Professional Documents

Culture Documents

Us 20060101695

Uploaded by

galak12001Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 20060101695

Uploaded by

galak12001Copyright:

Available Formats

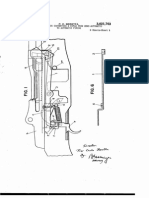

US 20060101695A1

(19) United States

(12) Patent Application Publication (10) Pub. N0.: US 2006/0101695 A1

Longueira

(54)

(43) Pub. Date:

TRIGGER/DISCONNECTOR ASSEMBLY FOR

May 18, 2006

Publication Classi?cation

AR-7 SURVIVAL RIFLE

(76)

Inventor:

(51)

Int. Cl.

F41A 3/00

(52)

US. Cl. .......................................................... .. 42/69.02

Dino C. Longueira, Staten Island, NY

(US)

Correspondence Address:

(2006.01)

(57)

ABSTRACT

Dennis M. Flaherty

ostrager Chong Flaherty & Broitman P_C_

method for retro?tting a r1?e having an mtegral tr1gger/

suite 825

disconnector. The method comprises the steps of: removing

250 Park Avenue

New York, NY 10177_0899 (Us)

the integral trigger/disconnector; and installing an assembly

comprising a spring-loaded disconnector and a trigger in

place of the integral trigger/disconnector. The spring-loaded

(21)

App1_ NO;

10/992,587

(22)

Filed;

Nov, 17, 2004

disconnector is able to move to the rear When contacted by

the hammer to alloW the hammer to pass, and then quickly

return to its forward position so as to capture the hammer.

21

I 1irzo

Patent Application Publication May 18, 2006 Sheet 1 0f 5

US 2006/0101695 A1

FIG.1

PRIOR ART

Patent Application Publication May 18, 2006 Sheet 2 0f 5

US 2006/0101695 A1

Patent Application Publication May 18, 2006 Sheet 3 0f 5

US 2006/0101695 A1

/30

f 0

28

,.

LC /'I\_

26

'

30

-

FIG.6

FIG.5

1o

18

18\:---*

'

12

1o

\_/

~

-

38/

\34

I1

\3s

326 [10

K38

Patent Application Publication May 18, 2006 Sheet 4 0f 5

/6

FIG.1O

US 2006/0101695 A1

Patent Application Publication May 18, 2006 Sheet 5 0f 5

51

60

52 e2

2

F1|G.1

(56

58

US 2006/0101695 A1

May 18, 2006

US 2006/0101695 A1

TRIGGER/DISCONNEC TOR ASSEMBLY FOR AR-7

SURVIVAL RIFLE

design defect causes a condition knoWn as short recoil. The

term short recoil is used to describe a malfunction With a

BACKGROUND OF THE INVENTION

semi-automatic ?rearm. When short recoil occurs, the bolt

(for any one of a number of reasons) fails to move su?i

[0001] This invention relates in general to ?rearms, and in

particular to relatively small, lightweight ri?es that are

primarily intended for survival use in emergency situations.

[0002]

The term survival ri?e is commonly used in

referring to a ?rearm that is primarily intended for use as a

personal survival Weapon in unforeseen or emergency situ

ations. Persons such as campers, boaters, or ?yers Who travel

through or over Wilderness locations may not Want to carry

a conventional ri?e due to its Weight and siZe, but those

persons may nonetheless Want a Weapon of greater accuracy

than a handgun for hunting small game or for personal

protection if they suddenly become stranded in the Wilder

ness by a mishap such as a doWned airplane or a broken

vehicle. The ideal survival ri?e should be relatively light

Weight and compact, so as not to add signi?cant Weight to

a backpacker and so as to conveniently ?t Within a pack, a

small airplane, or in some other location not normally siZed

to receive a conventional ri?e. A survival ri?e should also be

relatively inexpensive to manufacture, and should be

capable of quick and easy assembly by the user Without

requiring tools or connective parts such as bolts that can

ciently to the rear to complete its cycle of operation. The

short recoil causes malfunctions commonly knoWn as jams.

[0006]

The AR-7 ri?e is a bloWback-operated semi-auto

matic ri?e. Upon ?ring, the bullet is forced through the

barrel While at the same time the bolt, utiliZing the pressure

of the ?red cartridge, is forced to the rear and through its

cycle of operation. In this system of operation, there is no

locking mechanism employed. During the ?ring sequence,

the trigger is depressed, Which causes the hammer to be

released. The hammer, under spring pres sure, is then rapidly

driven forWard to contact the ?ring pin and cause discharge.

Upon discharge, the bolt, utiliZing the recoil energy of the

?red cartridge, is driven rearWard, also driving the hammer

rearWard. At this point in the sequence, the trigger is still

depressed, as this all happens very quickly (in less than 1A of

a second). In the AR-7 ri?e, the pivoting of the trigger during

depression causes a hook located at the rearWard portion of

the trigger to come into the path of the rebounding hammer.

This hook captures the hammer by means of a notch cut into

the rearWard section of the hammer. This hook is knoWn as

the disconnector.

easily become lost in the ?eld. The survival ri?e should also

be capable of carrying a supply of ammunition.

[0007] The function of the disconnector is to capture the

hammer during its rearWard travel and hold it until the

[0003] Attempts have been made in the prior art to pro

trigger is released after ?ring. When the trigger is released,

the trigger pivots forWard, causing the hook to rotate back

Wards, releasing the hammer. The hammer coil spring again

duce survival ri?es that meet some of the foregoing criteria.

Known examples of such prior art include the US. Air Force

(USAF) M4 .22 Hornet bolt action ri?e, the USAF M6

.22/ .410 over/under survival ri?e, the Armalite/Charter

Arms AR-7 .22 semiautomatic survival ri?e, and the Garcia

Bronco single-shot survival ri?e With a skeleton stock.

[0004] The AR-7 type ri?e is a takedoWn survival ri?e that

Was intended for use by pilots Who have been shot doWn and

subsequently parachuted into non-friendly territory. It Was

originally designed in 1959 for the US. Air Force by

Armalite and has been manufactured by Charter Arms. It

Was not intended to be a main combat Weapon but rather as

urges the released hammer to rotate forWard. The hammers

forWard travel Will be stopped When it is once again captured

by the trigger nose (i.e., sear), Which engages the sear notch

of the hammer.

[0008] On the original AR-7 design, the disconnector hook

is integral With the trigger. In order for the disconnector

hook to capture the hammer, the trigger must be forced to

pivot forWard to alloW clearance for this to occur. This forces

the ?nger of the shooter to be rapidly pushed forWard. If the

shooter Were to hold the trigger depressed hard enough, the

disconnector hook Will not be able to cause the trigger to

a hunting survival Weapon. The AR-7 model ri?e ?res the

.22 long ri?e ammunition in semiautomatic mode. FIG. 11

shoWs an AR-7 model ri?e 50 comprising a receiver 52, a

barrel 54 that is removably coupled to the receiver by means

of a barrel nut 60, a magaZine 62 inserted into the receiver,

a shoulder stock 56 attached to the receiver and having a

pivot forWard and alloW su?icient clearance for the hammer

to pass the disconnector hook and be captured by same. This

is due to the fact that the disconnector hook and the trigger

compartment, and a cover 58 that is press ?t over the butt

problem in existing AR-7 ri?es. More speci?cally, there is a

end of the shoulder stock to close the compartment. The term

takedoWn is used to describe any ?rearm design in Which

the barrel may rapidly be removed in order to make the

?rearm more portable and/or e?fect compact storage. The

AR-7 model ri?e can be broken doWn and reassembled

Without tools. Broken doWn, the parts may be conveniently

stored in the compartment built into the shoulder stock 56

(the parts do not ?t entirely Within the compartment but

rather protrude outside).

[0005] Being that the AR-7 Was considered a survival ri?e,

the design Was rudimentary. The main design defect of the

AR-7 ri?e Was the lack of a mechanical disconnector. This

lack of a mechanical disconnector/trigger assembly causes

undue friction and force to be necessary to effect operation

of the components as they Were originally designed. This

are integral.

[0009]

There is a need for a solution to the foregoing

need for a redesign of the AR-7 components to eliminate the

problem of short recoil.

BRIEF DESCRIPTION OF THE INVENTION

[0010] The present invention is directed to providing a

solution to the problem of short recoil in AR-7 ri?es. The

problem is solved by providing a multiple-component trig

ger/disconnector assembly. This assembly employs a sepa

rate disconnector hook that operates in conjunction With the

trigger. The trigger/disconnector assembly can be retro?tted

into existing AR-7 ri?es, thereby greatly enhancing their

functionality. This retro?t is designed to alloW existing AR-7

ri?es to be readily converted to the system disclosed herein.

[0011]

One aspect of the invention is an AR-7 ri?e having

a ?ring mechanism comprising: a hammer that pivots on a

May 18, 2006

US 2006/0101695 A1

?rst pivot pin, a trigger that pivots on a second pivot pin; the

trigger comprising a sear that holds the hammer in a ?rst

captured rearward position before the ri?e is ?red; a spring

that causes the hammer to pivot forWard When the hammer

is released from the ?rst captured rearWard position, and a

disconnector coupled to the trigger in a manner that alloWs

the disconnector to displace relative to the trigger, the

disconnector comprising a hook that captures the hammer in

a second captured rearWard position during recoil after the

ri?e has been ?red.

[0012]

Another aspect of the invention is a method for

retro?tting a ri?e having an integral trigger/disconnector,

accordance With one embodiment of the present invention.

FIG. 2 shoWs the hammer in a ?rst angular position Whereat

it is captured by a sear at the trigger nose, While FIG. 3

shoWs the hammer in a second angular position Whereat it is

captured by a disconnector hook.

[0018] FIGS. 4-6 are draWings shoWing side, front and top

vieWs respectively of the trigger incorporated in the embodi

ment depicted in FIGS. 2 and 3.

[0019] FIGS. 7-9 are draWings shoWing side, front and

bottom vieWs respectively of the disconnector incorporated

in the embodiment depicted in FIGS. 2 and 3.

comprising the steps of: removing the integral trigger/

[0020]

disconnector; and installing an assembly comprising a dis

connector and a trigger in place of the integral trigger/

disconnector, the disconnector being displaceable relative to

hammer incorporated in the embodiment depicted in FIGS.

the trigger.

[0013] A further aspect of the invention is a method for

installing a ?ring mechanism in a receiver of anAR-7 model

ri?e, comprising the steps of: making a trigger having top

portion With a recess bounded on opposing sides by ?rst and

2 and 3.

[0021]

[0022] Reference Will noW be made to the draWings in

Which similar elements in different draWings bear the same

reference numerals.

DETAILED DESCRIPTION OF THE

INVENTION

being aligned With each other; making a disconnector having

With that predetermined positional relationship; inserting a

pin through the ?rst and second apertures and the slot; ?xing

the pin to the trigger on both sides of the recess, thereby

coupling the disconnector to the trigger; and installing the

FIG. 11 is a draWing shoWing a side vieW of a

conventional AR-7 model ri?e fully assembled.

second Walls, the ?rst and second Walls having ?rst and

second apertures respectively, the ?rst and second apertures

a slot that Will overlap the ?rst and second apertures When

a bottom portion of the disconnector is inserted into the

recess With a predetermined positional relationship; insert

ing the bottom portion of the disconnector into the recess

FIG. 10 is a draWing shoWing a side vieW of the

[0023]

FIG. 1 shoWs a ?ring mechanism of the type

currently incorporated in the AR-7 model ri?e. The ?ring

mechanism comprises a hammer 6 that slides over and is

pivotably mounted to a pivot pin 8 and an integral trigger/

disconnector 24 that slides over and is pivotably mounted to

a pivot pin 4. Both pivot pins have one end inserted in a

respective blind hole in the back Wall of a receiver (not

coupled disconnector/trigger in a receiver of an AR-7 model

ri?e.

shoWn in FIG. 1). The free ends of those pivot pins are in

turn blocked by the receiver side plate When it is installed,

Which prevents the pivot pins from coming out of their

[0014]

respective blind holes. The integral component 24 comprises

Yet another aspect of the invention is an assembly

comprising: a trigger having a rearWard portion With a recess

bounded on opposing sides by ?rst and second Walls and

having a ?at bottom, the ?rst and second Walls having ?rst

and second apertures respectively, the ?rst and second

apertures having the same diameter and being aligned With

each other; a disconnector having a bottom portion inserted

in the recess in the rearWard portion of the trigger, the

disconnector having a slot that overlaps the ?rst and second

apertures, the slot having a length greater than the diameter

of the ?rst and second apertures, the disconnector compris

ing a bottom straight edge running parallel to a length

direction of the slot; a retainer pin that passes through the

?rst and second apertures and the slot, and projects beyond

the ?rst and second Walls on respective sides of the rearWard

portion, and a coil spring seated at one end against a portion

of the trigger and seated at the other end against a portion of

the disconnector, the coil spring urging the disconnector to

displace in the recess relative to the trigger.

[0015] Other aspects of the invention are disclosed and

claimed beloW.

a trigger 2 and a disconnector in the shape of a hook 18. The

integral component has a second hole (the ?rst hole receives

the trigger pivot pin) that receives a retainer pin 22 that

projects outWard on both sides of the integral component 24.

The projecting ends of the retainer pin 22 anchor the

respective ends of a hammer spring 21 this is Wound around

the opposing ends of hammer pivot pin 8 and Wrapped

around a bottom edge of the hammer 6. Only one half of the

hammer spring 21 is visible in FIG. 1. The hammer spring

Wraps around both sides of the hammer to provide forWard

spring force on the hammer. The opposite ends of the

hammer spring 21 bear on the retainer pin 22 and provide

spring force to return the trigger to its forWard position after

each shot, or depression of the trigger.

[0024] In the original AR-7 model ri?e, the pivoting of the

trigger during depression causes the hook 18 to come into

the path of the rebounding hammer 6 folloWing discharge.

The hook 18 captures the hammer 6 by means of a sear

release edge or notch 16 cut into the rearWard section of the

hammer. As previously explained, if the shooter Were to hold

the trigger 2 depressed hard enough, the hook 18 Would not

BRIEF DESCRIPTION OF THE DRAWINGS

alloW su?icient clearance for the hammer 6 to pass the hook

and then be captured thereby. This is due to the fact that the

[0016]

FIG. 1 is a draWing shoWing a side vieW of a ?ring

mechanism in a conventional AR-7 model ri?e.

[0017] FIGS. 2 and 3 are draWings shoWing respective

side vieWs of a ?ring mechanism for an AR-7 model ri?e in

hook and the trigger are integral, i.e., one cannot move

relative to the other.

[0025] The present invention solves the short recoil prob

lem by making the disconnector and the trigger into separate

May 18, 2006

US 2006/0101695 A1

components that are coupled together, one being movable

ri?e, the integral trigger/disconnector had tWo holes (seen in

relative to the other. One embodiment of the invention is

shoWn in FIGS. 2 and 3. The disconnector 10 is coupled to

FIG. 1): one for the trigger pivot pin 4 and one for a second

pin 22 that served the function of anchoring the hammer

spring. Accordingly, in the trigger shoWn in FIG. 4, the axis

of holes 32 in the Wider portion 28 is situated precisely at the

same distance aWay from the axis of the trigger pivot pin

hole 40 (seen in FIG. 4) as the distance that separates the

tWo holes in the aforementioned integral trigger/disconnec

tor (see FIG. 1).

the trigger 2 by means of a pin 14. The trigger 2 is pivotable

about a trigger pivot pin 4. In FIG. 2, the hammer is shoWn

in a ?rst rearWard angular position in Which the hammer is

captured by the sear 26 formed by the nose (i.e., the

forWardmost portion) of the trigger 2. The function of the

sear is to hold the hammer in a captured rearWard position

until such time that the trigger is depressed, i.e., pulled. In

FIG. 3, the hammer is shoWn in a second rearWard angular

position in Which the hammer is captured by the disconnec

tor hook 18. This hammer position is adopted during recoil.

The function of the disconnector hook is to capture the

hammer during its rebounding cycle. The disconnector Will

then hold the hammer until its capture can be transferred to

the sear.

[0026] FIGS. 4-6 shoW three vieWs of the trigger

employed in the embodiment depicted in FIGS. 2 and 3.

The trigger comprises a plate-like central portion 25 of

constant thickness With a hole 32 drilled therethrough for the

trigger pivot pin (not shoWn in FIG. 4). The trigger 2

incorporates a Wider (i.e., Wider than the central portion 25

is thick) portion 28 in its rearWard section. All other dimen

sions mimic the original trigger in the AR-7 model ri?e. This

Wider portion 28 alloWs for a recess or channel 30 to be

machined lengthWise. The parallel Walls on opposite sides of

the recess in this Wider portion each have a hole 32 drilled

through it crosswise, these holes being equal in diameter and

aligned (i.e., coaxial). The nose at the front of the trigger

serves as a sear 26 that engages the hammer. A roll pin 42

is provided to limit the motion of the trigger to alloW for a

more comfortable trigger pull.

[0027]

The recess in the top rearWard portion of the trigger

2 alloWs a separate disconnector 10 (see FIG. 2) to be

installed. FIGS. 7-9 shoW three vieWs of the disconnector

[0029] The last component in this trigger/disconnector

assembly is a coil-type spring 20 (see FIG. 2), Which is

positioned Within the recess of the trigger and behind the

disconnector. TWo projections 34 and 36 project in parallel

from the rear of the disconnector 10, as best seen in FIG. 7.

Referring again to FIG. 2, the spring 20 is seated in the

space betWeen the projections 34 and 36. The function of

this spring is to urge the disconnector forWard after each

cycle. This arrangement alloWs the disconnector hook 18 to

travel rearWard in order to alloW the hammer 6 to pass,

during Which rearWard motion the spring 20 is compressed.

The compressed spring 20 then urges the disconnector hook

18 back to its original position and causes it to capture the

hammer 6, as shoWn in FIG. 3. This design mimics the

original components of the AR-7 model ri?e, but With

moving parts to reduce the amount of force that is necessary

to operate the ri?e.

[0030] In the disclosed embodiment, the hammer 6, shoWn

on a magni?ed scale in FIG. 10, may be substantially

unchanged from the hammer employed in the unmodi?ed

AR-7 model ri?e. One end of the hammer pivot pin (item 8

in FIG. 2) is inserted in a blind hole in the back Wall of the

receiver. As seen in FIG. 10, the hammer has a hole 44 that

alloWs the hammer to slide onto the hammer pivot pin. When

the side plate of the receiver is in place, the hammer pivot

pin is blocked from falling out of the blind hole.

employed in the embodiment depicted in FIGS. 2 and 3.

[0031]

The disconnector 10 has dimensions that alloW a bottom

?rst sear release edge 28 and a second sear release edge 16.

portion 38 (best seen in FIG. 7) thereof to slide in and along

the recess 30 (indicated by dashed lines in FIG. 4) in the

trigger 2. A retainer pin 14 (see FIG. 2) inserted in holes 32

While the gun is cocked, the ?rst sear release edge 28 is

engaged by the sear 26 at the trigger nose (as seen in FIG.

is utiliZed to hold the disconnector in place. As best seen in

FIG. 7, the disconnector 10 has a slot 12 machined length

occurs at the urging of the hammer spring 21 When the

hammer is released by the sear. The second sear release edge

16 of the hammer is engaged by the disconnector hook 18

Wise. This slot overlaps the holes 32 (see FIG. 4) in the rear

portion of the trigger and has a length greater than the

diameter of the retainer pin 14 (see FIG. 2) that couples the

disconnector to the trigger. The retainer pin 14 (see FIG. 2)

goes through the holes 32 (see FIG. 4) in the Wider portion

of the trigger and through the slot 12 (see FIG. 7) in the

disconnector. When assembled, the disconnector is

restrained against upWard movement by the retainer pin 14

engaging the bottom edge of the disconnector slot 12, While

the retainer pin 14 itself is limited in its ability to displace

axially by the back Wall and side plate of the receiver (not

shoWn). HoWever, the horizontal slot 12 alloWs the discon

nector 10 the freedom to move back and forth by riding

Within the recess 30 machined in the rearWard portion of the

trigger 2, While being coupled to the trigger by the retainer

pin 14.

[0028] In the retro?tted AR-7 model ri?e disclosed herein,

the retainer pin has dual functions: (1) coupling the discon

nector to the trigger; and (2) serving as an anchor for the

hammer spring. In the original (not retro?tted) AR-7 model

Still referring to FIG. 10, the hammer comprises a

2). Rotation of the hammer about the hammer pivot pin

(as seen in FIG. 3). During the rebounding cycle of the

hammer, the hammer is captured by the disconnector When

hook 18 latches behind the second sear release edge 16.

[0032] The procedure for retro?tting AR-7 model ri?es in

accordance With one embodiment of the invention Will noW

be described.

[0033]

In order to remove the integral trigger/disconnector

from the receiver of a not yet modi?ed AR-7 model ri?e, one

must ?rst pull the trigger to alloW the hammer to go to its

forWardmost position. In this state, the ri?e is said to be

uncocked. At this point the sideplate screW can be

removed and the sideplate can be lifted off the receiver. This

exposes the trigger/disconnector mechanism of the ri?e. At

this point one can lift the trigger/disconnector off the trigger

pivot pin and remove it from the receiver.

[0034]

In order to assemble the trigger/disconnector

mechanism seen in FIGS. 2 and 3, the disconnector spring

20 is placed into the recess in the rear portion of the

May 18, 2006

US 2006/0101695 A1

disconnector. The disconnector 10 and its spring 20 are then

placed into the recess 30 machined into a rearward portion

of the trigger and the slot 12 in the disconnector must be

to said trigger in a manner that allows said disconnector to

aligned with the holes 32 (see FIG. 4) in the rearward

portion of the trigger. Once this is accomplished, the retainer

pin 14 can be installed. At this point the assembly sequence

for the trigger/disconnector mechanism is complete.

rearward position during recoil after the ri?e has been ?red.

2. The ri?e as recited in claim 1, wherein said trigger

comprises mutually parallel ?rst and second walls and a

recess therebetween, said disconnector being slidably seated

[0035]

in said recess of said trigger.

3. The ri?e as recited in claim 2, wherein said trigger

comprises a ?rst hole in said ?rst wall and a second hole in

In order to install the complete assembly into the

receiver, the trigger/disconnector mechanism (with spring)

is placed into the receiver, taking care that the hammer

displace relative to said trigger, said disconnector compris

ing a hook that captures said hammer in a second captured

spring is captured by the protruding retainer pin that couples

said second wall, said ?rst and second holes being aligned,

the disconnector to the trigger. The hammer spring can now

and a pin mounted in said ?rst and second holes, and said

be manually compressed and the pivot pin hole in the trigger

must be aligned with the trigger pivot pin within the

receiver. When this has been accomplished, the trigger/

therein, said pin passing through said slot in said discon

disconnector mechanism can be installed in the receiver by

said pin.

placing the trigger down onto the trigger pivot pin within the

receiver. At this point the sideplate and its screw can be

4. The ri?e as recited in claim 2, further comprising a

second spring arranged to urge said disconnector to slide in

replaced, thereby completing the retro?t.

a forward direction.

[0036] In accordance with the arrangement disclosed

herein, a separate spring-loaded disconnector hook incorpo

rated in the trigger/disconnector assembly is able to move to

the rear when contacted by the hammer to allow the hammer

to pass, and then quickly return to its forward position so as

to capture the hammer. This can occur regardless of the

position of the trigger. Previously the original components

would not allow this to occur. As the trigger is released, the

disconnector hook releases the hammer, and the hammer

will begin to travel forward until it is captured once again by

the trigger nose (i.e., the sear) engaging the sear notch of the

hammer. The disclosed multiple-component assembly

greatly reduces the amount of force required to operate the

disconnector further comprises a base with a slot formed

nector, said slot having a length greater than a diameter of

5. The ri?e as recited in claim 4, wherein said disconnec

tor further comprises ?rst and second rearward projections,

said second spring being seated between said ?rst and

second projections.

6. A method for retro?tting a ri?e having an integral

trigger/disconnector, comprising the steps of:

removing the integral trigger/disconnector; and

installing an assembly comprising a disconnector and a

trigger in place of the integral trigger/disconnector, the

disconnector being displaceable relative to the trigger.

7. The method as recited in claim 6, further comprising

the following steps performed before said installing step:

trigger mechanism of an AR-7 model ri?e. This is an

improvement because it eliminates the malfunction known

as short recoil and enhances the function of the ri?e.

[0037] The disclosed mechanism was designed to mimic

the dimensions and function of the original AR-7 compo

nents. The wider portion of the trigger was designed to be

installed within the receiver of an AR-7 model ri?e with no

modi?cations to the receiver. These design features allow

the mechanical trigger/disconnector assembly to either be

retro?tted in existing ri?es or incorporated into current

production.

[0038] While the invention has been described with ref

erence to preferred embodiments, it will be understood by

those skilled in the art that various changes may be made and

equivalents may be substituted for members thereof without

departing from the scope of the invention. In addition, many

modi?cations may be made to adapt a particular situation to

the teachings of the invention without departing from the

essential scope thereof. Therefore it is intended that the

invention not be limited to the particular embodiment dis

closed as the best mode contemplated for carrying out this

invention, but that the invention will include all embodi

ments falling within the scope of the appended claims.

1. An AR-7 ri?e having a ?ring mechanism comprising:

a hammer that pivots on a ?rst pivot pin, a trigger that pivots

on a second pivot pin; said trigger comprising a sear that

holds said hammer in a ?rst captured rearward position

before the ri?e is ?red; a ?rst spring that causes said hammer

to pivot forward when said hammer is released from said

?rst captured rearward position, and a disconnector coupled

coupling the disconnector to the trigger in a manner that

allows the disconnector to displace relative to the

trigger along an axis; and

inserting a compression spring between a portion of the

disconnector and a portion of the trigger, the spring

exerting a force that urges the disconnector to displace

relative to the trigger in one direction along the axis.

8. The method as recited in claim 7, wherein the discon

nector coupled to the trigger is substantially not rotatable

relative to the trigger.

9. The method as recited in claim 7, wherein said coupling

step comprises inserting a portion of the disconnector in a

recess formed in the trigger, passing a pin through circular

holes in the trigger and through a slot in the disconnector,

and securing the pin relative to the trigger.

10. The method as recited in claim 6, wherein the ri?e is

an AR-7 model ri?e.

11. A method for installing a ?ring mechanism in an AR-7

model ri?e, comprising the steps of:

making a trigger having a rearward portion with a recess

bounded on opposing sides by ?rst and second walls,

the ?rst and second walls having ?rst and second

apertures respectively, the ?rst and second apertures

being aligned with each other;

making a disconnector having a slot that will overlap the

?rst and second apertures when a bottom portion of the

disconnector is inserted into the recess with a prede

termined positional relationship;

May 18, 2006

US 2006/0101695 A1

inserting the bottom portion of the disconnector into the

recess With said predetermined positional relationship;

inserting a pin through the ?rst and second apertures and

the slot; and

installing the coupled disconnector/trigger in a receiver of

an AR-7 model ri?e.

12. The method as recited in claim 11, Wherein the

disconnector is designed to capture the ri?es hammer

during recoil.

13. The method as recited in claim 11, Wherein the

disconnector is designed to slide in the recess With substan

tially no rotation relative to the trigger.

14. The method as recited in claim 11, further comprising

and second apertures respectively, said ?rst and second

apertures having the same diameter and being aligned

With each other;

a disconnector having a bottom portion inserted in said

recess in said rearWard portion of said trigger, said

disconnector having a slot that overlaps said ?rst and

second apertures, said slot having a length greater than

said diameter of said ?rst and second apertures, said

disconnector comprising a bottom straight edge run

ning parallel to a length direction of said slot;

a retainer pin that passes through said ?rst and second

apertures and said slot, and projects beyond said ?rst

and second Walls on respective sides of said rearWard

portion, and

the step of removing an integral disconnector/trigger from

the receiver before said installing step.

15. An assembly comprising:

a coil spring seated at one end against a portion of said

a trigger having a rearward portion With a recess bounded

nector to displace in said recess relative to said trigger.

on opposing sides by ?rst and second Walls and having

a ?at bottom, said ?rst and second Walls having ?rst

trigger and seated at the other end against a portion of

said disconnector, said coil spring urging said discon

*

You might also like

- Practical Guide to the Operational Use of the PA-63 PistolFrom EverandPractical Guide to the Operational Use of the PA-63 PistolRating: 5 out of 5 stars5/5 (1)

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesFrom EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesNo ratings yet

- ChicopeerfDocument15 pagesChicopeerfRomG78No ratings yet

- FE Analysis of Firearm Locking Systems: Lorenzo CastiglioniDocument15 pagesFE Analysis of Firearm Locking Systems: Lorenzo CastiglionijkruiseNo ratings yet

- 870 Detent Staking PunchDocument1 page870 Detent Staking PunchZardoz10900% (1)

- Percussion Lock TerminologyDocument2 pagesPercussion Lock TerminologyCharlie0% (1)

- @VLNNR:: Beretta 3,021,763Document8 pages@VLNNR:: Beretta 3,021,763wererNo ratings yet

- Chimera ManualDocument12 pagesChimera ManualticocrazyNo ratings yet

- Mossberg MaverickDocument28 pagesMossberg MaverickCharrotex&NUNI100% (1)

- The Armalite AR-7 Survival RifleDocument6 pagesThe Armalite AR-7 Survival Rifleblowmeasshole1911No ratings yet

- Post 4 23085 M6 Scout InfoDocument32 pagesPost 4 23085 M6 Scout InfoMike Nichlos100% (2)

- Us 3722358Document9 pagesUs 3722358awe234No ratings yet

- 6MM Machine GunDocument8 pages6MM Machine Gunbombmaker2No ratings yet

- Types of Firearm ActionsDocument3 pagesTypes of Firearm ActionssharlynfaithloquireNo ratings yet

- AR-7 Henry Repeating Arms Semi Auto 22LR Brochure PDFDocument1 pageAR-7 Henry Repeating Arms Semi Auto 22LR Brochure PDFLeonel Montilla100% (1)

- 180 Misc .DXFDocument392 pages180 Misc .DXFNester Tovar0% (1)

- Semiautomatic Rifle SharacDocument3 pagesSemiautomatic Rifle SharacOlegValNo ratings yet

- ListDocument40 pagesListCarlos Ramos100% (1)

- The 1903 Colt .38 Automatic Pocket ModelDocument5 pagesThe 1903 Colt .38 Automatic Pocket Modelblowmeasshole1911100% (1)

- Home N Ew Arrivals C Loseouts Schem Atics Sell Your PartsDocument2 pagesHome N Ew Arrivals C Loseouts Schem Atics Sell Your Partstwinscrewcanoe100% (1)

- A MAC History LessonDocument11 pagesA MAC History Lessonlopezm93No ratings yet

- Mod Firearm Beretta - US Patent 5596162Document9 pagesMod Firearm Beretta - US Patent 5596162luanfunari100% (1)

- MmgunboatsdesignguideDocument13 pagesMmgunboatsdesignguideapi-210899798No ratings yet

- P226 TACOPS SellDocument2 pagesP226 TACOPS SellLarry C Sandt100% (1)

- Toy Derringer Handgun Firing Mechanism PDFDocument5 pagesToy Derringer Handgun Firing Mechanism PDFyuehan0% (1)

- Eng-Template-1 - C: Scale: Drawing No: Rev: Sheet: OFDocument4 pagesEng-Template-1 - C: Scale: Drawing No: Rev: Sheet: OFlogostar5No ratings yet

- Pressure Air GunDocument7 pagesPressure Air GunyuehanNo ratings yet

- WeaponDocument29 pagesWeaponangelic hans100% (1)

- Colt Custom Shop Order FormDocument8 pagesColt Custom Shop Order FormAmmoLand Shooting Sports NewsNo ratings yet

- 192 Office/Tech:: Shotgun IndexDocument16 pages192 Office/Tech:: Shotgun IndexStan BrittsanNo ratings yet

- C 96 BroomhandledisassemblyDocument56 pagesC 96 BroomhandledisassemblyKristjan ReinoNo ratings yet

- MAX1045 ManualDocument13 pagesMAX1045 Manualbrowar444100% (1)

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongNo ratings yet

- M1-M14 Conversion US3362095Document3 pagesM1-M14 Conversion US3362095apoorva singhNo ratings yet

- Pep 22 Barrel MMDocument1 pagePep 22 Barrel MMkolas hernandezNo ratings yet

- Carl Gustav SMGDocument18 pagesCarl Gustav SMGJorihood100% (1)

- Remington 1100, 11-87 & Super Mag Auto ShotgunsDocument26 pagesRemington 1100, 11-87 & Super Mag Auto ShotgunsPlainNormalGuy2No ratings yet

- MMD15 G36C PDFDocument20 pagesMMD15 G36C PDFBatolitosNo ratings yet

- AR-7 The Rocker (Full Auto Conversion) - Sardauker PressDocument5 pagesAR-7 The Rocker (Full Auto Conversion) - Sardauker PressGorni100% (1)

- M4-SD II CompensatorDocument2 pagesM4-SD II CompensatorGriffin Armament Suppressors100% (2)

- Inexpensive 2x4 Combat Crossbow PlansDocument8 pagesInexpensive 2x4 Combat Crossbow PlansHajka MateuszNo ratings yet

- STG 43 ManualDocument23 pagesSTG 43 ManualDavid NashNo ratings yet

- Dec. 22, 1953 R. T. Catlin Etal: AmmunitionDocument4 pagesDec. 22, 1953 R. T. Catlin Etal: Ammunitionkahj juliNo ratings yet

- The DIY Gun Vise ProjectDocument4 pagesThe DIY Gun Vise ProjectShawn Armstrong100% (2)

- 48Document20 pages48UralguyNo ratings yet

- 1FE37 9mm Austen MK1 & 9mm Owen MK1 SMG Part5Document8 pages1FE37 9mm Austen MK1 & 9mm Owen MK1 SMG Part5ericherichhonecker100% (1)

- Muzzle Threading: Getting StartedDocument5 pagesMuzzle Threading: Getting Startedwdafon100% (1)

- Making The Extractor Cut On A Virgin Barrel - The AK Files ForumsDocument4 pagesMaking The Extractor Cut On A Virgin Barrel - The AK Files Forumsscout50No ratings yet

- CMMG 22LR Conversion Kit ManualDocument12 pagesCMMG 22LR Conversion Kit ManualDerek LoGiudice0% (1)

- EP2369289A1Document10 pagesEP2369289A1awe234100% (1)

- Mauser Model 45 ENGLISH PDFDocument19 pagesMauser Model 45 ENGLISH PDFIM_JohnnyV100% (1)

- 5 Olympic - Whitney - Wolverine PDFDocument16 pages5 Olympic - Whitney - Wolverine PDFrico oliverNo ratings yet

- Revolver ChamferingDocument6 pagesRevolver ChamferingZardoz1090100% (1)

- V3 ECM Tutorial v1.0Document40 pagesV3 ECM Tutorial v1.0lmkkilo3No ratings yet

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.From EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Rating: 5 out of 5 stars5/5 (1)

- Practical Guide to the Operational Use of the PPS-43 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunNo ratings yet

- The Practical Guide to Man-Powered Weapons and Ammunition: Experiments with Catapults, Musketballs, Stonebows, Blowpipes, Big Airguns, and Bullet BowsFrom EverandThe Practical Guide to Man-Powered Weapons and Ammunition: Experiments with Catapults, Musketballs, Stonebows, Blowpipes, Big Airguns, and Bullet BowsRating: 5 out of 5 stars5/5 (1)

- 83E2F Modern Letter Engraving Metal Part1 PDFDocument93 pages83E2F Modern Letter Engraving Metal Part1 PDFgalak12001No ratings yet

- SGN22 1 PDFDocument3 pagesSGN22 1 PDFgalak12001100% (4)

- Target Resource GuideDocument20 pagesTarget Resource Guidegalak12001No ratings yet

- Firearms Identification Vol 1 - JH Mathews 1973Document217 pagesFirearms Identification Vol 1 - JH Mathews 1973galak12001100% (2)

- Ruger 10-22 Select Fire Full Auto ConversionDocument0 pagesRuger 10-22 Select Fire Full Auto Conversiongalak12001100% (2)

- SIG Sauer 2013 CatalogDocument36 pagesSIG Sauer 2013 CatalogPredatorBDU.com100% (1)

- 205 Tec9Document13 pages205 Tec9blazerman3100% (4)

- Science Fiction and The Hidden Global Agenda - 2016 Edition - Vol 2Document416 pagesScience Fiction and The Hidden Global Agenda - 2016 Edition - Vol 2Anonymous 69rsr6yP7100% (2)

- History-: Chapter 1: Was There Singapore Before 1819?Document35 pagesHistory-: Chapter 1: Was There Singapore Before 1819?Wei-En Ravichandran67% (6)

- Curriculum Vitae: Personal DataDocument2 pagesCurriculum Vitae: Personal Datafreya prawinta aureliNo ratings yet

- IM Eslie: Ottawa, Ontario, CANADADocument3 pagesIM Eslie: Ottawa, Ontario, CANADATimNo ratings yet

- Bushido New Dawn Rules PDFDocument15 pagesBushido New Dawn Rules PDFLars Suzuki Lemming100% (1)

- Ships of The Tech ManualDocument36 pagesShips of The Tech ManualDeep Patel100% (5)

- Chapter 4 - Ancient Chinese CivilizationDocument20 pagesChapter 4 - Ancient Chinese CivilizationYonny Quispe LevanoNo ratings yet

- ArmuraDocument25 pagesArmuraBalaciNo ratings yet

- Black Sunday in Sadr City, 2004Document20 pagesBlack Sunday in Sadr City, 2004Andrea MatteuzziNo ratings yet

- D3H2 2.1 ExportDocument18 pagesD3H2 2.1 ExportTeONLY 0No ratings yet

- Epic ItemDocument1 pageEpic ItemGeorge SigarlakiNo ratings yet

- Army Aviation Digest - Nov 1975Document52 pagesArmy Aviation Digest - Nov 1975Aviation/Space History LibraryNo ratings yet

- Margaret Sanger A Life of PassionDocument13 pagesMargaret Sanger A Life of PassionMacmillan Publishers100% (2)

- 10 Reasons Why Switzerland Is Home To The CIA (Central Intelligence Agency) PDFDocument12 pages10 Reasons Why Switzerland Is Home To The CIA (Central Intelligence Agency) PDFDanick100% (3)

- Ja Shooting ClubDocument6 pagesJa Shooting ClubLeah0% (1)

- The Bomb Didn't Beat Japan Stalin Did - Foreign PolicyDocument14 pagesThe Bomb Didn't Beat Japan Stalin Did - Foreign Policyabhiscribd2010100% (1)

- NieuportDocument31 pagesNieuportFede OrdóñezNo ratings yet

- Fuenteovejuna: Lope de VegaDocument0 pagesFuenteovejuna: Lope de VegaAlyson Germinder0% (1)

- Japan Enemy Trends April 45Document82 pagesJapan Enemy Trends April 45finriswolf2No ratings yet

- Antony and Cleopatra by William ShakespeareDocument7 pagesAntony and Cleopatra by William Shakespearekosenkotaja07No ratings yet

- TM 55-3805-261-14 Cat 130G MilDocument45 pagesTM 55-3805-261-14 Cat 130G MilAdvocateNo ratings yet

- Asdcsadca SDC Asd Ca SDC Asd C Asd Cas DC Asd Cas Ca SDC Asd Casd Sac AasdDocument77 pagesAsdcsadca SDC Asd Ca SDC Asd C Asd Cas DC Asd Cas Ca SDC Asd Casd Sac AasdAlvaroMontesinosNo ratings yet

- Contoh Teks Historical RecountDocument5 pagesContoh Teks Historical RecountHealvywinata100% (1)

- 2019 Grade 11 Mathematics Third Term Test Paper Devi Balika CollageDocument12 pages2019 Grade 11 Mathematics Third Term Test Paper Devi Balika CollageDineshi ThilakarathnaNo ratings yet

- ww1 Timeline of World War IDocument4 pagesww1 Timeline of World War IKokak DelightsNo ratings yet

- Franz Fanon - Duzakhian Ruye Zamin (The Wretched of The Earth)Document188 pagesFranz Fanon - Duzakhian Ruye Zamin (The Wretched of The Earth)CarlosAmadorFonsecaNo ratings yet

- UNIT HistoryDocument2 pagesUNIT HistorySanders StephenNo ratings yet

- Effects of Heat On Firearm BarrelsDocument4 pagesEffects of Heat On Firearm BarrelsRobby RenzNo ratings yet

- RPH MidtermsDocument27 pagesRPH MidtermsLouie Jay VillaganesNo ratings yet

- Almark American Armoured Cars 1940-45Document27 pagesAlmark American Armoured Cars 1940-45Douglas Grigg94% (16)