Professional Documents

Culture Documents

Installation of Solar Power Plant

Uploaded by

Ram Sree RamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation of Solar Power Plant

Uploaded by

Ram Sree RamCopyright:

Available Formats

Installation of 100 KW rooftop solar power plant

ENERGY

1.1. Introduction

Energy plays a pivotal role in our daily activities. The degree of development and

civilization of a country is measured by the amount of utilization of energy by human

beings. Energy demand is increasing day by day due to increase in population,

urbanization and industrialization. The world's fossil fuel supply viz. coal, petroleum and

natural gas will thus be depleted in a few hundred years. The rate of energy consumption

increasing, supply is depleting resulting in inflation and energy shortage. This is called

energy crisis. Hence alternative or renewable sources of energy have to be developed to

meet future energy requirement.

1.2. Energy Classification

Energy can be classified into 3 types. Those are

1. Primary and Secondary Energy

2. Commercial and Non Commercial Energy

3. Renewable and Non renewable Energy

1.2.1. Primary and Secondary Energy

Primary energy sources are those that are either found or stored in nature.

Common primary energy sources are coal, oil, natural gas, and biomass (such as wood).

Other primary energy sources available include nuclear energy from radioactive

substances, thermal energy stored in earth's interior, and potential energy due to earth's

gravity. The major primary and secondary energy sources are Coal, hydro power, natural

gas, petroleum etc.

Primary energy sources are mostly converted in industrial utilities into secondary

energy sources for example coal, oil or gas converted into steam and electricity. Primary

energy can also be used directly. Some energy sources have non-energy uses, for example

coal or natural gas can be used as a feedstock in fertilizer plants.

Department of EEE, AITS, RAJAMPET Page 1

Installation of 100 KW rooftop solar power plant

1.2.2. Commercial Energy and Non Commercial Energy

The energy sources that are available in the market for a definite price are known

as commercial energy. By far the most important forms of commercial energy are

electricity, coal and refined petroleum products. Commercial energy forms the basis of

industrial, agricultural, transport and commercial development in the modern world. In

the industrialized countries, commercialized fuels are predominant source not only for

economic production, but also for many household tasks of general population.

The energy sources that are not available in the commercial market for a price are

classified as non-commercial energy. Non-commercial energy sources include fuels such

as firewood, cattle dung and agricultural wastes, which are traditionally gathered, and not

bought at a price used especially in rural households. These are also called traditional

fuels. Non-commercial energy is often ignored in energy accounting.

1.2.3. Renewable and Non- Renewable Energy

All forms of energy are stored in different ways, in the energy sources that we use

every day. These sources are divided into two groups -- renewable (an energy source that

we can use over and over again) and nonrenewable (an energy source that we are using

up and cannot recreate in a short period of time).

Renewable and nonrenewable energy sources can be used to produce secondary

energy sources including electricity and hydrogen. Renewable energy sources include

solar energy, which comes from the sun and can be turned into electricity and heat. Wind,

geothermal energy from inside the earth, biomass from plants, and hydropower and ocean

energy from water are also renewable energy sources.

Department of EEE, AITS, RAJAMPET Page 2

Installation of 100 KW rooftop solar power plant

Figure 1.1: Renewable Energy Sources and Non-Renewable Energy Sources

However most of our energy from non-renewable energy sources, which include

the fossil fuels - oil, natural gas, and coal. They're called fossil fuels because they were

formed over millions and millions of years by the action of heat from the Earth's core and

pressure from rock and soil on the remains (or "fossils") of dead plants and animals.

Another nonrenewable energy source is the element uranium, whose atoms we split

(through a process called nuclear fission) to create heat and ultimately electricity.

All these energy sources to generate the electricity for our homes, businesses,

schools, and factories. Electricity "energizes" our computers, lights, refrigerators,

washing machines, and air conditioners, to name only a few uses. The energy to run our

cars and trucks. Both the gasoline used in our cars, and the diesel fuel used in our trucks

are made from oil. The propane that fuels our outdoor grills and makes hot air balloons

soar is made from oil and natural gas.

1.3. Energy Scenario

The present energy scenario is discussed under categorical division of India,

Andhra Pradesh.

1.3.1. Energy Scenario in India

The utility electricity sector in India had an installed capacity of 288 GW as of 31

January 2016. Renewable Power plants constituted 28% of total installed capacity and

Department of EEE, AITS, RAJAMPET Page 3

Installation of 100 KW rooftop solar power plant

Non-Renewable Power Plants constituted the remaining 72%. The gross electricity

generated by utilities is 1,106 TWh (1,106,000 GWh) and 166 TWh by captive power

plants during the 201415 fiscal. The gross electricity generation includes auxiliary

power consumption of power generation plants. India became the world's third largest

producer of electricity in the year 2013 with 4.8% global share in electricity generation

surpassing Japan and Russia.

During the year 2014-15, the per capita electricity generation in India was 1,010

kWh with total electricity consumption (utilities and non utilities) of 938.823 billion or

746 kWh per capita electricity consumption. Electric energy consumption in agriculture

was recorded highest (18.45%) in 2014-15 among all countries. The per capita electricity

consumption is lower compared to many countries despite cheaper electricity tariff in

India. Sources of electricity in India by Installed Capacity as of 2016. By the end of

calendar year 2015, despite poor hydro electricity generation, India has become power

surplus country with huge power generation capacity idling for want of electricity

demand.

The calendar year 2016 started with steep fall in the international price of energy

commodities such as coal, diesel oil, naphtha, bunker fuel and LNG which are used in

electricity generation in India. Earlier many of the power stations which are using fuels

other than coal are unable to operate due to high cost of LNG and petro products. This

situation has changed due to glut in petroleum products globally.

The prices are falling to such an extent that these fuels have become cheaper to

give competition for pit head coal based power generators. Many of the stranded gas and

liquid fuel based power stations would be competing with indigenous coal based power

stations in an electricity market where demand growth is not encouraging.

Department of EEE, AITS, RAJAMPET Page 4

Figure 1.1: Power generation capacity in India by source, 2015

Installation of 100 KW rooftop solar power plant

All the segments of the electricity sector such as fuel suppliers, fuel transporters

(railways, harbours, pipelines, etc.), Electricity generators, electricity transmission

companies and distribution companies would be facing severe competition to cut down

the prices and improve their operating efficiency in a final consumer dictated market. If

Discoms, keep on charging exorbitant tariffs to bulk consumers, they would be opting for

solar/wind power plants or take over an existing power plant to meet their captive

consumption. Due to tepid growth in electricity consumption, coal stocks are

continuously building up at power stations as well as coal mines.

1.3.2. Andhra Pradesh Energy Scenario

Andhra Pradesh receives some of the highest irradiation in India. The state has

significant renewable purchase obligations (RPO) stemming from its high power demand.

In addition, Andhra Pradesh has Indias best performing state power utility (State

Electricity Board, SEB). The state has announced its solar policy recently. Andhra

Pradesh receives a global horizontal irradiation (GHI) of 1,900 2,000 KWh/m2/Year.

Andhra Pradesh has a significant total solar RPO requirement of 551MW until

2016. Solar projects worth 100 MW have already been allocated or are in the process of

allocation to meet these obligations. The long-term power scenario of Andhra Pradesh

provides an opportunity for solar energy. The state currently has a total power demand of

Department of EEE, AITS, RAJAMPET Page 5

Installation of 100 KW rooftop solar power plant

51,563 GWh and a peak load demand of 13,177 MW, the second highest in the country,

after Maharashtra.

This demand is expected to grow by 48% in next five years as compared to a

range of growth of 32% to 72% in rest of the states. Currently there is a total deficit of

2,519 GWh and peak load deficit of 1,586 MW in meeting the power requirements of the

state. The peak load deficit is higher than the national average (~9.8%). Solar availability

is the highest at the peak load time in hot weather conditions.

1.4. Energy and Pollution

The usage of conventional energy resources in industry leads to environmental

damages by polluting the atmosphere. Few of examples of air pollution are Sulphur

dioxide (SO2), Nitrous oxide (NOX) and Carbon oxides (CO, CO2) emissions from boilers

and furnaces, chloro fluro carbons (CFC) emissions from refrigerants use, etc. In

chemical and fertilizers industries, toxic gases are released. Cement plants and power

plants spew out particulate matter and volatile organic compounds (VOCs). But most of

the renewable energy is pollution free.

1.5. Energy from Sun

Various types of non conventional energy sources are such as geothermal ocean

tides, wind and sun. All non conventional energy sources have geographical limitations.

but Solar energy has less geographical limitation as compared to other non conventional

energy sources because solar energy is available over the entire globe, and only the size

of the collector field needs to be increased to provide the same amount of heat or

electricity. It is the primary task of the solar energy system designer to determine the

amount, quality and timing of the solar energy available at the site selected for installing

a solar energy conversion system so among all these solar energy seems to hold out the

greatest promise for the mankind.

Department of EEE, AITS, RAJAMPET Page 6

Installation of 100 KW rooftop solar power plant

It is free, inexhaustible, non-polluting and devoid of political control. Solar water

heaters, space heaters and cookers are already on the market and seem to be economically

viable. Solar photo voltaic cells, solar refrigerators and solar thermal power plants will be

'technically and economically viable in a short time. It is optimistically estimated that

50% of the world power requirements in the middle of 21st century will come only from

solar energy. Enough strides have been made during last two decades to develop the

direct energy conversion systems to increase the plant efficiency 60% to 70% by avoiding

the conversion of thermal energy into mechanical energy. Still this technology is on the

threshold of the success and it is hoped that this will also play a vital role in power

generation in coming future.

In one minute, the sun provides enough energy to supply the world's energy needs

for one year. In one day, it provides more energy than the world's population could

consume in 27 years. The energy is free and the supply is unlimited. All this needed to do

is find a way to use it. The largest solar electric generating plant in the world produces a

maximum of 354 megawatts (MW) of electricity and is located at Kramer Junction,

California. Since India has abundant sources of RE especially sunlight, it can cater to all

the energy needs of the country. The country receives an average radiation of 5 KWh per

square meter (m) per day and with 2300 to 3200 sunshine hours per year. The potential of

solar photovoltaic has therefore been estimated at 20 MW per square km and that of solar

thermal applications at 35 Mw per sq m.

Department of EEE, AITS, RAJAMPET Page 7

Installation of 100 KW rooftop solar power plant

1.6. Ways for Converting Solar Energy into Electrical Energy

There are two ways by which we can convert solar energy into electrical energy.

These are as shown in figure 1.3.

Figure 1.3: Ways to convert solar energy into Electrical Energy

Solar Thermal: The solar collectors concentrate sunlight to heat a heat transfer

fluid to a high temperature. The hot heat transfer fluid is then used to generate

steam that drives the power conversion subsystem producing electricity. Thermal

energy storage provides heat for operation during periods without adequate

sunshine.

Figure 1.4: Solar Thermal

Solar Photovoltaic: Another way to generate electricity from solar energy is to

use photovoltaic cells, magic slivers of silicon that converts the solar energy

Department of EEE, AITS, RAJAMPET Page 8

Installation of 100 KW rooftop solar power plant

falling on thermal directly into electricity. Large scale applications of

photovoltaic for power generation, either on the rooftops of houses or in large

fields connected to the utility grid are promising as well to provide clean, safe

and strategically sound alternatives to current methods of electricity generation.

Figure 1.5: Solar Photovoltaic

1.7. Comparison between Solar Photovoltaic Plant and Solar Thermal

Power Plant

Many people associate solar energy directly with photovoltaic and not with solar

thermal power generation. In contrast to photovoltaic's plants, solar thermal power plants

are not based on the photo effect, but generate electricity from the heat produced by

sunlight. A fossil burner can drive the water-steam cycle during periods of bad weather or

at night. In contrast to photovoltaic's systems, solar thermal power plants can guarantee

capacity. Due to their modularity, photovoltaic operation covers a wide range from less

than one Watt to several megawatts and solar thermal power plants are small units in the

kilowatt range. On the other hand, Global solar irradiance consists of direct and diffuse

irradiance. When skies are overcast, only diffuse irradiance is available. While solar

thermal power plants can only use direct irradiance for power generation, photovoltaic

systems can convert the diffuse irradiance as well. That means, they can produce some

electricity even with cloud-covered skies. From economical point of view market

introduction of photovoltaic systems is much more aggressive than that of solar thermal

power plants, cost reduction can be expected to be faster for photovoltaic systems. But

Department of EEE, AITS, RAJAMPET Page 9

Installation of 100 KW rooftop solar power plant

even if there is a 50% cost reduction in photovoltaic systems and no cost reduction at all

in solar thermal power plants.

SOLAR PHOTOVOLTAIC TECHNOLOGY

2.1. Introduction

Photovoltaic's offer consumers the ability to generate electricity in a clean, quiet

and reliable way. Photovoltaic systems are comprised of photovoltaic cells, devices that

convert light energy directly into electricity. Because the source of light is usually the

sun, they are often called solar cells. The word photovoltaic comes from photo meaning

Department of EEE, AITS, RAJAMPET Page 10

Installation of 100 KW rooftop solar power plant

light and voltaic which refers to producing electricity. Therefore, the photovoltaic

process is producing electricity directly from sunlight. Photovoltaic are often referred to

as PV.

2.2. Brief History

In 1839 Edmond Becquerel accidentally discovered photovoltaic effect when he

was working on solid-state physics. In 1878 Adam and Day presented a paper on

photovoltaic effect. In 1883 Fxitz fabricated the first thin film solar cell. In 1941 Ohl

fabricated silicon PV cell but that was very inefficient. In 1954 Bell labs Chopin, Fuller,

Pearson fabricated PV cell with efficiency of 6%. In 1958 PV cell was used as a backup

power source in satellite Vanguard-1. This extended the life of satellite for about 6 years.

2.3. Photovoltaic Cell

A device that produces an electric reaction to light, producing electricity. PV cells

do not use the sun's heat to produce electricity. They produce electricity directly when

sunlight interacts with semiconductor materials in the PV cells.

Figure 2.1: Photovoltaic cell

A typical PV cell made of crystalline silicon is 12 centimeters in diameter and

0.25 millimeters thick. In full sunlight, it generates 4 amperes of direct current at 0.5

volts or 2 watts of electrical power.

2.3.1. Basic Theory of Photovoltaic Cell

Photovoltaic cells are made of silicon or other semi conductive materials that

are also used in LSIs and transistors for electronic equipment. Photovoltaic

Department of EEE, AITS, RAJAMPET Page 11

Installation of 100 KW rooftop solar power plant

cells use two types of semiconductors, one is P-type and other is N-type to

generate electricity.

When sunlight strikes a semiconductor, it generate pairs of electrons (-) and

protons (+).

Figure 2.2: Basic theory of Photovoltaic cell 1

When an electron (-) and a proton (+) reach the joint surface between the two

types of semiconductors, the former is attracted to N-type and the latter to the Ptype semiconductor. Since the joint surface supports only one way traffic, they are

not able to rejoin once they are drawn apart and separated.

Figure 2.3: Basic theory of Photovoltaic cell 2

Since the N-type semiconductor now contains an electron (-), and P-type

semiconductor contains a proton (+), an electromotive (voltage) force is

generated. Connect both electrodes with conductors and the electrons runs from

N- type to P-type semiconductors, and the proton from P-type to N-type

semiconductors to make an electrical current.

Department of EEE, AITS, RAJAMPET Page 12

Installation of 100 KW rooftop solar power plant

Figure 2.4: Basic theory of Photovoltaic cell 3

2.3.2. Series and Parallel Connection of PV Cells

Solar cells can be thought of as solar batteries. If solar cells are connected in

series, then the current stays the same and the voltage increases.

Figure 2.5: Series connection of cells

If solar cells are connected in parallel, the voltage stays the same, but the current

increases.

Figure 2.6: Parallel connection of cells

Solar cells are combined to form a" module" to obtain the voltage and current

are desired.

2.3.3. Types of Photovoltaics Cells

There are essentially two types of PV technology, crystalline and thin-film.

1. Crystalline can again be broken down into two types:

Mono crystalline Cells - These are made using cells cut from a single cylindrical

crystal of silicon. While mono crystalline cells offer the highest efficiency

Department of EEE, AITS, RAJAMPET Page 13

Installation of 100 KW rooftop solar power plant

(approximately

18%

conversion

of

incident

sunlight),

their

complex

manufacturing process makes them slightly more expensive.

Polycrystalline Cells - These are made by cutting micro-fine wafers from ingots

of molten and recrystallized silicon. Polycrystalline cells are cheaper to produce,

but there is a slight compromise on efficiency (approximately 14% conversion of

incident sunlight).

2. Thin film PV is made by depositing an ultra thin layer of photovoltaic material

onto a substrate. The most common type of thin-film PV is made from the

material a-Si (amorphous silicon), but numerous other materials such as CIGS

(copper indium/gallium dieseline) CIS (copper indium solenoid), CdTe (Cadmium

Teluride), dye-sensitized cells and organic solar cells are also possible.

2.4. Photovoltaic Modules

PV cells are the basic building blocks of PV modules. For almost all applications,

the one-half volt produced by a single cell is inadequate. Therefore, cells are connected

together in series to increase the voltage. Several of these series strings of cells may be

connected together in parallel to increase the current as well.

These interconnected cells and their electrical connections are then sandwiched

between a top layer of glass or clear plastic and a lower level of plastic or plastic and

metal. An outer frame is attached to increase mechanical strength, and to provide a way

to mount the unit. This package is called a "module" or "panel". Typically, a module is

the basic building block of photovoltaic systems. PV modules consist of PV cells

connected in series (to increase the voltage) and in parallel (to increase the current), so

that the output of a PV system can match the requirements of the load to be powered. The

PV cells in a module can be wired to any desired voltage and current.

The amount of current produced is directly proportional to the cell's size,

Department of EEE, AITS, RAJAMPET Page 14

Installation of 100 KW rooftop solar power plant

conversion efficiency, and the intensity of light. Groups of 25 series connected PV cells

are packaged together into standard modules that provide a nominal 900 volts.

2.5. Describing Photovoltaic Module Performance

To insure compatibility with storage batteries or loads, it is necessary to know the

electrical characteristics of photovoltaic modules. As a reminder, "I" is the abbreviation

for current, expressed in amps. "V" is used for voltage in volts, and "R" is used for

resistance in ohms.

2.5.1. The Standard V-I Characteristic Curve of Photovoltaic Module

A photovoltaic module will produce its maximum current when there is

essentially no resistance in the circuit. This would be a short circuit between its positive

and negative terminals. This maximum current is called the short circuit current,

abbreviated Isc. When the module is shorted, the voltage in the circuit is zero.

The maximum voltage is produced when there is a break in the circuit. This is

called the open circuit voltage, abbreviated Voc. Under this condition the resistance is

infinitely high and there is no current, since the circuit is incomplete.

These two extremes in load resistance and the whole range of conditions in

between them are depicted on a graph called V-I (current-voltage) curve. Current,

expressed in amps, is on the vertical Y-axis. Voltage, in volts, is on the horizontal X-axis

as shown in Figure 2.7.

Department of EEE, AITS, RAJAMPET Page 15

Installation of 100 KW rooftop solar power plant

Figure 2.7: The standard V-I characteristic curve of Photovoltaic Module

The short circuit current occurs on a point on the curve where the voltage is zero.

The open circuit voltage occurs where the current is zero. The power available from a

photovoltaic module at any point along the curve is expressed in watts. Watts are

calculated by multiplying the voltage times the current (watts = volts amps).

At the short circuit current point, the power output is zero, since the voltage is

zero.

At the open circuit voltage point, the power output is also zero, but this time it is

because the current is zero.

The power, expressed in watts, at the maximum power point is described as peak,

maximum, or ideal, among other terms. Maximum power is generally abbreviated as "I

(mp)." Various manufacturers call it maximum output power, output, peak power, rated

power, or other terms. The voltage& Current (V-I) curve is based on the module being

under standard conditions of sunlight and module temperature. It assumes that there is no

shading on the module.

2.5.2. Impact of Solar Radiation on V-I Characteristic Curve of Photovoltaic Module

Standard sunlight conditions on a clear day are assumed to be 1000 watts of solar

energy per square meter (1000 W/m2) sometimes this called "one sun" or a "peak sun".

Less than one sun will reduce the current output of the module by a proportional amount.

Department of EEE, AITS, RAJAMPET Page 16

Installation of 100 KW rooftop solar power plant

For example, if only one-half sun (500 W/m2) is available, the amount of output current

is roughly cut in half.

Figure 2.8: Change in Photovoltaic module voltage and current on change in solar

radiation

For maximum output, the face of the photovoltaic modules should be pointed as

straight toward the sun as possible.

2.6. Types of Photovoltaic System

PV technology was first applied in space, by providing electricity to satellites.

Today, PV systems can be used to power just about anything on Earth. On the basis

working operation PV systems operate in four basic forms.

Grid Connected PV Systems - These systems are connected to a broader

electricity network. The PV system is connected to the utility grid using a high

quality inverter, which converts DC power from the solar array into AC power

that conforms to the grid's electrical requirements. During the day, the solar

electricity generated by the system is either used immediately or sold off to

electricity supply companies. In the evening, when the system is unable to supply

immediate power, electricity can be bought back from the network.

Department of EEE, AITS, RAJAMPET Page 17

Installation of 100 KW rooftop solar power plant

Figure 2.9: Grid Connected PV Systems

Standalone Systems: PV systems not connected to the electric utility grid are

known as Off Grid PV Systems and also called "stand-alone systems". Direct

systems use the PV power immediately as it is produced, while battery storage

systems can store energy to be used at a later time, either at night or during cloudy

weather. These systems are used in isolation of electricity grids, and may be used

to power radio repeater stations, telephone booths and street lighting. PV systems

also provide invaluable and affordable electricity in developing countries like

India, where conventional electricity grids are unreliable or non-existent.

Figure 2.10: Off Grid PV Systems

Hybrid System: A hybrid system combines PV with other forms of power

generation, usually a diesel generator and Biogas is also used. The other form of

power generation is usually a type which is able to modulate power output as a

function of demand. However more than one form of renewable energy may be

used e.g. wind and solar. The photovoltaic power generation serves to reduce the

consumption of nonrenewable fuel.

Department of EEE, AITS, RAJAMPET Page 18

Installation of 100 KW rooftop solar power plant

Figure 2.11: Hybrid System

Grid Tied with Battery Backup PV system: Solar energy stored in batteries can

be used at night time. Using net metering, unused solar power can be sold back to

the grid. With this system, you will have power even if your neighborhood has

lost power.

2.7. Grid Connected PV System

Because as day by day the demand of electricity is increased and that much

demand cannot be meeting up by the conventional power plants. And also these plants

create pollution. The renewable energy it will be better but throughout the year the

generation of all renewable energy power plants. Grid tied PV system is more reliable

than other PV system. No use of battery reduces its capital cost so we go for the grid

connected topology. If generated solar energy is integrated to the conventional grid, it

can supply the demand from morning to afternoon (total 6 hours mainly in sunny

days) that is the particular time range when the SPV system can fed to grid. As no

battery backup is there, that means the utility will continue supply to the rest of the

time period. Grid-connected systems have demonstrated an advantage in natural

disasters by providing emergency power capabilities when utility power was

interrupted. Although PV power is generally more expensive than utility-provided

power, the use of grid connected systems is increasing.

Department of EEE, AITS, RAJAMPET Page 19

Installation of 100 KW rooftop solar power plant

SOLAR PARAMETERS

3.1. Fill Factor

The short-circuit current and the open-circuit voltage are the maximum current

and voltage respectively from a solar cell. However, at both of these operating points, the

power from the solar cell is zero. The "fill factor", more commonly known by its

abbreviation "FF", is a parameter which, in conjunction with V oc and Isc, determines the

maximum power from a solar cell. The FF is defined as the ratio of the maximum power

from the solar cell to the product of Voc and Isc. Graphically, the FF is a measure of the

"squareness" of the solar cell and is also the area of the largest rectangle which will fit in

the V-I curve. The FF is illustrated below.

Department of EEE, AITS, RAJAMPET Page 20

Installation of 100 KW rooftop solar power plant

Figure 3.1: Short circuit current and open circuit voltage characteristics

Graph of cell output current (red line) and power (blue line) as function of

voltage. Also shown are the cell short-circuit current (I sc) and open-circuit voltage (Voc)

points, as well as the maximum power point (Vmp, Imp).

As FF is a measure of the "squareness" of the V-I curve, a solar cell with a higher

voltage has a larger possible FF since the "rounded" portion of the V-I curve takes up less

area. The maximum theoretical FF from a solar cell can be determined by differentiating

the power from a solar cell with respect to voltage and finding where this is equal to zero.

Hence

.(3.1)

Giving:

...(3.2)

Department of EEE, AITS, RAJAMPET Page 21

Installation of 100 KW rooftop solar power plant

However, the above technique does not yield a simple or closed form equation.

The equation above only relates Voc to Vmp, and extra equations are needed to find I mp and

FF. A more commonly used expression for the FF can be determined as

..(3.3)

Fill Factor Calculator 1:

Open Circuit Voltage=0.63 v

V Ideality Factor n= 1

Temperature T= 300 K

V Fill Factor= 72.3 FF

However, large variations in open-circuit voltage within a given material system

are relatively uncommon. For example, at one sun, the difference between the maximum

open-circuit voltage measured for a silicon laboratory device and a typical commercial

solar cell is about 120 mV, giving maximum FF's respectively of 0.85 and 0.83. However,

the variation in maximum FF can be significant for solar cells made from different

materials. For example, a GaAs solar cell may have a FF approaching 0.89.

The above equation also demonstrates the importance of the ideality factor, also

known as the "n-factor" of a solar cell. The ideality factor is a measure of the junction

quality and the type of recombination in a solar cell. For the simple recombination

mechanisms discussed in Types of Recombination, the n-factor has a value of 1.

However, some recombination mechanisms, particularly if they are large, may introduce

recombination mechanisms of 2. A high n-value not only degrades the FF, but since it will

also usually signal high recombination, it gives low open-circuit voltage.

Limitations in the equation described above is that they represent a maximum

possible FF, although in practice the FF will be lower due to the presence of parasitic

Department of EEE, AITS, RAJAMPET Page 22

Installation of 100 KW rooftop solar power plant

resistive losses, which are discussed in Effects of Parasitic Resistances. Therefore, the FF

is most commonly determined from measurement of the V-I curve and is defined as the

maximum power divided by the product of Voc & Isc.

.(3.4)

Fill Factor Calculator 2:

Open-circuit voltage, Voc =36 V

Short-circuit current, Isc = 8.6 A

Voltage at max power, Vmp =30 V

Current at max power, Imp = 8.33A

Resulting fill factor, FF =80.2 %

3.2. Efficiency

The efficiency is the most commonly used parameter to compare the performance

of one solar cell to another. Efficiency is defined as the ratio of energy output from the

solar cell to input energy from the sun. In addition to reflecting the performance of the

solar cell itself, the efficiency depends on the spectrum and intensity of the incident

sunlight and the temperature of the solar cell. Therefore, conditions under which

efficiency is measured must be carefully controlled in order to compare the performance

of one device to another. Terrestrial solar cells are measured under AM1.5 conditions and

at a temperature of 25C. Solar cells intended for space use are measured under AM0

Department of EEE, AITS, RAJAMPET Page 23

Installation of 100 KW rooftop solar power plant

conditions. Recent top efficiency solar cell results are given in the page Solar Cell

Efficiency Results.

The efficiency of a solar cell is determined as the fraction of incident power

which is converted to electricity and is defined as:

(3.5)

.(3.6)

Where Voc is the open-circuit voltage.

Isc is the short-circuit current.

FF is the fill factor.

is the efficiency.

Efficiency Calculator:

Open Circuit Voltage, VOC =0.63V

Short Circuit Current, ISC = 9.24A

Fill Factor, FF =72.33 %

Input Power, Pin = 4.02W

Maximum Power, Pmax= 4.2 W

Efficiency, n= 17.39%

3.3. Short Circuit Current

The short-circuit current is the current through the solar cell when the voltage

across the solar cell is zero (i.e., when the solar cell is short circuited). Usually written as

ISC, the short-circuit current is shown in figure 3.2.

Department of EEE, AITS, RAJAMPET Page 24

Installation of 100 KW rooftop solar power plant

Figure3.2: V-I characteristics of solar cell with short-circuit current.

The short-circuit current is due to the generation and collection of light-generated

carriers. For an ideal solar cell at most moderate resistive loss mechanisms, the shortcircuit current and the light-generated current are identical. Therefore, the short-circuit

current is the largest current which may be drawn from the solar cell.

When comparing solar cells of the same material type, the most critical material

parameter is the diffusion length and surface passivation. In a cell with perfectly

passivated surface and uniform generation, the equation for the short-circuit current can

be approximated as:

(3.7)

Where G is the generation rate, and L n and Lp are the electron and hole diffusion

lengths respectively. Although this equation makes several assumptions which are not

true for the conditions encountered in most solar cells, the above equation nevertheless

indicates that the short-circuit current depends strongly on the generation rate and the

diffusion length.

Department of EEE, AITS, RAJAMPET Page 25

Installation of 100 KW rooftop solar power plant

Silicon solar cells under an AM1.5 spectrum have a maximum possible current of

46 mA/cm2. Laboratory devices have measured short-circuit currents of over 42 mA/cm 2,

and commercial solar cell have short-circuit currents between about 28 mA/cm 2 and 35

mA/cm2.

Figure 3.3: Vsc as function of band gap

3.3.1. Illuminated Current and Short Circuit Current

IL is the light generated current inside the solar cell and is the correct term to use

in the solar cell equation. At short circuit conditions the externally measured current is

Isc. Since Isc is usually equal to IL, the two are used interchangeably and for simplicity and

the solar cell equation is written with I sc in place of IL. In the case of very high series

resistance (> 10 cm2) Isc is less than IL and writing the solar cell equation with Isc is

incorrect.

Another assumption is that the illumination current IL is dependent on the

incoming light and is independent of voltage across the cell. However, I L varies with

voltage in the case of drift-field solar cells and where carrier lifetime is a function of

injection level such as defected multi crystalline materials.

Department of EEE, AITS, RAJAMPET Page 26

Installation of 100 KW rooftop solar power plant

3.4. Open Circuit Voltage

The open-circuit voltage, VOC, is the maximum voltage available from a solar cell,

and this occurs at zero current. The open-circuit voltage corresponds to the amount of

forward bias on the solar cell due to the bias of the solar cell junction with the lightgenerated current. The open-circuit voltage is shown in figure 3.4.

Figure 3.4: V-I characteristics of solar cell with open circuit voltage.

An equation for Voc is found by setting the net current equal to zero in the solar cell

equation.

(3.8)

The above equation shows that Voc depends on the saturation current of the solar

cell and the light-generated current. While Isc typically has a small variation, the key

effect is the saturation current, since this may vary by orders of magnitude. The saturation

current, I0 depends on recombination in the solar cell. Open-circuit voltage is then a

measure of the amount of recombination in the device. Silicon solar cells on high quality

single crystalline material have open-circuit voltages of up to 730 mV. under one sun and

Department of EEE, AITS, RAJAMPET Page 27

Installation of 100 KW rooftop solar power plant

AM1.5 conditions, while commercial devices on multi crystalline silicon typically have

open-circuit voltages around 600 mV.

The VOC can also be determined from the carrier concentration:

(3.9)

Where kT/q is the thermal voltage, N A is the doping concentration, n is the

excess carrier concentration and ni is the intrinsic carrier concentration. The determination

of VOC from the carrier concentration is also termed Implied VOC.

Voc as a Function of Band gap, EG

Where the short-circuit current (ISC) decreases with increasing band gap, the opencircuit voltage increases as the band gap increases. In an ideal device the VOC is limited

by radiative recombination and the analysis uses the principle of detailed balance to

determine the minimum possible value for J0.

The minimum value of the diode saturation current is given by:

(3.10)

Where q is the electronic charge.

is the StefanBoltzmann constant.

k is Boltzmann constant.

T is the temperature and

Department of EEE, AITS, RAJAMPET Page 28

Installation of 100 KW rooftop solar power plant

Evaluating the integral in the above equation is quite complex.

Figure 3.5: Diode saturation current as a function of band gap.

The J0 calculated above can be directly plugged into the standard solar cell

equation given at the top of the page to determine the V OC so long as the voltage is less

than the band gap, as is the case under one sun illumination.

Figure 3.6: VOC as function of band gap for a cell with AM 0 and AM 1.5.

The VOC increases with band gap as the recombination current falls. There is drop

off in VOC at very high band gaps due to the very low ISC.

Department of EEE, AITS, RAJAMPET Page 29

Installation of 100 KW rooftop solar power plant

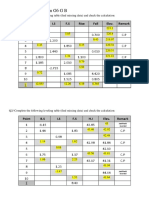

College management wants to install 100kw roof top solar power plant in our

college and call for quotation. Based on the college requirement the companies which are

mentioned below submitted their proposals.

1.

2.

3.

4.

5.

6.

RADIUM SOLAR

ARGO SOLAR PRIVATE LIMITED

VARSHNI POWER

TRANS SOLAR TECHNOLOGIES

ORB ENERGY AND

SIRIUS SOLAR ENERGY SYSTEM

Finally college management decided to give plant contract to Sirius solar

energy system.

Steps involved in plant construction are

1. Panel making

2. Solar plant installation

3. Grid connection

These steps are explained in next chapters.

Department of EEE, AITS, RAJAMPET Page 30

Installation of 100 KW rooftop solar power plant

PANEL MAKING

4.1. Introduction

In solar power plant main functioning part is Solar panel. The information about

solar panel making process is given in this chapter in detailed.

4.2. Physical Size

Length and Width: Although length and width varies slightly, most companies

are manufacturing solar panels in standard sizes. The most typical size used for

installations is 65 inches by 39 inches, while the common size for commercial

applications is 77 inches by 39 inches. The smaller size is a better fit for

residential projects to maximize available roof space. Most commercial projects

have hundreds of panels and this is the slightly larger panel is a more ideal choice.

Depth: The depth of solar panels range between 1.4 inches to 1.8 inches, although

we are seeing more manufacturers move to a 1.8 inch depth.

Weight: Residential solar panels weigh about 40 pounds while the slightly wider

commercial

panels weigh closer to 50 pounds. The weight of the solar panels

may be important in scenarios where reinforcement is needed and there is no

access to the framing.

PV cells are working element in solar panel. PV cells are not made in India so we

import the PV cells in the form of sheets from Taiwan and Arab countries. This is one of

the reason for high cost of solar panels. The imported PV cell sheet is shown in figure

4.1.

Department of EEE, AITS, RAJAMPET Page 31

Installation of 100 KW rooftop solar power plant

Figure 4.1: PV cell sheet

The imported solar PV cell sheet is cut in to small PV cells by using laser cutting

in size of 156mm x 156 mm. The equipment used in cutting is shown in figure 4.2.

Figure 4.2: Laser cutting equipment

After cutting the cells in required size we test the V-I characteristics of the PV cell

as shown in figure 4.3.

Department of EEE, AITS, RAJAMPET Page 32

Installation of 100 KW rooftop solar power plant

Figure 4.3: PV Cell performance testing equipment and V-I Characteristics

After testing of cells we choose the required number of cells based on the panel

rating we want. Normally there are three types of voltage rating panels (24v, 36v, 60v). In

this plant 36v PV panels are used. For making 36v panel 60 PV cells are needed. Each

cell having 0.6voltage rating so for 36v (60*0.6=36).

4.3. Soldering Process

The 60 PV cells are connected in series by using soldering process. The materials

used in soldering process are:

1. Soldering Iron

2. Soldering Iron Stand

3. 3mm tabbing wire-pre soldier coated

4. 5mm tabbing wire-pre soldier coated

5. Scissors

6. Ruler

7. Holding Tool

8. Solder Pen

9. Solder Paste-Only used to tin the Solder Iron

10. Solder wire-Only used to tin the Solder Iron

11. Solar Cell

Soldering process is shown in figure 4.4.

Department of EEE, AITS, RAJAMPET Page 33

Installation of 100 KW rooftop solar power plant

Figure 4.4: Soldering process of PV Cells.

Solar cells are connected in series i.e positive and negative connection by tin leads

through soldering process. These tin leads are act as buses. After soldering process the pv

cells are placed on a EVA sheet as shown in figure 4.5.

Figure 4.5: EVA sheet with PV cells.

4.4. EVA Sheets

Solar EVA is brand name of ethylene-vinyl acetate (EVA) base encapsulating

sheet. The various characteristic properties from EVA resin provide excellent features as

described below, and some additional features, such as high temperature resistance and

Department of EEE, AITS, RAJAMPET Page 34

Installation of 100 KW rooftop solar power plant

weather resistance, were added for use in severe environments with sunshine. Excellent

durability (high temperature, high humidity, and weather resistance)

Excellent adhesive bonding to glass, cell, and back side film (back sheet)

Excellent encapsulating properties during the lamination process

Excellent optical transmission and transparency

Excellent flexibility, protecting cells from physical stress during the lamination

process.

This EVA sheet with PV cells is placed in a Aluminum frame and finally it is

covered with trephine glass. This glass protects the PV cells from atmospheric conditions.

Figure 4.6: Aluminum frame and glass arrangement

Glass has several strong points concerning optical properties:

-It can be produced in large and homogeneous panes

-Its optical properties are not affected by ageing

- It is produced with perfectly flat and parallel surfaces

The main characteristics of glass are transparency, heat resistance, pressure and

breakage resistance and chemical resistance.

Department of EEE, AITS, RAJAMPET Page 35

Installation of 100 KW rooftop solar power plant

4.5. Refractive Index

If light from an optically less dense medium (air) meets an optically denser

medium (glass), then the light ray is split at the surface interfaces. The measure of

deflection determines the refractive index. For float glass, this refractive index is n=1.52.

Aluminum extrusion provides a clear economic advantage in the product of solar

application. The lower weight of aluminum (1/3rd of steel) allows far more material to be

used at a lower cost. Because of its recyclability, light weight, high strength and high

corrosion resistance, it has become a preferred material. By using aluminum is saving on

costs of solar panel and transportation.

After connecting PV cells in series we get two leads out of the frame in these two

leads one act as a positive and other act as a negative lead .they are shown in figure 4.7.

Figure 4.7: Solar panel terminals.

For protection of Solar panel we use the two types of diodes the function of these

diodes is explained below.

The P-N junction diode acts like solid state one way electrical valve that only

allows electrical current to flow through them in one direction only. The advantage of this

is that diodes can be used to block the flow of electric current from other parts of an

electrical solar circuit. When used with a photovoltaic solar panel, these types of silicon

diodes are generally referred to as Blocking Diodes.

Department of EEE, AITS, RAJAMPET Page 36

Installation of 100 KW rooftop solar power plant

Bypass Diodes are used in parallel with either a single or a number of

photovoltaic solar cells to prevent the current(s) flowing from good, well-exposed to

sunlight solar cells overheating and burning out weaker or partially shaded solar cells by

providing a current path around the bad cell. Blocking diodes are used differently than

bypass diodes.

Bypass diodes in solar panels are connected in parallel with a photovoltaic cell

or panel to shunt the current around it, whereas blocking diodes are connected in series

with the PV panels to prevent current flowing back into them.

The connection of diodes is shown in figure 4.8.

Figure 4.8: Diode connection in solar panel

4.5. Panel Testing

Panel testing process is done in two ways .One is temperature testing and other is

electrical testing.

In temperature testing we test the panel under 1000 degree centigrade. it gives the

result how much temperature it will bear.

Department of EEE, AITS, RAJAMPET Page 37

Installation of 100 KW rooftop solar power plant

Figure 4.9: Temperature testing equipment.

In electrical testing the performance characteristics of the solar panel are tested. In

this test the rating of the panel like rated voltage, current and short circuited current are

observed. It shows in figure 4.10.

Figure 4.10: Electrical testing equipment.

Department of EEE, AITS, RAJAMPET Page 38

Installation of 100 KW rooftop solar power plant

Table 4.1: Solar panel specifications

Rated Power (P Max)

Open Circuit Voltage

Short Circuit Current (I Sc)

Rated Voltage (V Max)

Rated Current (Imp)

Power Tolerance

Specification are at STC

Cell Temperature

250W

36.00V

8.60A

30.00V

8.33A

3%

2

1000W/m Insulation, AM 1.5

250

SOLAR POWER PLANT INSTALLATION

5.1. Introduction

Department of EEE, AITS, RAJAMPET Page 39

Installation of 100 KW rooftop solar power plant

Solar modules are installed on rooftops where there is danger of personnel falling

off of the roof. Scaffolding, stepladders, and ladders may be dangerous and require

caution. The installation of solar modules involves work in high places, take extreme

precautions to avoid falling from roof. To prevent accidents, safety regulations must be

observed. Always take the following precautions to prevent accidents and injury.

1. Take the following precautions before starting work.

Plan the job and visit the site before starting work.

On site, do not work alone. Always work with atleast one other person.

Inspect power tools before using them.

2. When conditions make it necessary, tell workers to stop working.

When it is raining, or there is a strong probability that it will start raining.

Immediately after rain, and when work areas are slippery.

When high wind conditions exist, or are expected, or when a high wind warning

has been issued.

When it is snowing, or when there is snow underfoot.

When the condition of the scaffolding and ladders are not satisfactory.

3. Wear appropriate work clothes and protective equipment.

Work clothes for both the upper and lower body should fit well and allow you to

move freely.

Always wear protective equipment such as harnesses and lifelines.

Wear a helmet and secure it correctly.

Wear non-slip shoes. Shoes get dirty when worn on a roof, so keep the soles

clean.

4. Observe safety regulations for ascending and descending ladders and stepladders.

Before use, always inspect ladders and stepladders to makes sure they are in

good condition.

Choose a safe spot to anchor ladders and stepladders.

Always work with a partner. One person should hold the ladder steady.

Ladders from a first-story roof to a second-story roof are very dangerous. Do not

set up a ladder on a roof. When there is no other choice, straddle the ridge and

Department of EEE, AITS, RAJAMPET Page 40

Installation of 100 KW rooftop solar power plant

lay down a rubber anchor mat, and secure the ladder to the mat. Always

one person hold the ladder firmly.

have

When you use a two-stage ladder, secure it with ropes or stays to prevent it from

sliding sideways, and have two persons hold the ladder steady.

Use ladders with steps broad enough to permit safe work.

5. When working in high places wear harnesses and use scaffolding.

When working at heights of 6 ft or more, use scaffolds or other equipment to

ensure a stable work platform.

Scaffolds should be designed and erected by a qualified person.

When it is difficult to erect a stable work platform, install safety nets, wear

harnesses, and take other measures to prevent falls.

Regulations mandate the use of harnesses. Fasten harnesses securely, and check

that the length of lifelines is 6 ft or less.

Attach the primary support line securely to a metal fixture installed for that

purpose on a ridge or beam.

6. Install enclosures and covers.

Install enclosures, guardrails, or covers at the end of work decks that are 10 ft or

more above ground, at openings, and at other dangerous locations.

When it is extremely difficult to install enclosures, guardrails, or covers, or

when they must be removed to work in that location, install a safety net,

wear

harnesses, and take other measures to prevent falls.

7. Protect against falling objects.

When objects are thrown down from a height of 6 ft or more, appoint a

surveillance person on the ground and warn others about falling objects.

Do not allow third parties to enter the work area during construction.

Arrange tools and materials neatly and secure them with ropes, or use bags or

other measures to prevent falling objects.

8. Other

When there are electric power lines near the roof or eaves, request the power

utility to take advance measures to prevent shock.

Department of EEE, AITS, RAJAMPET Page 41

Installation of 100 KW rooftop solar power plant

Check the health of workers before starting work.

Lift packaged modules by grasping both sides of the package. Do not lift by

grasping the band, as the band can break.

Never step or sit on the glass surface of a solar module.

5.2. Points to Check When Selecting The installation Location

Check the following items before starting installation work.

Refer to the inverter installation manual for more information about inverter installation

and electrical work.

5.2.1. Condition of Building Where Solar Power System Is To Be Installed

Inspection of Roof Structure

It is important to inspect the structural integrity of the roof and the durability of

the roof materials. The SRS mounting structure and solar modules require a strong base

for durable and reliable operation in local environments.

Always wear a safety harness when working on the roof. Inspect the roof surface

in the area of the installation for cracks, water leakage, and roofing material quality and

uniformity. This is especially important if the roof is older than 14 years.

Inspect the roof for sags and other abnormalities. A sag or deep depression in the

roof may indicate a structural weakness in the support system that may require correction.

The following illustrations detail typical roof construction as well as old roof problems.

.

Figure 5.1: Site selection of Rooftop Solar power plant

5.2.2. Inspection of the Roof Support System

Department of EEE, AITS, RAJAMPET Page 42

Installation of 100 KW rooftop solar power plant

This may require access to the attic. Check that all rafters, trusses and other

materials are in good condition. Check for indication of previous water leaks. Measure

the spacing of the rafters or trusses to confirm the dimensions and prepare for the system

layout. Determine the location of the electrical roof penetration and wire run, if wiring is

planned for this area.

5.2.3. Checking the Solar Power System Installation Location Code Compliant

Installation

Determine the wind loads for the installation site. Check with your local building

and safety department for the specific requirements.

Make certain that the roof structure can support the live and dead loads resulting

from the installation of the PV array.

Consult with a professional engineer if additional assistance is required.

Determine the basic wind speed from the IBC wind speed chart (for US

locations).

Determine the exposure category A through D (get latest definitions from IBC or

local building code).

Determine total pressure by compiling basic wind speed, exposure and roof

height. Check with Sharp technical support if your total pressure exceeds 45 PSF.

Reference the chart wind speeds to determine your design wind pressure (PSF).

Determine exposure categories A through D for various roof heights.

Based on the loading in step 7, makes certain that the roof structure can support

the load.

The modules and system are UL listed to standard 1703. The UL 1703 test is

performed at 1.5 times the design load of 30 lbs per square foot, or 45 lbs per

square foot. The system has been load tested by Sharp to 50 PSF use in locations

subject to higher values.

Building departments often require a design safety factor of 1.5 or greater for

structures. The maximum structural loading listed in this guide, does not include

an added safety factor.

To achieve maximum loading, use at least the same number of sliders as modules

on each rail.

Department of EEE, AITS, RAJAMPET Page 43

Installation of 100 KW rooftop solar power plant

Install solar modules facing south, if possible. Installations facing east and west

are also possible, although the amount of power generated will be lower.

Check the roof from a southern orientation, and check for obstacles that will cast

a shadow. These factors will lower the amount of power generated. Explain this to

the users and obtain their consent.

Install in a location that has good sun exposure throughout the year. Less power is

generated in shaded locations.

5.3. System Sizing

The system sizing and specifications for the 100 KW power plant unit is shown below:

Site Information

Proposal site for The Plant is Rajampet in kadapa district, India. Its co-ordinates are:

Latitude

: 14o 18888 N

Longitude

: 79o 166 E

One way to describe locations on Earth is by latitude and longitude. Latitude is a

measure of how far north or south a place is from the Equator. Because the Equator is at

the midpoint of Earth, its latitude is 0. All other locations are measured starting from the

Equator and moving north or south. To measure distance east or west you would use

longitude lines. The starting point for measuring longitude is called the Prime Meridian.

It goes through Greenwich, England. Similar to the Equator, its longitude is 0. Longitude

lines run between the geographic North and South Poles. To describe the position of a

place on Earth you would use both latitude and longitude. By locating where a location's

latitude and longitude intersect, you can easily find it on a map. Both latitude and

longitude are measured in degrees.

Table 5.1: Plant details

DESCRIPTION

DETAILS

Department of EEE, AITS, RAJAMPET Page 44

UNITS

Installation of 100 KW rooftop solar power plant

Plant size, wattage

Project cost in Rs

Technology type

Mounting type

Space Required

100

71-10.65=60.35

multi crystalline

SEASONAL TILT

1400

Kw

Lakhs

Wp

------Sq Ft.

Figure 5.2:100 KW Rooftop Solar power plant model diagram

5.4. Installation Work

Before starting installation work we need to mark on the roof top. Based on the

building position we give the markings. In this project distance between the two lines is

18 meters.

5.4.1. Checking Layout

Before installing sliders, check layout of rails and splices.

Place sliders on all tiles that were identified to be drilled for tile standoffs.

Pre-assemble rails and splices.

Department of EEE, AITS, RAJAMPET Page 45

Installation of 100 KW rooftop solar power plant

Figure 5.3: Bolt Tightening

Place rails with splices into position. Ensure slider locations do not overlap

splices.

If these overlap or seem too close, shift rails horizontally or move sliders to next

rafter or remove splices to switch the long and short rails to opposite sides.

Reattach splices after rails are switched and recheck for overlap.

Figure 5.4: Distance between two supporting poles

5.4.2. Installing the Flashings (Optional)

Flashings can improve water and ice management on the roof by directing the

water around the rail slider assembly. It is ideal for use in new construction, reroof, and in

locations with significant precipitation. The flashings are installed below the standard

slider assembly. Each flashing is similar in size to the slider assembly. The flashing has a

large flange around its perimeter to allow for integration with the surrounding shingles.

Department of EEE, AITS, RAJAMPET Page 46

Installation of 100 KW rooftop solar power plant

There are 3 alignment marks on the flashing and identification for the orientation of the

part.

Confirm the locations of each standard slider assembly. Follow the same rules for

installation as the slider foot. The flashings located on the bottom rail (close to

the eave), should be aligned with the chalk lines created in the roof layout.

Flashings used to support the center rails, should be centered on the rail line. The

flashings located at the top rail (close to the ridge), should have minimal exposure

beyond the rail.

Dry fit the flashing in the location marked for installation. Use a utility knife to

cut the surrounding shingles to assure a flush and water resistant fit. Install

flashing over a layer of shingles to insure water Resistance.

Figure 5.5: Marking of drilling holes

Invert the flashing, peel off the protective backing paper and apply a bead of

roofing silicone along the top and sides in the flange area. Leave the bottom

flange clear for water drainage. Make sure that the shingles are at room

temperature, ~68F. When shingles are cold, they become brittle and are difficult

to work with. Use a putty knife to lift the shingles and slide in the flashing.

Apply a bead of silicone on the top and sides of the flange that contact the

surrounding shingles. Press the area to create tight seal.

Peel off the backing paper from the standard slider. Place the standard slider

assembly on the flashing and secure with the supplied flashing screws 110 mm.

Department of EEE, AITS, RAJAMPET Page 47

Installation of 100 KW rooftop solar power plant

Figure 5.6: Bead silicon fills in hole

5.4.3. Installing Tile Slider Assembly

Identify the locations for the roof tile sliders so that each slider is located in the

valley of the tile.

Number two tiles, one above the other. The lower tile will be removed to install

the aluminum support plate.

Mark the edge of the upper tile on the lower tile to insure proper alignment upon

assembly.

Figure 5.7: Covered with concrete mixture

Remove the lower tile from the roof.

Place the roof tile slider on the lower tile and align with the horizontal line

marked above. Mark two holes for roof tile standoff.

Drill 2 holes using the Sharp supplied drill bit (AE112). A high speed drill

(approximately 1000 rpm) is required for this process. Exert a pressure of 40 to 50

lb. Make certain to dip the tip of the drill in water after drilling each hole. This

will cool the drill bit. Clean any debris and dust after drilling.

Locate the rafter and place the aluminum support plate on the deck. Install two 80

mm screws through the plate, spaced ~ 5" apart, into the rafter. Install four 35 mm

Department of EEE, AITS, RAJAMPET Page 48

Installation of 100 KW rooftop solar power plant

screws through the plate and into the deck. The screws should be spaced equally

along the upper and lower edges of the plate.

Place 2 butyl pads under the holes drilled in the tile. The butyl should be located

on the underside of the tile. Reinstall the tile on to the roof, minding the locations

marked previously.

Inject Sharp supplied silicone caulk, AE107 into the holes to form a dome. The

dimensions of the dome are ~ 0.75" in height and 1.5" in diameter.

Insert 2 top butyl pads onto the tile standoff legs.

Figure 5.8: The tile standoff legs

Insert the tile roof stand off into the drilled holes until it rests on top of the

aluminum support plate.

Place the tile slider over the standoff and secure with two 135 mm screws.

Push the top butyl pad into the silicone dome. Make certain that the silicone caulk

forms a bead around the butyl pad.

Figure 5.9: the top butyl pad into the silicone dome

Insert the roof tile slider bracket into the slider and prepare for rail installation.

5.4.4. System Protection

Grounding

Department of EEE, AITS, RAJAMPET Page 49

Installation of 100 KW rooftop solar power plant

Upon completion of the array ground wire, bring to the rooftop junction box. Use

at least a 10 AWG ground wire for this purpose. The ground will continue down to the

DC disconnect and to the inverter. The inverter must be grounded to a ground rod. All of

the Rails in an installation shall be provided with protective earth grounding wires when

installed. Drill 6 holes each whole 10 ft depth. These holes are filled with carbon powder.

Accomplishing a code compliant grounding system is critical to the safety of the

system. Continuous grounding of all modules and mounting system components is

required.

1. Install outdoor rated ground lugs or ring terminals with ground wire (per above

drawings). Use the marked ground hole on either end of the rail.

2. Connect a minimum solid conductor, copper, ground wire to the ground lug or ring

terminal.

3. Land the end of the ground wire in the array junction box.

Lightning Arresters and Over Voltage Protection

Solar PV systems will be provided with lighting and over voltage protection

through proper earth marts. The lightning conductors will be provided to protect the

entire solar array field from lightning strikes. The lightning conductors shall be earthed

through flats and connected to earth marts with earth pits. The earth pits are provided

with masonry enclose with cast iron cover plate having locking arrangement, watering

pipe using charcoal and salt.

Department of EEE, AITS, RAJAMPET Page 50

Installation of 100 KW rooftop solar power plant

Figure 5.10: Grounding arrangement and lightning arrester

5.4.5. Installing Module Support Rails

Create appropriate rail length by incorporating rail splice kit. Place splice under

rails to be joined and fasten using 4 M8 bolts. Hand tighten 5 turns and use a 13

mm socket wrench to tighten to appropriate torque.

Place rail on standard slider top bracket.

Insert M8 bolts through AD804 dock washer and fasten to standard slider bottom

bracket.

Use shim kit to level the height of the rail on the roof. Place shim between rail and

standard slider top bracket. Slide the shim into the bolt so that it is fully engaged.

5.4.6. Installing Front Cover

Prior to the installation of the bottom row of modules (located close to the eave of

the roof) a front cover is installed to provide a finished appearance.

1. Place each front cover over the top of the support rail as shown in figure 5.11.

Figure 5.11: Place rail on standard slider top bracket

2. Place a module mounting clip, AD801 into the support rail. Make certain that

the lip of the module clip captures the front cover as shown. Each module clip

should be located approximately 8" (200 mm) in from the edge of the solar

module.

5.4.7. Installing Side Cover

Attach the side covers to the open ends of the rail covers.

Department of EEE, AITS, RAJAMPET Page 51

Installation of 100 KW rooftop solar power plant

Use two side cover screws to secure each cover. To save time, install side covers

prior to installing rail covers.

5.4.8. Arrangement of Modules

For placing solar modules first we construct the solar array frame as shown in the

Figure 5.12.

Figure 5.12: Module structure

Based on the no. of panels placing we construct the solar array frame. in this plant

we fix the 10 solar modules in frame. For constructing the frame we use the molding steel

rods. This frame is fixed on the two legs as shown in figure 5.13 solar modules are

arranged in the array manner.

Figure 5.13: solar array fixed in the frame

5.5. Connecting the Solar Modules

Department of EEE, AITS, RAJAMPET Page 52

Installation of 100 KW rooftop solar power plant

Connect each array according to the solar array connection examples.

There is a cable + (positive) and a cable - (negative) on the rear side of each solar

module. Connect the waterproof connectors on these cables, making sure to push

the connectors all the way in.

Figure 5.14: Connection of positive and negative cables

On the first solar module, connect the positive home run cable to the positive

array output cable, and connect the negative cable to the positive cable of the

second solar module. On the second solar module, connect the negative cable to

the positive cable of the third solar module. Continue until you have series

connected the appropriate number of modules for the desired voltage.

When you have made direct connections between the specified number of solar

modules, use a digital multimeter to measure the voltage and current output of the

array. Do this for each string, and record the measurement results.

This information is needed to check for solar module wiring mistakes, and it will

also be needed by the electrician who makes the connections to the inverter.

Organize the cables between solar modules. Bundle the cables so that they do not

touch the roof, and use cable clips to fasten them to the rear side of the module

frame. Leaves and other debris can be caught around cables that are allowed to

touch the roof, and over the years loose dirt can build up, potentially causing the

roof to leak. Use cable clips to secure wire to the module frame. Push clips onto

the module frame where needed. Push wire into clip to secure.

Department of EEE, AITS, RAJAMPET Page 53

Installation of 100 KW rooftop solar power plant

Tape the output cables for each array together, and write the number of solar

modules in the array on the tape, so that it can be understood by the electrician

who makes the connections to the inverter.

Figure 5.15: String number indicating

Tape the + (positive) and - (negative) cable ends separately.

Always protect the array output cables with conduit wherever they touch the roof

or are exposed to sunlight.

Figure 5.16: Strings arrangement

5.6. Testing Module Strings for Correct Voltage

For an array of 25 modules directly connect the Junction box and measure in the

following order.

Department of EEE, AITS, RAJAMPET Page 54

Installation of 100 KW rooftop solar power plant

Measure the voltage of the 25 solar modules. As shown in figure 5.17.

Figure 5.17: Measurement of voltage and Junction box connection

Switch the tester to DC and measure. The voltage will vary depending on the

amount of sunlight, but the value should be from 800 to 900 VDC.

The voltage will vary depending on the amount of sunlight, but it should measure,

about 814 V.

Be careful of shock. Check the measurements

a. For the 100kWp plant required no. of PV panels = 400.

b. Multiply the value measured for a single solar module in step (1) by the

number of solar modules.

c. Compare this value to the measured value (814V) for the whole array. The

string wiring is correct if the difference is 86 V or less.

d. Total output voltage is from solar photovoltaic

structure = 1000 V.

e. Total output current is from solar photovoltaic

structure=8*8=64 A.

5.7. Inverter Connection

Solar inverters are also called as photovoltaic solar inverters. These devices can

help you save lot of money. The small-scale grid one have just two components i.e. the

panels and inverter while the off grid systems are complicated and consists of batteries

which allows users to use appliances during the night when there is no Sunlight available.

Department of EEE, AITS, RAJAMPET Page 55

Installation of 100 KW rooftop solar power plant

Figure 5.18: Advanced energy AE 3TL 8 Inverter

The solar panel and the batteries that are placed on rooftops attract Sun rays and

then convert the Sunlight into electricity. The batteries too grab the extra electricity so

that it can then be used to run appliances at night.

5.7.1. WORKING OF SOLAR INVERTER

Now after knowing what a solar inverter is, lets talk about its working. Solar

panels produce direct electricity with the help of electrons that are moving from negative

to positive direction. Most of the appliances that we use at home work on alternative

current. This AC is created by the constant back and forth of the electrons from negative

to positive. In AC electricity the voltage can be adjusted according to the use of the

appliance. As solar panels only produce Direct current the solar inverter is used to

convert the DC to AC.

An inverter produces square waves or a sine wave which can be used for running

lights, televisions, lights, motors etc. However these inverters also produce harmonic

distortion. Expensive inverters make use of lots of steps to produce a sine wave and thus

are found in residential solar inverters. Basically inverters should be a large one so that it

supplies enough power to all the necessary appliances.

An inverter s easy to buy but choosing the right solar inverter for your appliance

is more important. Thus you must always consult a solar professional before buying on.

We know that the energy derived from sun is solar energy which is one of the cleanest

sources of energy. Also it can be used to provide lighting to houses.

Department of EEE, AITS, RAJAMPET Page 56

Installation of 100 KW rooftop solar power plant

The photovoltaic tiles that attract energy from Sun and converts it into a clean

form of electricity which can be used to light, houses, industries and companies. The

cells of photovoltaic consist of positive and negative silicon that is placed underneath a

slice of glass. When the protons of the Sunlight hit the PV cells they knock the neutrons

present in the silicon. Now the negative charged neutrons get attracted to the silicon but

then are held inside a magnetic field. The wires attached on the silicon catch hold of these

neutrons and while connecting to the circuit, current is formed. This then gives space for

direct electricity and for converting that into alternate electricity an inverter is used so

that the house appliances can run. As mentioned before major of the house appliances

work on alternate current hence an inverter is used to convert DC to AC.

5.7.2. Commissioning

Before commissioning the inverter, be sure the following steps have been

complicated.

Confirm the correct power supply connection

Confirm the correct connection of PV strings

Confirm that connections are protected such that they cannot be pulled off

inadvertently.

Turning on the device

Verify that devices connected to line voltage. If not, insert the external power fuse

or turn on the circuit breaker.

Create voltage by connecting the DC circuit breaker. The inverter only starts if there

is sufficient voltage available.

Setting the country abbreviation and the menu language

When switching on for the first time an initial configuration is necessary. When

country abbreviation defines the country-specific grid monitoring parameters. The menu

language is automatically set when the country abbreviation is selected. The menu

Department of EEE, AITS, RAJAMPET Page 57

Installation of 100 KW rooftop solar power plant