Professional Documents

Culture Documents

PACE 3000 Service Manual PDF

Uploaded by

Krum KashavarovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PACE 3000 Service Manual PDF

Uploaded by

Krum KashavarovCopyright:

Available Formats

1.

Preface, safety regulations

2. System

description

SPACE 3000

Service Manual

3.

2.1 Overview

2.2 Functions

2.3 Components

2.4 Terminal

2.5

2.6

Delivery settings

4. Troubleshooting

4.1 Troubleshooting methods

8

9

Repairs

5. Periodical

inspections

6. Connecting

accessories

Settings

7.

4.2 Troubleshooting SPACE

10

4.3

11

4.4 Repairs

12

4.5

13

5.1 Service

14

5.2

15

6.1 Connecting accessories

16

6.2 Settings

17

6.3

18

6.4

19

SPACE information

20

SPACE 3000, Service manual

1 Preface, safety regulations

1 Preface, safety regulations

Contents

Preface......................................................................................... 3

Safety regulations ......................................................................... 4

Read this for your safety .................................................... 4

Excluded personnel ........................................................... 4

Extract from EN12999:2000 ............................................... 5

Extract from EN12644-1 .................................................... 6

2000-12-20

SPACE 3000, Service manual

1 Preface, safety regulations

2000-12-20

SPACE 3000, Service manual

1 Preface, safety regulations

PREF

ACE

PREFACE

This service manual describes the microprocessor

controlled electronic safety system, which is used to

control the various functions on a HIAB crane.

The information in this manual is divided into seven

different main sections. Some of the sections are

divided into subsections.

The new structure of the binder will make it easier for

you, the service engineer in the HIAB organisation, to

find the information you are looking for.

If for example a customer wants to have a winch

mounted on his crane, all information regarding electrical connection and changing of settings will be found

under section 6.1 Connecting accessories.

If you want to learn more about how the system works

all information regarding function and components will

be found under section 2 System description.

We hope that you will like the improved layout of the

manual.

If there is something regarding the information or

structure in the manual that you think could be improved please let us know. Your information will be of

great value to us and will be used when updating the

manual.

HIAB AB,

Product support dept.,

Technical documentation

2000-12-20

SPACE 3000, Service manual

1 Preface, safety regulations

SAFETY REGULA

TIONS

REGULATIONS

Read this for your safety

The HIAB Cargo Handling Equipment can be hazardous if it is not operated correctly. Make sure you read

and understand the general safety information given in

this chapter.

The equipment must be operated in accordance with

the instructions given in the relevant Operators

Manual. Using the equipment in any other way or for

any other purpose is prohibited.

Warnings, cautions, notes and tips are given in this

manual. Their meanings are as follows:

WARNING

A Warning is given where wrong action could result in

death or injury to the operator and nearby personnel.

Warnings must always be adhered to, and given

precedence over written and verbal instructions as well

as Cautions.

CAUTION

A Caution is given where wrong action could result in

damage to the equipment. Cautions must always be

adhered to, and given precedence over Notes, and

written and verbal instructions.

NOTE!

A note emphasises an important piece of information or

an instruction.

Warnings and Cautions that apply to the general

operation of the HIAB Cargo Handling

Equipment are given in the relevant Operators Manual.

TIP!

Tip to make work easy to carry out.

Excluded personnel

Untrained personnel must not operate or carry out

repairs to the Cargo Handling Equipment.

2000-12-20

SPACE 3000, Service manual

1 Preface, safety regulations

Extract from EN12999:2000

7.2.4

Maintenance manual

7.2.4.1

The manual shall contain information and

instructions to ensure that maintenance can

be carried out safely, and foreseen hazards

which may occur shall be noted.

Information and drawings for the identification

of parts which may need replacement during

maintenance shall be shown.

The manual shall include information for the

in-service inspections and tests that are

required to be carried out by a competent

person to ensure that the crane is safe to

use. The instructions shall detail the

necessary periodic checks and tests

procedures for the crane and the limiting and

indicating devices. Specific time period and/

or monitoring procedures may be listed.

The manual shall contain instructions on

examinations and tests which shall be

carried out after alterations or repairs to a

crane before putting back into use.

7.2.4.2

The manufacturer shall provide advice how to

disconnect tubing and lines when pressure

may be retained in the hydraulic lines when

the power supply has been switched off.

7.2.4.3

The manual shall include information on

materials and parts requiring specialized

repairing techniques (e.g. welding at low

temperature).

2000-12-20

SPACE 3000, Service manual

1 Preface, safety regulations

Extract from EN12644-1

5.5

Maintenance instructions (preventative

and corrective)

This section shall include:

a) drawings and parts lists as appropriate

b) preventative maintenance tasks and

intervals

c) safety precautions during maintenance

d) maintenance parameters (pressure

settings, torque values, rope discard

criteria, tolerances, etc.)

e) checklists, test values and associated

schematic diagrams

f) reference to specialist repair processes

g) reference to special tools

h) checks, inspections, examinations and

tests, which are needed in accordance

with the design of the crane, including the

safe conditions for carrying them out, with

advice for the recording of all defects and

incidents

NOTE!

Guidance for periodical checks,

inspections, examinations and tests is

given in ISO 12480-1.

i) criteria and, if appropriate, adequate

records to enable determination of the

approach to the design constraints of the

cranes components. If specific indicating

or recording devices are used to achieve

this, instructions for use and maintenance

are to be given

NOTE!

Futher guidance is given in ISO 12482-1.

2000-12-20

SPACE 3000, Service manual

1 Preface, safety regulations

j) precautions required to maintain the crane

for significant periods of non-use (on site

or dismantled)

k) where appropriate, the examination and

test programme after a significant period

of non-use, the necessary action before

using the orane (such as lubricating,

cleaning components, check of electric

wiring etc.). The same, or a specific

programme, shall apply following severe

weather condition

NOTE!

Further guidance is given in ISO 12480-1.

l) repair conditions or reference to the

manufacturer for advice. The instruction

handbook shall draw attention to and wam

against servicing of the crane by nonspecialised personnel, and to replacement

parts which are not guaranteed in

accordance with the manufacturers

specification

NOTE!

Guidance for the content of spare parts

manual is given in ISO 10973.

m) conditions which are allowed to repair the

elements of the crane instead of replacing

them. ln this situation the manufacturer

needs to consider if the original fitness for

purpose result can still be valid after

certain repairs. Those components which

are needed for preventative maintenance

shall be listed in the handbook. Any

necessary reference and source of

supply, together with replacement

procedures and tools that are needed

shall also be given.

Before first use of any crane it shall be

verified by a visual assessment that

instruction handbook(s) have been

provided in accordance with this

standard.

2000-12-20

SPACE 3000, Service manual

1 Preface, safety regulations

2000-12-20

SPACE 3000, Service Manual

2.1 Overview

2.1 Overview

Contents

General......................................................................................... 3

SPACE ......................................................................................... 4

CAN-Communication ......................................................... 4

Standard box (SPACE box) ................................................ 4

User interface .................................................................... 5

Column box ........................................................................ 5

Sensors ............................................................................. 5

Indicators ........................................................................... 5

Dump valve ........................................................................ 6

Signalling components ....................................................... 6

Function ....................................................................................... 7

SPACE Operating Principles ............................................. 7

Switch on ................................................................ 7

Beginning Operation ............................................... 8

During Operation .................................................... 8

SPACE, system overview .................................................. 9

2000-12-20

SPACE 3000, Service Manual

2.1 Overview

2000-12-20

SPACE 3000, Service Manual

2.1 Overview

GENERAL

SPACE 3000 is a microprocessor controlled electronic

safety system used to control the various functions on

a HIAB crane (Fig. 1).

SPACE stands for:

S = Speed

P = Payload

A = Accessories

C = Certificate

E = Electronics

SPACE 3000 contains a microprocessor that is the

system's "brain". On the crane there are various

sensors and indicators which send signals to the

microprocessor regarding the crane's load, position

and movements.

This then decides how the crane can be operated and

stops or reduces unpermitted movements and speeds.

SPACE 3000

1070-328

To utilise all the functions in SPACE 3000 a control

valve type 91 is required, however the 50 type control

valves can be used with reduced SPACE functions.

ADC

Fig. 1

2000-12-20

SPACE 3000, Service Manual

2.1 Overview

SP

ACE

SPACE

(Fig. 2)

A CL/DUO system consists of e.g.:

1

1

Standard box (microprocessor)

2

User interface

Empty box

Column box

Pressure sensors

4

Indicators

Dump valve

Spool sensors.

5

ADC

A Space 3000 PRO system also include:

Extended box

SPACE 3000

MSC valve

The modules are connected in a star-shaped pattern

with the Standard box in its centre.

1070-327

CAN-Communication

The Standard box, the User interfaces and other

components such as Cabin warning are with 7-wire

shielded cables. The modules use a CAN-bus for

communication. It was developed for the automotive

industry with high demands on reliability and suppression of disturbances. The CAN-bus uses two wires, but

will still function if one of them is interrupted or shorted

to a permanent voltage.

1. Tilt indicators

2. Pressure sensors

3. Column box

4. Slewing sector indicators

5. Standard box

6. Dump valve

7. Spool sensors

Fig. 2

Standard box

The Standard box is the heart of the system. The

microprocessor monitors crane operation.

Main power supply is connected to the Standard box.

2000-12-20

SPACE 3000, Service Manual

2.1 Overview

User interface

(Fig. 3)

The User interface is the communication centre of the

SPACE 3000. It gives information about the system

and is also where the user controls the system.

The User interface is located on the Standard box and

on an empty box. It can also be located on an

Extended box (if present). Maximum four User

interfaces can be fitted on a crane.

The information from pressure sensors, tilt indicators

etc. on the boom system is assembled in the Column

box on the loader body. The Column box is connected

to the Standard box with a 9-conductor cable.

SPACE 3000

1070-316

Column box

ADC

Fig. 3

Indicators

An indicator gives an on/off signal, which correspond to

e.g. the position of outer boom.

The inner boom and outer boom indicators (option on

certain cranes) give the position of the inner boom and

outer boom. The slewing sector indicators (option on

certain cranes) give information of slewing position of

the crane.

Sensors

A sensor gives an analogue signal, which correspond

to e.g. the pressure in the inner boom cylinder.

The pressure sensors register the pressures in the

inner boom and outer boom cylinders.

The spool sensors gives information of the position of

the spools.

2000-12-20

SPACE 3000, Service Manual

2.1 Overview

Dump valve

(Fig. 4)

The dump valve controls the oil flow:

When active, oil goes to the control valve

When inactive, i.e. without power, this flow stops and

all crane functions stop.

Signalling components

Fig. 4

It is possible to connect additional warning lamps and

sounders to the HIAB cranes. The Cabin warning is a

popular factory fitted option, giving a warning to the

operator both from the truck cab and externally, that the

boom system is pointing upwards and should be

lowered before moving the truck.

Many of the additional warning systems are installed by

the equipment installers and designed to exact

customer requirements.

2000-12-20

SPACE 3000, Service Manual

2.1 Overview

FUNCTION

SP

ACE Operating

SPACE

Principles

The purpose of this section is to give a brief overview of

the basic principles employed in the operation of the

SPACE system. It is not intended to be an accurate

description of a particular system, but a familiarisation

section for the engineer who has not worked with

SPACE before or one who has maybe not been in

contact with a full SPACE system for sometime.

Switch on

(Fig. 5)

SPACE is switched on by pressing the ON/OFF button

on the User interface.

If the button is pressed for more then 2 s when system

is switched on the lamp test is activated, as long as

the button is pressed all red LEDs light, when

released all red LEDs continue to light for 3 s then all

green LEDs light for 3 s.

ADC

10

70

-3

31

SPACE 3000

Fig. 5

2000-12-20

SPACE 3000, Service Manual

2.1 Overview

Beginning operation

(Fig. 6)

When operation begins with the movement of a control

valve lever, the spool sensor for the relevant spool

sends a signal to the Standard box. A signal is then

sent from the Standard box to the dump valve which

will open, allowing oil to enter the valve and the

hydraulic function to begin.

SPACE 3000

1070-325

ADC

Fig. 6

During operation

100%

90%

1070-314

(Fig. 7)

Whilst the crane is operating SPACE monitors signals

sent from the spool sensors, tilt indicators and pressure sensors. In the event of any of the signals moving

outside the pre-determined parameters set in SPACE,

a warning is given that the crane has reached 90% of

it's capacity the red LEDs 1-3 on the User interface

will flash. If operation continues to increase the loading

of the crane the signal to the dump valve will be

switched off and crane operation will cease. The red

LEDs 1-4 will be lit constantly. SPACE will now wait

for an operation command that will reduce the loading

on the crane and operation will restart automatically.

SPACE will not accept any command that will increase the loading of the crane once OLP has been

activated.

Fig. 7

2000-12-20

SPACE 3000, Service Manual

2.1 Overview

SP

ACE, system overview

SPACE,

This table shows the possible connections between

the four different crane types and control systems,

valves and remote controls.

Control System

Crane type

V50

V50 RD

CL

SPACE 3000

SPACE

DUO

SPACE 3000

SPACE

PRO

HI PRO

2000-12-20

V91

V91 CD 5000

SPACE 3000

SPACE 5000

SPACE 3000, Service Manual

2.2 Functions

2.2 Functions

Contents

General......................................................................................... 3

Functions ..................................................................................... 4

Overload protection (OLP) ................................................. 4

OLP Basic crane .................................................... 4

OLP Winch ............................................................. 5

OLP Manual extensions .......................................... 5

OLP Disconnection ................................................ 5

Automatic Duty Control (ADC) ................................ 6

Manual Speed Control (MSC) ................................. 6

Automatic Dumping of Oil (ADO) ............................ 7

Stability ............................................................................... 8

Slewing Sector ........................................................ 8

Fixed platform ......................................................... 9

Cabin warning ......................................................... 9

Automatic damping on slewing (ADS) .................... 9

2000-12-20

SPACE 3000, Service Manual

2.2 Functions

2000-12-20

SPACE 3000, Service Manual

2.2 Functions

GENERAL

This section contains functions that SPACE 3000 is

equipped with as a standard for the majority of cranes.

This section also describes a number of functions that

can be obtained with the accessories supplied by

HIAB and options that are only program possibilities in

SPACE 3000. HIAB has no standard solutions how to

apply sensors e.g.

Please contact HIAB for information of supply sources

of these components.

2000-12-20

SPACE 3000, Service Manual

2.2 Functions

FUNCTIONS

Overload protection (OLP)

OLP Basic crane

100%

90%

1070-314

LEDs on the User interface (Fig. 1) show the increased

load in the inner or outer boom cylinders. At 100% load

OLP cuts in, stopping moment increasing movements.

The LEDs have a steady red light until the overload

situation is over .

Boom movements that increase the cranes load

moment to 100% are stopped as set out in Fig. 2

and 3.

Fig. 1

When the outer boom is directed upwards (Fig. 2):

inner boom downwards

outer boom downwards

extension outwards

inner boom upwards (if OLP-pressure in the inner

boom cylinder).

Fig. 2

When the outer boom is directed downwards

(Fig. 3):

inner boom upwards

outer boom upwards

extension outwards

inner boom downwards. Applies only if:

crane has mechanical link

OLP-pressure in inner boom cylinder

Fig. 3

inner boom angle more than 25.

2000-12-20

SPACE 3000, Service Manual

2.2 Functions

OLP Winch

When winch reaches 90% of permitted load the winch

LED on the User interface starts flashing. At 100%

load OLP cuts in, stopping load increasing movements. The LED has a steady red light until the

overload situation is over.

When the wire is almost completely unwound (three

turns left on drum) winch lowering is stopped. Operator

has to winch in to reverse situation.

OLP Manual extensions

(Fig. 4)

When using manual extensions the button shall be

pressed and the LED will have a steady green light.

NOTE!

For information how to change OLP-settings

for manual extensions, see section 6.2

Settings.

ADC

-3

31

SPACE 3000

70

In certain OLP-situations the crane boom can be

locked. It is possible to disconnect the OLP for approx

5 seconds.

Press the "RELEASE" button (Fig. 5), while moving

one control lever (time starts to "count" when you

move the lever). The red LED will flash.

During this period it is possible to operate a suitable

crane function to correct the overload situation. Only

one unallowed function at a time can be operated.

Extension out can't be operated.

There is a waiting time of 30 seconds before the

release operation can be activated again.

Fig. 4

10

OLP Disconnection

Fig. 5

2000-12-20

SPACE 3000, Service Manual

2.2 Functions

Automatic Duty Control (ADC)

ADC

ADC

SPACE 3000

1070-335

(Fig. 6)

Automatic Duty Control (ADC) is a patent pending

function in SPACE 3000/5000.

The purpose of ADC is that the crane knows in which

type of lifting mode it is.

SPACE will automatically calculate the maximum

lifting capacity in each lifting mode so that the crane

will be used in an optimised way without any risk of

overloading the crane structure.

ADC is sensed by the spool sensor on the sixth lever

or if function winch is used.

If sixth lever or winch is used ADC will automatically be

chosen again after 60 seconds inactivity in these

functions.

ADC is automatically chosen at start up, which is

indicated by a LED on the user interface.

ADC increases the lifting capacity without any

reduction in lifting speed. In winch mode the lifting

capacity is increased.

Fig. 6

1070

Manual Speed Control (MSC) is a function in SPACE

3000, which is protected by patent.

When the capacity of the crane is calculated the

speed of the crane is an essential factor. If the speed

is reduced, the capacity can be increased without any

risk of overloading the crane structure.

On cranes with Manual Speed Control (MSC) SPACE

3000 continuously receives signals from pressure

sensors on inner and outer boom cylinders. When the

load is above approx. 90 % of the maximum allowed

load, SPACE activates MSC by opening a hydraulic

valve. The speed of the function is reduced to 25% in

one step.

MSC will be automatically switched off when the load

in cylinder decreases.

When MSC is activated the maximum stroke in the

spool is hydraulically reduced in both directions. The

operator will notice that the lever movement will be

reduced.

MSC increases the lifting capacity depending on type

of crane.

-337

Manual Speed Control (MSC)

Fig. 7

MSC is only available on cranes fitted a 91-valve and

an Extended box.

2000-12-20

SPACE 3000, Service Manual

2.2 Functions

Automatic Dumping of Oil

(ADO)

To prevent high pressure and thereby unnecessary

heating of the oil there is an automatic dumping

function. When no lever movement has been made for

3 seconds SPACE opens the dump valve and the oil is

returned directly to the hydraulic tank. As soon as the

operator moves a lever the valve closes.

2000-12-20

SPACE 3000, Service Manual

2.2 Functions

Stability

Slewing Sector

When the truck has insufficient stability in a certain

sector, e. g. in front of the cabin indicators can be

fitted defining this sector (Fig. 8). The system is

programmed to allow only reduced load in the indicated sector. For load sensing inner boom cylinder

pressure is used.

This function is optional on certain cranes.

If you slew the crane into a reduced sector with too

much load the OLP will cut in and slewing stops.

You may now slew the crane back or operate according to normal OLP logic.

If you lift a load in a reduced sector and OLP cuts in, it

is possible to use normal OLP logic, but possible to

slew out of the sector only on the side where you

came into the sector.

1070-043

It is possible to define two different slewing sectors,

each with different load capacity. In addition there is

the normal sector with 100% capacity.

Fig. 8

NOTE!

For information how to set parameters

when using a special slewing sector

sector,, see

section 6.2 Settings.

2000-12-20

SPACE 3000, Service Manual

2.2 Functions

Fixed platform

(Fig. 9)

Fixed platform is known in some countries as Stand up

platform.

It is possible to connect this function to SPACE. It will

prevent the operator from slewing the boom into the

fixed platform or themselves.

Slewing sector, inner boom and outer boom angle

indicators are used to define permitted lifting areas

when operating the crane from fixed platform.

This function is only available on cranes fitted with an

Extended box.

NOTE!

For information how to set parameters, see

section 6.2. Settings.

Fig. 9

Cabin warning

Signal in the cabin (normally a lamp) is possible if one

of following conditions is fulfilled:

the system is ON and the stop button is pulled out

the system is ON and tilt indicator indicates "UP"

the system is OFF and the tilt indicator indicated

"UP" when powering off (provided there is current to

the lamp kit).

Even if the truck battery has been disconnected when

the inner boom was positioned to high the system will

remember that and the lamp in the cabin will light up

when the driver start the truck again.

Automatic damping on slewing

(ADS)

On crane with extended box it is possible to connect

ADS to the system. ADS is a system that

automatically reduces the oscillations in the slewing

function of cranes with many extensions.

ADS consists of two pressure sensors and one valve

which make it possible to move oil between piston side

and piston rod side of slewing cylinder.

2000-12-20

SPACE 3000, Service Manual

10

2.2 Functions

2000-12-20

SPACE 3000, Service Manual

2.3 Components

2.3 Components

Contents

General......................................................................................... 3

Boxes and sensors ...................................................................... 4

Connection plinths ............................................................. 4

Grease ............................................................................... 4

Bar code signs ................................................................... 4

Connection diagram ........................................................... 5

CL/DUO crane ........................................................ 5

PRO crane ............................................................. 6

Standard box ...................................................................... 7

Function .................................................................. 7

Connection plinths .................................................. 8

Jumpers ................................................................ 10

User interface ................................................................... 11

Function ................................................................. 11

Buttons .................................................................. 11

Indicator LEDs ..................................................... 12

Connection plinths ................................................ 14

Jumpers ................................................................ 15

Column box ...................................................................... 16

Function ................................................................ 16

Connection plinths ................................................ 16

Extended box ................................................................... 18

Function ................................................................ 18

Connection plinths ................................................ 19

Operation ................................................................................... 20

Jumper settings ............................................................... 20

Channels and connection plinths ..................................... 21

Slewing sector indicators ................................................. 22

Function ................................................................ 22

2000-12-20

SPACE 3000, Service Manual

2.3 Components

Spool sensor .................................................................... 22

Winch box ........................................................................ 23

Function ................................................................ 23

Logic operation................................................................. 24

Plug ....................................................................... 24

Connection plinths ................................................ 25

2000-12-20

SPACE 3000, Service Manual

2.3 Components

GENERAL

This section contains components that SPACE 3000

is equipped with as a standard and also describes a

number of accessories supplied by HIAB for the

majority of cranes.

2000-12-20

SPACE 3000, Service Manual

2.3 Components

BOXES AND SENSORS

Boxes and sensors are moulded in with plastics.

The size of cable inlets are PG9 or PG 13.5.

Connection plinths

The connection boxes in SPACE 3000 consist of a

case with several cable inlets and a cover that is

mounted with screws. Under the cover there are

different types of connection plinths depending on the

box type.

The connections are marked with e.g. P2.1, P2.2,

P2.3 in pictures and wiring diagrams (Fig 1).

P2 is the connection plinth.

.1 is plinth number 1 which normally is the first from

left seen from the cable side.

Grease

Fig. 1

All the boxes, plinths and connections should be

greased. Use grease of type Statoil SG32W Grease

way or SHELL GREASE 1398 Si2, a white oil with a

non-organic additive for thickening.

Bar code signs

Almost all SPACE 3000 components are marked with

bar code signs (Fig. 2). All the boxes have two signs,

one inside and one outside the box. On the sign there

is one bar code and figures for sub supplier, one bar

code and figures for serial number of the component or

box and one bar code and figures for the part number

of the component. The components name or an

abbreviation is written in English.

Fig. 2

2000-12-20

SPACE 3000, Service Manual

2.3 Components

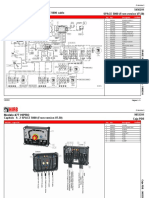

Connection diagram

The connection diagrams is show example of a CL/

DUO crane (Fig. 3) and a PRO crane (Fig. 4).

Below the diagrams are component lists.

CL/DUO crane

1. Tilt indicator, inner boom

2. Pressure sensor, inner boom

3. Tilt indicator, outer boom (option on certain cranes)

4. Pressure sensor, outer boom

5. Column box

6. Fixed platform angle indicator, inner boom (option on certain cranes)

7. Fixed platform angle indicator, outer boom (option on certain cranes)

8. Winch indicators (winch box) (option on certain cranes)

9. User interface 1

10. Standard box

11. Dump valve

12. Horn (option on cranes with outreach below 12 m)

13. Slewing sector indicators (option on certain cranes)

14. Terminal connection

15. On platform indicator (option on certain cranes)

16. Spool sensor (2 spools)

17. Spool sensor (4 spools)

18. Empty box

19. User interface 2

Fig. 3

2000-12-20

SPACE 3000, Service Manual

2.3 Components

PRO crane

4

6

5

2

8

1

23

22

24

25

21

10

26

24 V 11

17

16

12

1070-321

20

19

15

14

13

18

1. Tilt indicator, inner boom

2. Pressure sensor, inner boom

3. Tilt indicator, outer boom (option on certain cranes)

4. Pressure sensor, outer boom

5. Column box

6. Fixed platform angle indicator, inner boom (option on certain cranes)

7. Fixed platform angle indicator, outer boom (option on certain cranes)

8. Winch indicators (winch box) (option on certain cranes)

9. User interface 3

10. Empty box

11. Dump valve

12. Horn (Option on cranes with outreach below 12 m)

13. Slewing sector indicators (option on certain cranes)

14. Spool sensor (2 spools)

15. Spool sensor (4 spools)

16. Dump valve 91M (option on certain cranes)

17. MSC valve 91M (option on certain cranes)

18. Cabin warning (option on certain cranes)

19. Pressure sensor ADS (option on certain cranes)

20. Valve ADS (option on certain cranes)

21. Extended box

22. User interface 2

23. User interface 1 (option on certain cranes)

24. Standard box

25. Terminal connection

26. On platform indicator (option on certain cranes)

Fig. 4

2000-12-20

SPACE 3000, Service Manual

2.3 Components

Standard box

Function

(Fig. 5)

The Standard box is the central unit of the system. It

supplies power to all the other units in the system. It

consists of two parts, a connection terminal board and

a display.

The Standard box distributes power to all the other

modules of the system. Nominal supply is 24 V DC,

but the system will be fully operational between

16V32V.

There is two a digit indicator (A) in the box which

displays a number if an error should occur in the

system and the number of errors.

Example: The digit 4 and a dot, followed by 03 without

a dot indicates that there are four errors and the lowest

number of these is no. 03.

If there are no errors the number 0 flashes.

The Standard box is aquipped with several automatic

fuses and one 7.5 A automotive fuse (B).

Fig. 5

2000-12-20

SPACE 3000, Service Manual

2.3 Components

Connection plinths

(Fig. 5)

Plinth

Description

P1

From Spool sensors 1-4

P3

Communication with terminal

P1.1

Ground

P3.1

Ground

P1.2

24 V

P3.2

24 V

P1.3

Signal from spool sensor 1 (0-5 V)

P3.3

Data out

P1.4

Signal from spool sensor 2 (0-5 V)

P3.4

Data in

P1.5

Signal from spool sensor 3 (0-5 V)

P1.6

Signal from spool sensor 4 (0-5 V)

P4

From on platform indicator/manual

extension in indicator

P2

From Spool sensors 5-6

P4.1

Ground

P2.1

Ground

P4.2

24 V

P2.2

24 V

P4.3

Signal from on platform indicator

P2.3

Signal from spool sensor 5 (0-5 V)

P2.4

Signal from spool sensor 6 (0-5 V)

Fig. 5

2000-12-20

SPACE 3000, Service Manual

P5

From Column box

P8

To horn

P5.1

Ground

P8.1

Ground

P5.2

24 V

P8.2

24 V ( 2 A)

P5.3

Signal from inner boom pressure sensor

(4-20 mA)

P9

To dump valve

P9.1

Ground

P9.2

24V

P10

Power in

P10.1

Ground to truck

P10.2

24 V from truck, 10A

P5.4

Signal from outer boom pressure sensor

(4-20 mA)

P5.5

Signal from outer boom tilt indicator

(10 or 19 mA)

P5.6

Signal from inner boom tilt indicator

(10 or 19 mA)

P5.7

Signal from winch indicator (4-20 mA)

P5.8

Signal from second inner boom tilt indicator

or inner & outer boom fixed platform angle

indicator (0/24 V)

Signal from hydraulic extension in indicator

or second tilt indicator (0/24 V)

P5.9

P6

From slewing sector 1/2

P6.1

Ground

P6.2

24 V

P6.3

Signal from indicator 1, positive (0/24 V)

P6.4

Signal from indicator 1, negative (0/24 V)

P6.5

Signal from indicator 2, positive (0/24 V)

P6.6

Signal from indicator 2, negative (0/24 V)

P7

CAN (From/to user interface 1)

P7.1

Ground

P7.2

24 V

P7.3

CAN +

P7.4

CAN -

P7.5

Emergency stop out

P7.6

Emergency stop in

P7.7

On/off

2000-12-20

2.3 Components

NOTE!

Only plinth P10 shows the 24 V supply from

truck.

All other plinths show lower voltage

depending on a filtering unit between them

and P10.

SPACE 3000, Service Manual

2.3 Components

Jumpers

(Fig. 6)

In the Standard box the jumpers are located in the

lower centre of the box. There is one row with five

jumpers.

The four jumpers to the right (B1-4) represent the

number of User interface in the system.

If all four jumpers are strapped, four interfaces are

connected.

The fifth jumper (I) is only for internal use, and

strapping it has no effect.

Fig. 6

10

2000-12-20

SPACE 3000, Service Manual

2.3 Components

User interface

Function

(Fig. 7)

The User interface is the communication centre of the

SPACE 3000. It gives information about the system

and is also where the user controls the system.

The User interface is mounted on the Standard box

and the extended box (if present). It can also be

mounted on an Empty box. Maximum four User

interfaces can be fitted on a crane.

Buttons

(Fig. 7)

1. Power On

Enables power to SPACE. If button is pressed for

more then 2 s when system is on the LED test is

activated, as long as the button is pressed all red

LED`s light, when released all red LED`s continue to

light for 3 s then all green LED`s light for 3 s.

Fig. 7

2. Release

Enables power to:

- OLP release if crane has OLP

- Dump valve/valves if not OLP, if Extended box

present also dump valve 2 (switched off after 10

minutes and when a crane function is used

dump valve 2 is always switched off).

3. Emergency stop

In danger the emergency stop button is pressed.

Power to the dump valve is cut and the crane stops.

The emergency stop button is to be turned

clockwise to reset.

4. Horn

Enables power to the horn if present.

5. Manual extension

Enables power to manual extension logic.

2000-12-20

11

SPACE 3000, Service Manual

2.3 Components

Indicator LEDs

4

5

6

There are also two groups of LED`s in the inner boom

and outer boom. Each group contain four LED`s. Two

are two-coloured, green/red, and two are red. The

purpose of the LED`s is to show the pressure in the

cylinders. For detailed information, see table below.

10

ADC

1070-339

(Fig. 8)

The display consists of eight LED`s which indicates

button positions, errors, stability sector, winch etc.

For detailed information, see table below.

SPACE 3000

9 8

7

1. Power On, green

2. Stab sector, green

3. Service/error, green/red

4. Inner boom pressure, green/red

5. Winch, red

6. ADC, green

7. Manual extension, green

8. Release, red

9. Release, green

10. Outer boom pressure, green/red

Fig. 8

12

2000-12-20

SPACE 3000, Service Manual

2.3 Components

LED

State

Meaning

1. Power On, green

On

Flash

System is on.

An emergency stop button is depressed, dump power to

space is interrupted or no jumper is strapped in user

interface.

2. Stab sector, green

On

Crane is in sector and capacity is lowered.

3. Service

Error

Green, on

Red, on

Red, flashing

Time for service of the crane.

Error detected in the system.

CAN communication error.

4. Inner boom pressure

All LED`s off

< 50 % of OLP pressure

Green LED 1 on

50 - 69 % of OLP pressure

Green LED`s 1-2 on

70 - 89 % of OLP pressure

Red LED`s 1-3 flashes 90 - 99 % of OLP pressure

Red LED`s 1-4 on

100 % of OLP pressure

5. Winch, red

Flashing

On

Flashing fast

90 % of OLP pressure

100 % of OLP pressure

The outer boom is over a given angle when the system is

switched off.

6. ADC, green

On

Crane is working with hook (added) capacity.

7. Manual extension, green On

Manual extension logic on.

8. Release, red

On

Flashing

OLP.

Release button pushed and allowed to run crane

(OLP case).

9. Release, green

On

Dump valve on.

10.Outer boom pressure

All LED`s off

< 50 % of OLP pressure

Green LED 1 on

50 - 69 % of OLP pressure

Green LED`s 1-2 on

70 - 89 % of OLP pressure

Red LED`s 1-3 flashes 90 - 99 % of OLP pressure

Red LED`s 1-4 on

2000-12-20

100 % of OLP pressure

13

SPACE 3000, Service Manual

2.3 Components

Connection plinths

(Fig. 9)

Plinth

Description

P1

CAN (From/to Standard box)

P1.1

Ground

P1.2

24 V

P1.3

CAN +

P1.4

CAN -

P1.5

Emergency stop out

P1.6

Emergency stop in

P1.7

On/off

P2

CAN (From/to Cover 2, Extended box)

P2.1

Ground

P2.2

24 V

P2.3

CAN +

P2.4

CAN -

P2.5

Emergency stop out

P2.6

Emergency stop in

P2.7

On/off

Fig. 9

14

2000-12-20

SPACE 3000, Service Manual

2.3 Components

Jumpers

(Fig. 10)

The jumpers are located in the higher right side of the

User interface. There is one row with five jumpers.

The four jumpers to the right (B1-4) tell the Standard

box which address the current User interface has.

Only one jumper should be strapped and each User

interface must have unique strapping.

The fifth jumper (I) is only for internal use, and

strapping it has no effect.

Fig. 10

2000-12-20

15

SPACE 3000, Service Manual

2.3 Components

Column box

Function

(Fig. 11)

This connection box is fitted to the crane column. All

the signals from the pressure sensors and indicators

(max. 7) on the boom system are collected in the box.

The Column box is connected to the SPACE box using

a 9-conductor cable.

Connection plinths

(Fig. 11)

P1

To Standard box

P1.1

Ground

P1.2

24 V

P1.3

Signal from inner boom pressure sensor

(4-20 mA)

P1.4

Signal from outer boom pressure sensor

(4-20 mA)

P1.5

Signal from outer boom tilt indicator

(10 or 19 mA)

P1.6

Signal from inner boom tilt indicator

(10 or 19 mA)

P1.7

Signal from winch indicator (4-20 mA)

P1.8

Signal from second tilt indicator or inner &

outer boom fixed platform angle indicator

(0/24 V)

P1.9

Signal from hydaulic extension in indicator

or second tilt indicator (0/24 V)

Fig. 11

16

2000-12-20

SPACE 3000, Service Manual

P2

From winch/manual extension in

indicator

P2.1

Ground

P2.2

24 V to winch indicators

P2.3

2.3 Components

P4

From pressure sensors/tilt indicators

P4.1

24 V to inner boom pressure sensor

P4.2

Signal from inner boom pressure sensor

(4-20 mA)

Signal from winch indicators (4-20 mA)

P4.3

24 V to outer boom pressure sensor

P2.4

Ground

P4.4

P2.5

24 V to outer boom fixed platform angle

indicator or hydraulic extension in indicator

Signal from outer boom pressure sensor

(4-20 mA)

P4.5

24 V to outer boom tilt indicator

P4.6

Signal from outer boom tilt indicator

(4-20 mA)

P4.7

24 V to inner boom tilt indicator

P4.8

Signal from inner boom tilt indicator

(4-20 mA)

P2.6

Connection to outer boom fixed platform

angle indicator (0/24 V) or hydraulic

extension in indicator

NOTE!

Outer boom fixed platform angle indicator

should be connected to P2.46 if no hydraulic extension in indicator is present in

system. If hydraulic extension in indicator is

present, outer boom fixed platform angle

indicator should be connected to P3.46

instead.

P3

From fixed platform angle indicators

P3.1

Ground

P3.2

24 V to inner boom fixed platform angle

indicator

P3.3

Signal from inner boom fixed platform angle

indicator (0/24 V)

P3.4

Ground

P3.5

Signal from P3.3, inner boom fixed platform

angle indicator (0/24 V)

P3.6

Signal from P3.3, inner boom fixed platform

angle indicator (0/24 V, if there is a jumper

between P3.5 and P3.6) or signal from outer

boom fixed platform angle indicator (0/24 V)

NOTE!

P3.3 and P3.5 are connected in series.

2000-12-20

17

SPACE 3000, Service Manual

2.3 Components

Extended box

Function

(Fig. 12)

The Extended box is present if Space 3000 is

equipped with MSC, ADS or external dump.

There is a digit indicator (A) in the box which display a

number if an error should occur in the system and the

number of errors. To interpret these numbers there is

an error list.

Example: The digit 4 and a dot, followed by 03 without

a dot indicates that there are four errors and the

lowest number of these is no. 03.

If there are no errors the number 0 flashes.

There is a row with five jumpers in the Extended box.

NOTE

The jumpers are only for internal use and

should under no circumstances be

strapped.

Fig.12

18

2000-12-20

SPACE 3000, Service Manual

2.3 Components

Connection plinths

P1

To ADS valve

P7

CAN (From/to extra boxes)

P1.1

Ground, not same potential as other ground.

P7.1

Ground

P1.2

24 V (1 A)

P7.2

24 V

P7.3

CAN +

P2

From ADS pressure 1

P7.4

CAN -

P2.1

24 V

P7.5

Emergency stop out

P2.2

Signal from pressure sensor (4-20 mA)

P7.6

Emergency stop in

P3

From ADS pressure 2

P3.1

24 V

P8

To dump 2 valve (V91M)

P3.2

Signal from pressure sensor (4-20 mA)

P8.1

Ground

P8.2

24 V (2 A)

P9

To MSC valve (V91M)

P9.1

Ground

P9.2

24 V (2 A)

P10

Extra sensor input

P10.1

Ground

P10.2

24 V

P10.3

Signal from extra Indicator (0/24 V)

P1

1

P11

To extra dump valve

P11.1

Ground

P11.2

24 V

P4

Extra sensor input

P4.1

Ground

P4.2

24 V

P4.3

Signal from extra indicator (0/24 V)

P5

From spool sensors 7-8

P5.1

Ground

P5.2

24 V

P5.3

Signal from spool sensor 7 (0-5 V)

P5.4

Signal from spool sensor 8 (0-5 V)

P6

CAN (From/to User interface 2)

P6.1

Ground

P6.2

24 V

P6.3

CAN +

P6.4

CAN -

P6.5

Emergency stop out

P6.6

Emergency stop in

2000-12-20

19

SPACE 3000, Service Manual

2.3 Components

OPERA

TION

OPERATION

Jumper settings

The Standard box and the different User interfaces

must be configured in the correct way otherwise the

system will not function.

The Standard box must know how many User faces

there are in the system.

Each User interface must have a unique address.

This example shows a system with two User interface.

(Fig. 13)

In the Standard box B1 and B2 are strapped

informing SPACE that two User interfaces are in the

system.

Fig.13

In User interface 1 (Fig. 14) B1 is strapped and in

User interface 2 B2 is strapped.

Fig.14

20

2000-12-20

SPACE 3000, Service Manual

2.3 Components

Channels and connection

plinths

This connection diagram shows the connection

between an input channel and its connection plinth in

Standard box (A) or Extended box (B).

E.g. C12=P5.4 in Standard box.

C 13

C 20

C 12

C 11

C 10

C 19

C9

C8

C 14

C 15

C 21 C 22

A

C5

C4

C3

C2

C1

C0

C 17 C 6

C7

1070-332

C 18

Fig.15

2000-12-20

21

SPACE 3000, Service Manual

2.3 Components

Slewing sector indicators

Function

The indicators are positioned on the crane to define a

slewing sector with insufficient stability. To define one

slewing sector two slewing sector indicators are

needed. On a crane it can be one or two slewing

sectors with different restricted load capacity. The

indicators are fitted on the crane column, above the

sector plates (Fig. 16).

The system is programmed to limit loads within these

sectors. The indicators are of the proximity type and

should be activated in the safe sectors (the plate

should be over the sensor). If the cable breaks SPACE

interprets this as if the crane is in the limited sector.

The indicators for slewing sector 1 and 2 are

connected to the Standard box (P6).

Fig.16

NOTE!

For information and settings, see section

Connecting accessories 6.1.

Spool sensor

1070

-342

(Fig. 17)

The spool sensors give information of the position of

the spools. There are two different spool sensors, one

for two spools and one for four spools. The sensors are

fitted directly on the valves.

NOTE!

For information and settings, see section

Settings 6.2.

22

Fig.17

2000-12-20

SPACE 3000, Service Manual

2.3 Components

Winch box

Function

The winch can be positioned on the loader body, inner

boom, outer boom, outer end of the crane, jib or the

outer end of the jib. OLP-logic is dependent on where

the winch is positioned.

The winch can have four indicators connected to a

special Winch box (Fig. 18) according to:

WTOP

Possible top block switch connected to

the screw terminal P2.

WEND

The switch three turns remaining is

connected to the screw terminal P3.

WLOAD

Torque switch is connected to the screw

terminal P4.

WDIS

Indicator wire completely wound in is

connected to screw terminal P5.

Indicators gives 24 V signal when not activated.

Plugs (A) may not be removed unless a winch

indicator is to be connected.

NOTE!

These plugs are different from the plugs in

the Column box.

The Winch box is connected to the SPACE system via

the Column box using a three-conductor cable

connected to the screw terminal P1.

Fig. 18

2000-12-20

23

SPACE 3000, Service Manual

2.3 Components

Logic operation

The 2-tonne winch has a torque indicator, WLOAD (1)

and a switch for three turns remaining WEND (2) as

standard (Fig. 19).

Winches can also be equipped with a WTOP indicator

(hook near the boom) and a WDIS indicator (cable fully

wound in).

If the indicator WLOAD is active it is not possible to

wind the winch in.

If the indicator WTOP is active it is only possible to

wind the winch out.

If the indicator WEND is active it is only possible to

wind the winch in.

If the indicator WDIS is active you can only operate the

winch by pressing the emergency override button. This

will allow you to run the winch for about 20 seconds.

Press the button again to continue. Waiting time does

not apply as it does with normal override operation.

Normally the winch is controlled from the 5th valve

function. If the winch is to be controlled from another

function, parameter changes are demanded.

Fig. 19

NOTE!

For information and settings, see section 6.1

Connecting accessories.

Plug

If you disconnect the winch and instead connect a tool

to the winchs valve function you must connect a plug

in the contact on the cable which runs between the

SPACE system and the winch box. This plug tells

SPACE that the winch is disconnected and that the

function should be regarded as a tool (Fig. 20).

Fig. 20

24

2000-12-20

SPACE 3000, Service Manual

2.3 Components

Connection plinths

(Fig. 21)

To Column box

P1

P1.1

Ground

P1.2

24 V

P1.3

Signal (4-20 mA, in steps) from winch

indicators

P2 - P5 From winch indicators

Px.1

Ground

Px.2

24 V

Px.3

Signal from winch indicator (0-24 V)

Fig. 21

2000-12-20

25

SPACE 3000, Service Manual

26

2.3 Components

2000-12-20

SPACE 3000, Service Manual

2.4 Terminal

2.4 Terminal

Contents

Handheld PC ................................................................................ 3

Equipment needed for HIAB terminal ................................. 4

New Users .............................................................. 4

HP95/200 Users ..................................................... 4

Things to be aware of when using a handheld PC ............. 5

Battery Power ......................................................... 5

Time Bug ................................................................ 5

Memory Cards ........................................................ 5

Installation of HIAB Windows CE terminal programs ......... 6

What is needed? ..................................................... 6

Installation ............................................................... 6

Windows CE terminal functions ................................................... 7

Login .................................................................................. 7

Main menu ......................................................................... 7

Init ...................................................................................... 7

Init System Overview .............................................. 8

Init Auto ................................................................... 8

Init Type .................................................................. 11

Init Levers .............................................................. 11

Calibrate ................................................................ 11

Variables .......................................................................... 12

Detailed ................................................................. 13

User Interface ....................................................... 13

Extended ............................................................... 14

Errors ............................................................................... 15

Error Counters ...................................................... 15

Parameters ...................................................................... 16

Change Par Value ................................................. 16

2000-12-20

SPACE 3000, Service Manual

2.4 Terminal

File ................................................................................... 16

Counters .......................................................................... 17

Service log ............................................................ 17

Reset Counters .................................................... 17

Dos terminal ............................................................................... 18

General ............................................................................ 18

Init Auto ................................................................. 18

Variable list ....................................................................... 22

Variables ..................................................................................... 22

OLP ................................................................................. 24

MSC ................................................................................. 24

Analogue inputs................................................................ 25

Levers .............................................................................. 25

Pressure sensors ............................................................ 26

Digital inputs .................................................................... 26

Stability ............................................................................. 28

Various ............................................................................. 28

Timers ........................................................................................ 29

Timer list .......................................................................... 29

Parameters ................................................................................ 30

Parameter list .................................................................. 30

OLP ................................................................................. 32

MSC ................................................................................. 33

Pressure sensors ............................................................ 33

Digital inputs .................................................................... 34

Stability ............................................................................. 35

Service ............................................................................. 36

Various ............................................................................. 37

2000-12-20

SPACE 3000, Service Manual

2.4 Terminal

HANDHELD PC

A Handheld PC is a small computer that has Windows

CE as its operating system.

The Handheld PCs has a lot of advantages:

1. Easy to use. If you know Windows, then you are

already familiar with Windows CE.

2. Cheaper than a Laptop.

3. Communication with a PC through serial cable.

Files can be copied to the PC and stored there.

Update of the HIAB terminal program versions will

be easier.

Fig. 1

4. Instead of a mouse there is a stylus pen used for

clicking directly onto the screen.

5. Handheld PCs have the Pocket Office version of the

ordinary Office package. If you write anything in for

example Pocket Word you can send that file to the

PC and read it in Word.

6. Its small size (approx the same size as a HP95)

and therefore easy to pack in a bag, compared to

the bulky Laptop.

HIAB will not produce any hardware for a specific

Handheld PC, this means that there will not be any

sort of special protection made for them.

2000-12-20

SPACE 3000, Service Manual

2.4 Terminal

Equipment needed for

HIAB terminal

New Users

PC System

PC, using Windows. With a 1,44 Mb Floppy drive.

PC Interface 365 0766 from HIAB. Includes

Interface, diskette with programs and instructions.

Handheld System

Handheld PC. Currently we support only Hewlett

Packard HP 680/690. Do not buy anything else but

these computers, since the programs depend very

much on the hardware of the Handheld PC,

especially the processor.

Handheld Interface 370 9426 from HIAB. Includes

Interface, diskette with Windows CE programs and

instructions.

HP95/200 Users

HIAB will continue to update the DOS programs to

work with the latest versions of Space boxes.

HP Interfaces 361 0888 and 367 3103 will remain as

spare parts.

2000-12-20

SPACE 3000, Service Manual

2.4 Terminal

Things to be aware of

when using a handheld PC

Battery Power

The Handheld PC does not get any power whatsoever

from the SPACE system, so it needs to have fully

charged batteries at all time.

The Handhelds have a feature that turns off the power

after between 15 minutes when on battery power. The

battery of a HP 690 lasts for 7-8 hours of continuous

use. If the battery is fully charged when starting a job

the battery power should not be a problem.

Charge the battery for the Handheld PC at all times

when it is not used, because if the battery is drained

all information is lost on the Handheld PC, and the

terminal programs must be reinstalled.

Battery is drained even if the Handheld PCs power is

switched off.

Fig. 2

Time Bug

Currently there is a time bug in Windows CE, when the

date is asked for in the programs the returned date

from Windows CE is incorrect.

Symptom:

S3000 CE.exe will not start due to an illegal year.

Wrong year in the file headers from files saved using

the HIAB terminal programs.

Solution:

Chose a city within USA when selecting Home City,

this cures the time problem. But set the date and time

to your date and time.

Memory Cards

HIAB will not sell memory cards for Handheld

systems. This is because the programs come on a PC

Diskette.

Handheld systems support the RAM cards that were

used for HP 95/200. An even better and cheaper

memory card is CompactFlash cards which have a

much higher storage capacity than RAM cards.

It is a good idea to put a backup of the terminal

programs onto a CompactFlash card so you dont

need to reinstall the HIAB terminal programs if the

battery is completely drained. Do also remember to

take backups of Crane.dat and Crane.s3d.

2000-12-20

SPACE 3000, Service Manual

2.4 Terminal

Installation of HIAB

Windows CE terminal

programs

What is needed?

A PC with Windows 95 or later.

A Handheld PC recommended from HIAB.

Installation programs. This comes with the Handheld

Interface as a PC Diskette.

Installation

This installation assumes that the program to install is

Space CE. Use the same procedure for the other

terminal programs.

1. Establish a connection between the PC and the

Handheld PC. Refer to the Handheld PC

manufacturers users guide for information regarding

this.

2. Insert the diskette labeled Handheld Installation

into the PC.

3. Copy Space CE.exe to a temporary folder on the

PCs hard drive.

4. Start the Space CE.exe that is now on the hard

drive. This will extract the installation files.

5. Start the newly extracted Setup.exe. Follow the

instructions on the screen.

6. When asked Install using default directory, answer

Yes.

7. Wait for the files to be installed on the Handheld

PC, this takes some time without any indication on

the screen, so be patient.

8. Ignore the error message saying that Space CE

was not installed successfully, remove it using add/

remove programs. This error message is wrong,

the installation is successful.

9. Space CE is now installed in the HIAB folder.

2000-12-20

SPACE 3000, Service Manual

2.4 Terminal

WINDOWS CE

TERMINAL FUNCTIONS

Login

(Fig. 3)

Type in your User ID and Password then

click on button OK.

Main menu

(Fig. 4)

At the top is the program version of the

Space 3000, and the program serial

number.

Below that, there is the crane serial

number and further down we have the

Crane Type.

Top right is your Access level, and below

is your Display level.

From access level Service its possible

to chose diplay level Diagnostic.

Fig. 3

Fig. 4

Init

(Fig. 5)

Here are all the Init Menus:

System Overview, Auto, Type, Levers and

Prog SerNo.

Fig. 5

2000-12-20

SPACE 3000, Service Manual

2.4 Terminal

Init System Overview

Sub menu 1

(Fig. 6)

Shows an overview of how the system is

set up. You can see if the system has

ADC, MSC etc. You can also see where

the different indicators are connected.

Init Auto

Fig. 6

Sub menu 1

Automatic Parameter Initialization

Slew Sector 1

Sector Type:

Platf 1 Low

Cap (%)

Slew Sector 2

Sector Type:

Cap (%)

Yes

No

OLP

60

Winch

60

ADS

Yes

No

Ext In Indicator

Yes

Manual Extension

Cap (%)

50

75

No

Pressure Settings (bar)

Height Warn

Yes

No

Cancel

IB

+2%

265

OB

+1%

273

OK

1070-365

Slew Sector 1 and 2

(Fig. 7)

Here you set which slewing sectors are

present is the system. You can choose

from:

- No Sector

- OLP

- Stop

- Platf 0 Low

- Platf 1 Low

- Platf 2 Low

- Platf 2S Low

Fig. 7

No sector:

No slewing sector sensor is present in

system.

OLP:

Is used when the crane has a stability

sector.

Stop:

Stops the crane when entering the

slewing sector.

2000-12-20

SPACE 3000, Service Manual

Automatic Parameter Initialization

Slew Sector 1

Sector Type:

Platf 0 Low:

No tilt indicators for the Fixed Platform.

Platf 1 Low

Cap (%)

Slew Sector 2

Sector Type:

Cap (%)

Yes

No

OLP

60

Winch

60

ADS

Yes

No

Platf 1 Low:

One tilt indicator on the inner boom.

Platf 2 Low:

Tilt indicators for the Fixed Platform on

both inner and outer boom. The

indicators are not connected in series.

Ext In Indicator

Yes

Manual Extension

Cap (%)

50

75

No

Pressure Settings (bar)

Height Warn

Yes

No

Cancel

IB

+2%

265

OB

+1%

273

OK

1070-365

Platf is for Fixed Platform and the

number tell how many tilt indicators are

used for the Fixed Platform.

2.4 Terminal

Fig. 7

Platf 2S Low:

Tilt indicators connected in series for the

Fixed Platform on both inner and outer

boom.

This setting is only used when both

platform indicators are connected to

plinth P3 in Column box.

Cap (%):

Only used if the sector is set as OLP,

and sets the capacity of the inner boom

pressure when crane is in the slew

sector.

Winch

(Fig. 7)

Yes & No. Tells SPACE 3000 if Winch is

mounted or not.

Ext In Indicator

(Fig. 7)

Yes & No. Tells SPACE 3000 if a

hydraulic extension in indicator is

mounted or not.

ADS

(Fig. 7)

Yes & No. Tells SPACE 3000 if ADS is

mounted or not.

2000-12-20

SPACE 3000, Service Manual

Automatic Parameter Initialization

Slew Sector 1

Sector Type:

Platf 1 Low

Cap (%)

Slew Sector 2

Sector Type:

Cap (%)

Yes

No

OLP

60

Winch

60

ADS

Yes

No

Ext In Indicator

Yes

Manual Extension

Cap (%)

50

75

No

Pressure Settings (bar)

Height Warn

Yes

No

Cancel

IB

+2%

265

OB

+1%

273

OK

1070-365

Height Warn

(Fig. 7)

If the crane has a tilt indicator on the

inner boom this option will be set to Yes,

whether you have a Height Warning kit or

not. The program checks if the crane is

equipped with an M-Link, which needs an

inner boom tilt indicator. Which means

that if you have selected the correct

Crane Type in InitType, then the program

will not remove the inner boom setting if

you selected No and have an M-Link.

2.4 Terminal

Fig. 7

Pressure settings (bar)

(Fig. 7)

Sets ib_p_lim_corr and ob_p_lim_corr.

The display shows inner and outer boom

pressure. Select correction values by

clicking on the arrows.

Manual Extension

(Fig. 7)

Sets the capacity when Manual

extension is selected on the User

Interface. The first value (should be the

lowest value) is used when the hydraulic

extensions are fully in or if no ext_in

sensor is connected and the second

value (higher) when the hydraulic

extensions are out.

10

2000-12-20

SPACE 3000, Service Manual

2.4 Terminal

Init Type

Sub menu 1

(Fig. 8)

Sets parameters for the selected crane

type. Click select to set the parameters.

Button File is only used if more than one

Crane.dat file is used

.

Fig. 8

Init Levers

Sub menu 1

(Fig. 9)

This menu can be used for three things;

Firstly to check if the calibration of the

levers was good or not. Move the lever on

the valve and see that the sliders on the

screen will move appropriately. Secondly

you can also see if the correct function is

connected to this lever, the name of the

function is above the slider. Third, see if

the correct functions are used for this

crane. The Terminal checks parameter

lev_ad_chan to see what functions are

used, and then only shows those functions on the screen. To calibrate the

levers press button Calibrate.

Fig. 9

Calibrate

Sub menu 2

(Fig. 10)

Follow the instructions on the screen

when calibrating the levers. To skip a

Tool lever press button Skip Lever. To

abort calibration press Back. You dont

have to press any key during calibration

just follow the commands on the screen.

As opposed from the DOS version where

you have to press Enter after every

command.

2000-12-20

Fig. 10

11

SPACE 3000, Service Manual

2.4 Terminal

Variables

(Fig. 11)

This display is called the Summary display.

Here you can read off several variables simultaneously.

Here you can do a lot of troubleshooting by viewing the information from the variables.

Slew

Inner Boom

Outer Boom

Extension

Winch

Tool 1

Tool 2

Tool 3

Pressure

Lim

%

26

104

109

0

100

0

MPa

t0 l0 e0 d0

Lev %

0

-43

0

100

0

0

0

0

0

0

Max +

100

0

0

100

100

100

100

100

100

100

Max 0

50

50

100

100

100

100

100

100

100

Tilt

up

Sect

-1,0

down

Platform

in

up

down

off

Extended

Detailed

User Interface

Back

Fig. 11

1 Winch

Shows which winch indicators are connected to the system.

t = top, l = load, e = end, d = disable

0 = non active, 1 = active ? = not connected

(wtop, wload, wend and wdis)

Winch variables is only shown if winch is chosen in Init Auto menu.

2 Pressure MPa Shows current working pressure in inner and outer boom in MPa (ib_p_mom and ob_p_mom).

%

Shows current working pressure in inner and outer boom in % of maximum pressure (ib_p_filt

and ob_p_filt).

Lim Shows maximum permitted working pressure in inner and outer boom in %.

The value is normally 100 but can be higher if ADC and/or MSC is activated. If manual

extension or an OLP slewing sector indicator is activated the value is lower than 100.

(ib_olp_lim and ob_olp_lim).

3 Lev %

Shows signals from spool sensors. Maximum is +/- 100 (lever).

4 Max +

Max -

Shows maximum permitted spool stroke in % of full stroke for each function and

direction. 0 means that the movement is stopped (max_speed_p and max_speed_n).

5 Tilt

Shows signals from inner and outer boom tilt indicator.

up = up

down = down

? = not connected

(ib_tilt and ob_tilt)

12

2000-12-20

SPACE 3000, Service Manual

6 Sect

2.4 Terminal

Sect shows one sector value if only one slewing sector is set for this crane, otherwise it will show

both sector values. (stab_sects)

7 Platform Platform is the indicators for the Fixed Platform. From the top of this box and down we have:

In or Out of the Fixed Platform slewing sector.

Inner boom Fixed Platform tilt indicator up or down.

Outer boom Fixed Platform titl indicator up or down.

On, if there is a person on the Fixed Platform, otherwise Off.

(stand_ib_low, stand_ob_low and stand_on)

Detailed

Sub menu 1

(Fig. 12)

Select variable class and then select

variable. The variable value will now be

shown in the variable value box.

Fig. 12

User Interface

Sub menu 1

(Fig. 13)

Translates the variable cov_stat file to

plain text. Here you can see the status

of the User Interfaces of the system.

Only the UIs that are connected are

shown. The status is shown with simple

Yes/No answers.

Fig. 13

2000-12-20

13

SPACE 3000, Service Manual

2.4 Terminal

Extended

Sub menu 1

(Fig. 14)

Translates the variable ext_stat file to