Professional Documents

Culture Documents

SR21 Slotsensors Manual RevC e

Uploaded by

Nandor KermeciCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SR21 Slotsensors Manual RevC e

Uploaded by

Nandor KermeciCopyright:

Available Formats

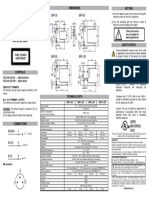

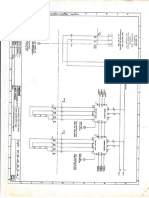

CONNECTIONS

M8 connector

SR21-IR / SR21-RG

INSTRUCTION MANUAL

CONTROLS

TECHNICAL DATA

OUTPUT LED (YELLOW)

The yellow LED ON indicates output activation.

READY/ERROR LED (RED/GREEN)

The green LED continuously ON indicates a normal operating condition. Refer to the SETTING

paragraph for the correct setting phase indications.

The red LED continuously ON or blinking indicates an error status.

Refer to ERROR INDICATIONS paragraph for the correct indications during the different functioning

phases.

AUTO-SET PUSH-BUTTON

Activates the different setting modes using the READY/ERROR LED indications.

The pressure on the AUTO-SET push-button can be brief when pressed for at least 3 sec., or long

when pressed longer.

Refer to SETTING paragraph for operating mode indications.

Power supply:

Ripple:

Consumption

(output current excluded):

Outputs:

Output current:

Output saturation voltage:

Response time:

Switching frequency:

T rise:

T fall:

Humidity:

Indicators:

Setting:

Data retention:

Operating temperature:

Storage temperature:

Emssion frequency:

Emission type:

Ambient light rejection:

Slot width:

Detectable object limits:

Housing material:

Lens material:

Mechanical protection:

Connections:

Weight:

DIMENSIONS

16

12

OUTPUT

POWER SUPPLY

20

26

18

50

18

26

LOCK SCREW

NPN and PNP on different poles;

pull up/down resistance= 33 K

100 mA max.

short-circuit protection

2 V max. with NPN

2 V max. with PNP

(values at maximum output current)

20 s max.

25 kHz max.

1 s (NPN; R = 1 K)

120 s (NPN; C = 4.7 nF)

33 K pull-up internal resistance

1 s (PNP; R = 1 K)

120 s (PNP; C = 4.7 nF)

pull-down internal resistance 33 K

35 85% rH non-condensing

Bicolour READY/ERROR LED (green/red)

OUT LED (yellow)

AUTO-SET push-button

EEPROM non volatile memory

-20 60C

-20 70C

Modulated light at 50 kHz 10%

infrared 880 nm

visible red/green (633 nm/570 nm)

EN 60947-5-2

2 mm

Min. 0.5mm width

ZAMA

glass

IP65

M8 4-pole connector

115 g.

Static setting (MANUAL)

Recommended in presence of transparent irregular profiles and requires a separate acquisition of the

label and of the support with manual positioning.

The best result is obtained acquiring the most transparent area of the label and the most opaque area of

the support.

90

4.25

55 mA max.

SETTING

n2 M4x8

7.5

10 30 Vdc;

reverse polarity protection

2 Vpp max.

7.5

PUSH-BUTTON

M8

20

mm

LEDS

97.5

NOTE

To install the sensor using the connector positioned at 90, unscrew the blocking screw and rotate the

fixing block in an anti-clockwise direction. At the end rescrew the blocking screw.

Static setting (MANUAL)

Recommended in presence of transparent irregular profiles and requires a separate acquisition of the

label and of the support with manual positioning.

The best result is obtained acquiring the most transparent area of the label and the most opaque area of

the support.

Setting steps:

1) With LED solidly ON, position the label in the sensor slot if the output has to be activated in

correspondence of the label (NORMAL output), or position the support if the output has to be

activated in correspondence of the support (INVERTED output). Use the specific references for

centering.

2) Briefly press AUTO-SET. The green and yellow LEDs turn OFF. The object acquisition phase begins.

The object must not be moved until the green LED blinks rapidly.

3) While the green LED continues to blink rapidly, position the second object (support or label) in the

sensor slot using the

specific references for centering.

4) Briefly press AUTO-SET. The rapidly blinking green LED turns OFF. The detection of the second

object begins. The

object must not be moved until the green LED turns solidly ON.

5) The green READY LED solidly ON indicates that the sensor has detected a sufficient contrast

between the label and the support. The sensor can function with the new setting. A different indication

signals an error due to insufficient contrast.

Setting steps:

1) With LED continuously ON, position the label in the sensor slot if the output has to be activated in

correspondence of the label (NORMAL output), or position the support if the output has to be

activated in correspondence of the support (INVERTED output). Use the specific references for

centring.

2) Briefly press AUTO-SET. The green and yellow LEDs turn OFF. The object acquisition phase begins.

The object must not be moved until the green LED doesnt blink rapidly.

3) When the green LED blinks postion the second object (support or label) in the sensor slot using the

specific references for centring.

4) Briefly press AUTO-SET. The green LED turns OFF. The detection of the second object begins. The

object must not be moved until the green LED doesnt turn ON continuously.

5) The green READY LED continuously ON indicates that the sensor has detected a sufficient contrast

between the label and the support. The sensor can function with the new setting. A different indication

signals an error due to insufficient contrast.

Dynamic setting with NORMAL or INVERTED output

The programming has to be carried-out during normal movement of the label ribbon inside the sensor

slot. Recommended for labels and supports with a rather uniform transparency degree.

Setting steps:

1) With green LED continuously ON, start the movement of the label ribbon in the sensor slot.

2) Press AUTO-SET until the green LED blink slowly.

3) Release the push-button. The sensor acquires the transparency degree of both the moving labels and

support in approximately 2 sec. cycles. Leave the sensor in this acquisition phase for the time

necessary to guarantee the detection of the major number of points possible. The duration depends

on the ribbon speed and dimensions of the labels and support.

4) Setting with NORMAL output: briefly press AUTO-SET. The green READY LED continuously ON

indicates that the sensor has detected a sufficient contrast between the label and support. The sensor

begins to function with the new setting and the output is activated in correspondence of the label. A

different indication signals an error due to insufficient contrast.

5) Setting with INVERTED output: press AUTO-SET until the green LED blinks rapidly three times.

Release the pus-button. The green READY LED continuously ON indicates that the sensor has

detected a sufficient contrast between the label and the support. The sensor begins to function wth

the new setting and the output is activated in correspondence of the support. A different indication

signals an error due to insufficient contrast.

ERROR INDICATIONS

READY/ERROR LED blinking with slow red and green alternation: indicates that the setting (static or

dynamic) has failed due to insufficient transparency or contrast between label and support. In this case

the sensor maintains the previous setting and returns to normal functioning pressing and releasing

AUTO-SET.

READY/ERROR LED red blinking at average speed: during normal functioning and only with active

output, indicates a short-circuit or overload of the outputs or insufficient power supply. The indication

disappears when the cause is removed.

PUSH-BUTTON BLOCKING AND UNBLOCKING

The push-button can be blocked to avoid accidental movements during normal sensor functioning. The

block can be maintained even after the turning OFF and turning ON of the sensor. The blocking and

unblocking operations are given below:

1) With sensor turned OFF press AUTO-SET

2) Re-power sensor keeping the push-button pressed. The sensor inverts the block status: if the pushbutton was unblocked the bock is activated and the red LED is continuously ON, if the push-button

was blocked the sensor unblocks it and at sensor re-powering the green LED is continuously ON.

3) The sensor begins to operate with normal functioning. The setting can not be modified if the pushbutton is blocked.

DECLARATION OF CONFORMITY

We DATALOGIC AUTOMATION declare under our sole responsibility that these products are conform to the 2004/108/CE and

successive amendments.

WARRANTY

DATALOGIC AUTOMATION warrants its products to be free from defects.

DATALOGIC AUTOMATION will repair or replace, free of charge, any product found to be defective during the warranty period of 36

months from the manufacturing date.

This warranty does not cover damage or liability deriving from the improper application of DATALOGIC AUTOMATION products.

DATALOGIC AUTOMATION

Via Lavino 265 - 40050 Monte S.Pietro - Bologna Italy

Tel: +39 051 6765611 - Fax: +39 051 6759324

www.automation.datalogic.com e-mail:info.automation.it@datalogic.com

DATALOGIC AUTOMATION cares for the environment: 100% recycled paper.

DATALOGIC AUTOMATION reserves the right to make modifications and improvements without prior notification.

Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many countries, including the U.S.A. and the E.U.

826003051 Rev.C

Copyright Datalogic 2007-2009

You might also like

- Tech Sheet W10280489 Rev DDocument48 pagesTech Sheet W10280489 Rev DEmmanuel Vieira VillasanaNo ratings yet

- SMD CatalogDocument80 pagesSMD Catalogpbradaric91% (11)

- Analysis of Radome-Enclosed AntennasDocument319 pagesAnalysis of Radome-Enclosed Antennasnhung_3375% (4)

- Ec 5Document2 pagesEc 5DRESPLNo ratings yet

- Nikon D3500: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandNikon D3500: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- IR-357 CAP-Xa 01EDocument688 pagesIR-357 CAP-Xa 01Ekrsrinivasaraju100% (1)

- Nikon D500: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandNikon D500: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- 3-033-R002 SF Leak Detector Owner's ManualDocument16 pages3-033-R002 SF Leak Detector Owner's ManualAnonymous u0wETydFNo ratings yet

- Fit IPL-R: Instruction ManualDocument8 pagesFit IPL-R: Instruction Manualana carolina PereiraNo ratings yet

- Tài liệu cảm biến bắt màu BANNER R58 Expert - R58ECRGB1Document12 pagesTài liệu cảm biến bắt màu BANNER R58 Expert - R58ECRGB1Nguyễn Văn Dũng100% (4)

- User Manual - Ennologic Dual Laser Infrared Thermometer eT650D and eT1050DDocument56 pagesUser Manual - Ennologic Dual Laser Infrared Thermometer eT650D and eT1050DCalidad Los MonosNo ratings yet

- Banner R58 Color Mark SensorsDocument11 pagesBanner R58 Color Mark SensorsMemik TylnNo ratings yet

- Dual Laser Infrared (Ir) Thermometer With Color Alert: User ManualDocument9 pagesDual Laser Infrared (Ir) Thermometer With Color Alert: User ManualSupriadi Bin AhmadNo ratings yet

- Auto Meter VF: Instruction Manual Manuel D'instructionsDocument37 pagesAuto Meter VF: Instruction Manual Manuel D'instructionsPablo Cabello EspinozaNo ratings yet

- Oregon Scientific BAA628HG Weather StationDocument10 pagesOregon Scientific BAA628HG Weather StationphilaskNo ratings yet

- Q45U Ultrasonic Sensors With Analog Outputs (Short Range) : Temperature CompensationDocument8 pagesQ45U Ultrasonic Sensors With Analog Outputs (Short Range) : Temperature CompensationAlan Abdiel RuizNo ratings yet

- Airwell Dci Inverter Diagnostics Air SMDocument8 pagesAirwell Dci Inverter Diagnostics Air SMJorge Marrero DiazNo ratings yet

- Data Logger Log100/110: ManualDocument6 pagesData Logger Log100/110: ManualCarlos Andrés MarroquinNo ratings yet

- A320 Hearthsure User Manual 20160406 LRDocument20 pagesA320 Hearthsure User Manual 20160406 LRCIBMEDICS SASNo ratings yet

- User ManualDocument34 pagesUser ManualDavid RadelNo ratings yet

- Conversor de SeñalDocument7 pagesConversor de SeñalGustavo OviedoNo ratings yet

- Oregon Scientific Wireless Sensor ManualDocument4 pagesOregon Scientific Wireless Sensor ManuallouarnNo ratings yet

- Outdoor High-Security Digital Motion Detector: Installation GuideDocument36 pagesOutdoor High-Security Digital Motion Detector: Installation GuideMetalurgica VISILUNo ratings yet

- Premio 20 DTDocument35 pagesPremio 20 DThyakueNo ratings yet

- Metravi GM-197 Gauss Meter User ManualDocument20 pagesMetravi GM-197 Gauss Meter User ManualRichaNo ratings yet

- EnOcean Occupancy Sensor Operational Description v1.2 04Document11 pagesEnOcean Occupancy Sensor Operational Description v1.2 04Reeta DuttaNo ratings yet

- FS-V30 31CM Im 96M11291 GB 1070-1Document6 pagesFS-V30 31CM Im 96M11291 GB 1070-1Santi ElisahNo ratings yet

- FS-V21/21G/21R (P) /21X: Instruction ManualDocument8 pagesFS-V21/21G/21R (P) /21X: Instruction ManualEduard SteNo ratings yet

- Instruction ManualDocument8 pagesInstruction Manualana carolina PereiraNo ratings yet

- 545-950 ThermaGuard 2021Document2 pages545-950 ThermaGuard 2021AbelNo ratings yet

- Quick Start Guide: Insteon Motion Sensor Models: 2842-222, 2842-422, 2842-522Document4 pagesQuick Start Guide: Insteon Motion Sensor Models: 2842-222, 2842-422, 2842-522IBJSC.comNo ratings yet

- Operation ManualDocument17 pagesOperation ManualLenny Marionel Adames MateoNo ratings yet

- Manual - EXTECH Mini IR Thermometer 42510 - English User's ManualDocument4 pagesManual - EXTECH Mini IR Thermometer 42510 - English User's ManualedmenesesNo ratings yet

- HTO Sensor Air Humidity and Temp SensorDocument8 pagesHTO Sensor Air Humidity and Temp SensorZill RafiNo ratings yet

- Color Mark Sensor Setup GuideDocument14 pagesColor Mark Sensor Setup GuideByron Xavier Lima CedilloNo ratings yet

- LT40 UM-enDocument9 pagesLT40 UM-enferdecoNo ratings yet

- Installation Instructions Photoswitch Bulletin 42Ft Selfćteach Fiber OpticDocument4 pagesInstallation Instructions Photoswitch Bulletin 42Ft Selfćteach Fiber OpticFito RahNo ratings yet

- ManualDocument70 pagesManualAnonymo -308No ratings yet

- Honeywell IS2535 Install GuideDocument2 pagesHoneywell IS2535 Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Oregon Scientific RMR606HGPADocument16 pagesOregon Scientific RMR606HGPACreed JonesNo ratings yet

- User'S Guide: Humidity and Temperature USB DataloggerDocument5 pagesUser'S Guide: Humidity and Temperature USB DataloggervickersNo ratings yet

- User Guide White LED Light Meter Model LT40Document9 pagesUser Guide White LED Light Meter Model LT40PubcrawlNo ratings yet

- Prevod 1 Argus LCMDocument16 pagesPrevod 1 Argus LCMAlejandra Cale RadowitzNo ratings yet

- Manual Service Aoc - E943fwskDocument51 pagesManual Service Aoc - E943fwskEduardo BentoNo ratings yet

- K108 GK5 712 ManDocument8 pagesK108 GK5 712 ManDavid KasaiNo ratings yet

- DIXEL Ceh 2 PDFDocument166 pagesDIXEL Ceh 2 PDFMihailNo ratings yet

- Mounting and Wiring SensorDocument2 pagesMounting and Wiring SensorYohn MartNo ratings yet

- NT538 Instruction ManualDocument15 pagesNT538 Instruction ManualHubert Maraza JaliriNo ratings yet

- 147EN ConfigDocument74 pages147EN ConfigdanhertanuNo ratings yet

- Jl269led Portable Gas DetectorDocument12 pagesJl269led Portable Gas DetectorKaren Lizeth BermudezNo ratings yet

- K110 Windscale+plus w/LND712p Geiger Counter: GreenDocument8 pagesK110 Windscale+plus w/LND712p Geiger Counter: GreenDavid KasaiNo ratings yet

- Non-Contact Forehead IR Thermometer: User's ManualDocument8 pagesNon-Contact Forehead IR Thermometer: User's ManualTedosNo ratings yet

- H 10PM ManualDocument20 pagesH 10PM ManualMartin MerinoNo ratings yet

- Prog Digistat 24 HR 8716145055Document11 pagesProg Digistat 24 HR 8716145055James SkinnerNo ratings yet

- Light Meter: Model SDL400Document12 pagesLight Meter: Model SDL400Mari AlmendrasNo ratings yet

- Deif Generator ControlDocument21 pagesDeif Generator Controlmariwasasiamceramics100% (1)

- PortaLite - Short Manual v1206Document3 pagesPortaLite - Short Manual v1206Jerome ParentNo ratings yet

- Oregon Scientific Bar688hg User GuideDocument13 pagesOregon Scientific Bar688hg User Guidet_obermaislNo ratings yet

- Weather Station ManualDocument10 pagesWeather Station ManualbobmouldNo ratings yet

- Healtech Rapport EngagéDocument4 pagesHealtech Rapport EngagéFoggy211No ratings yet

- Banner QL50 Luminescence SensorsDocument8 pagesBanner QL50 Luminescence SensorsMemik TylnNo ratings yet

- Manual Lampara Estroboscopica DT-315PDocument17 pagesManual Lampara Estroboscopica DT-315PStiven Giraldo NuñezNo ratings yet

- BIOBASE Blood Collection Monitor BCM-12B User ManualDocument5 pagesBIOBASE Blood Collection Monitor BCM-12B User Manualsoporte03No ratings yet

- Ja 63FDocument1 pageJa 63FAndy ColeNo ratings yet

- Vitafonbook PDFDocument141 pagesVitafonbook PDFxenniaxNo ratings yet

- 30 LED ProjectsDocument31 pages30 LED ProjectsVlatko KrstevskiNo ratings yet

- Ba Ds 019 02 10 en LowDocument40 pagesBa Ds 019 02 10 en LowNandor KermeciNo ratings yet

- CatalogDocument204 pagesCatalogNandor KermeciNo ratings yet

- General Terms and Conditions GTCS: 1. ScopeDocument4 pagesGeneral Terms and Conditions GTCS: 1. ScopeNandor KermeciNo ratings yet

- Lubricators LOE, D SeriesDocument14 pagesLubricators LOE, D SeriesNandor KermeciNo ratings yet

- Datalogic SR31 ManualDocument2 pagesDatalogic SR31 ManualNandor KermeciNo ratings yet

- SRFlaser Slotsensors Manual RevF EngDocument1 pageSRFlaser Slotsensors Manual RevF EngNandor KermeciNo ratings yet

- SRFlaser Slotsensors Manual RevF EngDocument1 pageSRFlaser Slotsensors Manual RevF EngNandor KermeciNo ratings yet

- Img 0006Document6 pagesImg 0006Nandor KermeciNo ratings yet

- Dok 1Document1 pageDok 1Nandor KermeciNo ratings yet

- Lubricators LOE, D SeriesDocument14 pagesLubricators LOE, D SeriesNandor KermeciNo ratings yet

- Datalogic SR31 ManualDocument2 pagesDatalogic SR31 ManualNandor KermeciNo ratings yet

- ADocument1 pageANandor KermeciNo ratings yet

- Avances de Desarrollos TIC - Simenes - Marzo - 09Document65 pagesAvances de Desarrollos TIC - Simenes - Marzo - 09sacostaNo ratings yet

- PT4115 LED Step-DownDocument18 pagesPT4115 LED Step-DownNandor KermeciNo ratings yet

- Elcobrandt Microwave Oven Technical TrainingDocument56 pagesElcobrandt Microwave Oven Technical TrainingNandor KermeciNo ratings yet

- Promag w400Document92 pagesPromag w400Nandor KermeciNo ratings yet

- GBDocument2 pagesGBNandor KermeciNo ratings yet

- GBDocument2 pagesGBNandor KermeciNo ratings yet

- BDocument3 pagesBNandor KermeciNo ratings yet

- G3 Profibus DP - Technical ManualDocument72 pagesG3 Profibus DP - Technical ManualNandor KermeciNo ratings yet

- Avances de Desarrollos TIC - Simenes - Marzo - 09Document65 pagesAvances de Desarrollos TIC - Simenes - Marzo - 09sacostaNo ratings yet

- GBDocument4 pagesGBNandor KermeciNo ratings yet

- GBDocument6 pagesGBNandor KermeciNo ratings yet

- P586gb (Generation C)Document28 pagesP586gb (Generation C)Nandor KermeciNo ratings yet

- Goldstar Repair Tips (ET)Document11 pagesGoldstar Repair Tips (ET)Nandor KermeciNo ratings yet

- Datasheet SD6109 PDFDocument10 pagesDatasheet SD6109 PDFNandor KermeciNo ratings yet

- C++ Windows APIDocument2 pagesC++ Windows APIPaulNo ratings yet

- Regarding The Change of Names Mentioned in The Document, Such As Mitsubishi Electric and Mitsubishi XX, To Renesas Technology CorpDocument37 pagesRegarding The Change of Names Mentioned in The Document, Such As Mitsubishi Electric and Mitsubishi XX, To Renesas Technology CorpАнтон ПNo ratings yet

- Casio Eqw A1200 Manual Operation Qw5325Document9 pagesCasio Eqw A1200 Manual Operation Qw532517072909No ratings yet

- AgileMesh Manual Ver. 2Document46 pagesAgileMesh Manual Ver. 2fgrefeNo ratings yet

- The Minimum You Need To Know About Java and xBaseJDocument186 pagesThe Minimum You Need To Know About Java and xBaseJRoland Hughes100% (1)

- Programming Using MON08Document16 pagesProgramming Using MON08Paula PinzonNo ratings yet

- GamingDocument19 pagesGamingArjun VatwaniNo ratings yet

- Physics 4AL: Mechanics Lab ManualDocument110 pagesPhysics 4AL: Mechanics Lab Manualroblesgd+scribdNo ratings yet

- SV8100 General Desc ManualDocument214 pagesSV8100 General Desc Manualimella17No ratings yet

- RAMPAS DIY - DiySkateDocument80 pagesRAMPAS DIY - DiySkateC0STNo ratings yet

- Computer BasicssDocument6 pagesComputer BasicssChhavi ResuNo ratings yet

- GRT Autopilot Installation-Setup PDFDocument34 pagesGRT Autopilot Installation-Setup PDFRizki AldillaNo ratings yet

- 4-Port Usb KVM Switch: Dkvm-4UDocument32 pages4-Port Usb KVM Switch: Dkvm-4Uapex1310No ratings yet

- What Is RouterboardDocument35 pagesWhat Is Routerboardnic123456456No ratings yet

- UTS Semester Ganjil 2021/2022 Mata Kuliah Pend. Bahasa Asing 1Document3 pagesUTS Semester Ganjil 2021/2022 Mata Kuliah Pend. Bahasa Asing 1puteri amandaNo ratings yet

- Leica Cs20-Cs35 DsDocument2 pagesLeica Cs20-Cs35 DsJelena TerzicNo ratings yet

- DeviceNet PDFDocument43 pagesDeviceNet PDFCristhianMauricioQuezadaNo ratings yet

- XSLF CookbookDocument6 pagesXSLF CookbookjimakosjpNo ratings yet

- UNIT II - Multi Core ArchitectureDocument102 pagesUNIT II - Multi Core ArchitectureVivek DubeyNo ratings yet

- Honeywell Purge Timer S427B, CDocument2 pagesHoneywell Purge Timer S427B, CRyan TrialsNo ratings yet

- J2SE (Core JAVA) NotesDocument146 pagesJ2SE (Core JAVA) NotesPriyanka NNo ratings yet

- W 27 e 512Document16 pagesW 27 e 512MassimoNo ratings yet

- Advanced Risc MachinersDocument21 pagesAdvanced Risc MachinersAANCHALNo ratings yet

- BK Precision CatalogDocument118 pagesBK Precision CatalogTony WilliamsNo ratings yet

- ALDE111 - Student Tutorial Letter and Assessment Plan - 2023Document7 pagesALDE111 - Student Tutorial Letter and Assessment Plan - 2023Tshepo OscarNo ratings yet

- ISCOM2924GF-4GE - 4C Configuration Guide (A - 01) PDFDocument337 pagesISCOM2924GF-4GE - 4C Configuration Guide (A - 01) PDFKijush MaharjanNo ratings yet

- Nixie Clock Type Nixie QTC': Assembly Instructions and User GuideDocument58 pagesNixie Clock Type Nixie QTC': Assembly Instructions and User GuideMicah StevensNo ratings yet