Professional Documents

Culture Documents

06-16E BuildingPowerDistribution

Uploaded by

Nestor S. ReEyesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06-16E BuildingPowerDistribution

Uploaded by

Nestor S. ReEyesCopyright:

Available Formats

U NIVERSITY

OF

W ASHINGTON

Facilities Services

Design Guide

Electrical

Building Power Distribution

Basis of Design

This section applies to the design and installation of building power distribution systems.

Design Criteria

This section contains the architectural, structural and mechanical provisions for the building

electrical systems. The electrical designer shall coordinate these requirements with the other

disciplines to insure these requirements are satisfied.

Use attached drawing, Typical Building Power Distribution Riser, as a guide for building

power systems.

Coordinate with Campus Engineering the distribution concepts, including load calculations,

calculated fault duties, protective device coordination methods and grounding practices being

utilized on the design.

Architectural Provisions

Provide separate service entrance electrical rooms for each of the normal and emergency

systems in the basement, preferably adjacent to the utility tunnel and on an exterior wall.

Equipment access shafts to the outside and walk-in access from the tunnel system shall be

provided wherever possible. The design shall take into consideration the possibility of

flooding when below grade. Provide emergency power lights with battery back-up to

illuminate main service equipment area. Provide at least one phone outlet in main electrical

room.

Distribution within the building shall be via readily accessible electrical rooms and/or closets.

These must be independent from all other types of rooms or closets, i.e., communications,

telephone, custodial, audiovisual, etc.

As a general guide, provide one floor electrical distribution room to serve each 15,000 to

20,000 square feet.

Equipment room and equipment space requirements should exceed minimum NEC

requirements and shall be large enough to accommodate the equipment along with space

provisions for future equipment. Eventually, panels will become full, requiring the addition of

new panels. This is true even for fairly new facilities and is especially prevalent in laboratory

and science buildings. These future wall and floor space provisions shall be shown on the

design drawings so that space is reserved. Typically, 6-foot hot sticks are used to work on

high voltage equipment. Provide adequate working space per NEC, WAC 296-44 and the

National Electrical Safety Code.

Distribution switchboards, panelboards, and dry transformers over 30 kVA shall be in

electrical rooms. Rooms shall be stacked for riser efficiency, and be centrally located to keep

feeder lengths to a minimum. Several rooms may be necessary to accommodate the

building configuration and system design. Refer to attached drawing, Typical Floor Electrical

Room.

Closets should be a minimum 2 feet deep by 6 feet wide and equipped with full width double

doors opening into a building corridor.

Branch panels shall be located in closets located throughout the floor or wing. In laboratories

and similar areas, branch panels may be mounted on or in common corridor walls.

REV:06 JUN2015

16E - 01

University of Washington Campus Engineering 2015

Transformer ambient noise and EMF emissions from electrical equipment and risers can

negatively impact the equipment and function in neighboring spaces. This includes spaces

immediately above and below these rooms, closets and risers. Therefore, the space plan

shall be reviewed to determine if modifications are required.

Provide adequately sized access pathways for the repair, maintenance and eventual

replacement of the equipment. Equipment access pathways shall be large enough to allow

for the removal of transformers, primary switches and other large pieces of equipment.

These paths of egress shall be shown on the building drawings. Weights of transformers

could exceed floor loading if other than slab-on-grade basement areas are necessary for

egress. Make sure that lifting eyes and floor loading are accommodated for in the design.

Padmount transformers and switchgear must be accessible by vehicular crane and have

sufficient working space per NEC, WAC 296-44 and the National Electrical Safety Code.

Mechanical Provisions

Coordinate ventilation requirements in electrical rooms and closets containing transformers

or other heat generating sources with mechanical engineer. Convection-type ventilation of

the electrical rooms via air/access shafts to the outside has been used in the past at the

University. Unfortunately, this allows dirt and debris to get into rooms and equipment,

resulting in increased maintenance costs. Therefore, the ventilation shall be supplied and

filtered by a ventilation system.

Coordinate fire protection requirements in electrical rooms and vaults with the Architect and

Mechanical Engineer. The system shall satisfy the code while minimizing the risk of

electrocution. Sprinklers in high voltage electrical vaults create extremely hazardous

conditions when they discharge, creating an electrocution hazard for workers.

Avoid installation of mechanical piping and ductwork in electrical vaults, rooms or closets

except where required for operation of the electrical equipment. Piping and ductwork must

never be installed directly over any transformer or switchgear. Sprinklers installed to protect

the electrical equipment are the only exception. Drain lines from the floors above shall not be

piped through the electrical rooms below. It is not allowed to use drip pans as a mitigating

means that would allow for the piping to be installed in these areas.

Structural Provisions

Provide concrete bases and housekeeping pads for all transformers and equipment,

seismically designed with structural connections to the floor slab, and channel or angle iron

frames for welded equipment fastening.

Provide supports and restraints for Seismic Zone III requirements for all equipment and

raceways.

Coordinate conduit penetrations in slabs, floors, shear walls, structural members, and other

structural elements.

Laboratory Buildings

Since laboratory buildings will need constant renovation to keep up with changing

technology, they are divided up into lab modules. Each lab (one of more modules) will

periodically need to be isolated from the rest of the building to facilitate the renovation without

impacting the remainder of the building. Provide circuiting isolation for each lab module. All

electrical systems shall be down fed to minimize the number of floor penetrations.

If utility corridors can be provided to serve a variety of purposes through laboratory areas,

then it would be highly desirable to provide local panelboards, in these utility corridors,

dedicated to individual or small groups of laboratories.

REV:06 JUN2015

16E - 02

University of Washington Campus Engineering 2015

U NIVERSITY

OF

W ASHINGTON

Facilities Services

Design Guide

Electrical

Building Power Distribution

Lab areas will be designed with the capacity of at least 1 power outlet per 30 square feet.

Dedicated circuits will be supplied for all refrigerators, centrifuge and specialty devices.

Provide hospital grade receptacles in all research laboratories and procedure rooms in the

Health Sciences and other physical sciences.

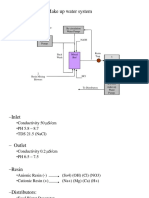

Refer to attached drawing, Laboratory Demand Load, to approximate power required for

laboratory areas. Laboratory power systems shall be flexible to allow the anticipated

increase in laboratory loads. Local distribution shall be provided based on calculated load.

However, more generous conduit sizing, sleeving, space allocated in principal electrical

cabinets or closets shall be provided to make it convenient to bring in new feeders to supply

additional power for load increases.

Dedicated receptacles and isolated ground receptacles are often required for special or

sensitive equipment. Extensive use of dedicated receptacles in laboratories can quickly use

up all the circuit breakers in the branch circuit panelboard. The Electrical Engineer shall

insure that these needs are identified on the room datasheets and that adequate panel space

is provided. Define this early in the design process.

Classroom Services

(Information maintained by Classroom Support Services.)

Classroom electrical services should be protected from surges and spikes. There should be

no elevator motors, compressor motors, blower motors, or other types of equipment on the

side of the power transformer that feeds the classroom circuits.

New construction and major renovation should provide for between 40 and 50 percent future

expansion (space only) in electrical service in each classroom.

Each classroom should have a minimum of two dedicated 20A circuits not shared by any

other room.

Classrooms seating under 50 persons should have a minimum of FOUR duplex receptacles:

one on each side wall and one in each front corner. In addition, each room should have a

minimum of two double duplex receptacles: centered on each of the front and rear walls.

Locate all receptacles at 18 AFF.

Auditoria should have a minimum of FOUR duplex receptacles (two on each side wall) and a

minimum of THREE double duplex receptacles (spaced evenly along the front wall.) Locate

all receptacles at 18 AFF.

Provide a duplex electrical outlet in the ceiling for ceiling mounted video projector in Level C

and E rooms. Locate service within 4 feet of ceiling mounting bracket as directed by CSS

staff. Ceiling outlet should be on circuit not shared with other outlets.

Auditoria projection rooms should have both 120v and 220v service. 220v service is required

for data projectors. The specific type of 220v outlet and its location will be determined with

CSS staff during the design/development stage of the project.

Auditoria should have a breaker panel in the projection booth or control room that provides

electrical service for all functions specific to that room. Breaker panels inside instructional

rooms are otherwise not acceptable. Panels should be located in either corridors or electrical

closets.

Electrical service is required at podium floor boxes in Level C and E rooms.

Floor duplex outlets are required in all classrooms to support overhead projectors and other

portable equipment.

REV:06 JUN2015

16E - 03

University of Washington Campus Engineering 2015

Classrooms may use owner-provided equipment. Provide appropriate wiring and raceways

necessary for power and communication systems for owner-provided equipment.

Refer to Section 18A, Classroom Support Services for additional information.

Design Evaluation

The following information is required to evaluate the design:

Programming: Space planning and provisions for power distribution systems. Statement on

power distribution system layout and basis of design.

Schematic Design Phase: Design requirements and location of electrical rooms and closets.

Design intent for power distribution system including point of connections and modifications

to existing systems. Preliminary power one-line diagram and riser diagram. Electrical load

estimate. Outline specification.

Design Development Phase: Preliminary plans for electrical rooms and closets. Identify

equipment access pathways. Identify electrical EMF and noise mitigating requirements.

Provide electrical room ventilation provisions. Seismic and housekeeping pad design details.

Updated power one-line diagrams and riser diagrams. Preliminary load calculations. Draft

specifications.

Construction Document Phase: Finalize plans electrical rooms and closets. Final power

one-line diagrams and riser diagrams. Final detail drawings of sections, elevations, and

schedules for power distribution equipment. Completed load calculations. Completed

specifications.

Submittals

Provide standard industry submittal requirements.

Refer to requirements specified in related sections.

Products, Materials and Equipment

Refer to requirements specified in related sections

Installation, Fabrication and Construction

Refer to requirements specified in related sections.

END OF DESIGN GUIDE SECTION

REV:06 JUN2015

16E - 04

University of Washington Campus Engineering 2015

U NIVERSITY

OF

W ASHINGTON

Facilities Services

Design Guide

Electrical

Building Power Distribution

Laboratory Demand Load

REV:06 JUN2015

16E - 05

University of Washington Campus Engineering 2015

Typical Building Power Distribution Riser

REV:06 JUN2015

16E - 06

University of Washington Campus Engineering 2015

U NIVERSITY

OF

W ASHINGTON

Facilities Services

Design Guide

Electrical

Building Power Distribution

Typical Floor Electrical Room

REV:06 JUN2015

16E - 07

University of Washington Campus Engineering 2015

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Freight88 Freight Class CheatsheetDocument11 pagesFreight88 Freight Class Cheatsheetexamen707160% (5)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Home Automation SystemDocument18 pagesHome Automation SystemChandrika Dalakoti77% (13)

- Techinical Information Handbook Wire and Cable PDFDocument328 pagesTechinical Information Handbook Wire and Cable PDFctsak83% (6)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Fire Sprinkler Guide IBC 2015Document43 pagesFire Sprinkler Guide IBC 2015asdthu100% (5)

- Togaf Foundation Test BankDocument115 pagesTogaf Foundation Test Bankmike67% (3)

- Piping Stress Handbook PDFDocument381 pagesPiping Stress Handbook PDFDar FallNo ratings yet

- DC Healthcare Broch0208 Final PDFDocument16 pagesDC Healthcare Broch0208 Final PDFAshraf Nabil SanhouryNo ratings yet

- Habi Li Seetrai Ni Ngcenter, I Nc. 61 I Sabelrami R Oroad, Pur Ok6A, Tambo-Hi Napl Anon, I L I Ganci T Y, 9200telno. (063) 2250809Document11 pagesHabi Li Seetrai Ni Ngcenter, I Nc. 61 I Sabelrami R Oroad, Pur Ok6A, Tambo-Hi Napl Anon, I L I Ganci T Y, 9200telno. (063) 2250809Nestor S. ReEyesNo ratings yet

- Orion HP Frictionloss PDFDocument4 pagesOrion HP Frictionloss PDFSanthosh ThekkethottiyilNo ratings yet

- Comml Hi Rise PLMBG System DesignDocument4 pagesComml Hi Rise PLMBG System DesignNestor S. ReEyesNo ratings yet

- Mastering Electrical EngineeringDocument361 pagesMastering Electrical EngineeringRuiVagner100% (13)

- Valves Piping and Pipelines Handbook PDFDocument694 pagesValves Piping and Pipelines Handbook PDFangel gabriel perez valdezNo ratings yet

- HVAC Procedures Forms ManualDocument279 pagesHVAC Procedures Forms Manualgeneroso67100% (12)

- On DWVDocument4 pagesOn DWVNestor S. ReEyesNo ratings yet

- HVAC Chilled Water Distribution SchemesDocument56 pagesHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- PlumbingDocument208 pagesPlumbingBenson AnselmoNo ratings yet

- Codes of Practice for Fire Service InstallationsDocument187 pagesCodes of Practice for Fire Service Installationswholook275No ratings yet

- Smoke Control in Very Tall Buildings - PastDocument4 pagesSmoke Control in Very Tall Buildings - PastNestor S. ReEyesNo ratings yet

- Electrical Design Manual: December 2015Document72 pagesElectrical Design Manual: December 2015gl1188No ratings yet

- Dew A Auxiliary Systems PresentationDocument37 pagesDew A Auxiliary Systems PresentationNestor S. ReEyesNo ratings yet

- UntitledDocument128 pagesUntitledapi-61200414No ratings yet

- Discrimination and Harassment SlideshowDocument36 pagesDiscrimination and Harassment SlideshowAnit SharmaNo ratings yet

- Introduction To Green Building 20jan18Document48 pagesIntroduction To Green Building 20jan18Nestor S. ReEyesNo ratings yet

- LL242Document42 pagesLL242philipsdNo ratings yet

- Welding and Cutting Safety GuideDocument25 pagesWelding and Cutting Safety GuideAnonymous XybLZfNo ratings yet

- Crisis Management A Leadership Challenge Kaufman08Document68 pagesCrisis Management A Leadership Challenge Kaufman08Rizky ArdaniNo ratings yet

- ForkliftDocument71 pagesForkliftNestor S. ReEyesNo ratings yet

- Arc Flash Case StudyDocument28 pagesArc Flash Case StudyNestor S. ReEyesNo ratings yet

- Welding, Cutting and BrazingDocument24 pagesWelding, Cutting and BrazingAjesh Kumar MuraleedharanNo ratings yet

- Workplace Violence Prevention PolicyDocument115 pagesWorkplace Violence Prevention PolicyNestor S. ReEyesNo ratings yet

- Welding Safety Kemp Rev909Document64 pagesWelding Safety Kemp Rev909Nestor S. ReEyes100% (1)

- Preventing Harassment in Workplace TrainingDocument37 pagesPreventing Harassment in Workplace TrainingNestor S. ReEyesNo ratings yet

- IPECS 50 Innstallation ManualDocument58 pagesIPECS 50 Innstallation ManualpeterNo ratings yet

- City Walk'-A Shopping Hub at Shaheed Udyan, Varanasi: SynopsisDocument4 pagesCity Walk'-A Shopping Hub at Shaheed Udyan, Varanasi: SynopsisjioijNo ratings yet

- infoPLC Net ErrorCodes 2015-02-05Document556 pagesinfoPLC Net ErrorCodes 2015-02-05Ivan Cordero ValerianoNo ratings yet

- Smoke Control - SimplifiedDocument15 pagesSmoke Control - SimplifiedHermi DavidNo ratings yet

- Win Shuttle Transaction Required SAP AuthorizationsDocument2 pagesWin Shuttle Transaction Required SAP Authorizationsb092840No ratings yet

- Ds 8 K Tool Announcement PresentationDocument17 pagesDs 8 K Tool Announcement PresentationAshish KuvawalaNo ratings yet

- How McAfee Took First Step To Master Data Management SuccessDocument3 pagesHow McAfee Took First Step To Master Data Management SuccessFirst San Francisco PartnersNo ratings yet

- Bidirectional Visitor CounterDocument17 pagesBidirectional Visitor CounterPankaj KumarNo ratings yet

- Housekeeping Work CardsDocument15 pagesHousekeeping Work Cardsmanish sharma33% (3)

- Converting shipping containers into sewage treatment unitsDocument1 pageConverting shipping containers into sewage treatment unitsSyafiq KamaluddinNo ratings yet

- Resume - Jeremy DeLaBruereDocument1 pageResume - Jeremy DeLaBruerejeremyd82No ratings yet

- Apache HIVEDocument105 pagesApache HIVEhemanth kumar p100% (1)

- Yokogawa ManualDocument60 pagesYokogawa ManualBrijesh SrivastavNo ratings yet

- Socket ProgrammingDocument19 pagesSocket Programmingmsanees005No ratings yet

- C Pipe SupportDocument25 pagesC Pipe Supportsanjay421100% (2)

- Log Book - Ansal School of Architecture - Docx 4t Year PDFDocument7 pagesLog Book - Ansal School of Architecture - Docx 4t Year PDFsameen rizviNo ratings yet

- SIP Easy For The Schneider PowerLogic ION6200Document2 pagesSIP Easy For The Schneider PowerLogic ION6200sahil4INDNo ratings yet

- 6FC5 297-6AD10-0BP1 SINUMERIK 810 840 Hardware Configuration CCUsDocument148 pages6FC5 297-6AD10-0BP1 SINUMERIK 810 840 Hardware Configuration CCUsSam eagle goodNo ratings yet

- Bridge Chap 2Document34 pagesBridge Chap 2Tesfamichael AbathunNo ratings yet

- 14 Sebastien Dudek HomePlugAV PLCDocument51 pages14 Sebastien Dudek HomePlugAV PLCntcaseNo ratings yet

- Maintaining Nursery QualityDocument5 pagesMaintaining Nursery QualityIndu LekhaNo ratings yet

- Building Construction ARP-431: Submitted By: Shreya Sood 17BAR1013Document17 pagesBuilding Construction ARP-431: Submitted By: Shreya Sood 17BAR1013Rithika Raju ChallapuramNo ratings yet

- Catalog of LayerZero Power Systems ProductsDocument9 pagesCatalog of LayerZero Power Systems ProductsLayerZeroNo ratings yet

- GHJFHDocument7 pagesGHJFHVarun Tank100% (1)

- Dr. Ommid Saberi - WSPDocument20 pagesDr. Ommid Saberi - WSPJack ZackNo ratings yet

- Enson: Ar. Johnny V. Henson Uap Ar. Gabrielle Jan S. Henson UapDocument1 pageEnson: Ar. Johnny V. Henson Uap Ar. Gabrielle Jan S. Henson UapBrylle De GuzmanNo ratings yet

- FRP Skylight Subcontractor ListDocument2 pagesFRP Skylight Subcontractor ListjimdabrondNo ratings yet