Professional Documents

Culture Documents

Aeration, Coagulation and Flocculation Processes in Water Treatment Plant: Case Study Water Treatment Plant Around Maiduguri, Borno State Nigeria.

Uploaded by

AJER JOURNALOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aeration, Coagulation and Flocculation Processes in Water Treatment Plant: Case Study Water Treatment Plant Around Maiduguri, Borno State Nigeria.

Uploaded by

AJER JOURNALCopyright:

Available Formats

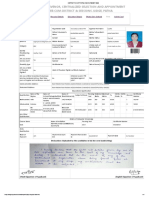

American Journal of Engineering Research (AJER)

2016

American Journal of Engineering Research (AJER)

e-ISSN: 2320-0847 p-ISSN : 2320-0936

Volume-5, Issue-1, pp-150-153

www.ajer.org

Research Paper

Open Access

Aeration, Coagulation and Flocculation Processes in Water

Treatment plant: Case Study Water Treatment Plant around

Maiduguri, Borno State Nigeria.

1

Hussaini A Abdulkareem, 2Bitrus Auta and 1Nuhu Abdullahi

Department of Mechanical Engineering School of Industrial Engineering College of Engineering

Kaduna Polytechnic, Nigeria .

2

Applied Science Department School of Science and Technical Education College of Science and Technology

Kaduna Polytechnic, Nigeria

Abstract: The paper identify and explain three of the most commonly use processes of enhancing the quality

and purity of water treatment namely aeration which is the process that provides oxygen from the atmosphere to

effect beneficial changes in the raw water such as taste, odor and colour, coagulation that is the addition of

chemical substances to water in order to aid settlement of the dissolved particles, by forming large floc and

flocculation which is use of gentle stirring in water, which floc has formed to induce the particles to coalesce

and grow into bigger and denser floc particles, for quicker increase of the rate of settlement.

I.

INTRODUCTION

Absolutely pure water is rarely found in existence in nature, and man cannot exist without water, so

there has always been a demand for pure portable water. (3) Most waters have to be purified before they can be

used for portable purposes. Raw water is so infinitely variable in quality, that there is no fixed starting point to

the treatment process, and within much narrower limits, there is any rigidly fixed finishing point either. There is

virtually no water that is impossible to purify into potable standards. To slake man's thirst, drinking water must

be whole some and palatable. Accordingly it may be free from disease-producing organisms and poisonous or

physiological undesirable substances[1].

The source of raw water determines its inherent quality, the quality of which is difficult to foresee, hence there

is the need to collect samples of the raw water for a certain period of time and carry out some tests to ascertain

the characteristic purities of the raw water and the relative quantity of each impurity. Naturally occurring water

can generally be classified as; groundwater, or surface water. Each has its own characteristic, but in general,

ground water is the purest form of water available, and may not require much treatment compared to its

counterpart (surface water). The associated impurities of surface and ground waters can be classified as shown

in table 1.

It is worthwhile to look into, what processes actually take place in these stages, and the components required for

the processes. The processes, which take place, are governed by certain scientific theories relating to the

behavior of the liquid particles, and the impurities associated, with them in the various purification stages.

This can generally be outlined as; screening; raw-water storage; pre-chlorination; aeration; algal control;

straining; preliminary setting; mixing; coagulations; flocculation; settlement, filtration and sterilization. In this

presentation we shall only look at aeration, coagulations and flocculation processes.

II.

AERATION

This treatment process provides oxygen from the atmosphere to effect beneficial changes in the raw

water. At the same time it may liberate undesirable gases such as carbon dioxide, hydrogen. The principle

behind this is that of mixing the raw water with normal air from the atmosphere to replenish or add to the raw

water quality. This trend generally improves the water taste, odor, and colour and may also affect the killing of

some pathogens. This is usually done by splashing the water over trays to break up the stream into countless

droplets or by reversing the effect and blowing air bubbles through the water.

Gases are absorbed or liberated front water until equilibrium is reached between the natural content of each gas

in there and its content in the water [1].

www.ajer.org

Page 150

American Journal of Engineering Research (AJER)

2016

Aerators are commonly found to be necessary if any of the following conditions are present in the raw water.

(a) Hydrogen sulphide (tests, odor etc.);

(b) Carbon dioxide (corrosive tendencies);

(c) Test due to algal growth (caused by volatile oils release);

(d) Iron and Manganese in solution;

(e) De-aeration

(f) Above increase oxygen content, while (a) (b) liberate excess gas.

III.

COAGULATION

Coagulation can be said to be the addition of chemical substances to water in order to aid settlement of

the dissolved particles, by forming large floc. (Gelatinous precipitates). There are many substances which react

suitably with water to produce such an effect and these are known collectively as coagulants, examples of these

are A12 (SO4)3.18 H2O, known as alum (Aluminum sulphate), ferrous sulphate or FeSO4.7H2O sodium

Aluminates etc. [l]. Use of additional chemicals, which while not themselves true coagulants, intensify and

improve floc formation otherwise called coagulant aids. Coagulants should be added immediately downstream

of any re-setting basin which may have been considered necessary. Their primary purpose is to assist in the

removal of the more finely divided sediment and colloids. Most of the larger and heavier particles settle unaided

in the pre-settling basin thus permitting the coagulants to work more efficiently on the finer particles [1].

Where floc formation is poor, or for reasons of overall economy, coagulant aids may be added. By producing a

heavier faster-setting floc, this allows small basins to be used, and smaller doses of the main coagulants may

also be possible. The choice of the best coagulant for any particular water is determined by experiment [1].

Immediately coagulants are introduced into the water, rapid mixing is essential. Floc starts to form and

immediately after this, the water is stirred very gently for the fine particles adhere to each other and grow into

settle-able floc. This gentle stirring action occurs to some degree naturally in all basins but can be greatly

accentuated by methods designed to encourage the rolling action required. [1]

Certain designs of basins are multi-chambered and therefore flocculation does not infact proceed more

separately than might appear to be the case at first glance. The pH of water is very vital in coagulation because,

it indicates the right type of coagulant and dosage required to form the heaviest floc at the waters characteristic

pH value, which can also be determined using the jar test. Acid waters i.e. those having a pH of 5-6.5 are often

difficult to clarify, due to the high dosage of coagulants and alkalis required. Waters of pH between 6.2 - 7 with

a reasonable degree of alkalinity reacts well with aluminum sulphate. Alkaline waters with PH values of 7 - 7.8

may again be difficult and absorb high doses of alum. [1]

www.ajer.org

Page 151

American Journal of Engineering Research (AJER)

2016

Coagulants can be added to the water either as a solution, which is the commonest way or in powder or

slurry form. As treatment is a continuous process, dosing must also proceed in continuous and controlled

fashion. The types of feed of coagulants can generally be classified as solution feeds and dry feeders. The two

essential parts of solution feed system comprise a tank in which a solution of the correct strength may be stored

and closing rate or flow controller. The tank should hold 24 hours supply and be duplicated so that one tank may

be in service while the other is being replenished. There should be some sort of continues stirring mechanism to

reduce the risk of settlement after initial preparation. Many coagulants (particularly ferric chloride and alum) are

corrosive and the tanks should be lined with acid resisting material, commonly rubber, glass or special cement.

The dosing mechanism should be capable of being controlled manually. There are two kinds of dosers: gravityfeed, and displacement pumps or tippers. The rate of flow can be altered in the former by altering the length of

piston stroke of the specially made plunger pumps. The speed at which tippers operate can also be regulated. In

big works of sophisticated design, dosing is automatically controlled. A dry feeder incorporates a hopper which

contains the feeds measuring device; this often takes the form of a revolving table from which a scraper of

adjustable length deflects a greater or lesser amount of powder into the raw water. If the powder is not very

soluble it may be mixed with water and fed as slurry. In humid/tropical conditions, trouble by caking is

sometimes experienced on dry feeders and for this reason solution feeders are preferred. Most mixers lend

themselves to automation, with the rate of flow of coagulate dependent on the rate of flow of water through the

works on a small or unsophisticated works where the rate of flow tends to be constant, the simplicity of manual

regulation is much to be preferred [1]. The design considerations for coagulation are basically that of knowing

the right amount or dosage of chemicals to be added and the time taken for such a treatment.

IV.

FLOCCULATION

Flocculation as a means of further improvement in the water is a relatively new invention, which

emerged in about the 19thcentury. This is the process whereby the water purification stage of coagulation is

further enhanced by the rotating members to form large floc which become heavy and easy to settle in the

bottom of the tank [5]. The use of gentle stirring in water, which floc has formed to induce the particles to

coalesce and grow is known as flocculation. The bigger and denser the floc particles, the quicker are the rate of

settlement. The source of power for flocculating devices are mechanical and pneumatically. Generally speaking,

seldom used in large plants, even though they possess quite useful features ([2].

When the dosed water carrying floc finally passes into the flocculator through the inlet port, a certain rolling

motion is inevitable, which can be accentuated by baffles in Horizontal flow basin or in an upward flow basin

by the sludge blanket [1].

However in many basins there is ample evidence that better results can be obtained if mixing and flocculation

can be intensified. In recent years much research has been done on both and sound theoretical rules have been

laid down. There are methods of theoretical approach, the mixing and flocculation can be carried out either by

mechanical means in specially built chambers or in suitable baffled channel or interconnected chambers. The

latter methods requires no mechanical equipment but lacks flexibility, because the system can be designed for

maximum efficiency only at one rate of flow and at one temperature, where-as the speed of mechanical paddles

can be adjusted to suit the variations of flow, temperature and silt conditions. However, the cost added to the

complexity of mechanical equipment introduces additional complications to be avoided in a developing country,

and in practice a sinuous inlet channel preceded by violent mixing generally provides a reasonable effective

solution [1]. If the pipe or channel through which the incoming water enters the basin is so dimensioned as to

ensure a velocity greater than 1m/s, and if the channel or directed at an end wall so that the flow is forced to

reverse abruptly through 180o, any coagulant introduced into the water before that sudden reversal will be

adequately mixed and flock will form almost instantaneously.

Unlike the absolute necessity for thorough mixing, the need for flocculation as a separate process may or may

not be essential much depends on the nature of the suspended solids. For rivers carrying coarse and heavy

sediment the main problem is to prevent the silt settling and blocking the inlet channels before it reaches the

basin [1].

Shallow depth settling may present operational difficulties in developing countries, so separate flocculators are

mostly found before conventional horizontal flow basins where colloids are a problem and the complication of

additional machinery may be avoided by having the flocculating action imparted to the water by the gently

rolling motion resulting from passing water along a sinuous channel. In practice a channel providing a velocity

of flow of about 0.3m/s with cross-walls ensuring 12-20 changes of direction though 180o (with well rounded

corners), has often proved to be very effective. The emphasis must be placed on the comparative smoothness of

flow required. Under no circumstances should velocity or turbulence be such as to break up the floc this can be

seen in fig. 1 below. Similarly table: 1 show the recommended GT values for flocculation.

www.ajer.org

Page 152

American Journal of Engineering Research (AJER)

2016

Fig: 1 Sinous Flow Channel

TABLE 1: RECOMMENDED GT VALUES FOR FLOCCULATION [1]

V.

CONCLUSION

The need for pure water for human use and consumption cannot be overemphasis. Different method

and processes for water treatment to meet up with the world health organization standard (WHO) for a portable

drinking water are available both in the literature and practical applications. However in this presentation three

of the most widely used and the most cost effective have been identify particularly within a villages and small

communities with surface water sources. That is aeration which explain the principle of pass air into the water

under certain condition with a view to liberate undesirable gases such as carbon dioxide, hydrogen and also

improves the water taste, odor, and colour and may also affect the killing of some pathogens. While coagulation

involve the addition of chemicals such as alum to water in order to aid settlement of the dissolved particles, by

forming large floc. This is followed by gentle stirring by rotating members to form large floc which become

heavy and easy to settle in the bottom of the tank referred to as flocculation.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

Smsrthurst G.: Basic Water Treatment 1997; Thomas Telford Ltd, London

M. Fair, Gordon/C. Geyer, John/A. Okun, Daniel. Water and Waste water Engineering Vol.1, 1968, John Willey and Sons Inc.

James G. V.: Water Treatment. Lorch: Handbook of Water Purification 1981, McGraw-Hill (UK), (London; | New York :)

M. Fair, Gordon/C. Geyer, John/A. Okun, Daniel; Water and Waste water Engineer Vol. 2, 1968, John Willey and Sons Inc.

Mogarr, F: Water and Waste Water Utilization in Hot Climate

Dunn, P.D.: Appropriate Technology 1978, MacMillan Press Ltd

Ernest, F. B, Horace W. K, James E. L, C. Y. Wei; Handbook of Hydraulics 1996, McGraw-Hill

Wilcork, Dennis: Water Engineering (March 1, 1996), McGraw-Hill Education; 7 editions

Maria J. Ferrua, R. Paul Singh; Understanding the fluid dynamics of gastric digestion using Computational modeling, Procedia

Food Science 1 (2011) 1465 1472, 11th International Congress on Engineering and Food ICEF11

www.ajer.org

Page 153

You might also like

- Questions Bank For Molecular Biology Answer Sheet PDFDocument51 pagesQuestions Bank For Molecular Biology Answer Sheet PDFsajjad hussainNo ratings yet

- Sine and Cosine Exam QuestionsDocument8 pagesSine and Cosine Exam QuestionsGamer Shabs100% (1)

- Hemodynamic MCQ From GhadeerDocument3 pagesHemodynamic MCQ From GhadeerKehkashan Khan100% (1)

- Body Fluids & ElectrolytesDocument26 pagesBody Fluids & ElectrolytesMohamad Zekry Zuhairy100% (1)

- Identify The Choice That Best Completes The Statement or Answers The QuestionDocument14 pagesIdentify The Choice That Best Completes The Statement or Answers The QuestionCamille BaybayNo ratings yet

- Rbcs Modifie 2Document6 pagesRbcs Modifie 2Habib UllahNo ratings yet

- Renal MCQ 4Document10 pagesRenal MCQ 4AzizNo ratings yet

- Keb Combivis 6 enDocument232 pagesKeb Combivis 6 enhaithamNo ratings yet

- Method Statement Pressure TestingDocument15 pagesMethod Statement Pressure TestingAkmaldeen AhamedNo ratings yet

- Part 1 Examination in Medical Microbiology and Virology Sample MCQs and EMQsDocument7 pagesPart 1 Examination in Medical Microbiology and Virology Sample MCQs and EMQsLian BaylosisNo ratings yet

- Fluids and Electrolytes MCQ S LJDocument5 pagesFluids and Electrolytes MCQ S LJVicviclookThekingNo ratings yet

- 004 Pathology MCQ ACEM Primary CellularDocument3 pages004 Pathology MCQ ACEM Primary CellularbmhshNo ratings yet

- PACL Lodha Commette Final NOTICE of SALE With Property DetailsDocument4 pagesPACL Lodha Commette Final NOTICE of SALE With Property DetailsVivek Agrawal100% (2)

- 1989 Volvo 740 Instruments and ControlsDocument107 pages1989 Volvo 740 Instruments and Controlsskyliner538No ratings yet

- MCQs On AutoimmunityDocument8 pagesMCQs On AutoimmunityShatabdi A Chakravarty100% (1)

- MCQ FMS 4 (2016) With AnswersDocument13 pagesMCQ FMS 4 (2016) With Answersstella pangestikaNo ratings yet

- Medical SemiologyDocument8 pagesMedical SemiologyCpopNo ratings yet

- Paraproteins A Review Article and MCQ'sDocument10 pagesParaproteins A Review Article and MCQ'slataseyaniNo ratings yet

- Renal MCQDocument6 pagesRenal MCQMikiyas TeferaNo ratings yet

- Porphyria QuestionsDocument3 pagesPorphyria QuestionsDana0% (1)

- MCQS CNS PathologyDocument14 pagesMCQS CNS PathologyFourth YearNo ratings yet

- 017 Pathology MCQ ACEM Primary GITDocument3 pages017 Pathology MCQ ACEM Primary GITRebeenMustafaNo ratings yet

- Public Health COC ExamDocument19 pagesPublic Health COC ExamTut Kong RuachNo ratings yet

- BOTANY Mycology, Microbiology P-II .MCQDocument11 pagesBOTANY Mycology, Microbiology P-II .MCQFarheen Iqbal100% (1)

- Amy MCQsDocument3 pagesAmy MCQsHamid Iqbal100% (1)

- Clinical Pathology and General Pathology - Paper IDocument1 pageClinical Pathology and General Pathology - Paper IrichuNo ratings yet

- Haematology Mcq1Document9 pagesHaematology Mcq1CallumNo ratings yet

- MCQs On Urinary Tract InfectionDocument5 pagesMCQs On Urinary Tract InfectionTofik Mohammed100% (1)

- 4 2 PDFDocument9 pages4 2 PDFMahtab KhalifpourNo ratings yet

- RBC DiorderDocument13 pagesRBC DiorderHabib UllahNo ratings yet

- Tropical MCQS: C. Visceral LeishmaniasisDocument29 pagesTropical MCQS: C. Visceral Leishmaniasisساره ابوالقاسمNo ratings yet

- Ic2 HLTM Jan 2008 MCQDocument9 pagesIc2 HLTM Jan 2008 MCQhela mahjoubNo ratings yet

- Parasitology Lec ExamDocument6 pagesParasitology Lec ExamArianne Joy C. TamarayNo ratings yet

- Tissue healing mcq pathologyDocument2 pagesTissue healing mcq pathologyM.ruhan ShafiqNo ratings yet

- Acid Base Balance Quiz AnswersDocument3 pagesAcid Base Balance Quiz AnswersAishwarya BharathNo ratings yet

- Hemoglobin Determination: Cyanmethemoglobin MethodDocument31 pagesHemoglobin Determination: Cyanmethemoglobin Methodبراءة أحمد السلاماتNo ratings yet

- UTI MCQDocument10 pagesUTI MCQHomman TommanNo ratings yet

- Practical Lecture GIT Module PathologyDocument25 pagesPractical Lecture GIT Module Pathologyjwan ahmedNo ratings yet

- Iyamu Et Al 2011Document8 pagesIyamu Et Al 2011drojiehgodwinNo ratings yet

- Glycolysis MCQs: Net ATP Yield & Key EnzymesDocument7 pagesGlycolysis MCQs: Net ATP Yield & Key Enzymessherazahmedroy0% (1)

- MCI Screening Test 2005Document46 pagesMCI Screening Test 2005Iboyaima SinghNo ratings yet

- MCQ Block 13Document15 pagesMCQ Block 13Liliana Surya Fatimah0% (1)

- Microbiology (Chapter - Immunology) Solved MCQs (Set-1)Document5 pagesMicrobiology (Chapter - Immunology) Solved MCQs (Set-1)خلطة علومNo ratings yet

- Bio Chem Important MCQsDocument4 pagesBio Chem Important MCQsAbdullahNo ratings yet

- Pathanatomy Full MCQ SDocument47 pagesPathanatomy Full MCQ SAbhishek RaoNo ratings yet

- Final ExamsDocument16 pagesFinal ExamsSadru Prince SnigleNo ratings yet

- Urinary RenalDocument44 pagesUrinary RenalgorekaNo ratings yet

- Bichem Module - 1-2014 With 1 and 2Document41 pagesBichem Module - 1-2014 With 1 and 2Mukunda MurariNo ratings yet

- PathoDocument12 pagesPathoola nagarNo ratings yet

- Acid Fast Stain MCQsDocument2 pagesAcid Fast Stain MCQsMahi ShafiqueNo ratings yet

- Topics of Systematic Pathology (To Be Taught in The Second Term)Document8 pagesTopics of Systematic Pathology (To Be Taught in The Second Term)Gamal DawoodNo ratings yet

- MCQ InfectionsDocument10 pagesMCQ Infectionsعلي الكوافيNo ratings yet

- Bacteriology McqsDocument11 pagesBacteriology McqsRimsha Naveed100% (2)

- MCQ on Acute and Chronic InflammationDocument2 pagesMCQ on Acute and Chronic InflammationPrahul100% (1)

- 8 - Measels & RubellaDocument5 pages8 - Measels & Rubellaamen shanavasNo ratings yet

- Immunology MCQ BY: Dr. AlgassimDocument4 pagesImmunology MCQ BY: Dr. AlgassimmohamedNo ratings yet

- Module 1. General and Special Questions of Clinical Laboratory Diagnostics Text Test QuestionDocument229 pagesModule 1. General and Special Questions of Clinical Laboratory Diagnostics Text Test QuestionA.h.MuradNo ratings yet

- Book Back MCQDocument51 pagesBook Back MCQClinton ThomasNo ratings yet

- Diuretics Mcqs ExplainedDocument2 pagesDiuretics Mcqs ExplainedHawi BefekaduNo ratings yet

- Dunne TheuseofStreamingCurrentMonitorsinoptimisingcoagulantdosageinWater CERIProceedings PDFDocument7 pagesDunne TheuseofStreamingCurrentMonitorsinoptimisingcoagulantdosageinWater CERIProceedings PDFAna Carolina FrançaNo ratings yet

- Design of A Water Treatment Mechanical Mixer For A Pre-Chlorination Tank As An Effective Algae Control, Aeration and Coagulation ProcessingDocument12 pagesDesign of A Water Treatment Mechanical Mixer For A Pre-Chlorination Tank As An Effective Algae Control, Aeration and Coagulation ProcessinginventionjournalsNo ratings yet

- Water Conditioning Processes 1. Distillation: Distilled Water Herbicides PesticidesDocument6 pagesWater Conditioning Processes 1. Distillation: Distilled Water Herbicides PesticidesClintNo ratings yet

- Water PurificaitonDocument13 pagesWater PurificaitonbekkuNo ratings yet

- Jar TestDocument3 pagesJar Testkhairil akramNo ratings yet

- The Differentiation Between The Turbulence and Two-Phase Models To Characterize A Diesel Spray at High Injection PressureDocument7 pagesThe Differentiation Between The Turbulence and Two-Phase Models To Characterize A Diesel Spray at High Injection PressureAJER JOURNALNo ratings yet

- Performance Analysis of LTE in Rich Multipath Environments Considering The Combined Effect of Different Download Scheduling Schemes and Transmission ModesDocument6 pagesPerformance Analysis of LTE in Rich Multipath Environments Considering The Combined Effect of Different Download Scheduling Schemes and Transmission ModesAJER JOURNALNo ratings yet

- Experimental Investigation On The Effects of Digester Size On Biogas Production From Cow DungDocument6 pagesExperimental Investigation On The Effects of Digester Size On Biogas Production From Cow DungAJER JOURNALNo ratings yet

- Pixel Based Off-Line Signature Verification SystemDocument6 pagesPixel Based Off-Line Signature Verification SystemAJER JOURNALNo ratings yet

- Comparative Analysis of Cell Phone Sound Insulation and Its Effects On Ear SystemDocument6 pagesComparative Analysis of Cell Phone Sound Insulation and Its Effects On Ear SystemAJER JOURNALNo ratings yet

- Production and Comparartive Study of Pellets From Maize Cobs and Groundnut Shell As Fuels For Domestic Use.Document6 pagesProduction and Comparartive Study of Pellets From Maize Cobs and Groundnut Shell As Fuels For Domestic Use.AJER JOURNALNo ratings yet

- Switching of Security Lighting System Using Gsm.Document12 pagesSwitching of Security Lighting System Using Gsm.AJER JOURNALNo ratings yet

- Structure and Surface Characterization of Nanostructured Tio2 Coatings Deposited Via HVOF Thermal Spray ProcessesDocument9 pagesStructure and Surface Characterization of Nanostructured Tio2 Coatings Deposited Via HVOF Thermal Spray ProcessesAJER JOURNALNo ratings yet

- Experimental Evaluation of Aerodynamics Characteristics of A Baseline AirfoilDocument6 pagesExperimental Evaluation of Aerodynamics Characteristics of A Baseline AirfoilAJER JOURNALNo ratings yet

- An Evaluation of Skilled Labour Shortage in Selected Construction Firms in Edo State, NigeriaDocument12 pagesAn Evaluation of Skilled Labour Shortage in Selected Construction Firms in Edo State, NigeriaAJER JOURNALNo ratings yet

- Improved RSA Cryptosystem Based On The Study of Number Theory and Public Key CryptosystemsDocument7 pagesImproved RSA Cryptosystem Based On The Study of Number Theory and Public Key CryptosystemsAJER JOURNALNo ratings yet

- Recycling of Scrapped Mating Rings of Mechanical Face SealsDocument5 pagesRecycling of Scrapped Mating Rings of Mechanical Face SealsAJER JOURNALNo ratings yet

- Minimizing Household Electricity Theft in Nigeria Using GSM Based Prepaid MeterDocument11 pagesMinimizing Household Electricity Theft in Nigeria Using GSM Based Prepaid MeterAJER JOURNALNo ratings yet

- Unmanned Aerial Vehicle and Geospatial Technology Pushing The Limits of DevelopmentDocument6 pagesUnmanned Aerial Vehicle and Geospatial Technology Pushing The Limits of DevelopmentAJER JOURNALNo ratings yet

- A Concept of Input-Output Oriented Super-Efficiency in Decision Making Units.Document6 pagesA Concept of Input-Output Oriented Super-Efficiency in Decision Making Units.AJER JOURNALNo ratings yet

- The Role of Citizen Participant in Urban Management (Case Study: Aligudarz City)Document6 pagesThe Role of Citizen Participant in Urban Management (Case Study: Aligudarz City)AJER JOURNALNo ratings yet

- An Exponent-Based Propagation Path Loss Model For Wireless System Networks at Vehicular SpeedDocument12 pagesAn Exponent-Based Propagation Path Loss Model For Wireless System Networks at Vehicular SpeedAJER JOURNALNo ratings yet

- Weighted Denoising With Multi-Spectral Decomposition For Image CompressionDocument13 pagesWeighted Denoising With Multi-Spectral Decomposition For Image CompressionAJER JOURNALNo ratings yet

- Utilization of "Marble Slurry" in Cement Concrete Replacing Fine AgreegateDocument4 pagesUtilization of "Marble Slurry" in Cement Concrete Replacing Fine AgreegateAJER JOURNALNo ratings yet

- WHY JESUS CHRIST CAME INTO THE WORLD?... (A New Theory On "TIE MINISTRY")Document12 pagesWHY JESUS CHRIST CAME INTO THE WORLD?... (A New Theory On "TIE MINISTRY")AJER JOURNALNo ratings yet

- Statistical Method of Estimating Nigerian Hydrocarbon ReservesDocument10 pagesStatistical Method of Estimating Nigerian Hydrocarbon ReservesAJER JOURNALNo ratings yet

- Theoretical and Experimental Study of Cavitation Dispersing in "Liquid-Solid" System For Revelation of Optimum Influence ModesDocument10 pagesTheoretical and Experimental Study of Cavitation Dispersing in "Liquid-Solid" System For Revelation of Optimum Influence ModesAJER JOURNALNo ratings yet

- The Design and Implementation of A Workshop Reservation SystemDocument7 pagesThe Design and Implementation of A Workshop Reservation SystemAJER JOURNALNo ratings yet

- Eye State Detection Using Image Processing TechniqueDocument6 pagesEye State Detection Using Image Processing TechniqueAJER JOURNALNo ratings yet

- Urbanization and The Risk of Flooding in The Congo Case of The City of BrazzavilleDocument6 pagesUrbanization and The Risk of Flooding in The Congo Case of The City of BrazzavilleAJER JOURNALNo ratings yet

- DMP Packet Scheduling For Wireless Sensor NetworkDocument8 pagesDMP Packet Scheduling For Wireless Sensor NetworkAJER JOURNALNo ratings yet

- Distinct Revocable Data Hiding in Ciphered ImageDocument7 pagesDistinct Revocable Data Hiding in Ciphered ImageAJER JOURNALNo ratings yet

- Frequency Selective Fading in Wireless Communication Using Genetic AlgorithmDocument6 pagesFrequency Selective Fading in Wireless Communication Using Genetic AlgorithmAJER JOURNALNo ratings yet

- Risk Assessment and Risk MappingDocument7 pagesRisk Assessment and Risk MappingAJER JOURNALNo ratings yet

- Head Determination and Pump Selection For A Water Treatment Plant in Villages Around Maiduguri, Borno State, NigeriaDocument5 pagesHead Determination and Pump Selection For A Water Treatment Plant in Villages Around Maiduguri, Borno State, NigeriaAJER JOURNALNo ratings yet

- Drug Delivery Technologies and Future DirectionsDocument14 pagesDrug Delivery Technologies and Future Directionsraju1559405No ratings yet

- OWASP Dependency-Check Plugin: DescriptionDocument10 pagesOWASP Dependency-Check Plugin: DescriptionFelipe BarbosaNo ratings yet

- IPIECA - IOGP - The Global Distribution and Assessment of Major Oil Spill Response ResourcesDocument40 pagesIPIECA - IOGP - The Global Distribution and Assessment of Major Oil Spill Response ResourcesОлегNo ratings yet

- The Three Key Linkages: Improving The Connections Between Marketing and SalesDocument5 pagesThe Three Key Linkages: Improving The Connections Between Marketing and SalesRuxandra PopaNo ratings yet

- Long Standoff Demolition Warheads For Armor, Masonry and Concrete TargetsDocument27 pagesLong Standoff Demolition Warheads For Armor, Masonry and Concrete Targetsahky7No ratings yet

- GTA Max Profit Bunker Locations Update v1.4Document1 pageGTA Max Profit Bunker Locations Update v1.4Sam FarrelNo ratings yet

- DrainHoles - InspectionDocument14 pagesDrainHoles - Inspectionohm3011No ratings yet

- Raj Priya Civil Court Clerk FinalDocument1 pageRaj Priya Civil Court Clerk FinalRaj KamalNo ratings yet

- Attribute Achievement FormDocument15 pagesAttribute Achievement FormMiguel MenesesNo ratings yet

- MinistopDocument23 pagesMinistopAlisa Gabriela Sioco OrdasNo ratings yet

- Job Interview CV TipsDocument2 pagesJob Interview CV TipsCarlos Moraga Copier100% (1)

- KEC115/6/7x: Ac Generator Short Circuit and Over Current GuardDocument4 pagesKEC115/6/7x: Ac Generator Short Circuit and Over Current GuardRN NNo ratings yet

- VNACS Final Case ReportDocument9 pagesVNACS Final Case ReportVikram Singh TomarNo ratings yet

- Making An Appointment PaperDocument12 pagesMaking An Appointment PaperNabila PramestiNo ratings yet

- De Thi Thu Tuyen Sinh Lop 10 Mon Anh Ha Noi Nam 2022 So 2Document6 pagesDe Thi Thu Tuyen Sinh Lop 10 Mon Anh Ha Noi Nam 2022 So 2Ngọc LinhNo ratings yet

- Environmental ScienceDocument5 pagesEnvironmental Sciencearijit_ghosh_18No ratings yet

- Guidelines To MAS Notice 626 April 2015Document62 pagesGuidelines To MAS Notice 626 April 2015Wr OngNo ratings yet

- How To Retract BPS Data Back To R3 When There Is No Standard RetractorDocument3 pagesHow To Retract BPS Data Back To R3 When There Is No Standard Retractorraphavega2010No ratings yet

- MCS Adopts Milyli Software Redaction Tool BlackoutDocument3 pagesMCS Adopts Milyli Software Redaction Tool BlackoutPR.comNo ratings yet

- Case NoDocument13 pagesCase NoLaurente JessicaNo ratings yet

- Mechanical Function of The HeartDocument28 pagesMechanical Function of The HeartKarmilahNNo ratings yet

- Aditi Pant Internship ReportDocument14 pagesAditi Pant Internship ReportDR.B.REVATHYNo ratings yet

- Adjective: the girl is beautifulDocument15 pagesAdjective: the girl is beautifulIn'am TraboulsiNo ratings yet

- Berserker - Lifting Wood and Stone Like A Viking Strongman Bodybuilding Functional StrengthDocument10 pagesBerserker - Lifting Wood and Stone Like A Viking Strongman Bodybuilding Functional Strengthluciferr71No ratings yet

- Lab 1 Boys CalorimeterDocument11 pagesLab 1 Boys CalorimeterHafizszul Feyzul100% (1)