Professional Documents

Culture Documents

Page 265-271 Measurement

Uploaded by

Sahil GrgCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Page 265-271 Measurement

Uploaded by

Sahil GrgCopyright:

Available Formats

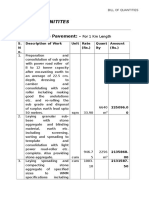

MEASUREMENTS OF QUANTITIES

265

MEASUREMENTS OF QUANTITIES

10

10.1. Flexible Pavement: - For 1 Km Length

S.

No

No

Description of Work

.

.

1. Preparation

and

consolidation

of

sub

grade with power road

roller of 8 to 12 tonne

capacity after excavating

earth to an average of

22.5 cm. depth, dressing

to

camber

and

consolidating with road

roller including making

good the undulations

etc. and re-rolling the

sub grade and disposal

of surplus earth lead

upto 50 metres.

1

2. Laying

granular

subbase

with

stone

aggregate and blinding

material,

earth

etc.

including

screening,

sorting and spreading to

template

and

consolidation with light

power road-roller etc.

complete. Also providing

stone aggregate.

1

3. Laying spreading and

compacting

stone

aggregate of specified

sizes

to

WMM

specifications including

1000

9+2x2.

14 =

13.28

1000

9+2x1.

14 =

11.28

H/D

Conte

nt

0.50

6640

m3

0.20

2256

m3

MEASUREMENTS OF QUANTITIES

266

4.

5.

spreading

in

uniform

thickness, hand picking,

rolling with 3 wheeled

road / vibratory roller 810 tonne in stages to

proper

grade

and

camber, applying and

brooming requisite type

of

screening/binding

material

to

fill

up

interstices

of

coarse

aggregate watering and

compacting

to

the

required density. Also

providing

stone

aggregate.

Providing and applying

prime

coat using hot

straight run bitumen of

grade 80/ 100 including

heating the

bitumen,

spraying the bitumen

with

mechanically

operated

spray

unit

fitted

on

bitumen

boiler,

cleaning

and

preparing the existing

road surface as per

specifications, on W.B.M.

@ 0.75 Kg / sqm.

Providing and applying

tack coat using bitumen

emulsion (Rapid Setting)

complying

with

IS

8887-1995, spraying the

bitumen emulsion with

mechanically

operated

spray

unit,

cleaning

and

preparing the

existing road surface as

1

1

1000

1000

1000

7+2X0.

5+

2X0.25

0=

8.50

8.50

8.50

0.25

---

2125

m3

8500

m2

8500

m2

MEASUREMENTS OF QUANTITIES

267

6.

7.

per specifications, on

W.B.M @ 0.3kg/sqm.

Providing

and

laying

Dense

Bituminous

Macadam on prepared

surface with specified

graded crushed stone

aggregate

for

profile

corrective base/ binding

course including loading

of aggregate with FE

loader and hot mixing

of stone aggregate, filler

and bitumen in hot mix

plant, transporting the

mixed

material

by

tippers to paver and

laying

the

mixed

material

with

paver

finisher

fitted

with

electronic

sensing

device to the required

level and

grade and

rolling by road roller as

per

MORTH

specifications,

to

achieve

the

desired

density, but excluding

the cost of primer / tack

coat, 80mm

average

compacted

thickness

with bitumen of 60/70

grade @ 5% (percentage

by weight of total mix)

and lime filler @ 2%

(percentage by weight of

Aggregate).

Providing

and

laying

Dense

Bituminous

concrete on prepared

1

1

1000

1000

7+2X0.

5+

2X0.12

5=

8.25

7+2x0.

5 = 8.0

0.08

0.04

660

m3

320

m3

MEASUREMENTS OF QUANTITIES

268

8.

9.

surface with

specified

graded stone aggregate

for

wearing

course

including loading

of

aggregate

with

F.E.

loader

,

and

hot

mixing of bitumen with

filler

and

stone

aggregate in hot mix

plant , transporting the

mixed material

by

tippers to paver and

laying

the

mixed

material with mechanical

paver

finisher

fitted

with electronic sensing

device to the required

level and grade and

rolling with road rollers,

as

per

MORTH

specification, to achieve

the desired density and

compaction

but

excluding cost of primer/

tack

coat.

40

mm

compacted

thickness

with bitumen of grade

60/ 70 @ 5.5% and

lime @3% (percentage

by weight of total mix).

Brick edging in full brick

width and half brick

depth

including

excavation, refilling and

disposal of surplus earth

lead upto 50 metres.

With F.P.S. bricks of class

designation 75

Dry brick pitching half

brick thick in drains

1

1

1000

1000

-0.3 +

2x0.42

---

1000

m

1140

m2

MEASUREMENTS OF QUANTITIES

269

10

.

11

.

including supply of bricks

and

preparing

the

surface complete, With

F.P.S. bricks of class

designation 75

Providing and applying

2.5mm

thick

road

marking strips (retroreflective) of specified

shade/colour using hot

thermoplastic

material

by fully/semi automatic

thermoplastic

paint

applicator

machine

fitted with profile shoe,

glass beads dispenser,

propane

tank

heater

and

profile

shoe

heater,

driven

by

experienced

operator

on

road

surface

including

cost

of

material, labour ,T&P,

cleaning

the

road

surface

of

all

dirt,

seals,

oil, grease and

foreign

material

etc.

complete as per direction

of

Engineer-in-charge

and

accordance

with

applicable specifications. 83

Surface dressing on new 1

surface

with

paving

bitumen of grade A-90/S90 of approved quality

using

2.25

kg of

bitumen per sqm with

1.65

cum

of stone

chippings

13.2

mm

nominal size per 100

= 1.14

4.5

1000

0.1

7.0

---

37.35

m2

7000

m2

MEASUREMENTS OF QUANTITIES

270

sqm of road surface

including

consolidation

with road roller of 6 to

8 tonne capacity etc.

complete.

10.2. Rigid Pavement: - For 1 Km Length

S.

No

No

Description of Work

.

.

1. Preparation

and

consolidation

of

sub

grade with power road

roller of 8 to 12 tonne

capacity after excavating

earth to an average of

22.5 cm. depth, dressing

to

camber

and

consolidating with road

roller including making

good the undulations

etc. and re-rolling the

sub grade and disposal

of surplus earth lead

upto 50 metres.

1

2. Laying

granular

sub- 1

base

with

stone

aggregate and blinding

material,

earth

etc.

1000

1000

9+2x2.

0=

13.0

9+2x1.

0=

11.0

H/D

0.50

0.20

Conte

nt

6500

m3

2200

m3

MEASUREMENTS OF QUANTITIES

271

3.

4.

including

screening,

sorting and spreading to

template

and

consolidation with light

power road-roller etc.

complete. Also providing

stone aggregate.

Dry

Lean

Cement

Concrete

sub-base

Construction of dry lean

c/c sub-base over a

prepared sub-grade with

coarse

and

fine

aggregate, the size of

coarse aggregate not

exceeding

25

mm,

aggregate cement ratio

not to exceed 15:1,

aggregate

gradation

after blending, cement

content not to be less

than

150

kg/cum,

optimum

moisture

content

to

be

determined during trial

length

construction

concrete strength not to

be less than 10 MPa at 7

days,

mixed

in

a

batching

plant,

transported to site, laid

with

a

paver

with

electronic

sensor,

compacting with 8-10

tonne vibratory roller,

finishing and curing.

Cement

concrete

pavement Construction

of un-reinforced, dowel

jointed, plain cement

1000

7+2X0.

5+

2X0.12

5=

8.25

0.10

825

m3

MEASUREMENTS OF QUANTITIES

272

5.

6.

concrete pavement over

a prepared sub-base with

43 grade cement @ 400

kg per cum, coarse and

fine

aggregates

conforming to IS: 383,

maximum size by coarse

aggregate not exceeding

25 mm, mixed in a

batching

and

mixing

plant as per approved

mix design, transported

to site, laid with a fixed

form or slip form paver,

spread, compacted and

finished in a continuous

operation

including

provision of contractor,

expansion, construction

and longitudinal joints,

joint filler, separation

membrane,

sealant

primer, joint sealant,

debonding strip, dowel

bar, tie rod, admixtures

as

approved,

curing

compound, finishing to

lines and grades as per

drawing.

Brick edging in full brick

width and half brick

depth

including

excavation, refilling and

disposal of surplus earth

lead upto 50 metres.

With F.P.S. bricks of class

designation 75

Dry brick pitching half

brick thick in drains

including supply of bricks

1000

1000

7+2X0.

5= 8.0

--

0.3 +

0.25

2000

m3

--

1000

m

MEASUREMENTS OF QUANTITIES

273

7.

and

preparing

the

surface complete, With

F.P.S. bricks of class

designation 75

1

Providing and applying

2.5mm

thick

road

marking strips (retroreflective) of specified

shade/colour using hot

thermoplastic

material

by fully/semi automatic

thermoplastic

paint

applicator

machine

fitted with profile shoe,

glass beads dispenser,

propane

tank

heater

and

profile

shoe

heater,

driven

by

experienced

operator

on

road

surface

including

cost

of

material, labour ,T&P,

cleaning

the

road

surface

of

all

dirt,

seals,

oil, grease and

foreign

material

etc.

complete as per direction

of

Engineer-in-charge

and

accordance

with

applicable specifications. 83

1000

4.5

2x0.42

= 1.14

0.1

--

1140

m2

--

37.35

m2

You might also like

- Dir FDocument50 pagesDir FSahil GrgNo ratings yet

- Phone BookDocument3 pagesPhone BookSahil GrgNo ratings yet

- Delhi PincodeDocument5 pagesDelhi Pincodeharshil12No ratings yet

- Page 164-166 RecommendationsDocument3 pagesPage 164-166 RecommendationsSahil GrgNo ratings yet

- Hungama 15Document1 pageHungama 15Sahil GrgNo ratings yet

- Transportation Engineering Lab ManualDocument42 pagesTransportation Engineering Lab Manualउमेश गावंडे89% (9)

- HJHJBHBJKDocument97 pagesHJHJBHBJKSahil GrgNo ratings yet

- Wefewf 103-109Document8 pagesWefewf 103-109Sahil GrgNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- HCGHVJ1 - 13Document16 pagesHCGHVJ1 - 13Sahil GrgNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- UPPCL Pay Bill Excel 2003Document3 pagesUPPCL Pay Bill Excel 2003Sahil GrgNo ratings yet

- WritDocument1 pageWritSahil GrgNo ratings yet

- Page 257-264 Schedule of RatesDocument11 pagesPage 257-264 Schedule of RatesSahil GrgNo ratings yet

- Classified List of Sale of Publication 30-11-2008Document29 pagesClassified List of Sale of Publication 30-11-2008Sahil GrgNo ratings yet

- CPWD Books and Specifications ListingDocument8 pagesCPWD Books and Specifications ListingSahil GrgNo ratings yet

- Page 164-166 RecommendationsDocument3 pagesPage 164-166 RecommendationsSahil GrgNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- CPWD Books and Specifications ListingDocument8 pagesCPWD Books and Specifications ListingSahil GrgNo ratings yet

- Paper1 East ABCFGHI PDFDocument17 pagesPaper1 East ABCFGHI PDFSatyajitMannaNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- Fci Key 2015Document18 pagesFci Key 2015Prakash JpNo ratings yet

- CPWD Books and Specifications ListingDocument8 pagesCPWD Books and Specifications ListingSahil GrgNo ratings yet

- FAQsadDocument15 pagesFAQsadSahil GrgNo ratings yet

- TB 1 Fly Ash Types & BenefitsDocument1 pageTB 1 Fly Ash Types & BenefitsSahil GrgNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fuselage Design For Stress Caused Due To Wing at Various Load ConditionsDocument48 pagesFuselage Design For Stress Caused Due To Wing at Various Load ConditionsSri Tech Engineering100% (1)

- Heat treatment techniques in 40 charactersDocument7 pagesHeat treatment techniques in 40 charactersHmwDyNo ratings yet

- BoilerTubes - TechnitubeDocument24 pagesBoilerTubes - TechnitubeMMPAPNo ratings yet

- Fracture MechanicsDocument15 pagesFracture Mechanicsmurari_v50% (8)

- Cab-O-Sil M-5 Fumed Silica: Name of Library Here Datasheet Number Hydrophilic Fumed SilicaDocument2 pagesCab-O-Sil M-5 Fumed Silica: Name of Library Here Datasheet Number Hydrophilic Fumed SilicaN ShahNo ratings yet

- Productinformation MoCheck304316 eDocument1 pageProductinformation MoCheck304316 edsuraj wickramasinghaNo ratings yet

- Xlpe CableDocument18 pagesXlpe Cablesopan saNo ratings yet

- A. Local Related Literature and StudiesDocument7 pagesA. Local Related Literature and StudiesYsay SomeraNo ratings yet

- Info Iec60227-1 (Ed2.2) en DDocument6 pagesInfo Iec60227-1 (Ed2.2) en Dbeby nisaNo ratings yet

- Effect of Surface Treatments On Fretting Fatigue of Ti-6Al-4VDocument9 pagesEffect of Surface Treatments On Fretting Fatigue of Ti-6Al-4Vdileep mNo ratings yet

- Grade V Science Task Week 2Document2 pagesGrade V Science Task Week 2Jinrey NituraNo ratings yet

- TDS Proofex 3000 Saudi ArabiaDocument3 pagesTDS Proofex 3000 Saudi Arabiarangarajan1989No ratings yet

- ACO Plastic Channel H50 DefDocument12 pagesACO Plastic Channel H50 DefOpeyemi TodowedeNo ratings yet

- Geometrical Properties Material Properties: Design of Saw Tooth/Slabless StairDocument4 pagesGeometrical Properties Material Properties: Design of Saw Tooth/Slabless StairSudip ShresthaNo ratings yet

- Mix Design - FlyashDocument1 pageMix Design - FlyashAjay MahaleNo ratings yet

- MTC 304 Mineral Insulated Thermocouple With Connection HeadDocument1 pageMTC 304 Mineral Insulated Thermocouple With Connection HeadDanut AnghelNo ratings yet

- Cell Holder ABSDocument2 pagesCell Holder ABSRachit RanjanNo ratings yet

- Fatada VentilataDocument1 pageFatada VentilataAndrei DumitruNo ratings yet

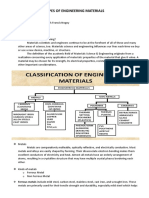

- Types of Engineering MaterialsDocument3 pagesTypes of Engineering MaterialsMark Francis Pangilinan Nogoy100% (2)

- ADVANCED MULTI-STOREY CONSTRUCTION Notes-1Document38 pagesADVANCED MULTI-STOREY CONSTRUCTION Notes-1kgatoNo ratings yet

- PPI Listing Of: TR-4/2018 HDB/HDS/PDB/ Sdb/Mrs/Crs Listed MaterialsDocument58 pagesPPI Listing Of: TR-4/2018 HDB/HDS/PDB/ Sdb/Mrs/Crs Listed MaterialsSaradhi Medapureddy100% (1)

- Incoterms Chart 2010Document2 pagesIncoterms Chart 2010Mohamad ArrajNo ratings yet

- Flooring Materials, Walling Materials, Ceiling and Acoustical Materials, & Roofing MaterialsDocument58 pagesFlooring Materials, Walling Materials, Ceiling and Acoustical Materials, & Roofing MaterialsGio Padilla100% (1)

- Al Jazeera Engineering Laboratories For Quality Control W.L.LDocument17 pagesAl Jazeera Engineering Laboratories For Quality Control W.L.LDeepthi RNo ratings yet

- 6 - Introduction To Precast ConcreteDocument16 pages6 - Introduction To Precast ConcreteM Bilal ZahidNo ratings yet

- SET XP ICC ES Evaluation 1464386 PDFDocument19 pagesSET XP ICC ES Evaluation 1464386 PDFReinel OrjuelaNo ratings yet

- Potting and Low Pressure Molding PDFDocument31 pagesPotting and Low Pressure Molding PDFWilson LombogNo ratings yet

- Bottom-Up vs Top-Down Nanofabrication MethodsDocument2 pagesBottom-Up vs Top-Down Nanofabrication MethodsManojkumar ANo ratings yet

- Libro 1Document198 pagesLibro 1AlejandroNo ratings yet

- R-Value TableDocument4 pagesR-Value TableKKNo ratings yet