallurgical Physical ChemistryAlvin Garcia PalancaNo ratings yet

- Ap Chemistry: Kinetics Practice Problems: Rate of Reaction - (Clo (Clo (CL ) ) ) 3 2 T T TDocument13 pagesAp Chemistry: Kinetics Practice Problems: Rate of Reaction - (Clo (Clo (CL ) ) ) 3 2 T T TAbu Sufyan ButtNo ratings yet

- Continuous Process Technology A Tool ForDocument8 pagesContinuous Process Technology A Tool ForAmjadRiazNo ratings yet

- Lecture Notes On Separation of Stable IsotopesDocument31 pagesLecture Notes On Separation of Stable IsotopesKaranam.Ramakumar100% (1)

- Template-Based Synthesis of Nanomaterials PDFDocument12 pagesTemplate-Based Synthesis of Nanomaterials PDFVandam65No ratings yet

- Lithography GuideDocument29 pagesLithography GuidezanibtahiraNo ratings yet

- Nano Electro Mechanical System NemsDocument26 pagesNano Electro Mechanical System NemsAnaMilerNo ratings yet

- Optimal Designs of Staggered Dean Vortex Micromixers: Molecular SciencesDocument25 pagesOptimal Designs of Staggered Dean Vortex Micromixers: Molecular SciencesGoji SabaNo ratings yet

- Two Step SinteringDocument4 pagesTwo Step Sinteringrajadasari5682No ratings yet

- Module 2: Polymer Reactions Step-Growth Polymerization KineticsDocument35 pagesModule 2: Polymer Reactions Step-Growth Polymerization KineticsYu An Shih100% (1)

- dx10 02 3 Gen2factor PDFDocument18 pagesdx10 02 3 Gen2factor PDFELFER OBISPO GAVINONo ratings yet

- Module 2: Polymer Reactions Background: Polymerization KineticsDocument10 pagesModule 2: Polymer Reactions Background: Polymerization KineticsYu An Shih100% (1)

- Midterm Review SolutionsDocument16 pagesMidterm Review SolutionsKate SongNo ratings yet

- 58 PolymerDocument33 pages58 Polymermuhammad rizky fitraNo ratings yet

- A Compilation of Laboratory ReportsDocument57 pagesA Compilation of Laboratory ReportsEli Leopoldo Geneston100% (3)

- New Technologies For Electrochemical Applications-CRC Press (2020)Document289 pagesNew Technologies For Electrochemical Applications-CRC Press (2020)senaNo ratings yet

- Carbon Nanostructures PDFDocument99 pagesCarbon Nanostructures PDFVishal WaghNo ratings yet

- Engineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandEngineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Coulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesFrom EverandCoulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesAjay Kumar RayNo ratings yet

- Structure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsFrom EverandStructure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsNo ratings yet

- 27.pecchi. Potentiometric Method For Determining..Document7 pages27.pecchi. Potentiometric Method For Determining..Azrael ArteagaNo ratings yet

- Hair Conditioners: Incroquat Btms - What Is It?Document14 pagesHair Conditioners: Incroquat Btms - What Is It?Flora WhitneyNo ratings yet

- Admapn016en 0905Document8 pagesAdmapn016en 0905Hendrias Ari SujarwoNo ratings yet

- Mechanisms of Air Entrainment in ConcreteDocument9 pagesMechanisms of Air Entrainment in Concretecarjamu100% (1)

- Strategies To Design Modified Activated Carbon Fibers For The Decontamination of Water and AirDocument32 pagesStrategies To Design Modified Activated Carbon Fibers For The Decontamination of Water and AirMadhanNo ratings yet

- Sugarcane Bagasse Removes Foron Blue DyeDocument8 pagesSugarcane Bagasse Removes Foron Blue DyekartikaNo ratings yet

- Ion ExchangeDocument10 pagesIon ExchangecoolgubbyNo ratings yet

- Adsorption Technology in Water TreatmentDocument6 pagesAdsorption Technology in Water Treatmenttgg666100% (1)

- Ackley - Yang - 1991 - Adsorption Characteristics of High-Exchange ClinoptilolitesDocument8 pagesAckley - Yang - 1991 - Adsorption Characteristics of High-Exchange Clinoptilolites周世奇No ratings yet

- Sublimation of Ammonium Salts: A Mechanism Revealed by A First-Principles Study of The NH CL SystemDocument8 pagesSublimation of Ammonium Salts: A Mechanism Revealed by A First-Principles Study of The NH CL Systemc ganesh100% (1)

- Green Biorefinery - Separation of Lactic Acid From Grass Silage JuiceDocument12 pagesGreen Biorefinery - Separation of Lactic Acid From Grass Silage JuiceJeremy CiminiNo ratings yet

- Adsorption - Solved ProblemsDocument5 pagesAdsorption - Solved Problemsshaik mohammed Arshad100% (1)

- Ourse: CHE442 - SEPARATION PROCESS 1 (3 Credits /compulsory)Document8 pagesOurse: CHE442 - SEPARATION PROCESS 1 (3 Credits /compulsory)Anonymous TUXPKUSRDUNo ratings yet

- Rehan Shahab 2022Document14 pagesRehan Shahab 2022qaisarchemistNo ratings yet

- PHARMACEUTICSDocument40 pagesPHARMACEUTICSSaad Hassan100% (1)

- 1 s2.0 S1385894721041814 MainDocument21 pages1 s2.0 S1385894721041814 MainBest WishesNo ratings yet

- LHHW Models and The KSSA 1h6gbxoDocument42 pagesLHHW Models and The KSSA 1h6gbxoNeel PatelNo ratings yet

- Soil Science GlossaryDocument93 pagesSoil Science GlossaryShima Tan100% (1)

- Hemical Ngineering Inetics: Based On CHEM - ENG 408 at Northwestern UniversityDocument49 pagesHemical Ngineering Inetics: Based On CHEM - ENG 408 at Northwestern UniversityzamijakaNo ratings yet

- Module 2 - Part 2 (Ce 361 - Advanced Concrete Technology)Document20 pagesModule 2 - Part 2 (Ce 361 - Advanced Concrete Technology)Rahul patilNo ratings yet

- MCQ Pharmacognosy and Phytochemistry IDocument7 pagesMCQ Pharmacognosy and Phytochemistry IUma Maheswar RaoNo ratings yet

- 3D Graphene, Fundamentals, Synthesis, and Emerging Applications (2023) - Ram K. GuptaDocument434 pages3D Graphene, Fundamentals, Synthesis, and Emerging Applications (2023) - Ram K. GuptaGardener AyuNo ratings yet

- Air Quality Standards ISO 8573Document9 pagesAir Quality Standards ISO 8573nidhink18No ratings yet

- Accepted Manuscript: Journal of Photochemistry and Photobiology A: ChemistryDocument39 pagesAccepted Manuscript: Journal of Photochemistry and Photobiology A: ChemistryYon tinyayaNo ratings yet

- ACTIVATED CARBON ADSORPTION APPLICATIONSDocument37 pagesACTIVATED CARBON ADSORPTION APPLICATIONSAbd AzizNo ratings yet

- Mycotoxins and Bacterial Toxins: Types, Characteristics and EffectsDocument103 pagesMycotoxins and Bacterial Toxins: Types, Characteristics and EffectsSunil100% (1)

- Class Notes - BT101 - 1679890571Document133 pagesClass Notes - BT101 - 1679890571Aayush GehlotNo ratings yet

- 28-3-62-Kinetic Study of Dry Reforming of Methane Over Ni-Ce - Al2O3 Catalyst With DeactivationDocument11 pages28-3-62-Kinetic Study of Dry Reforming of Methane Over Ni-Ce - Al2O3 Catalyst With DeactivationWassachol SumarasinghaNo ratings yet

- Lecture 03. Adsorption of Gases and Liquids On SolidsDocument39 pagesLecture 03. Adsorption of Gases and Liquids On Solidsimran24No ratings yet

- Asian Water Principles of Ion Exchange Neumann 03 09 PDFDocument6 pagesAsian Water Principles of Ion Exchange Neumann 03 09 PDFEmmaColladoArredondoNo ratings yet