Professional Documents

Culture Documents

Series 9 Module 8 Feb 12

Uploaded by

GABRIEL GONZALEZCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series 9 Module 8 Feb 12

Uploaded by

GABRIEL GONZALEZCopyright:

Available Formats

Fundamental

The Continuing Professional Development Programme

02.2012 eiBi

series 9 MODULE 08

CURRENT THINKING ON...

Photovoltaic systems

PAUL CHANDLER, DEVELOPMENT DIRECTOR T4 SUSTAINABILITY LTD

hotovoltaic (PV) systems use

photovoltaic cells to capture

energy from sunlight and

convert it into direct current

(DC) electricity. This electricity can

then be used as DC (often stored in a

battery) or converted into alternating

current (AC) via an inverter. A PV

module or panel is formed from a

number of cells which are connected

within the module into sub-strings.

Modules are normally connected

together into one or more strings to

form what is known as an array.

The amount of energy in the

sunlight reaching the earths surface

is equivalent to around 10,000 times

the worlds energy requirements1.

On average, the UK receives around

1,000kWh per m2 each year2 (this

figure is larger in the south of England

than Scotland). However, only a

small portion of this incident energy

can be converted to electricity by

photovoltaic panels due to their

relatively low energy conversion

efficiency.

The intensity of daylight

(irradiation) at any point on the

earths surface at any time varies

hugely depending on the time of year,

time of day and cloud conditions.

When the sun is highest in the sky

and there are fewest clouds the least

energy is reflected back into space or

absorbed before it reaches the earth.

Therefore, maximum light intensity

(irradiance) is most likely in the UK at

around midday near summer solstice

(when the sun is highest in the sky). In

the UK, monthly irradiation in winter is

roughly one quarter of that in summer

due to the shorter days and the sun

being lower in the sky3.

As light passes through the

atmosphere gases and particles

absorb different frequencies by

various amounts. The absorption

due to the length of the path through

the atmosphere is described by the

air mass factor which describes the

distance perpendicular to the earths

surface and allows for the change in

spectrum of light.

Irradiation incident

A solar panel will receive the

maximum energy when it is

perpendicular to incident daylight

(irradiation). The irradiation incident

on a surface such as a solar panel

depends on its elevation (normally

measured from the horizontal) and

azimuth (e.g. south) and the position

of the sun. For example, a solar panel

lying horizontally will capture more

energy at summer solstice than a

vertical panel facing east.

As the position of the sun is

constantly changing it is not

possible for a fixed solar panel to be

perpendicular to the incident energy

all of the time. The optimal angle

for a fixed solar panel is that which

captures the most energy over the

course of a year. In the UK this is

facing south at an angle of elevation

of between 300 and 400.

Sunlight comprises beam and

diffuse components. The beam

portion comes direct from the sun

and casts hard shadows while the

diffuse portion has been scattered on

its journey through the atmosphere.

In the UK around 60 per cent of

sunlight (irradiation) is diffuse2. This

means that if a panel does not face

in the best direction, the reduction

in yield is not as significant as one

might expect. For example, panels

facing east or west (at an elevation of

30) are predicted by the Standard

Assessment Protocol (SAP) to have

an output of around 20 per cent less

than if they had faced south.

Photovoltaic modules (commonly

known as PV panels) comprise semi-

conductor materials that absorb

photons of light energy and liberate

direct current (DC) by releasing

charge (electron-hole pairs). The

most common types of modules are

made of crystalline silicon although

thin-film technology is becoming

increasingly popular.

Crystalline modules are made

from a number of cells (often 60)

connected together in series to give

the required voltage (e.g. 30V). Each

cell comprises a junction of positively

and negatively dopes silicon. If one cell

is shaded it can cause a hot-spot due

to the current flowing through it from

the illuminated cells, therefore the cells

within a module are connected into

substrings, each of which has a bypass

diode to prevent over-heating. The

modules provide electrical connection

points and mechanical protection for

the cells, typically through the use of

an aluminium frame, tempered glass

and encapsulation. Commercially

available crystalline modules have a

typical efficiency of around 14 per cent.

Photovoltaic cells require very high

purity silicon which is made by the

melting of silica sand at extremely

high temperatures followed by further

chemical processing. The silicon can

be made into either mono- or polycrystalline cells. Mono-crystalline

has a very regular structure and is

grown slowly by drawing a crystal at

high temperatures. Poly-crystalline is

produced faster and has a less regular

structure which gives lower energy

conversion efficiency (due to faster

hole pair recombination). Mono- and

poly-crystalline are visibly different

For details on how to obtain

your Energy Institute CPD

Certificate, see entry form

and details on page 32

Produced in association with

ENERGY IN BUILDINGS & INDUSTRY 29

series 9 module 08

Fundamental

as mono-crystalline cells are cut to

be semi-round and have a uniform

appearance (see photo below) while

poly-crystalline cells are square and

the individual crystals can be seen

(see photo right).

Efficiency drops

Electrical contacts are required

on the front and back of the cell to

take charge away from the junction.

Roughly half of the energy in the

incident radiation is not captured

by the cell as the photon energy

is too high or low to be absorbed.

Further losses are due to electrical

factors (potential difference and

recombination losses) and shading

from the contacts. Solar cells have

negative temperature coefficients

meaning their efficiency drops with

temperature.

Thin film modules are made by

deposition of a thin layer of semiconductor onto a substrate (typically

glass). Their manufacture can take

place at far lower temperatures than

silicon cells and requires considerably

less material, meaning production

costs are lower. Thin film modules

have considerably lower efficiency but

offer better performance in diffuse

light and have a better tolerance of

shading. During their initial period

of operation the efficiency of the

panels drops due to light-induced

degradation. Despite this, thin film

modules can be very useful for

building integration as they can be

semi-transparent and incorporated

into glazing or cladding materials.

Commercially available modules have

an efficiency of around 7 per cent.

Hybrid modules are available that

comprise mono-crystalline cells and

a thin film layer to provide a high

module efficiency (e.g. 17 per cent for

Sanyo HIT modules).

Electrical characteristics are

defined at standard test conditions

(STC) which are: irradiance of 1,000W

per m2, air mass factor of 1.5 and cell

temperature of 25C. The efficiency of

a module is defined as the electrical

output power of the module divided

by the solar power incident on it. A

higher efficiency module can produce

more electricity from a fixed area

(under standard test conditions).

Panels are described in terms

of their voltage and current

characteristic.

30 ENERGY IN BUILDINGS & INDUSTRY

The maximum voltage (Voc) occurs

when the module is not connected

to anything (known as open circuit).

When the module connections

are joined (short circuited) the

maximum current occurs (Isc). The

instantaneous power from the module

is the product of voltage and current

and has a maximum value for any

one irradiance level. As the incident

irradiance reduces the current

drops. The voltage also reduces with

irradiance (to a smaller extent) but is

mainly determined by temperature.

To obtain the maximum power

from a module in any given light level,

the current drawn must be chosen to

achieve the maximum power voltage

(Vmp). Most modern inverters and

charge regulators adapt dynamically

to operate at the current which

maximises the transfer of electrical

power. This technique is known as

maximum power point tracking.

Panel data sheets give the

following electrical parameters which

are used in system design:

electrical output e.g. 240W;

open circuit voltage and short circuit

current e.g. 37V and 9A; and

maximum power current and

voltages e.g. 30V and 8A.

These parameters are measured

at standard test conditions during

a flash test. However, modules

perform under a variety of conditions

(typically at lower irradiance). Also,

when modules are subject to high

levels of irradiance they are often

hotter than 25C. This means that

the temperature coefficient of the

A typical

monocrystalline

photovoltaic cell

module is important as it determines

the drop in efficiency with increase in

temperature. Daylight levels in the UK

are rarely more than 1,000W per m2

meaning that panels seldom perform

at the rated output.

The income that can be generated

from a system depends on the annual

yield which is determined by the

system size, irradiation (determined

by location, orientation, elevation and

shading), and panel performance.

Yields are often normalised to enable

comparison of performance i.e. kWh

per year from one kW of installed

capacity. Expected yields in the UK

can be calculated using the Standard

Assessment Procedure (SAP). SAP

takes into account orientation,

shading and elevation but does not

allow for location or panel technology

e.g. systems of the same size using

panels located in Scotland and

England are estimated as having the

same yield. The Standard Assessment

Procedure gives an expected annual

yield of around 800kWh per kW

of installed panel capacity for welllocated systems such as those facing

roughly south at standard roof pitch

and with little shading. Based on this

a 4kW domestic system can produce

over 3,000kWh each year (over half of

typical domestic electricity demand).

As mentioned above, panels

are tested under standard test

conditions but perform under a

variety of conditions. For this reason

the yields from 1kW of photovoltaic

modules at any one site in any one

year will vary between technologies

and even manufacturers. This can

be shown through simulation using

software such as PVSol and by data

from independent trials such as that

undertaken by Photon Magazine.

Yields can be reduced by small

levels of shading as systems typically

comprise modules in series: shading

of one module will reduce the

performance of the entire string in

which it is connected. This can be

minimised through the use of microinverters (one per panel). In addition,

if one cell in a module is shaded (e.g.

by a leaf) the entire sub-string in

which it is located will be by-passed

by internal diodes. Even partial shade

has a disproportionately large impact

on performance.

Consider shading

When considering system design the

location of any sources of shading

must be carefully considered. The

impact of shade will be greatest if it

occurs at the middle of the day and /

or the middle of the year when light

levels are at typically at their highest.

Off-grid systems generate

electricity and either use it directly

(e.g. in a water pump) or store it in

a battery for use as required. Such

systems must be carefully sized

so that the number of panels and

batteries are correctly selected to

meet the required energy demand

while minimising cost. The system

sizing must take into account

the profile of both irradiance and

electricity demand. This is because

the batteries cannot provide energy

storage for many months (i.e. the

panels must be sized to meet winter

demand) and irradiance varies on a

daily basis (i.e. several days energy

storage is required).

A typical off-grid system comprises

several panels, a charge regulator

and batteries. The charge regulator

links the panels and batteries to

prevent over-charging and undercharging of the batteries. The energy

stored in the batteries can be used

as direct current (DC) or converted

to alternating current power (AC) via

an inverter. Inverters allow standard

electrical appliances to be used

and power to be transmitted longer

distances more efficiently (due to

the higher voltages) but introduce

additional conversion losses.

For grid-connected systems

series 9 module 08

Photovoltaic systems

the number of panels is normally

determined by physical constraints

(such as roof space) or financial

considerations. Typical domestic

systems are 2- 4kW. The panels are

connected into strings to provide a

voltage and current suitable for an

inverter of the appropriate rating.

The system must be designed so that

the voltage of the string is less than

the maximum value for the inverter

but with the maximum power point

voltage within the maximum power

point tracking range of the inverter.

The inverter manufacturer's software

should be used to ensure the best

unit is selected for the array and the

correct number of strings used. For

a typical domestic installation the

panels are connected as one string of

modules providing, for example, 7A of

direct current (DC) at 500V.

The panels are connected to

an inverter which converts the

DC electricity to standard mains

electricity (230V AC). Inverters

are available with or without

transformers. Transformers offer the

advantage of electrical separation

between the DC and AC circuits but

add weight and energy losses. The

use of transformerless inverters in the

UK currently requires bonding of the

system to earth.

In a typical PV installation the AC

electricity from the inverter is fed

into the propertys electrical system.

Electricity generated is used on-site

with any surplus exported to the grid.

Under Engineering Recommendation

G83/1, certain microgeneration

systems smaller than 16A per phase

can be installed without prior

permission from the distribution

network operator as long as type

approved equipment is used and the

installations meet the requirements of

G83/1 (e.g. disconnection on under/

over voltage and frequency). For

larger systems permission should be

bill reduction (value of imports

offset by on-site generation);

generation tariff (paid for all

electricity generated regardless of

where it is used); and

export tariff (paid for exports

typically deemed at 50 per cent but

can be measured).

The Feed In Tariff comprises the

Generation and Export Tariffs and

is paid by an electricity supplier. To

obtain the FiT the system (assuming it

is smaller than 50kW) must be installed

by a Microgeneration Certification

Scheme (MCS) approved installer.

There is a very large amount of

solar energy reaching the UK each

year and it has significant variation

throughout both the year and

the day. Despite the low energy

conversion efficiency of PV modules

a typical domestic PV system can

produce enough electricity to make

a significant contribution towards a

homes electricity consumption.

A typical polycrystalline photovoltaic cell system

sought prior to connection but the

use of G83 approved equipment is

often allowed. Large systems (e.g.

over 30kW) may require the use of

G59 approved equipment which has

tighter operating parameters.

Lower systems costs

Photovoltaic systems are becoming

increasingly popular for gridconnected systems due to lower

systems costs, higher energy prices,

financial incentives and environmental

drivers. Encouraged by the successful

use of subsidies in Germany the UK

Government introduced the Feed

in Tariff to provide incentives for a

number of renewable technologies

including photovoltaics. Since the

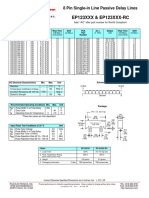

Electrical schematic for a small grid-connected PV system

introduction of the Feed In Tariff

there has been a huge increase in the

number of systems installed. There

have also been significant reductions

in installed costs (mainly due to lower

equipment costs) meaning that

photovoltaic systems provide higher

returns on investment than envisaged

by Government when the scheme

was introduced. The scheme has been

so popular that the rates paid have

been reduced, leading to uncertainty

in the sector about future uptake.

Photovoltaic modules currently

cost less than 1 per watt and the

typical cost of a domestic sized

system is around 3 per watt

(including balance of plant and

installation). Income is earned from:

Further reading

Choosing Solar Electricity: A Guide

to Photovoltaic Systems Brian Goss.

Photovoltaics in Buildings Guide

to the installation of PV systems 2nd

edition (2006).

Planning and installing Photovoltaic

Systems. A guide for installers,

architects and engineers (2nd edition

2008).

Photovoltaics in the UK: An

introductory guide for new

consumers:

http://www.eci.ox.ac.uk/research/

energy/downloads/pv-inthe-uk.pdf

References

1) Planning and installing Photovoltaic

Systems. A guide for installers,

architects and engineers (2nd edition

2008).

2) Photovoltaic Geographical

Information System (PVGis): http://

re.jrc.ec.europa.eu/pvgis/apps4/

pvest.php#

3) The Governments Standard

Assessment Procedure (SAP) for

Energy rating of Dwellings 2009 Appendix M. (Department of Energy

and Climate Change).

4) Photovoltaics in Buildings Guide

to the installation of PV systems 2nd

edition (2006).

5) Engineering Recommendation

G83/1-1 June 2008 (Energy Networks

Association).

ENERGY IN BUILDINGS & INDUSTRY 31

EIBI 02.2012

Fundamental

series 9 module 08: questions

Photovoltaic systems

Please mark your answers on the sheet below by placing a cross in the box next to the correct

answer. Only mark one box for each question. You may find it helpful to mark the answers in pencil

first before filling in the final answers in ink. Once you have completed the answer sheet in ink, return

it to the address below. Photocopies are acceptable.

How to obtain CPD accreditation

Energy in Buildings and Industry and the Energy

Institute are delighted to have teamed up to bring

you this Continuing Professional Development

initiative.

This is the eighth module in the ninth

series and focuses on photovoltaic systems.

It is accompanied by a set of multiple-choice

questions. To qualify for a CPD certificate readers must submit at

least eight of the ten sets of questions from this series of modules

to Energy in Buildings and Industry for the Energy Institute to

mark. Anyone achieving at least eight out of ten correct answers

on eight separate articles qualifies for an Energy Institute CPD

certificate. This can be obtained, on successful completion of the

course and notification by the Energy Institute, for a fee of 15 (for

members) or 25 (for non-members).

The articles, written by a qualified member of the Energy

Institute, will appeal to those new to energy management and

those with more experience of the subject.

The forthcoming modules in the ninth series will focus on:

refrigeration, and motors and drives. If you missed any of

the modules in this series (the previous modules focused on

monitoring and targeting, air conditioning, underfloor heating,

biomass boilers, building energy management systems, heat

pumps, and first steps in energy management) please let EiBI know

(mark.thrower@btinternet.com) and we will send you the missing

modules in pdf format either by e-mail or on a CD.

The previous 80 modules from the first eight series are also

available free of charge on CD.

MARKTHROWER, MANAGING EDITOR

Please complete your details below in block capitals

Name........................................................................................................................................... (Mr. Mrs, Ms).....................

1.

Which is the smallest component of a typical photovoltaic system?

n module

n Array

n Inverter

n Cell

2.

What yield might one expect from a well-positioned 10kW PV system in the UK?

n 8,000 kWh per year

n 10,000 kWh per m2

n 14,000 kWh per year

n 30,000 kWh per year

3.

Which pair of panel azimuth and elevation gives the best yield in the UK?

n Any direction, horizontal

n South facing, 36

n South facing, 50

n South facing, vertical

4.

Estimate the reduction in output caused by the shading of 1% of a panel.

n 1 per cent

n 10-50 per cent

n 80 per cent

n 100 per cent

5. What is the reduction in yield from a PV panel facing east rather than south (300

elevation)

n 5 per cent

n 20 per cent

n 50 per cent

n 70 per cent

6.

What does the Feed In Tariff provide an income for:

n Generation only

n Export into the grid only

n Generation and export

n On-site use only

7.

What factor would NOT affect the annual yield from a 250W PV panel:

n Efficiency at Standard Test Conditions

n Temperature

n Shading

n Location

Business....................................................................................................................................................................................

Business Addres....................................................................................................................................................................

8. What is the most common type of photovoltaic module currently used in the UK?

n Amorphous

n Crystalline

n Hybrid

n Thin-film

.....................................................................................................................................................................................................

.....................................................................................................................................................................................................

.....................................................................................................................................................................................................

Post Code ...............................................................................................................................................................................

email address..........................................................................................................................................................................

Tel No.......................................................................................................................................... ...............................................

Completed answers should be mailed to:

The Education Department, Energy in Buildings &Industry,

P. O. Box 825, Guildford, GU4 8WQ

32 ENERGY IN BUILDINGS & INDUSTRY

9.

What is the function of an inverter in an off- grid photovoltaic system?

n Charges the battery from the panels

n Measures the energy produced by the photovoltaic modules

n Converts the DC from the panels to AC for the grid

n Converts DC electricity to AC electricity

10.

In what way would you expect 250W PV panels of varying efficiencies to vary?

n Energy produced at Standard Test Conditions

n Predicted annual energy yield

n Area

n Rated power

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Platform of EverythingDocument51 pagesThe Platform of EverythingSi Pham QuocNo ratings yet

- Digital Design Mid-Sem Question PaperDocument2 pagesDigital Design Mid-Sem Question PaperAbhinav MishraNo ratings yet

- WiTECH Release Notes 12 03Document5 pagesWiTECH Release Notes 12 03Anonymous yQgdGKuNo ratings yet

- At The End of This Lecture You Will Be Able To:: - Linux Operating SystemDocument11 pagesAt The End of This Lecture You Will Be Able To:: - Linux Operating SystemAlex KharelNo ratings yet

- Post Event ReportDocument6 pagesPost Event ReportNida Saeed KhanNo ratings yet

- IEEE STD 859-1987 (R2002) PDFDocument14 pagesIEEE STD 859-1987 (R2002) PDFkonawaNo ratings yet

- Ey Smart ClosingDocument4 pagesEy Smart ClosingMuhammed JasilNo ratings yet

- GRE140Document24 pagesGRE140Zainul ArifinNo ratings yet

- P2M BookletDocument20 pagesP2M BookletAkaninyeneNo ratings yet

- Modulo Control TemperaturaDocument438 pagesModulo Control TemperaturaLewis MejiaNo ratings yet

- NIKHILDocument10 pagesNIKHILNishadh GajjarNo ratings yet

- BNCS Scripted PanelsDocument8 pagesBNCS Scripted PanelsNik FNo ratings yet

- PSP Fat Procedure - TemplateDocument6 pagesPSP Fat Procedure - TemplateMichael HaiseNo ratings yet

- Technocommercial OfferDocument14 pagesTechnocommercial Offerkrish659No ratings yet

- CTFL-AuT 2018 Sample Exam A v2.1 Questions PDFDocument17 pagesCTFL-AuT 2018 Sample Exam A v2.1 Questions PDFMartin DeusNo ratings yet

- 2020-03-04-Manuale-Tecnico-Louça Krupps - Uniko - Wi-Fi-rev03 - ENGDocument40 pages2020-03-04-Manuale-Tecnico-Louça Krupps - Uniko - Wi-Fi-rev03 - ENGLuis RolaNo ratings yet

- ABB FusesDocument9 pagesABB Fusesvrallam padiyaNo ratings yet

- Scada Compone NTS: Prepared By:-Animesh Ghosh Roll No - 4 M.Tech (EE)Document28 pagesScada Compone NTS: Prepared By:-Animesh Ghosh Roll No - 4 M.Tech (EE)Animesh GhoshNo ratings yet

- Chapter 07Document41 pagesChapter 07Prasanna Nivas ÄrrNo ratings yet

- 7PA22/23/26/27/30 Auxiliary Relays For Various Applications: Technical DataDocument7 pages7PA22/23/26/27/30 Auxiliary Relays For Various Applications: Technical DatasoltaniNo ratings yet

- Kernel (Computer Science) - Simple English Wikipedia, The Free EncyclopediaDocument7 pagesKernel (Computer Science) - Simple English Wikipedia, The Free EncyclopediaziaullahNo ratings yet

- Datasheet PCA EPA594 (CI Pente Filtro)Document1 pageDatasheet PCA EPA594 (CI Pente Filtro)vanmarteNo ratings yet

- Systems Operation Testing and Adjusting: Vital Information Management System (VIMS)Document162 pagesSystems Operation Testing and Adjusting: Vital Information Management System (VIMS)Carlos Andres Mendoza Chacón100% (3)

- Water Pipe Robot With Soft Inflatable ActuatorsDocument7 pagesWater Pipe Robot With Soft Inflatable ActuatorseyaoNo ratings yet

- Keywords Earthing Designs Substation Earthing Resistance Grid Potential Rise Mesh Voltage Step Voltage and Matlab Figures - CompressDocument6 pagesKeywords Earthing Designs Substation Earthing Resistance Grid Potential Rise Mesh Voltage Step Voltage and Matlab Figures - CompressDebasish RahaNo ratings yet

- Dlcoa - May - 2023 (Rev-2019-C Scheme)Document1 pageDlcoa - May - 2023 (Rev-2019-C Scheme)hajimastanbaapNo ratings yet

- Operation (Short) : FC120 Fire Control Panel (NL)Document8 pagesOperation (Short) : FC120 Fire Control Panel (NL)Pedro Sanchez RodriguezNo ratings yet

- CS8602 Compiler Design NotesDocument149 pagesCS8602 Compiler Design NotesSteffiNo ratings yet

- Drive Axle and Differential Assembly Repair (Wet Brake) : PART NO. 1624740 1400 SRM 1246Document136 pagesDrive Axle and Differential Assembly Repair (Wet Brake) : PART NO. 1624740 1400 SRM 1246KUATE JEAN CALVINNo ratings yet

- SG 247757Document478 pagesSG 247757ahmedalyNo ratings yet