Professional Documents

Culture Documents

2012 12 PotM ENU Technology That Is Shaping Smart Grid in Distribution Networks PDF

Uploaded by

reza515heiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2012 12 PotM ENU Technology That Is Shaping Smart Grid in Distribution Networks PDF

Uploaded by

reza515heiCopyright:

Available Formats

1

Technology that is Shaping Smart Grid in Distribution Networks

Benton Vandiver, OMICRON, USA

Abstract

This paper discusses the developments in the field

of medium voltage distribution equipment and their

implementation of new technologies that are

driving Smart Grid applications.

Introduction

It has been recognized in every country that

economic growth is heavily dependent upon the

reliable delivery of electricity to the customer,

whether that is a bulk industrial, commercial, or

residential customer. Further, efficiently using

every source of generation including "green"

sources has become a mandate of many countries.

The utility industry today is challenged to improve

power quality, availability, reliability and economics

in order to avoid costly interruptions of service to

all levels of customers. In the USA this started in

the 1960's shortly after the electric grid

infrastructure build out came to the point of

interconnecting most of the power delivery

systems. It was realized that reliability would be

increased if an operations center were monitoring

and controlling the distribution network, the term

Distribution Automation was coined to describe

that goal.

Many utilities installed SCADA systems so their

operations center could evaluate the status of the

distribution substation and attempt restoration of

the faulted circuits. However it was quickly realized

that more detailed monitoring was needed and

increased abilities to sectionalize circuit faults were

required. Sectionalizers and Reclosers with control

and communications were developed for this task

but they too were limited by the technology

available at that time. (Duquesne Light

implemented a 23kV DA system starting in 1974

consisting of 300 sectionalizers & reclosers.) The

scope and scale of these systems were cost

justified but not easy to implement and doubts

remained as to their reliability. Around this time the

energy crisis of 1973 and 1979 refocused the

industry to Demand Side Management (DSM)

which looked to control the end customer by

focusing on how and when they used electricity.

DSM systems (meters with communications and

some controls) were installed in order to give

localized control centers the ability to monitor and

issue control over certain customer equipment to

bring supply and demand into balance. This would

save investing in new generation and economic

incentives were provided to the customer to allow

this to happen when needed. The 1980's saw an

explosion of activity to install these systems as

they became better understood and marketed.

However, this technology didn't address the

original problem of fault isolation and system

reconfiguration. Hence, reliability still suffered. The

1990's brought a focus on power quality concerns,

mainly voltage sags, swells or unbalanced

conditions that occurred when there was a short

circuit fault in the distribution system or unwanted

harmonics from your neighbor. Again, the ability to

monitor and detect such conditions drove many of

the design and operational considerations in the

distribution network. The idea was to identify the

power quality issues and correct them increasing

customer satisfaction and reliability. To a large

extent this resulted in the realization that again the

ability to quickly and properly isolate the faulted

portion of the distribution system would do the

most good. Identifying harmonic sources like poor

grounding or improperly isolated industrial

machinery only went so far with a customer without

power. If the distribution circuit was switched off,

there was not much power quality to argue about.

In 2005 the term "Smart Grid" was coined to

describe the effort to "intelligently operate the

transmission and distribution network and integrate

the growing sector of Distributed Energy

Resources (DER) to the power grid". It was

envisioned that all of the past concepts could be

brought together to create this automated

intelligent power grid. However, again the

fundamental operational problems remained.

Fortunately, there had been a convergence of

sorts taking place before this "Smart Grid" was

conceived; a growing renaissance to solve the

issues of the distribution system operations in an

economic way that would actually define many of

the Smart Grid applications. The realization now is

that we do not have to conform to the "that's the

way we have always done it" mentality and we can

actually make vast improvements to the design

and flexible operation of a power system. The

technologies that are leading this renaissance are

seen in use every day the primary one being the

evolution of the microprocessor. But there are

many

industries

that

have

contributed:

communications, materials science, physics, power

electronics, etc.

OMICRON electronics GmbH 2012

Digital communications have

revolutionized our internet, cell phones,

and TV.

Modern digital multifunction protection and

control relays are widely accepted in

utilities.

Development of new materials and

interrupting technology reduces apparatus

size.

New sensor technology is smaller and

more accurate.

New industry standards allow for

integrating data and devices as systems at

all levels.

Distributed generation being deployed can

be an advantage for reliability.

The case of two or three-phase faults is quite

different. For three-phase faults all phases

experience a voltage sag, while for a two-phase

fault - the two faulted phases will have lower

voltages, with the healthy phase without a

significant change compared to the pre-fault levels.

Fig. 2 shows a plot of depth vs. duration of actual

cases from a high-volume manufacturing plant,

with some of them resulting in process shutdown

due to variable speed drives and vacuum pumps

failures.

One problem the 100+ year old utility industry has

suffered from was the traditional view of how the

grid is designed to operate instead of how it could

operate.

How to improve Power Quality

The prolonged effect of short circuit faults on

sensitive equipment supplied by distribution

feeders can lead to their failure and significant

losses. This is pushing the requirements for the

performance of distribution protection systems and

making them similar to transmission protection

systems requirements.

The improvement of power quality during short

circuit faults can be achieved in several different

ways. Like any other problem that has to be

solved, we need first to understand the nature of

the problem and its effect on sensitive users. The

most common short circuit faults in the system

single-phase to ground faults are characterized

by the fact that they introduce a voltage sag in the

faulted phase, and at the same time they result in

a voltage swell in the two healthy phases. This is

clearly seen in Figure 1 that shows the recorded

waveform and the voltage phasor diagram for a

single-phase to ground fault.

Fig. 2 ITI (CBEMA) curve from a manufacturing

plant

There are several factors that determine the

voltage level during a short circuit fault on the

transmission or distribution system:

System configuration

Fault location

Fault resistance

The first characteristic of voltage sag the depth

is something that we cant control, but we have to

study in order to be able to predict or estimate the

effects of different faults on the sensitive

equipment.

The second characteristic of the voltage sag the

duration is the parameter that we can control by

properly applying the advanced features of a stateof-the-art distribution automation system using

modern reclosers and sectionalizers with digital

protection and communications. Using the industry

standard IEC 61850 and especially the use of

GOOSE messages in distributed protection

schemes can reduce the fault clearing time of

these distribution systems.

Reclosers

Fig. 1 Phase voltages for a single-phase-toground fault (Phase A)

Reclosers have evolved into multifunctional fault

clearing systems. They contain all of the

components of a traditional substation fault

clearing system but within an optimized foot print

that can be mounted on a single distribution pole.

Further, the interrupter of these systems can be

operated as independent pole or ganged 3-pole

OMICRON electronics GmbH 2012

operator depending on the system conditions and

configuration requirements. Each reclose operation

can be adapted in both protection element and

setting applied and even change logic based on

evolving fault conditions. One system can even

"test" the line segment for a persistent fault by

applying a reduced current pulse to the line and

measure the response. This enables the recloser

to limit the damage to connected equipment and

system apparatus and only reclose when the fault

has been removed.

They contain state of the art digital protection and

control relays coupled with flexible communication

options for SCADA and distributed protection

functions. Recent advances have increased their

system ratings to match and even exceed

traditional circuit breakers installed in a substation,

up to 38kV and 20kAIC. In fact, most easily exceed

the duty cycle of traditional CB's and do not require

maintenance until accumulating upwards of 20,000

C-O operations. These recloser systems are also a

fraction of the installed cost of their traditional

equivalents. This is the reason they are now being

provided in all form factors for use in overhead,

pad mount, vault, and traditional substation

applications.

These technological advances and all-in-one

packaging allows for easier design and

engineering of a distribution network that can be

operated in a highly efficient and flexible way. In

fact this technology is key to making the

distribution part of a Smart Grid a reality.

Distributed Protection Applications

Peer-to-peer communications are used to perform

protection, control, monitoring and recording

functions. Any function can be divided into

subfunctions and functional elements. The

functional elements are the smallest parts of a

function that can exchange data. These functional

elements in IEC 61850 are called Logical Nodes.

When a function is executed based on the

exchange of messages between two or more

devices, it is called a distributed function.

Bay

computer

P..

IF 8

LC2

Protection

IED

IF 8

R...

LC1

P...

R...

Protection

IED

P...

Distributed

function

Fig. 4 Distributed Function definition in IEC 61850

The exchange of data is not only between

functional elements, but also between different

levels of the substation functional hierarchy. It

should be kept in mind that functions at different

levels of the functional hierarchy can be located in

the same physical device, and at the same time

different physical devices can be exchanging data

at the same functional level. (Figure 5)

Fig. 5 Selective backup protection demonstrating

distributed protection

Fig. 3 Recloser System

Figure 4 shows Logical Connections (LC) - the

communication links between functional elements in this case logical nodes of the P and R groups.

IEC 61850 also defines interfaces that may use

dedicated or shared physical connections - the

communication links between physical devices.

IEC 61850 is being extended for Wide Area

Network (WAN) applications to facilitate GOOSE

OMICRON electronics GmbH 2012

data and interlocking messages for transmission

protection systems and wide area protection

schemes. At the same time, it is being applied to

distributed generation applications of wind, solar,

and hydro generation. It is only natural that it would

also extend into the distribution automation

network applications.

The allocation of functions between different

physical devices defines the requirements for the

physical interfaces, and these can be extended

into the distribution feeder network to reclosers and

sectionalizers using fiber, digital radio, carrier, or

microwave. (It would even be possible to use

dedicated WiFi or GSM spectrum in some areas.)

All of the communication technologies easily

support TCP/IP and can function as either

dedicated or shared resources. The shared

interlocking and even data exchange using

GOOSE can provide fast fault isolation and reduce

service interruptions. Advanced logic and

algorithms for restoration schemes can be easily

implemented

when

secure

and

fast

communications between these devices are

implemented.

Coordinated SCADA and Protection

The protection and control in substations is

distributed in nature by the fact that each

protective relay is designed in general to provide

primary protection of individual substation

equipment such as distribution lines, transformers,

capacitor banks, etc. Extending this distributed

protection to the distribution feeder network was

limited in the past because of restrictions in secure

communications.

Today the wide spread deployment of digital

communications technology has allowed a once

crowded frequency spectrum to be re-allocated

and provide expanded access to more licensed

"digital spectrum" for critical infrastructure

applications. Utilities can now take advantage of

this and provide secure data and control links from

the substation to the distribution network.

The ability to provide both monitoring data and

control interlocking in both directions opens the

door for integrating SCADA and Protection

requirements within the network. Now, the ability to

both know where problems occur and optimize the

network reconfiguration in near real time, a utility

can provide the level of reliability and availability

demanded by the customer.

Where broad fall back schemes were implemented

at the substation level to preserve the network

during certain system events (like a sympathetic

trip logic scheme) a more defined response can be

applied. Instead of blocking, delaying, or adjusting

the protection's sensitivity on adjacent feeders, the

networked SCADA and Protection system can

know precisely the load condition, fault type and

network configuration, and use a scheme to isolate

the faulted segment with minimum impact to the

overall network. This could include single phase

tripping, active VAR control, and network

reconfiguration to minimize any inrush condition.

But this can also be applied to restoration schemes

and not just fault scenarios.

Fig. 6 Traditional sympathetic trip protection

Strategic Recloser Deployment

In the past, a dedicated control point was required

for a Demand Side Management system for each

piece of equipment that the local Operations

Center wanted to control. This limited the total

number of devices that could be part of the system

and as distribution systems grew, keeping up with

the rebalancing was difficult. However with the

Smart Grid technologies this can become a

distributed control function. Using the modern

Recloser as both a circuit sectionalizer and a

remote SCADA control the DSM function could

be better served locally and with more intelligence.

Given a scenario of a willing commercial or

industrial customer, a dedicated recloser could

monitor and control the demand usage of the

customer keeping the integrity of source network a

priority.

Fig. 7 Recloser Deployment in Loop Scheme

This could be reversed and viewed from the point

of a distributed generation source that ties into the

distribution network where security and uptime

should be maximized. The ability to have key

operational status from other network reclosers

OMICRON electronics GmbH 2012

and the local substation / operations center in near

real time provides both utility and distributed

generation customer the most flexible options. In

the past, having a distributed generation source

support an islanded distribution network would be

a dangerous proposition. But with proper two way

communications these scenarios would be

operationally possible. Modern reclosers are

utilizing improved sensor technology that allows bidirectional operation and protection. Accurate

synch check is a normal function and even active

synchronizing is a real possibility.

Functional Testing of Recloser

Systems

Since the recloser has evolved into a complex fault

clearing system it is necessary to approach testing

with the same tools being used in substation

protection systems. In fact, some recloser

operational logic is more complex than a typical

substation protection scheme. It is therefore

necessary that the test set used be able to provide

the correct system simulation waveforms and

control signals as found in the control cable

interface of the recloser controller. (Figure 8)

By the same token, the ability to test the switch or

interrupter requires being able to provide the

properly simulated control signals and measuring

the operational open / close sequences. Detection

of misaligned or slow operations is critical for

proper maintenance of the recloser system.

The ability to perform synchronized testing of

multiple reclosers that are part of a loop scheme or

automation network is a new but necessary

requirement to prove the field installations work as

designed and do not suffer from interference,

bandwidth issues, or other communication

problems when the systems are commissioned.

Fig. 8 Typical Recloser Controller Under Test

The testing of distributed protection functions can

be facilitated if they are based on IEC 61850

GOOSE. The main difference is that in this case

the test set needs to be able to act as IEC 61850

remote device(s), i.e. to be able to publish and

subscribe to GOOSE messages in the network.

Figure 9 shows a block diagram of typical SW tools

for effective test development.

For all practical considerations the procedures and

processes used for testing a communication based

transmission protection scheme can be directly

extended to the networked distribution automation

protection and control scheme. As such, training of

test personnel is a critical success factor for

implementing Smart Grid applications within a

utility.

Fig. 9 Test system/configuration tool, simplified

block diagram

Conclusions

This paper discusses the developments in the field

of medium voltage distribution equipment and their

implementation of new technologies that are

driving Smart Grid applications. The utility industry

today is challenged to improve power quality,

availability, reliability and economics in order to

avoid costly interruptions of service to all levels of

customers.

Recloser technology has evolved beyond the

typical substation circuit breaker and its protection

system. It is a multifunctional all-in-one fault

clearing system with expanded interrupting

capabilities and complex protection and control

logic. It is integrated with SCADA and digital

communications with a reduced footprint and cost

compared to traditional substation installations.

Reclosers can be applied in many configurations

such as pad mount, vault, overhead, and even

substation structures. They are gaining rapid

acceptance and are key to making a Smart Grid

system work. Testing these systems is as involved

OMICRON electronics GmbH 2012

as

wide

area

protection

schemes

or

communication based transmission protection. As

such they require test sets capable of testing this

new technology and require more training than

before.

About the Author

Benton Vandiver III received

his BSEE from the University

of Houston in 1979. He was

with Houston Lighting & Power

for 15 years and Multilin Corp.

for 4 years before joining

OMICRON electronics where

he is currently Technical

Director in Houston, TX. A

registered Professional Engineer in TX, he is also

an IEEE / PSRC member, USNC member, CIGRE

corresponding member. He holds a US Patent for

Communication-based Testing of IEDs and has

authored or co-authored over 80 technical

papers/articles in North America, and has many

outside interests and hobbies.

OMICRON electronics GmbH 2012

OMICRON is an international company serving the electrical power industry with

innovative testing and diagnostic solutions. The application of OMICRON products

allows users to assess the condition of the primary and secondary equipment on

their systems with complete confidence. Services offered in the area of consulting,

commissioning, testing, diagnosis, and training make the product range complete.

Customers in more than 140 countries rely on the companys ability to supply

leading edge technology of excellent quality. Broad application knowledge and

extraordinary customer support provided by offices in North America, Europe,

South and East Asia, Australia, and the Middle East, together with a worldwide

network of distributors and representatives, make the company a market leader in

its sector.

Americas

OMICRON electronics Corp. USA

12 Greenway Plaza, Suite 1510

Houston, TX 77046, USA

Phone: +1 713 830-4660

+1 800-OMICRON

Fax:

+1 713 830-4661

info@omicronusa.com

OMICRON

Asia-Pacific

OMICRON electronics Asia Limited

Suite 2006, 20/F, Tower 2

The Gateway, Harbour City

Kowloon, Hong Kong S.A.R.

Phone: +852 3767 5500

Fax:

+852 3767 5400

info@asia.omicron.at

Europe, Middle East, Africa

OMICRON electronics GmbH

Oberes Ried 1

6833 Klaus, Austria

Phone: +43 5523 507-0

Fax:

+43 5523 507-999

info@omicron.at

www.omicron.at www.omicronusa.com

You might also like

- TransformerDocument6 pagesTransformerrasheed313No ratings yet

- ISH-2011 Overview of Test Requirements on-HVDC-apparatus PDFDocument7 pagesISH-2011 Overview of Test Requirements on-HVDC-apparatus PDFreza515heiNo ratings yet

- Versatile AC Test System PDFDocument2 pagesVersatile AC Test System PDFreza515heiNo ratings yet

- TP - 101.01 - Short Circuit Impedance With Midas - 1110 PDFDocument4 pagesTP - 101.01 - Short Circuit Impedance With Midas - 1110 PDFreza515heiNo ratings yet

- ISH-2011 Requirements For-Testing HV-DC Equipment PDFDocument6 pagesISH-2011 Requirements For-Testing HV-DC Equipment PDFreza515heiNo ratings yet

- E1 34 PDFDocument7 pagesE1 34 PDFreza515heiNo ratings yet

- ISH 2011 - Paper Winding Resistance PDFDocument8 pagesISH 2011 - Paper Winding Resistance PDFreza515heiNo ratings yet

- Testing Power Quality Meters Using A CMC Test Set: SituationDocument8 pagesTesting Power Quality Meters Using A CMC Test Set: Situationreza515heiNo ratings yet

- Shunt Reactor PaperDocument6 pagesShunt Reactor Paperbukit_guestNo ratings yet

- E1 38 PDFDocument7 pagesE1 38 PDFreza515heiNo ratings yet

- ISH 2011 - The Achievable Voltage Measurement Uncertainty of The Bushing Tap Method During The Induced Voltage Test of Power Transformers PDFDocument7 pagesISH 2011 - The Achievable Voltage Measurement Uncertainty of The Bushing Tap Method During The Induced Voltage Test of Power Transformers PDFreza515heiNo ratings yet

- Tettex Information: Measuring Ratio On Power Transformers With Higher Test VoltagesDocument12 pagesTettex Information: Measuring Ratio On Power Transformers With Higher Test Voltagesreza515heiNo ratings yet

- E1 10 PDFDocument7 pagesE1 10 PDFreza515heiNo ratings yet

- E1 28 PDFDocument8 pagesE1 28 PDFreza515heiNo ratings yet

- E1 30 PDFDocument7 pagesE1 30 PDFreza515heiNo ratings yet

- E1 17 PDFDocument4 pagesE1 17 PDFreza515heiNo ratings yet

- E1 37 PDFDocument8 pagesE1 37 PDFreza515heiNo ratings yet

- E1 18 PDFDocument5 pagesE1 18 PDFreza515heiNo ratings yet

- E1 27Document11 pagesE1 27Neel GalaNo ratings yet

- E1 19 PDFDocument5 pagesE1 19 PDFreza515heiNo ratings yet

- E1 11Document6 pagesE1 11madhukarreddy2811No ratings yet

- E1 08 PDFDocument11 pagesE1 08 PDFreza515heiNo ratings yet

- 2013 03 PotM Monitoring of 420 KV XLPE Cable System in Underground Tunnel ENU PDFDocument5 pages2013 03 PotM Monitoring of 420 KV XLPE Cable System in Underground Tunnel ENU PDFreza515heiNo ratings yet

- Increasing The Trigger Range: Translated From ETZ-A, Vol. 92 (1971) Nr. 1, P. 56. - .57Document3 pagesIncreasing The Trigger Range: Translated From ETZ-A, Vol. 92 (1971) Nr. 1, P. 56. - .57Anil SinghNo ratings yet

- E1 09Document6 pagesE1 09bukit_guestNo ratings yet

- DSWpaper PDFDocument18 pagesDSWpaper PDFreza515heiNo ratings yet

- E1 03 PDFDocument8 pagesE1 03 PDFreza515heiNo ratings yet

- E1 04 PDFDocument7 pagesE1 04 PDFreza515heiNo ratings yet

- 2013 05 PotM Tuned Medium Band UHF PD Measurement Method For GIS ENU PDFDocument9 pages2013 05 PotM Tuned Medium Band UHF PD Measurement Method For GIS ENU PDFreza515heiNo ratings yet

- 2013 02 PotM ENU Performance Measurement PDFDocument6 pages2013 02 PotM ENU Performance Measurement PDFreza515heiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 3 DC Machines (Part2)Document40 pagesChapter 3 DC Machines (Part2)Simon LumNo ratings yet

- Bq24600 EvalDocument17 pagesBq24600 EvalAlexNo ratings yet

- Frequency Converter 50Hz To 60Hz DesignDocument8 pagesFrequency Converter 50Hz To 60Hz DesignwaynesgalaxyNo ratings yet

- Special Purpose MotorsDocument16 pagesSpecial Purpose MotorsHari ReddyNo ratings yet

- B2 Batch Report PDFDocument80 pagesB2 Batch Report PDFShruthi MudaliarNo ratings yet

- Efficiency and Regulation of Single-Phase TransformerDocument11 pagesEfficiency and Regulation of Single-Phase Transformersameerpatel15770No ratings yet

- El 5036 V2 PDFDocument86 pagesEl 5036 V2 PDFCriss TNo ratings yet

- Electrical Amplifier For The Control of Proportional Valves Without Electrical Position Feedback Type VT 3024Document8 pagesElectrical Amplifier For The Control of Proportional Valves Without Electrical Position Feedback Type VT 3024Mauricio GotteroNo ratings yet

- SF6 Circuit Breaker Nameplate Details Explanation - Electrical4uDocument8 pagesSF6 Circuit Breaker Nameplate Details Explanation - Electrical4uHawaz BeyeneNo ratings yet

- BAE146AVRO 146 RJ Maintenance Training Manual: Engine Starting ATA 80-00Document30 pagesBAE146AVRO 146 RJ Maintenance Training Manual: Engine Starting ATA 80-00Ale Torrico TamayoNo ratings yet

- Buddy™ Mig 500i Buddy™ Feed 402 Buddy™ Feed 402: Rugged & Reliable PackageDocument2 pagesBuddy™ Mig 500i Buddy™ Feed 402 Buddy™ Feed 402: Rugged & Reliable PackageKaung Sett LynnNo ratings yet

- Voltage RegulatorsDocument12 pagesVoltage RegulatorsErmin FazlicNo ratings yet

- Fault Detection and Protection of Transformer by Using MicrocontrollerDocument8 pagesFault Detection and Protection of Transformer by Using MicrocontrollerVelu SamyNo ratings yet

- Abb Flyer Diode ThyristorDocument2 pagesAbb Flyer Diode ThyristorHusejin Mehmedović100% (1)

- Toshiba Rechargeable Battery: Industrial Lithium-Ion BatteryDocument5 pagesToshiba Rechargeable Battery: Industrial Lithium-Ion BatterydeskinielNo ratings yet

- Micro TappDocument45 pagesMicro TappNaramuk Ak UhtumiramNo ratings yet

- Ecotecnia 48 750 Variable-Speed Wind TurbineDocument4 pagesEcotecnia 48 750 Variable-Speed Wind TurbineMarcWorldNo ratings yet

- Toshiba LTO CellDocument5 pagesToshiba LTO Celltou kaiNo ratings yet

- IGV C Controllers Electrical PartsDocument48 pagesIGV C Controllers Electrical PartsEl GaviNo ratings yet

- Electromagnetic Core Imperfection Detection (Elcid) : Presented at Latin America Power 2000, Caracas, Venezuela, May 2000Document20 pagesElectromagnetic Core Imperfection Detection (Elcid) : Presented at Latin America Power 2000, Caracas, Venezuela, May 2000ThiagoNo ratings yet

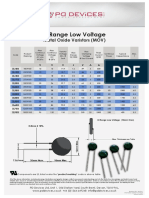

- D Range Low Voltage vPD1 PDFDocument1 pageD Range Low Voltage vPD1 PDFdeputadozeroNo ratings yet

- Alternating Current Test 1Document2 pagesAlternating Current Test 1SameerNo ratings yet

- A3941 DatasheetDocument21 pagesA3941 Datasheetsoft4gsmNo ratings yet

- Field: Zimbabwe Electricity Transmission Distribution CompanyDocument3 pagesField: Zimbabwe Electricity Transmission Distribution CompanyLawson SangoNo ratings yet

- PCE Catalogue 2011Document14 pagesPCE Catalogue 2011atnkpr_vn9368No ratings yet

- 2007 BatteriesGuide 0824Document3 pages2007 BatteriesGuide 0824Eli HazNo ratings yet

- Schematic Diagrams: Special NoteDocument16 pagesSchematic Diagrams: Special NotePedro CamachoNo ratings yet

- Racid inDocument8 pagesRacid inshyam_krishnan_16No ratings yet

- Electrical Circuits Course Chapter Series ParallelDocument65 pagesElectrical Circuits Course Chapter Series ParallelAdiba TasneemNo ratings yet

- tr150 PDFDocument103 pagestr150 PDFAnonymous ZLUrYLS7MNo ratings yet