Professional Documents

Culture Documents

JSS 50860

Uploaded by

Kaushik SenguptaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSS 50860

Uploaded by

Kaushik SenguptaCopyright:

Available Formats

RAKSHA MANTRALAYA

MINISTRY OF DEFENCE

JOINT SERVICES SPECIFICATION

ON

DETAILED SPECIFICATION

FOR

CONNECTORS, ELECTRICAL, CIRCULAR.

MULTI-CONTACT, THREADED

COUPLING, METRIC SHEET SIZE

JSS 50860 : 1993

Reaffirmed 1999

MANAKIKARAN NIDESHALAYA

RAKSHA UTPADAN TATHA POORTI VIBHAG

RAKSHA MANTRALAYA, 'H' BLOCK, DHQ PO

NEW DELHI - 110 011

DIRECTORATE OF STANDARDISATION

DEPARTMENT OF PRODUCTION & SUPPLIES

MINISTRY OF DEFENCE, 'H'- BLOCK, DHQ PO

NEW DELHI - 110 011

JSS 50860 : 1993

Reaffirmed 1999

RAKSHA MANTRALAYA

MINISTRY OF DEFENCE

JOINT SERVICES SPECIFICATION

ON

DETAILED SPECIFICATION

FOR

CONNECTORS, ELECTRICAL, CIRCULAR.

MULTI-CONTACT, THREADED

COUPLING, METRIC SHEET SIZE

JSS 50860 : 1993

Reaffirmed 1999

MANAKIKARAN NIDESHALAYA

RAKSHA UTPADAN TATHA POORTI VIBHAG

RAKSHA MANTRALAYA, 'H' BLOCK, DHQ PO

NEW DELHI - 110 011

DIRECTORATE OF STANDARDISATION

DEPARTMENT OF PRODUCTION & SUPPLIES

MINISTRY OF DEFENCE, 'H'- BLOCK, DHQ PO

NEW DELHI - 110 011

i

JSS 50860 : 1993

Reaffirmed 1999

RECORD OF AMENDMENTS

Amendment

No.

Date

Amendment

pertains to:

Sl.No./ Para No./

Column No.

Amended by

Authority

ii

Signature

&

Name & Appointment

Date

(IN BLOCK LETTERS)

JSS 50860 : 1993

Reaffirmed 1999

LIST OF MEMBERS ASSOCIATED WITH FORMULATION OF THIS

STANDARD

1.

This Joint Services Specification has been approved by Major General AR

Nambiar Chairman, Electronic Standardization Sub Committee in the meeting held on 16

Sep 98/ by circulation.

2.

The following members have been present / consulted in approving the

reaffirmation.

Sl.No

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

Name and Designation

Organization

Shri PK Jain Sc G

Shri MN Sen, Sc G

Brig ML Mathur

Shri VN Ray, Sc F

Shri SK Kimothi, Addl Director

Shri Prakash Chand Sc E

Cdr, VKC Bakshi

Lt Col J Nagarajan

Lt Col Mahesh Chand

Lt Col Ravi Mandla, JD

Shri A Pratap Kumar

Shri M Shafiulla

Shri KG Shenai DGM (QC)

Shri M Arun Kumar Chief Engineer

Col RK Bhanot (RTD)

Shri VV Surya Narayana, Sr Manager,

Shri Arjun Singh, SSO

Shri JR lamal, JDO

Shri SC Gupta SE

Shri JR Dass .Sc C

Lt Col Sheodan Singh

Shri IJ Arora JDo

iii

LCSO, Bangalore

SSPL, New Delhi

CQA (L), Bangalore

DSC Bangalore

STQC, DOE, New Delhi

Deal, Dehradun

JCES, New Delhi

CQA (AVL), Avadi

D of L&T, Drdo

OS (L), AhQ

CRI, C/O BE (GAD)

DGAQA, New Delhi

ITI Bangalore

ITI, Bangalore

ECIL, Delhi

ECIL, Hyderabad

DQAN, New Delhi

DOS (L), NHQ

HQ TGEME, Delhi Cantt

DSC Dehradun

Secretary, LSSC

LSSC

Dte of Signals, AHQ

WE Dte (WE-7), AHQ

DLRL, Hyderabad

HAL, Hyderabad

Dte of Rocket and Missile

LRDE, Bangalore

CEMILAC, RCMA, Hyderabad

CQA (WE), Bangalore

DGL (Air HQ)

CQA (EW), Secunderabad

CQA (S), Secunderabad

JSS 50860 : 1993

Reaffirmed 1999

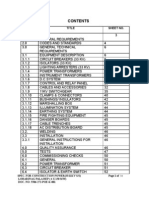

CONTENTS

Sl. No.

Page No.

0.

FOREWORD

1.

SCOPE

2.

RELATED SPECIFICATION AND DOCUMENTS

3.

INFORMATION TO BE SUPPLIED BY PURCHASER

4.

ILLUSTRATIONS AND DRAWINGS

5.

PATENTS

6.

DEFINITIONS

7.

MATERIALS, PROCESS AND FINISHES

8.

MARKING

9.

PACKAGING

10.

QUALIFICATION APPROVAL AND MAINTENANCE OF

QUALIFICATION APPROVAL PROCEDURE

11.

BATCH ACCEPTANCE PROCEDURE

11

12.

TEST PROCEDURE

14

13.

TEST DETAILS

15

14.

LIST OF PATTERNS

26

15.

TECHANICAL NOTES

27

16.

LIST OF STANDARDS

27

17.

SUGGESTION FOR IMPROVEMENT

82

APPENDIX A

83

APPENDIX B

85

APPENDIX C

86

APPENDIX D

87

APPENDIX E

89

APPENDIX F

112

REPLACEMENT GUIDE

113

iv

JSS 50860 : 1993

Reaffirmed 1999

0.

FOREWORD

0.1

This Specification has been prepared by Electronic Components

Standardisation Organisation (LCSO) on behalf of Electronic Standardisation SubCommittee on the authority of Standardisation Committee, Ministry of Defence.

0.2

This specification has been approved by the Ministry of Defence and is

mandatory for use by the Defence Services.

0.3

This specification should be used for design manufacture quality

assurance and procurement of the item.

0.4

Quality Assurance Authority for the item covered by this specification is

CQA(L) for Army, DQA (N) for Navy and Air Force. Enquiries regarding this

specification relating to any contractual conditions should be addressed to the Quality

Assurance Authority named in the tender or contract. Other technical enquiries should be

referred to :The Officer-in-Charge

Electronic Components Standardisation Organisation (LCSO)

DRDO Complex

C.V. Raman Nagar

Bangalore - 560 093

0.5

Copies of this specification can be obtained on payment from :The Controller

Controllerate of Quality Assurance (Electronics)

Jayachamarajendra Nagar PO

ngalore - 560 006

0.6

specifications holds good only for the supply order for which it is issued.

JSS 50860 : 1993

Reaffirmed 1999

1.

SCOPE

This specification relates to the detailed requirements for a range of

connectors, electrical, circular, multi-contact, threaded coupling, metric shell size. It

should be used in conjunction with 'JSS 50800 - General requirements for connectors, dc

and low frequency'.

2.

RELATED SPECIFICATIONS AND DOCUMENTS

2.1

Joint Services Specifications

2.1.1

General Specifications

2.1.2

JSS 50101 : 1985

(Part 1)

(Supersedes

JSS 50101:1972)

Environmental test methods for service

electronic components.

JSS 50102 : 1985

(Supersedes JSS

50102:1971)

General Specification and procedure for the

Qualification Approval and acceptance of

electronic components.

Detailed Specifications

JSS 50805 : 1975

Detailed specification for connectors,

electrical, printed wiring board and

insulated board.

Reaffirmed 1999

JSS 50806 : 1971

Detailed specification for connectors;

electrical, printed wiring board General

purpose.

Reaffirmed 1993

2.2

Source of Supply

2.2.1

from :-

Joint Services Specifications are obtainable on payment

The Controller

Controller ate of Quality Assurance (Electronics)

J.C. Nagar PO

Bangalore 560006

2

JSS 50860 : 1993

Reaffirmed 1999

3.

INFORMATION TO BE SUPPLIED BY PURCHASER

3.1

When ordering components to this specification, it is essential to quote the

relevant Defence Stores Catalogue Number, Style Reference and this specification.

4.

ILLUSTRATIONS AND DRAWINGS

4.1

Purpose - The essential purpose of the illustrations and drawings in this

specification is to ensure mechanical inter changeability. The illustrations and drawings

are not intended to restrict details of construction which do not affect interchangeability,

nor are they to be used as manufacturing drawings.

NOTE: It is essential that equipment designers Work to the limits stated and not to

the dimensions of individual components.

4.2

Projection - Third angle projection is used.

4.3

Dimensions - Dimensions are in millimeters.

4.4

Drawings - Where official drawings are quoted, they are mandatory.

Copies of such drawings are obtainable from the Officer-in-Charge, LCSO.

5.

PATENTS

5.1

Patent or design rights or copyright may subsist in connection with items

defined as standards, and the issue of this specification does not convey or imply any

license to use information which is the subject of such rights.

6.

DEFINITIONS

6.1

For the purpose of this specification, definitions contained in JSS 50101

and JSS 50102 together with the following shall apply.

6.2

Adaptor - A component, designed to provide connection(s) between two

or more other connectors where mechanical direct connection is impossible or electrical

direct connection undesirable.

6.3

parts.

Clearance - It is the shortest distance measured in air between conductive

JSS 50860 : 1993

Reaffirmed 1999

6.4

Connector - A component, normally Attached to a cable or to a piece of

apparatus for the purpose of providing connection(s) through a suitable mating part,

between cables and/or pieces of apparatus.

6.5

Creep age distance - It is the shortest distance over the outer surface of

insulation between conductive parts.

6.6

of a cable.

Free connector (plug) - A connector, designed for attachment to a free end

6.7

Fixed connector (socket or receptacle) - A connector, designed for

attachment to a chassis or peace of apparatus.

6.8

Mated set of connectors - Combination, when mated, of two connectors

designed for being coupled.

6.9

follows :

Style Reference - The style reference in this specification is derived as

(a)

The first group of letters "CCTM" represents the family of connectors "Connectors Circular, Threaded Coupling (metric shell size)".

(b)

The subsequent group of characters following a hyphen represent the class

of connector, as given below.

Class

Description

WPr

Medium Size, Sealed

WP

Medium Size, Unsealed

2PMr

Small Size, Sealed

2PM

Small Size, Unsealed

PC/R

Sub-miniature, Sealed

PC

Sub-miniature, Unsealed

JSS 50860 : 1993

Reaffirmed 1999

(c)

The next letter (s) separated by a slash-mark represent(s) the function of

the connector, as given below, and together with the preceding characters

denotes a unique pattern governed by a single outline drawing (with or

without cable clamps/ back shell).

Code

Function

Receptacle

PS

Plug, Straight (Free connector)

PA

Plug, Right-angled (free connector)

(d)

The next numeral (s) following a hyphen indicate (s) the size of connector

- shall, given by the mounting hole dia of the receptacle, in mm.

(e)

The subsequent numeral (s) following a hyphen indicate the total number

of contacts (either of same size or different sizes).

(f)

The last numeral following a hyphen represents a distinct contact

arrangement, for a specific size and specific number of contacts. (Details

(d), (e) and (f) together represent a unique insert arrangement appearing in

Appendix 'E').

(g)

The last letter following a hyphen represents the type of contact: M-Male

and F-Female.

(h)

The last group of letters "Sc" or "USc", if appearing, indicates a specific

outline drawing within the pattern, different from the basic connector (one

which has no accessories) under the pattern.

Example:i)

CCTM

Connector

Circular

threadedCoupling

(Metric

shell size)

-2PMr

Small

size,

Sealed

/R

Receptacle

-48

shell size

48 mm

-9

9

contacts

-7

-M

contact

Male

arrangement contact

number 7,

in shell size

48, and 9

contacts

JSS 50860 : 1993

Reaffirmed 1999

ii)

CCTM

Connector

Circular

threadedCoupling

(Metric

shell size)

-WP

Medium

size,

Unsealed

/ PS

Plug

with

straight

back

shell

-20

shell

size

20

mm

-5

5

contacts

-9

Contact

arrangement

number 9, in

shell size 20,

and 5

contacts

7.

MATERIALS PROCESSES AND FINISHES

7.1

MATERIALS

-F

-SC

Female Specific

contact Out line

Drawing

7.1.1

Body, Coupling Rings, Back-Shell and Cable Clamps These parts shall be

either die-cast or machined. For diecastings, Aluminium Alloy Grade LM6 or LM2A

shall be used (see also clause 7.3). For machined parts, Aluminium Alloy Grade Hb 15 or

HE 20 shall be used.

7.1.2

lnsert : Inserts shall be moulded from Neoprene. The mating face inserts

shall have a hardness Figure in the Shore a durompter range of 60 to 85.

7.1.3

Contacts : Male cuntarts shall be of Machined Brass female contacts

shall be as follows :

7.2

(a)

For open entry type - (slotted-sleeve construction), Phosphor Bronze shall

be uspd.

(b)

For closed entry type, the contact body shall be of machined Brass and

the spring member (contact-clip) shall be of Beryllium copper.

FINISHES

7.2.1

Shell, Coupling Rings, Back-shells and Cable Clamps These parts shall be

Cadmium plated with supplementary Chromate treatment, over copper under plate. The

resultant finish shall be 10.8 mm (min) thick, and shall have drab shade (light to dark).

7.2.2

Contacts: Contacts shall be silver plated to 7.5 mm (min) thickness over

copper under plate.

7.3

Workmanship: Die-cast parts shall be of unifrom quality, free injurious

blow-holes, porosity, hard-spots, shrinkage defects, cracks and other injurious defects

which will advers affect their serviceability. However, these defects shall be a cause for

rejection, only if the number and extent of blow-holes, sponginess and other defects

6

JSS 50860 : 1993

Reaffirmed 1999

exceed the limits mutually agreed to sponginess and other defects exceed the limits

mutually agreed to between the supplier and the procuring agency under the terms of

contract, which should also indicate the designated area (s) where such defects are

required to be substantially absent. All castings shall be completely cleaned prior to

assembly. Castings shall not be plugged or welded, nor shall imperfections be filled in.

7.4.0

Design and Construction : Connectors and accessories shell be designed

and constructed to withstand normal handling incident to installation and maintenance in

service.

7.4.1

Dissimilar Metals : When dissimilar metals are employed in intimate

contact with each other in a connector, or in a mated pair of connectors, suitable

protection against electrolytic corrosion shall be provided.

7.4.2

Non-magnetic Materials : All parts shall be made of materials which are

classed as non-magnetic.

7.4.3

Contacts : Contacts shall conform to the requirements of this specification.

Contacts shall be so designed that neither the male nor female contact shall be damaged

during mating of counterpart connectors. Inserts shall not be subject to damage by

soldering under an acceptable process.

7.4.4

Contact Arrangement : contacts shall be arranged in accordance with the

applicable insert arrangement number indicated in the designation of the connector part.

7.4.4.1

Contact Spacing : Unless otherwise specified, minimum mechanical

spacing shall be as indicated in Appendix 'E'.

7.4.5

Coupling Rings and Back-shall : Coupling rings shall be furnished with

ribs to provide adequate grip during coupling. Coupling rings shall be so designed that

the male and female contacts will engage or disengage as the ring is respectively

tightened or loosened. Coupling torque required for satisfactory mating are given in

Appendix 'C' (for information only).

7.4.6

Lubrication : All threads except those surfaces which are intended to

provide polting compound anchorage, shall be coated with a suitable lubricant.

7.4.7

Cable Clamps : To avoid strain due to twisting and pulling at terminations,

cable clamps shall be provided wherever necessary.

7.4.8

Shell Polarisation : Polarisation of connectors shall be with key and

mating keyway arrangement on counterpart connectors.

JSS 50860 : 1993

Reaffirmed 1999

7.5.0

Interchangeability and Inter mate ability:

7.5.1

Inter change ability: All connectors and accessories having the same

Defence Stores Catalogue Number shall be completely interchangeable with each other

with respect to installation and performance.

7.5.2

Inter mate ability: Counterpart connectors from different manufacturers

shall provide satisfactory engagement.

8.

MARKING

8.1

Connectors shall be marked with JSS style reference. The equipment part

number of foreign origin may also be marked, but however is not mandatory.

9.

PACKAGING

9.1

Packaging (preservation, identification and packaging) shall be in

accordance with the terms of the contract.

10.

QUALIFICATION APPROVAL

QUALIFICATION APPROVAL PROCEDURE

10.1

AND

MAINTENANCE

OF

PROVISION OF SAMPLES

(Note - A minimum of six contacts shall be wired with a minimum of

75mm length of the applicable wires. The contacts selected shall be those

having the least cree page path between adjacent contact pairs and where

the connector has more than one contact size, shall be chosen to represent

different contact sizes).

10.1.1

Approval of a single mating pair of style reference : The manufacturer

shall submit 12 mating pairs of the connector and these specimens shall be subjected to

all groups of tests.

10.1.2

Approval of a single reference with complementary inserts (male and

female) : If the manufacturer has the approval for given style with male insert

arrangement on plug and female insert arrangement on receptacle (or vice-versa),the style

with male insert arrangement on receptacle and female insert arrangement on plugs (or

vice-versa) shall be automatically granted approval.

JSS 50860 : 1993

Reaffirmed 1999

10.1.3

Approval for a shell size : The manufacturer shall submit 12 mating pairs

of a shell size under the corresponding mating pattern for which approval is desired, with

maximum number of contacts. These shall be subjected to all groups of tests. The other

insert arrangements of the same shell size under the corresponding patterns shall then be

granted extension of approval, by conducting 'Dimensions (Outline)' test on 3 specimens

each. Approval shall be extended to lower shell size under the corresponding pattern by

conducting Group '0' '1' and '6' tests (where applicable) on 3 specimens in each shell size

with highest number of contacts (In case the insert arrangements other than those with

maximum number of contacts differ from the latter in the choice of contact size, then

Group '0' tests shall be conducted on 3 specimen, instead of 'Dimensions (outline) 'test

only).

10.1.4

Approval of straight-plugs and right-angled plugs with identical shell size

and insert arrangement : If one variety of plug submitted for approval together with its

mating part, is approved, the approval shall extended to the other variety by conducting

'Dimensions (outline)' test on 2 specimens.

10.1.5

Approval of a pattern : If approval is desired for a pattern, the

manufacturer shall submit 12 specimens of a mated pair of maximum shell size and

maximum number of contacts under the pattern, and these shall be subjected to all groups

of tests. Extension of approval shall then be granted to other insert arrangements of the

same shell size and lower shell sizes, as in clause 10.1.3.

10.1.6

Extension of Approval from connector with cable clamp, to identical

connector without cable clamp, and vice-varsa :

(a)

Connector with cable clamp : If this is approved, then identical connector

without cable clamp shall be granted approval by conducting 'Visual

Examination' test on 3 specimens.

(b)

Connector without cable clamp : If this is approved, then identical

connector with cable clamp shall be granted approval by conducting

'Visual Examination' and group 6 tests on 3 specimens.

10.1.7

In each of the above cases, FIFTY specimens of female contacts for each

contact size, used in the connectors submitted for approval, shall also be submitted for

conducting Group '6' tests.

10.1.8

analysis.

The manufacturer shall also submit TWO sets of piece-parts for materials

JSS 50860 : 1993

Reaffirmed 1999

10.2

Grouping of Specimens: The specimens shall be grouped as indicated in

Table 1.

TABLE 1

QUALIFICATION APPROVAL TEST

(Clause 10.2)

Group

0

Number of Specimens

All

2

3

2

2

4

5

2

2

6 1/

50

Title of Test

Visual Examination

Dimensions (outline)

Materials Analysis

Polarisation

Engagement & Disengagement Force

Magnetic Permeability

Low Level Circuit

Contact Resistance

Voltage proof

Insulation Resistance

Sealing

Capacitance

Solderability

Impact (Bump)

Vibration

Impact (Shock)

Acceleration (Steady state)

Temperature Cycling

Climatic

Resistance to Contaminating fluids

Insert Retention (in shell)

Damp Heat (Steady state)

Life (Mechanical)

Life (Electrical)

Mould Growth

Corrosive Atmosphere (Salt Mist)

Dust

Contact Engagement and Separation

Force

10

Test Number

13.1.1

13.1.2

13.1.3

13.2

13.7

13.8

13.11

13.12

13.14

13.15

13.16

13.63

13.17

13.19

13.20

13.21

13.22

13.23

13.24

13.41

13.35

13.25

13.26

13.27

13.28

13.32

13.61

13.6

JSS 50860 : 1993

Reaffirmed 1999

1/ Applicable to female contacts only.

11.

BATCH ACCEEPTANCE PROCEDURE

11.1

Batch Acceptance shall be performed as described in JSS 50102.

11.2

Inspection Batch - An inspection batch shall be as specified in IS 10673,

and shall consist of connectors of the same style produced under essentially the same

conditions and offered for inspection at one time.

11

JSS 50860 : 1993

Reaffirmed 1999

11.3

100 Percent Acceptance Tests - These tests shall be performed in the order

given in Table 2.

TABLE 2

100 PERCENT ACCEPTANCE TEST

(Clause 11.3)

Test Number

Title of Test

13.1.1

Visual Examination

13.2

Polarisation

13.14

Voltage proof (5 seconds)

11.4

Sampling Tests - Tests bracketed together within a group or subgroup are

considered as sequence and must be performed as such using the same sample.

Information on resubmission of rejected batches is given in IS 10673.

11.4.1

Table 3.

Group A Tests - These tests shall be performed in the order given in

TABLE 3

GROUP A TEST

(Clause 11.4.1)

Test Number

Title of Test

13.1.2

Dimensions (outline)

13.7

Engagement & Disengagement force

13.12

Contact Resistance

13.15

Insulation resistance

13.16

Sealing

12

AQL (Percent

Defective)

Inspection

Level

1.0

II

JSS 50860 : 1993

Reaffirmed 1999

11.4.2

Table 4.

Group B Tests - These tests shall be performed in the order given in

TABLE 3

GROUP A TEST

(Clause 11.4.1)

Test Number

Title of Test

AQL

(Percent

Defective)

Inspection

Level

D/N/1

Material Analysis 2/

13.26

Life (Mechanical)

S-3

13.27

Life (Electrical)

S-3

Subgroup 1

13.1.3

Subgroup 2

Subgroup 3

13.17

Solderability

13.19

Impact (Bump)

13.24

Climatic

13.35

Insert Retention (in shell)

13.34

Contact Retention (in insert)

Subgroup 4

13.32

Corrosive Atmosphere (Salt mist) 3/

1/

Destructive/Non-destructive

2/

To be conducted on a set of piece parts to be supplied with the batch.

3/

Three samples shall be subjected to the, irrespective of the lot size and one or

more failures shall constitute rejection of the lot.

13

JSS 50860 : 1993

Reaffirmed 1999

12.0

TEST PROCEDURE

12.1

Atmospheric Conditions for Testing - Unless otherwise specified all tests

shall be performed under standard atmospheric conditions as defined in clause 14, section

2 of JSS 50101.

12.2

Pre-conditioning - Whenever necessary, a pre-conditioning procedure

shall be specified, to be followed before performing the actual tests.

12.3

Accuracy of Test Equipment - The accuracy of test equipment shall be

specified in the relevant test clause.

12.4

Probes - The use of sharp probes to make contact for testing purposes

must be avoided. The test condition must simulate the normal engagement of the mating

contacts.

12.5

Mounting - For the impact (bump) test and other similar tests imposing

shock or vibration conditions, connectors (sockets and plugs) shall be mounted in their

normal manner on the plates or jigs of such strength and rigidity that the connectors will

experience the full force of the test conditions.

12.6

Multicontacts - Where individual contact tests are specified and there are

more than six contacts of the same rating, the number tested shall be not less than six,

which shall be selected, where applicable, as having the least Cree page distance between

contacts or the metal housing, if any. Tests involving comparison shall be made on the

contacts originally tested.

12.7

Approved mating Components - Where an approved mating component is

specified for engagement with the component under test, the dimensions of the mating

component shall conform to the requirements of the appropriate drawings. When testing

printed circuit connectors, for mating sets read connectors and boards (or gauges).

12.8

Sizing and Test Gauges - The sizing and test gauges shall as specified in

the relevant detailed specification.

14

JSS 50860 : 1993

Reaffirmed 1999

13.

TEST DETAILS

Wherever the 'As specified' occurs against the "Specified Test Conditions"

or "Requirements", it indicates that details are given in the corresponding clauses of JSS

50800. Test Conditions and Requirements peculiar to the range of standards defined herein are given below :TEST

NUMBER

TITLE OF TEST

SPECIFIC TEST

CONDITIONS

REQUIREMENTS

13.1

General Examination

13.1.1

Visual Examination

As specified.

As

specified.

Where

applicable of clause 7.3

shall also be met.

13.1.2

Dimensions (outline)

As specified.

As in clause 16.

13.1.3

Materials Analysis

As specified.

As in clause 7.1 and 7.2

13.1.4

Weight

As specified.

The

weight

of

each

specimen shall not exceed

the maximum specified in

clause 16.

13.2

Polarization

As specified.

13.2.1

Polarising Device

As specified.

13.2.2

Mismating

13.6

Contact Engagement

and Separation Force

(applicable to female

contacts only)

As specified.

As specified.

a) Female contacts shall be

mounted in a suitable

fixture for the engagement

and separation of the

specified Gauge Pins (See

Appendix F)

The separation force shall

be within the following

limits:

b) The contact shall be

conditioned by inserting

fully and with drawing the

applicable test pin once.

1.0

1.5

2.0

2.5

3.0

1.5

2.0

2.0

2.0

3.0

c) The test pin shall be 3.5

inserted to a minimum of 5.5

70% of the depth of the 9.0

female contact.

4.0

5.0

8.0

15

Female

Separation

Contact Size Force

(N)

(dia in mm) (Min)

JSS 50860 : 1993

Reaffirmed 1999

TEST

NUMBER

TITLE OF TEST

SPECIFIC TEST

CONDITIONS

d) The test pin shall

disengaged

and

separation force shall

measured as the pin

withdrawn.

REQUIREMENTS

be

the

be

is

e) The test pin shall be

cleaned periodically to

remove any foreign surface

film which may affect the

separation force.

13.7

Engagement and

Disengagement Force

As specified.

Disengagement Force shall be as

specified in Appendix B

13.9

Magnetic

As specified

The relative permeability shall

not exceed 2.0

13.11

Low Level Circuit

As specified

Maximum Contact resistance

shall conform to the values

specified for different contact

sizes in clause 13.12.

13.12

Contact Resistance

As specified. The following The contact resistance shall be as

details shall apply:

follows:

Unless otherwise specified,

the resistance shall be

measured directly using a

regulated

D.C.

power

supply

and

digital

multimeter, magnitude of

test current shall be as

specified, probes used for

checking shall be connected

to outer diameter of the

contact and at a distance of

1 to 2 mm from the surface

of the insulator.

16

Contact

Dia

(mm)

1.0

1.5

2.0

2.5

3.0

3.5

5.5

9.0

Test

Contact

Current Resistance

(A)

(milliohms)

8

14

20

25

32

40

80

200

5.0

2.5

1.6

1.0

0.8

0.75

0.3

0.15

0.25

0.2

0.2

0.15

0.1

0.1

0.06

0.04

JSS 50860 : 1993

Reaffirmed 1999

TEST

NUMBER

13.14

TITLE OF TEST

Voltage proof

SPECIFIC TEST

CONDITIONS

REQUIREMENTS

As specified. Magnitude There shall be no breakdown or

and nature of test voltage flash over.

shall be as in clause 16.

Points of application:

a) Between the closest pair

of contacts,

b) Between the shell and the

contact closet to the shell.

Test voltage shall be

applied between all, but not

more than six peripheral

contacts.

13.15

Insulation Resistance

As specified.

The value shall be not less than

5000 Megohms.

a) Magnitude and nature of

test voltage in both

directions 500 Vdc 10

percent

b) Points of measurements:

Between all but not more

than six contacts adjacent to

the shell. The contacts

selected shall be those

having the closest spacing

between

measurement

points.

13.16

Sealing (applicable to

receptacles only)

The seal shall be tested as The rate of leakage shall not

specified in test number exceed 2cc per hour, in both

18A of JSS 50101 at a directions.

pressure differential of 150

kPa in both directions.

13.17

Solderability

As specified. Bit size A, As specified.

procedure 2 shall be

applied.

17

JSS 50860 : 1993

Reaffirmed 1999

TEST

NUMBER

TITLE OF TEST

SPECIFIC TEST

CONDITIONS

REQUIREMENTS

13.19

Impact (Bump)

As specified.

13.19.1

Preliminary

As specified. The adaptor

plate shall have the

following

dimensions,

90mm x 90 mm x 3.15 mm.

13.19.2

Electrical Loading

As

specified.

Loading

current shall be 1A.

13.19.3

Intermediate

Measurement

As specified.

Intermittency shall not be greater

than 10 micro-second.

13.19.4

Final Measurements

13.19.4.1

Visual Examination

As specified.

As specified.

13.19.4.2

Contact Resistance

As in clause 13.12

As in clause 13.12.

13.19.4.3

Sealing

As in clause 13.16.

As in clause 13.16.

13.20

Vibration

As specified, at the severity

given in clause 16.

13.20.1

Preliminary

As in clause 13.19.1

13.20.2

Electrical Loading

As in clause 13.19.2

13.20.3

Intermediate

Measurements

As in clause 13.19.3

As in clause 13.19.3.

13.20.4

Final Measurements

13.20.4.1

Visual Examination

As specified.

As specified.

13.20.4.2

Contact Resistance

As in clause 13.12

As in clause 13.12.

13.20.4.3

Sealing

As in clause 13.16.

As in clause 13.16.

13.21

Impact (Shock)

As specified, at the severity

given in clause 16.

13.21.1

Preliminary

As in clause 13.19.1

13.21.2

Electrical Loading

As in clause 13.19.2

13.21.3

Intermediate

Measurements

As in clause 13.19.3

18

As in clause 13.19.3

JSS 50860 : 1993

Reaffirmed 1999

TEST

NUMBER

TITLE OF TEST

SPECIFIC TEST

CONDITIONS

REQUIREMENTS

13.21.4

Final Measurements

13.21.4.1

Visual Examination

As specified.

As specified.

13.21.4.2

Contact Resistance

As in clause 13.12

As in clause 13.12.

13.21.4.3

Sealing

As in clause 13.16.

As in clause 13.16.

13.22

Acceleration (steady

state)

As specified, at the severity

given in clause 16.

13.22.1

Preliminary

As in clause 13.19.1

13.22.2

Electrical Loading

As in clause 13.19.2

13.22.3

Intermediate

Measurements

As in clause 13.19.3

As in clause 13.19.3.

13.22.4

Final Measurements

13.22.4.1

Visual Examination

As specified.

As specified.

13.22.4.2

Contact Resistance

As in clause 13.12

As in clause 13.12.

13.22.4.3

Sealing

As in clause 13.16.

As in clause 13.16.

13.23

Temperature Cycling

As specified, at the severity

given in clause 16. Transfer

time shall be 5 minutes min.

13.23.1

Preliminary

As specified.

As specified.

13.23.2

Final Measurements

13.23.2.1

Visual Examination

As specified.

As specified.

13.23.2.4

Voltage proof

As in clause 13.14.

As in clause 13.14.

13.24

Climatic

As specified, at the severity

given in clause 16.

13.24.1

Preliminary

As specified.

13.24.2

Intermediate

Measurements

As specified.

19

JSS 50860 : 1993

Reaffirmed 1999

TEST

NUMBER

TITLE OF TEST

SPECIFIC TEST

CONDITIONS

REQUIREMENTS

13.24.2.1

Visual Examination

As specified.

As specified.

13.24.3

Temperature (Dry

Heat)

As specified, at the severity

given in clause 16.

13.24.4

Damp Heat (Cyclic)

As specified.

13.24.5

Temperature (Cold)

As specified, at the severity As specified.

given in clause 16.

13.24.5.1

Engagement and

Disengagement force

As specified.

13.24.6

Air pressure (low)

As specified, at the severity

given in clause 16.

13.24.6.1

Voltage proof

As in clause 13.14.

13.24.7.2

Dam heat (cyclic)

(severity H13)

As specified.

a) Working test

As specified, Rated working As specified.

voltage as in clause 16.

b) Insulation

Resistance

As specified.

The values shall be not less than

100 Megohms.

As specified.

As in clause 13.14.

13.24.8

Final Measurements

13.24.8.1

Visual Examination

As specified.

As specified.

13.24.8.3

Low level circuit

As in clause 13.11

As in clause 13.11.

13.24.8.4

Contact Resistance

As in clause 13.12.

As in clause 13.12.

13.24.8.6

Voltage proof

As in clause 13.14.

As in clause 13.14.

13.24.8.8

Engagement and

Disengagement force

As in clause 13.7.

As in clause 13.7.

As in clause 13.16.

As in clause 13.16.

13.24.8.10 Sealing

20

JSS 50860 : 1993

Reaffirmed 1999

TEST

NUMBER

TITLE OF TEST

SPECIFIC TEST

CONDITIONS

REQUIREMENTS

13.25

Damp Heat (steady

state)

As specified, at the severity

given in clause 16.

13.25.1

Preliminary

As specified.

13.25.2

Electrical loading

As specified.

13.25.3

Intermediate

measurement

13.25.3.1

Working test

As in clause 13.24.7.2

As specified.

13.25.3.2

Insulation Resistance

As in clause 13.15.

The value shall be not less than

100 Megohms.

13.25.4

Final Measurements

13.25.4.1

Visual Examination

As specified.

As specified.

13.25.4.2

Contact Resistance

As in clause 13.12.

As in clause 13.12.

13.25.4.4

Voltage proof

As in clause 13.14.

As in clause 13.14.

13.25.4.7

Sealing

As in clause 13.16.

As in clause 13.16.

13.25.4.8

Solderability

As in clause 13.17.

As in clause 13.17.

13.26

Life (Mechanical)

As specified. Counter part

connectors shall be mated

and unmated 500 times at a

maximum rate of 600 cycles

per hour with the coupling

ring removed.

13.26.1

Final Measurements

13.26.1.1

Visual Examination

As specified.

As specified.

13.26.1.2

Contact Resistance

As in clause 13.12.

As in clause 13.12.

13.26.1.3

Engagement and

Disengagement

As in clause 13.7.

As in clause 13.7.

21

JSS 50860 : 1993

Reaffirmed 1999

TEST

NUMBER

13.27

TITLE OF TEST

Life (Electrical)

SPECIFIC TEST

CONDITIONS

REQUIREMENTS

As specified. The following The value shall be not less than

details and exceptions shall 30 Megohms.

apply:

a) Temperature

85C

severity

b) Insulation resistance

shall be measured while the

specimens are still at the

high temperature, after

completion of 1000 hrs.

13.27.1

Final Measurements

13.27.1.1

Visual Examinations

As specified.

As specified.

13.27.1.2

Contact Resistance

As in clause 13.12.

As in clause 13.12.

13.27.1.4

Voltage proof

As in clause 13.14.

As in clause 13.14.

13.27.1.6

Sealing

As in clause 13.16.

As in clause 13.16.

13.28

Mould Growth

As specified.

As specified.

13.32

Corrosive Atmosphere

As specified.

13.32.1

Final Measurements

13.32.1.1

Visual Examination

As specified.

As specified, except that

tarnishing of Silver plating on

the contacts shall not be

considered a failure.

13.32.1.2

Engagement and

Disengagement Force

As in clause 13.7.

As in clause 13.7.

13.32.1.5

Low level circuit

As in clause 13.11.

As in clause 13.11.

13.32.1.6

Contact Resistance

As in clause 13.12.

As in clause 13.12.

13.32.1.8

Voltage proof

As in clause 13.14.

As in clause 13.14.

13.32.1.9

Insulation Resistance

As in clause 13.15.

The values shall be not less than

100 Megohms.

22

JSS 50860 : 1993

Reaffirmed 1999

TEST

NUMBER

13.34

TITLE OF TEST

Contact Retention (In

Insert)

SPECIFIC TEST

CONDITIONS

REQUIREMENTS

As specified. An axial load The contacts shall be retained in

as specified below shall be their inserts when subjected to

applied at a rate of 4.5N per the loads.

sec until the specified load

has been reached. A

minimum of 20 percent but

not less than three of the

contacts in each connector

shall be tested. Axial load

shall

be

applied

to

individual contacts. The

grommet retaining nut shall

be

loose

and

the

measurements

of

the

displacement of the contacts

is not required.

Contact size Maximum

dia. (mm)

Axial load

1.5

2.0 & 2.5

3.0 & 3.5

5.5

9.0

13.35

Insert Retention (In

Shell)

60N

80N

114N

150N

As specified. The following The inserts shall not be dislodged

details and exceptions shall from their original position or

apply:

damaged.

a) The pressure shall be

applied at a rate of 69

kPa/Sec.

b) The insert shall retain the

pressure for 5 seconds.

23

JSS 50860 : 1993

Reaffirmed 1999

TEST

NUMBER

TITLE OF TEST

SPECIFIC TEST

CONDITIONS

REQUIREMENTS

c) The axial pressure

applied shall be as

follows:

Shell

size

13.35.1

13.35.1.1

Axial

Pressure

(kPa)

12

14

16

18

20

1034.25

22

24

27

28

689.5

30

32

33

36

517.13

39

40

42

413.7

48

55

310.27

Final

Measurements

As specified.

24

As specified.

JSS 50860 : 1993

Reaffirmed 1999

TEST

NUMBER

13.41

TITLE OF TEST

Resistance to

contaminating

fluids

SPECIFIC TEST

CONDITIONS

REQUIREMENTS

As specified, except After

the

test,

voltage proof test shall engagement/disengagement

shall be achievable by hand,

not be applied :

where applicable, or by

special

tools,

where

specified.

Test fluids:

a) Aero-shell fluid 41

b) Turbine oil 750

Duration of immersion

20 hours

For test

specification

Appendix D

fluid

See

13.49

External Bending

Moment

Under consideration

13.61

Dust

As specified.

As specified.

13.61.1

Contact Resistance

As in clause 13.12.

As in clause 13.12.

13.63

Capacitance

Capacitance between The capacitance shall not

all but not more than exceed 20 pF.

six closest adjacent

contact pairs shall be

measured using suitable

apparatus.

25

JSS 50860 : 1993

Reaffirmed 1999

14.

LIST OF PATTERNS

14.1

Preferred

Page No.

Pattern CCTM-WPr/R

Connectors, Circular, Threaded- coupling

(metric shell size), Receptacle, Normal size.

29 39

Pattern CCTM-WP/PS

Connectors, Circular, Threaded coupling

(metric shell size), Plug, Normal size, Straight

backshell.

40 47

Pattern CCTM-WP/PA

Connectors, Circular, Threaded coupling

(metric shell size), Plug, Normal size, Right

angled backshell.

48 53

Pattern CCTM-2PMr/R

Connectors, Circular, Threaded coupling

(metric shell size), Receptacle, Small size.

54 61

Pattern CCTM-2PM/PS

Connectors, Circular, Threaded coupling

(metric shell size), Plug Small size, Straight

backshell.

62 67

Pattern CCTM-2PM/PA

Connectors, Circular, Threaded coupling

(metric shell size), Plug, Normal size, Right

angled backshell.

68 73

Pattern CCTM-2PMr/DE

Connectors, Circular, Threaded coupling

(metric shell size), Receptacle, Sealed, Double

mating face, Without Mounting Provision.

74 76

Pattern CCTM-PC/R

Connectors, Circular, Threaded coupling

(metric shell size), Receptacle, Sub miniature,

Sealed, with or without backshell.

77 79

Pattern CCTM-PC/PS

Connectors, Circular, Threaded coupling

(metric shell size), Plug, Sub minature, with

Straight backshell.

80 82

26

JSS 50860 : 1993

Reaffirmed 1999

15.

TECHNICAL NOTES

15.1

The connectors covered in this specification are environment resistant,

providing interfacial sealing of the mated contacts. Connectors covered under each

Pattern are governed by a unique basic connector drawing, with or without accessories

such as backshells and cable-clamps. Contact to wire joints are protected by potting

compounds.

15.2

Patterns CCTM-WPr/R, WP/PS and WP/PA, Together constitute one

family of Normal size connectors, WPr/R for Panel mounting (fixed connector),

WP/PS being its mating straight-plug, and where space does not permit the cable-overhang from a straight plug, WP/PA, the right angled plug for directing the cable

downwards. Pattern CCTM-2PMr/R, 2PM/PS and 2PM/PA serve the same functions

respectively, and constitute the Small size family of connectors together with CCTM2PMr/DE the latter being a connector without mounting provision and having two

identical mating faces for interconnecting two cable-plug assemblies.

15.3

Patterns CCTM-PC/R and CCTM/PC/PS are a mating pair of

Subminiature connectors, PC/R being a panel-mounted receptacle and PC/PS being the

mating straight plug.

16.

LIST OF STANDARDS

16.1

This list gives details of connectors, electrical, circular, threaded-coupling

(metric shell size0 which have been selected as standards for use in Service electronic

equipment.

16.2

Pattern CCTM-WPr/R Connectors, Circular, Threaded coupling

(metric shell size), Receptacle, Normal size, Sealed.

16.2.1

JSS 50101 Classification:

Temperature Severity

T 55/125

Dam Heat Severity

H 13

Air Pressure (low)

P 17 : 4.4 kPa

Acceleration (steady state)

A 13 : 2 km/s

Impact (shock)

S 15 : 5 km/s, 1ms

Vibration

V 14 : 10 to 200 Hz

27

JSS 50860 : 1993

Reaffirmed 1999

16.2.2

Outline Drawings and Dimensions:

See Pages 30 to 32

16.2.3

Electrical Characteristics:

16.2.3.1

Rated Voltage : 500 Vac (rms) at sea level

Proof Voltage : 2000 Vac (rms) at sea level

16.2.3.2

Contact Current Rating :

Contract dia (mm)

1.5

2.5

3.5

5.5

9.0

Rated Current (A)

10

25

50

100

200

28

JSS 50860 : 1993

Reaffirmed 1999

Dimensions (mm)

Shell

Size

D1

d + 0.1

0

B + 1.0

0.2

12

12

M16 X 1.5

3.5

16

22

16

16

M20 1.5

3.5

19

26

20

20

M24 1.5

3.5

22

32

28

28

M33 1.5

3.5

30

40

32

32

M36 1.5

3.5

32

44

36

36

M39 1.5

3.5

34

46

40

40

M45 1.5

3.5

40

52

48

48

M52 1.5

3.5

48

60

55

55

M60 1.5

3.5

52

68

NOTE 1 Unless otherwise specified, tolerance is 0.1 mm.

Figure 1 Clause 16.1.2

29

L

(max)

65

JSS 50860 : 1993

Reaffirmed 1999

Shell

Size

12

L (mm) 51.0

0.2

16

20

28

55.0 58.0 63.0

32

67.0

NOTE Except L, all the dimensions are as in Fig 3.

Figure 2 (Clause 16.2.2)

30

30

69.0

40

69.0

JSS 50860 : 1993

Reaffirmed 1999

Shell

Size

D1

12

d1

d2

M16 X 1.5 16

M3

63

28

40

16

M20 1.5

19

M3

11

61

28

38

20

M24 1.5

22

M3

18

14

65

32

43

28

M33 1.5

30

M3

25

21

73

36

54

32

M36 1.5

32

M3

25

21

77

40

54

36

M39 1.5

34

M3

29

23

79

42

54

40

M45 1.5

40

M3

32

24

79

42

56

48

M52 1.5

48

M4

36

32

81

44

58

55

M60 1.5

52

M4

46

40

81

44

58

60

M64 1.5

54

M4

50

48

79

42

56

NOTE 1 Dimensions are in mm.

NOTE 2 Unless otherwise specified, tolerance is 10.2 mm.

NOTE 3. Dimension B and polarizing key as in Fig 1.

Figure 3 Clause 16.2.2

16.2.4

LIST OF STANDARDS

31

L1

Lt

JSS 50860 : 1993

Reaffirmed 1999

Defence Stores Style Reference

Catalogue

Number

Contact

Details

Contact

No. of

dia (mm) Contacts

2.5

Ref *

Total fig

for

insert

1

E24

Out

line

draw

ing

Current Mass

Rating

(kg)

of Insert (max)

(A)

Fig.1

25

0.025

50

0.035

14

0.04

14

0.055

5935-970000

5935-970001

CCTM-WPr/R-12-1-2-M

CCTM-WPr/R-12-1-2-F

5935-970002

CCTM-WPr/R-12-1-2-M-Sc

5935-970003

CCTM-WPr/R-12-1-2-F-Sc

5935-970004

CCTM-WPr/R-12-1-2-M-USc

5935-970005

CCTM-WPr/R-12-1-2-F-USc

5935-970006

CCTM-WPr/R-16-1-3-M

5935-970007

CCTM-WPr/R-16-1-3-F

5935-970008

5935-970009

CCTM-WPr/R-16-1-3-M-Sc

CCTM-WPr/R-16-1-3-F-Sc

Fig 2

5935-970010

5935-970011

CCTM-WPr/R-16-1-3-M-Usc

CCTM-WPr/R-16-1-3-F-Usc

Fig 3

5935-970012

5935-970013

CCTM-WPr/R-16-2-5-M

CCTM-WPr/R-16-2-5-F

5935-970014

5935-970015

CCTM-WPr/R-16-2-5-M-Sc

CCTM-WPr/R-16-2-5-F-Sc

Fig 2

5935-970016

5935-970017

CCTM-WPr/R-16-2-5-M-USc

CCTM-WPr/R-16-2-5-F-USc

Fig 3

5935-970018

5935-970019

CCTM-WPr/R-20-2-6-M

CCTM-WPr/R-20-2-6-F

Fig.

2

Fig.

3

3.5

1.5

1.5

* See Appendix E

32

E24

E2

E3

Fig.

1

Fig 1

Fig 1

JSS 50860 : 1993

Reaffirmed 1999

16.2.4

LIST OF STANDARDS (CONTD.)

Defence Stores Style Reference

Catalogue

Number

Contact

Details

Contact

No. of

dia (mm) Contacts

Ref *

Total fig

for

insert

Out

line

draw

ing

5935-970020

5935-970021

CCTM-WPr/R-20-2-6-M-Sc

CCTM-WPr/R-20-2-6-F-Sc

Fig.2

5935-970022

5935-970023

CCTM-WPr/R-20-2-6-M-USc

CCTM-WPr/R-20-2-6-F-USc

Fig. 3

5935-970024

5935-970025

CCTM-WPr/R-20-3-6-M

CCTM-WPr/R-20-3-6-F

5935-970026

5935-970027

CCTM-WPr/R-20-3-6-M-Sc

CCTM-WPr/R-20-3-6-F-Sc

Fig. 2

5935-970028

5935-970029

CCTM-WPr/R-20-3-6-M-Usc

CCTM-WPr/R-20-3-6-F-Usc

Fig 3

5935-970030

5935-970031

CCTM-WPr/R-20-3-7-M

CCTM-WPr/R-20-3-7-F

5935-970032

5935-970033

CCTM-WPr/R-20-3-7-M-Sc

CCTM-WPr/R-20-3-7-F-Sc

Fig 2

5935-970034

5935-970035

CCTM-WPr/R-20-3-7-M-USc

CCTM-WPr/R-20-3-7-F-USc

Fig 3

5935-970036

5935-970037

CCTM-WPr/R-20-4-8-M

CCTM-WPr/R-20-4-8-F

5935-970038

5935-970039

CCTM-WPr/R-20-4-8-M-Sc

CCTM-WPr/R-20-4-8-M-Sc

1.5

2.5

2.5

E3

E24

E3

Fig. 1

Fig 1

Fig 1

Fig 2

* See Appendix E

33

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

21

0.06

52

0.065

70

0.07

JSS 50860 : 1993

Reaffirmed 1999

16.2.4

LIST OF STANDARDS (CONTD.)

Defence Stores Style Reference

Catalogue

Number

Contact

Details

Contact

No. of

dia (mm) Contacts

Ref *

fig

Total

for

insert

Out

line

draw

ing

5935-970040

5935-970041

CCTM-WPr/R-20-4-8-M-USc

CCTM-WPr/R-20-4-8-F-USc

5935-970042

5935-970043

CCTM-WPr/R-20-5-7-M

CCTM-WPr/R-20-5-7-F

5935-970044

5935-970045

CCTM-WPr/R-20-5-7-M-Sc

CCTM-WPr/R-20-5-7-F-Sc

Fig. 2

5935-970046

5935-970047

CCTM-WPr/R-20-5-7-M-Sc

CCTM-WPr/R-20-5-7-F-Usc

Fig. 3

5935-970048

5935-970049

CCTM-WPr/R-20-5-10-M

CCTM-WPr/R-20-5-F

5935-970050

5935-970051

CCTM-WPr/R-20-5-10-M-Sc

CCTM-WPr/R-20-5-10-F-Sc

Fig 2

5935-970052

5935-970053

CCTM-WPr/R-20-5-10-M-Usc

CCTM-WPr/R-20-5-10-F-USc

Fig 3

5935-970054

5935-970055

CCTM-WPr/R-28-1-4-M

CCTM-WPr/R-28-1-4-F

5935-970056

5935-970057

CCTM-WPr/R-28-1-4-M-Sc

CCTM-WPr/R-28-1-4-M-Sc

Fig 2

5935-970058

5935-970059

CCTM-WPr/R-28-1-4-M-USc

CCTM-WPr/R-28-1-4-F-USc

Fig 3

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

35

0.075

73

0.08

100

0.06

Fig.3

1.5

1.5

5.5

* See Appendix E

34

E3

E4

E25

Fig. 1

Fig 1

Fig 1

JSS 50860 : 1993

Reaffirmed 1999

16.2.4

LIST OF STANDARDS (CONTD.)

Defence Stores Style Reference

Catalogue

Number

Contact

Details

Contact

No. of

dia (mm) Contacts

3.5

E26

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

Fig.1

70

0.07

175

0.08

70

0.07

200

0.09

CCTM-WPr/R-28-2-7-M

CCTM-WPr/R-28-2-7-F

5935-970062

5935-970063

CCTM-WPr/R-28-2-7-M-Sc

CCTM-WPr/R-28-2-7-F-Sc

Fig. 2

5935-970064

5935-970065

CCTM-WPr/R-28-2-7-M-Sc

CCTM-WPr/R-28-2-7-F-Usc

Fig. 3

5935-970066

5935-970067

CCTM-WPr/R-28-4-5-M

CCTM-WPr/R-28-4-5-F

5935-970068

5935-970069

CCTM-WPr/R-28-4-5-M-Sc

CCTM-WPr/R-28-4-5-F-Sc

Fig 2

5935-970070

5935-970071

CCTM-WPr/R-28-4-5-M-Usc

CCTM-WPr/R-28-4-5-F-USc

Fig 3

5935-970072

5935-970073

CCTM-WPr/R-28-7-9-M

CCTM-WPr/R-28-7-9-F

3.5

E26

Fig 1

5935-970074

5935-970075

CCTM-WPr/R-28-7-9-M-Sc

CCTM-WPr/R-28-7-9-M-Sc

5.5

E25

Fig 2

5935-970076

5935-970077

CCTM-WPr/R-28-7-9-M-USc

CCTM-WPr/R-28-7-9-F-USc

5935-970078

5935-970079

CCTM-WPr/R-32-1-5-M

CCTM-WPr/R-32-1-5-F

5935-970080

5935-970081

CCTM-WPr/R-32-1-5-M-Sc

CCTM-WPr/R-32-1-5-F-Sc

2

2

Out

line

draw

ing

5935-970060

5935-970061

2.5

5.5

Ref *

fig

Total

for

insert

Fig. 1

Fig 3

9.0

E27

Fig 1

Fig 2

* See Appendix E

35

JSS 50860 : 1993

Reaffirmed 1999

16.2.4

LIST OF STANDARDS (CONTD.)

Defence Stores Style Reference

Catalogue

Number

Contact

Details

Contact

No. of

dia (mm) Contacts

Ref *

fig

Total

for

insert

Out

line

draw

ing

5935-970082

5935-970083

CCTM-WPr/R-32-1-5-M-Sc

CCTM-WPr/R-32-1-5-F-Usc

5935-970084

5935-970085

CCTM-WPr/R-32-8-2-M

CCTM-WPr/R-32-8-2-F

5935-970086

5935-970087

CCTM-WPr/R-32-8-2-M-Sc

CCTM-WPr/R-32-8-2-F-Sc

Fig. 2

5935-970088

5935-970089

CCTM-WPr/R-32-8-2-M-Usc

CCTM-WPr/R-32-8-2-F-USc

Fig 3

5935-970090

5935-970091

CCTM-WPr/R-32-10-1-M

CCTM-WPr/R-32-10-1-F

5935-970092

5935-970093

CCTM-WPr/R-32-10-1-M-Sc

CCTM-WPr/R-32-10-7-M-Sc

Fig 2

5935-970094

5935-970095

CCTM-WPr/R-32-10-1-M-Usc

CCTM-WPr/R-32-10-1-F-USc

Fig 3

5935-970096

5935-970097

CCTM-WPr/R-32-12-1-M

CCTM-WPr/R-32-12-1-F

5935-970098

5935-970099

CCTM-WPr/R-32-12-1-M-Sc

CCTM-WPr/R-32-12-1-F-Sc

Fig 2

5935-970100

5935-970101

CCTM-WPr/R-32-12-1-M-Usc

CCTM-WPr/R-32-12-1-F-Usc

Fig 3

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

56

0.08

112

0.12

147

0.14

Fig. 3

1.5

1.5

2.5

1.5

* See Appendix E

36

4

6

10

E11

E11

E10

Fig. 1

Fig 1

Fig 1

JSS 50860 : 1993

Reaffirmed 1999

16.2.4

LIST OF STANDARDS (CONTD.)

Defence Stores Style Reference

Catalogue

Number

Contact

Details

Contact

No. of

dia (mm) Contacts

2.5

5.5

3

1

Ref *

fig

Total

for

insert

Mass

(kg)

(max)

Fig. 1

193

0.085

263

0.14

133

0.2

210

0.105

CCTM-WPr/R-36-4-13-M

CCTM-WPr/R-36-4-13-F

5935-970104

5935-970105

CCTM-WPr/R-36-4-13-M-Sc

CCTM-WPr/R-36-4-13-F-Sc

Fig. 2

5935-970106

5935-970107

CCTM-WPr/R-36-4-13-M-Usc

CCTM-WPr/R-36-4-13-F-USc

Fig. 3

5935-970108

5935-970109

CCTM-WPr/R-36-15-5-M

CCTM-WPr/R-36-15-5-F

5935-970110

5935-970111

CCTM-WPr/R-36-15-5-M-Sc

CCTM-WPr/R-36-15-5-M-Sc

5935-970112

5935-970113

CCTM-WPr/R-36-15-5-M-Usc

CCTM-WPr/R-36-15-5-F-USc

5935-970114

5935-970115

CCTM-WPr/R-40-16-2-M

CCTM-WPr/R-40-16-2-F

5935-970116

5935-970117

CCTM-WPr/R-40-16-2-M-Sc

CCTM-WPr/R-40-16-2-F-Sc

Fig 2

5935-970118

5935-970119

CCTM-WPr/R-40-16-2-M-Usc

CCTM-WPr/R-40-16-2-F-Usc

Fig 3

5935-970120

5935-970121

CCTM-WPr/R-40-3-9-M

CCTM-WPr/R-40-3-9-F

15

2.5

15

E17

Current

Rating

of

Insert

(A)

5935-970102

5935-970103

2.5

Out

line

draw

ing

E15

Fig 1

Fig 2

Fig 3

2.5

5.5

* See Appendix E

37

14

16

E28

E19

Fig 1

Fig 1

JSS 50860 : 1993

Reaffirmed 1999

16.2.4

LIST OF STANDARDS (CONTD.)

Defence Stores Style Reference

Catalogue

Number

Contact

Details

Contact

No. of

dia (mm) Contacts

Ref *

fig

Total

for

insert

Out

line

draw

ing

5935-970122

5935-970123

5935-970124

5935-970125

CCTM-WPr/R-40-3-9-M-Sc

CCTM-WPr/R-40-3-9-F-Sc

CCTM-WPr/R-40-3-9-M-Usc

CCTM-WPr/R-40-3-9-F-USc

5935-970126

5935-970127

CCTM-WPr/R-48-9-7-M

CCTM-WPr/R-48-9-7-F

5935-970128

5935-970129

CCTM-WPr/R-48-9-7-M-Sc

CCTM-WPr/R-48-9-7-M-Sc

Fig 2

5935-970130

5935-970131

CCTM-WPr/R-48-9-7-M-Usc

CCTM-WPr/R-48-9-7-F-USc

Fig 3

5935-970132

5935-970133

CCTM-WPr/R-55-31-3-M

CCTM-WPr/R-55-31-3-F

5935-970134

5935-970135

CCTM-WPr/R-55-31-3-M-Sc

CCTM-WPr/R-55-31-3-F-Sc

Fig 2

5935-970136

5935-970137

CCTM-WPr/R-55-31-3-M-Usc

CCTM-WPr/R-55-31-3-F-Usc

Fig 3

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

367

0.25

448

0.35

Fig. 2

Fig 3

2.5

5.5

1.5

2.5

3.5

* See Appendix E

38

5

3

14

14

3

31

E22

E23

Fig 1

Fig 1

JSS 50860 : 1993

Reaffirmed 1999

16.3

Pattern CCTM-WP/PS Connectors, Circular, Threaded coupling

(metric shell size) Plug, Normal Size, Straight

16.3.1

JSS 50101 Classification:

As in clause 16.2.1

16.3.2

Outline Drawing and Dimensions:

See Pages 40 and 41

16.3.3

Electrical Characteristics:

As in clause 16.2.3

39

JSS 50860 : 1993

Reaffirmed 1999

DIMENSIONS (mm)

Shell

Size

D1

D2

d1

L1

12

16

20

28

32

36

40

48

55

60

M16 X 1.5

M20 1.5

M24 1.5

M33 1.5

M36 1.5

M39 1.5

M45 1.5

M52 1.5

M60 1.5

M64 1.5

22.5

22.5

29.5

38.5

41.5

45.5

52.5

59.5

67.5

72.5

8

11

18

25

25

29

32

36

46

50

5

7

14

21

21

23

24

32

40

48

50

50

53

56

58

62

64

66

66

64

62

60

64

70

72

76

78

80

80

78

NOTE 1 Tolerance is 0.2 mm.

NOTE 2 Polarizing keyway shall be as follows

(Second view, width-wise)

Fig. 4 Clause 16.3.2

40

H

24.5

28.5

36

48

52

54

60

68

74

80

JSS 50860 : 1993

Reaffirmed 1999

NOTE FOR DIMENSIONS See Fig. 4

Fig 5 Clause 16.3.2

41

JSS 50860 : 1993

Reaffirmed 1999

16.3.4

LIST OF STANDARDS

Defence Stores Style Reference

Catalogue

Number

5935-970200

5935-970201

CCTM-WP/PS-12-1-2-M-Sc

CCTM-WP/PS-12-1-2-F-Sc

5935-970202

5935-970203

CCTM-WP/PS-12-1-2-M-Sc

CCTM-WP/PS-12-1-2-F-Sc

5935-970204

5935-970205

CCTM-WP/PS-16-1-3-M

CCTM-WP/PS-16-1-3-F

5935-970206

5935-970207

CCTM-WP/PS-16-1-3-M-Sc

CCTM-WP/PS-16-1-3-F-Sc

5935-970208

5935-970209

CCTM-WP/PS-16-1-3-M-USc

CCTM-WP/PS-16-1-3-F-USc

5935-970210

5935-970211

CCTM-WP/PS-16-2-5-M

CCTM-WP/PS-16-2-5-F

5935-970212

5935-970213

CCTM-WP/PS-20-2-5-M-Sc

CCTM-WP/PS-20-2-5-F-Sc

5935-970214

5935-970215

CCTM-WP/PS-20-2-5-M-USc

CCTM-WP/PS-20-2-5-F-USc

5935-970216

5935-970217

CCTM-WP/PS-20-3-6-M

CCTM-WP/PS-20-3-6-F

5935-970218

5935-970219

CCTM-WP/PS-20-3-6-M-USc

CCTM-WP/PS-20-3-6-F-USc

Contact

Details

Contact

No. of

dia (mm) Contacts

2.5

Ref *

fig

Total

for

insert

1

E24

Out

line

draw

ing

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

Fig.4

25

0.03

50

0.035

14

0.045

14

0.05

21

0.055

Fig. 5

3.5

E24

Fig. 4

Fig. 5

1.5

E2

Fig 4

Fig 5

1.5

E3

Fig 4

Fig 5

1.5

E3

Fig 4

Fig 5

* See Appendix E

42

JSS 50860 : 1993

Reaffirmed 1999

16.3.4

LIST OF STANDARDS (CONTD.)

Defence Stores Style Reference

Catalogue

Number

5935-970220

5935-970221

CCTM-WP/PS-20-3-7-M-Sc

CCTM-WP/PS-20-3-7-F-Sc

5935-970222

5935-970223

CCTM-WP/PS-20-3-7-M-USc

CCTM-WP/PS-20-3-7-F-USc

5935-970224

5935-970225

CCTM-WP/PS-20-4-8-M-Sc

CCTM-WP/PS-20-4-8-F-Sc

5935-970226

5935-970227

CCTM-WP/PS-20-4-8-M-USc

CCTM-WP/PS-20-4-8-F-USc

5935-970228

5935-970229

CCTM-WP/PS-20-5-7-M-Sc

CCTM-WP/PS-20-5-7-F-Sc

5935-970230

5935-970231

CCTM-WP/PS-20-5-7-M-USc

CCTM-WP/PS-20-5-7-F-USc

5935-970232

5935-970233

CCTM-WP/PS-20-5-10-M-Sc

CCTM-WP/PS-20-5-10-F-Sc

5935-970234

5935-970235

CCTM-WP/PS-20-5-10-M-USc

CCTM-WP/PS-20-5-10-F-USc

5935-970236

5935-970237

CCTM-WP/PS-28-1-4-M-Sc

CCTM-WP/PS-28-1-4-F-Sc

5935-970238

5935-970239

CCTM-WP/PS-28-1-4-M-USc

CCTM-WP/PS-28-1-4-F-USc

Contact

Details

Contact

No. of

dia (mm) Contacts

2.5

Ref *

fig

Total

for

insert

3

E27

Out

line

draw

ing

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

Fig.4

52

0.055

70

0.05

35

0.055

73

0.065

100

0.06

Fig. 5

2.5

E3

Fig. 4

Fig. 5

1.5

E3

Fig 4

Fig 5

2.5

E4

Fig 4

Fig 5

5.5

E25

Fig 4

Fig 5

* See Appendix E

43

JSS 50860 : 1993

Reaffirmed 1999

16.3.4

LIST OF STANDARDS (CONTD.)

Defence Stores Style Reference

Catalogue

Number

5935-970240

5935-970241

CCTM-WP/PS-28-2-7-M-Sc

CCTM-WP/PS-28-2-7-F-Sc

5935-970242

5935-970243

CCTM-WP/PS-28-4-7-M-USc

CCTM-WP/PS-28-4-7-F-USc

5935-970244

5935-970245

CCTM-WP/PS-28-4-5-M-Sc

CCTM-WP/PS-28-4-5-F-Sc

5935-970246

5935-970247

CCTM-WP/PS-28-4-5-M-USc

CCTM-WP/PS-28-4-5-F-USc

5935-970248

5935-970249

CCTM-WP/PS-28-7-9-M-Sc

CCTM-WP/PS-28-7-9-F-Sc

5935-970250

5935-970251

CCTM-WP/PS-28-7-9-M-USc

CCTM-WP/PS-28-7-9-F-USc

5935-970252

5935-970253

CCTM-WP/PS-32-1-5-M-Sc

CCTM-WP/PS-32-1-5-F-Sc

5935-970254

5935-970255

CCTM-WP/PS-32-1-5-M-USc

CCTM-WP/PS-32-1-5-F-USc

5935-970256

5935-970257

CCTM-WP/PS-32-8-2-M-Sc

CCTM-WP/PS-32-8-2-F-Sc

5935-970258

5935-970259

CCTM-WP/PS-32-8-2-M-USc

CCTM-WP/PS-32-8-2-F-USc

Contact

Details

Contact

No. of

dia (mm) Contacts

3.5

Ref *

fig

Total

for

insert

2

E26

Out

line

draw

ing

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

Fig.4

175

0.065

175

0.075

49

0.07

200

0.08

100

0.08

Fig. 5

2.5

E6

Fig. 4

Fig. 5

1.5

E6

Fig 4

Fig 5

9.0

E27

Fig 4

Fig 5

1.5

E11

Fig 4

Fig 5

* See Appendix E

44

JSS 50860 : 1993

Reaffirmed 1999

16.3.4

LIST OF STANDARDS (CONTD.)

Defence Stores Style Reference

Catalogue

Number

5935-970260

5935-970261

CCTM-WP/PS-32-10-1-M-Sc

CCTM-WP/PS-32-10-1-F-Sc

5935-970262

5935-970263

CCTM-WP/PS-32-10-1-M-Sc

CCTM-WP/PS-32-10-1-F-Sc

5935-970264

5935-970265

CCTM-WP/PS-32-12-1-M-Sc

CCTM-WP/PS-32-12-1-F-Sc

5935-970266

5935-970267

CCTM-WP/PS-32-12-1-M-Sc

CCTM-WP/PS-32-12-1-F-Sc

5935-970268

5935-970269

CCTM-WP/PS-36-4-13-M-Sc

CCTM-WP/PS-36-4-13-F-Sc

5935-970270

5935-970271

CCTM-WP/PS-36-4-13-M-USc

CCTM-WP/PS-36-4-13-F-USc

5935-970272

5935-970273

CCTM-WP/PS-36-15-5-M-Sc

CCTM-WP/PS-36-15-5-F-Sc

5935-970274

5935-970275

CCTM-WP/PS-36-15-5-M-USc

CCTM-WP/PS-36-15-5-F-USc

5935-970276

5935-970277

CCTM-WP/PS-40-16-2-M-Sc

CCTM-WP/PS-40-1-4-F-Sc

5935-970278

5935-970279

CCTM-WP/PS-40-16-M-Sc

CCTM-WP/PS-40-16-2-F-Sc

Contact

Details

Contact

No. of

dia (mm) Contacts

1.5

Ref *

fig

Total

for

insert

10

E11

Out

line

draw

ing

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

Fig.4

112

0.12

147

0.13

193

0.13

133

0.17

133

0.17

Fig. 5

1.5

12

E10

Fig. 4

Fig. 5

2.5

5.5

3

1

E17

Fig 4

Fig 5

1.5

14

16

E28

Fig 4

Fig 5

1.5

14

16

E28

Fig 4

Fig 5

* See Appendix E

45

JSS 50860 : 1993

Reaffirmed 1999

16.3.4

LIST OF STANDARDS (CONTD.)

Defence Stores Style Reference

Catalogue

Number

5935-970280

5935-970281

CCTM-WP/PS-40-3-9-M-Sc

CCTM-WP/PS-40-3-9-F-USc

5935-970282

5935-970283

CCTM-WP/PS-40-3-9-M-USc

CCTM-WP/PS-40-3-9-F-USc

5935-970284

5935-970285

CCTM-WP/PS-48-9-7-M-Sc

CCTM-WP/PS-48-9-7-F-Sc

5935-970286

5935-970287

CCTM-WP/PS-48-9-7-M-USc

CCTM-WP/PS-48-9-7-F-USc

5935-970288

5935-970289

CCTM-WP/PS-55-31-3-M-Sc

CCTM-WP/PS-55-31-3-F-Sc

5935-970290

5935-970291

CCTM-WP/PS-55-31-3-M-USc

CCTM-WP/PS-55-31-3-F-Sc

Contact

Details

Contact

No. of

dia (mm) Contacts

5.5

Ref *

fig

Total

for

insert

3

E19

Out

line

draw

ing

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

Fig.4

210

0.18

367

0.20

448

0.275

Fig. 5

2.5

E22

Fig. 4

Fig. 5

1.5

2.5

3.5

14

14

3

31

E23

Fig 4

Fig 5

* See Appendix E

46

JSS 50860 : 1993

Reaffirmed 1999

16.4

Pattern CCTM-WP/PA Connectors, Circular, Threaded coupling

(metric shell size) Plug, with Right angled back shell, Normal size.

16.4.1

JSS 50101 Classification:

As in clause 16.2.1

16.4.2

Outline Drawing and Dimensions:

See Page 48

16.4.3

Electrical Characteristics:

As in clause 16.2.3

47

JSS 50860 : 1993

Reaffirmed 1999

DIMENSIONS (mm)

Shell

Size

D1

D2

12

16

20

28

32

36

40

48

55

60

M16 X 1.5

M20 1.5

M24 1.5

M33 1.5

M36 1.5

M39 1.5

M45 1.5

M52 1.5

M60 1.5

M64 1.5

21.5

25.5

29.5

38.5

41.5

45.5

52.5

59.5

67.5

72.5

51

56

64

73

73

76

80

90

98

103

H

39

36

45

62

66

67

72

81

106

94

Figures 6 and 7 Clause 16.4.2

48

H1

47

50

59

76

80

81

86

95

102

108

d1

8

11

18

25

25

29

32

36

46

50

d2

5

7

14

21

21

23

24

34

40

80

JSS 50860 : 1993

Reaffirmed 1999

16.4.4

LIST OF STANDARDS

Defence Stores Style Reference

Catalogue

Number

5935-970400

5935-970401

CCTM-WP/PA-12-1-2-M-Sc

CCTM-WP/PA-12-1-2-F-Sc

5935-970402

5935-970403

CCTM-WP/PA-12-1-2-M-USc

CCTM-WP/PA-12-1-2-F-USc

5935-970404

5935-970405

CCTM-WP/PA-16-1-3-M-Sc

CCTM-WP/PA-16-1-3-F-Sc

5935-970406

5935-970407

CCTM-WP/PA-16-1-3-M-USc

CCTM-WP/PA-16-1-3-F-USc

5935-970408

5935-970409

CCTM-WP/PA-16-2-5-M-Sc

CCTM-WP/PA-16-2-5-F-Sc

5935-970410

5935-970411

CCTM-WP/PA-16-2-5-M-USc

CCTM-WP/PA-16-2-5-F-USc

5935-970412

5935-970413

CCTM-WP/PA-20-2-6-M-Sc

CCTM-WP/PA-20-2-6-F-Sc

5935-970414

5935-970415

CCTM-WP/PA-20-2-6-M-USc

CCTM-WP/PA-20-2-6-F-USc

5935-970416

5935-970417

CCTM-WP/PA-20-3-6-M-Sc

CCTM-WP/PA-20-3-6-F-Sc

5935-970418

5935-970419

CCTM-WP/PA-20-3-6-M-USc

CCTM-WP/PA-20-3-6-F-USc

Contact

Details

Contact

No. of

dia (mm) Contacts

Ref *

fig

Total

for

insert

2.5

E24

Out

line

draw

ing

Current

Rating

of

Insert

(A)

Mass

(kg)

(max)

Fig.6

25

0.04

50

0.05

14

0.06

14

0.07

21

0.075

Fig. 7

3.5

E24

Fig. 6

Fig. 7

1.5

E2

Fig 6

Fig 7

1.5

E3

Fig 6

Fig 7

1.5

E3

Fig 6

Fig 7

49

JSS 50860 : 1993

Reaffirmed 1999

16.4.4

1

LIST OF STANDARDS (CONTD.)

2

5935-970420

5935-970421

CCTM-WP/PA-20-3-7-M-Sc

CCTM-WP/PA-20-3-7-F-Sc

5935-970422

5935-970423

CCTM-WP/PA-20-3-7-M-USc

CCTM-WP/PA-20-3-7-F-USc

5935-970424

5935-970425

CCTM-WP/PA-20-3-7-M-Sc

CCTM-WP/PA-20-3-7-F-Sc

5935-970426

5935-970427

CCTM-WP/PA-20-4-8-M-USc

CCTM-WP/PA-20-4-8-F-USc

5935-970428

5935-970429

CCTM-WP/PA-20-5-7-M-Sc

CCTM-WP/PA-20-5-7-F-Sc

5935-970430

5935-970431

CCTM-WP/PA-20-5-7-M-USc

CCTM-WP/PA-20-5-7-F-USc

5935-970432

5935-970433

CCTM-WP/PA-20-5-10-M-Sc

CCTM-WP/PA-20-5-10-F-Sc

5935-970434

5935-970435

CCTM-WP/PA-20-5-10-M-USc

CCTM-WP/PA-20-5-10-F-USc

5935-970436

5935-970437