Professional Documents

Culture Documents

AttockCostAuditreport 2009

Uploaded by

Farukh NaveedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AttockCostAuditreport 2009

Uploaded by

Farukh NaveedCopyright:

Available Formats

ATTOCK CEMENT PAKISTAN LIMITED

Cost Auditors Report

For the year ended June 30, 2009

SIDDIQI & COMPANY

Cost & Management Accountants

Suite # 147, First Floor, Haroon Shopping Emporium, Sector 15-A/1, North Karachi-75850 (Pakistan).

Tel: (92-21) 36971814 - 36931527, Fax (92-21) 36931527, E-mail <siddiqicompany@yahoo.com>

Attock Cement Pakistan Limited

Cost Audit Report, 2009

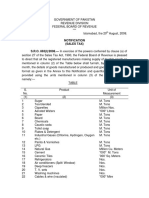

COST AUDITORS REPORT, 2008-2009

ATTOCK CEMENT PAKISTAN LIMITED

INDEX

Section 1

1.

2.

Page #

Corporate Information

The Company & Its Manufacturing Process

Section 2

Cost auditors Report

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14

15.

16.

17.

Capacity

Costing Accounting System

Production

Raw Material

Wages & Salaries

Stores & Spare Parts

Depreciation

Overheads

Royalty / Technical Aid Payment

Abnormal Non-Recurring Features

Cost of Production

Sales

Profitability

Cost Auditors Observation and Conclusions

Reconciliations with Financial Statements

Cost Statements

Miscellaneous

Schedules (1 to 3)

1

2

2

2

3

5

6

6

7

9

9

9

10

10

10

12

12

12

13-15

Statement of Production Capacity

Statement of Stock in Trade

Section 3

Departmental Cost Statements

1.

Quarry

2.

Transportation

3.

Crushing

4.

Stock Hall Storage

5.

Raw Mill (For Mix / Slurry)

6.

Kiln

7.

Grinding (Cement)

8.

Packing & Storage

9.

Air Compressing

10. Power Generated / Purchased and Consumed

11. Factory General

12. Summary of Cost Report

Cost of Sales of Ground Slag

Annexures

I

II

III

IV

V

VI

VII

VIII

IX

X

XI

XII

Attock Cement Pakistan Limited

Cost Audit Report, 2009

01. CORPORATE INFORMATION

Board of Directors

Chairman

Dr. Ghaith R. Pharaon

Chief Executive

Babar Bashir Nawaz

Directors

Laith G. Pharaon

Wael G. Pharaon

Shuaib A. Malik

Abdus Sattar

Bashir Ahmad

Babar Bashir Nawaz

Alternate Directors

Fakhrul Islam Baig

Irfan Amanullah

Audit Committee of the Board

Chairman

Abdus Sattar

Members

Bashir Ahmad

Fakhrul Islam Baig

Company Secretary

Irfan Amanullah

Statutory Auditors

A. F. Ferguson & Co.

Chartered Accountants

Cost Auditors

SIDDIQI & COMPANY

Cost & Management Accountants

Bankers

Faysal Bank Limited

MCB Bank Limited

Habib Bank Limited

National Bank of Pakistan

Bank Al-Falah Limited

Allied Bank Limited

KASB Bank Limited

Pak Kuwait Investment Co. (Pvt) Limited

Bank of Punjab

Bank Al-Habib

First Women Bank Limited

First Credit & Investment Bank Limited

JS Bank Limited

NIB Bank Limited

United Bank Limited

Pak Libya Holding Co. (Pvt.) Limited

Registered Office

D-70, Block-4, Kehkashan-5

Clifton, Karachi-75600.

Telephone# (92-21) 35309773-4, Fax # 35379775

Email. acpl@attockcement.com

Website: www.attockcement.com

Factory

Hub Chowki, Lasbella, Baluchistan.

Attock Cement Pakistan Limited

Cost Audit Report, 2009

02. THE COMPANY

&

MANUFACTURING PROCESS

1.

THE COMPANY

The Company was incorporated in Pakistan on October 14, 1981 as a public limited

Company and is listed on Karachi Stock Exchange. Its main business activity is

manufacturing and sale of cement.

2.

OPERATIONS

Basically the main objective of the Company is to manufacture and sell Cement.

3.

MANUFACTURING PROCESS

The Company is using the Dry Process Technology for manufacturing of cement. It owns

leased lime stone quarries. The process consists of the following departments:(i)

Lime Stone Quarry / Transportation

(ii)

Crushing

(iii)

Raw Mill (Mix / Slurry)

(iv)

Kiln

(v)

Grinding (Cement Mill)

(vi)

Packing & Storage

The major raw materials include:

(i)

Shale / Overburden

(ii)

Lime Stone

(iii)

Gypsum

(iv)

Slag

Packing Paper bags of 50 Kg. each are used in packing.

4.

FACTORY LOCATION

The Companys cement manufacturing plant is located in Tehsil Hub, District Lasbella,

Baluchistan, Pakistan.

Attock Cement Pakistan Limited

Cost Audit Report, 2009

COST AUDITORS REPORT

We, SIDDIQI & COMPANY, Cost & Management Accountants having been appointed to

conduct an audit of cost accounts of ATTOCK CEMENT PAKISTAN LIMITED, have examined

the books of account and the statement prescribed under clause (e) of sub-section 230 of the

Companies Ordinance, 1984 and the other relevant record for the year ended June 30, 2009,

and report that:1.

we have obtained all the information and explanations which to the best of our knowledge

and belief were necessary for the purpose of this audit.

2.

in our opinion:

3.

(a)

proper cost accounting records as required by clause (e) of sub-section (1) of section

230 of the Companies Ordinance, 1984 (XLVII of 1984), and as required by these

rules, have been kept by the Company;

(b)

proper returns, statements and schedules for the purpose of audit of cost accounts

relating to branches were not required as the Company has no branches in or

outside Pakistan.

(c)

the said books and records give the information required by the rules in the manner

so required; and

in our opinion and, subject to best of our information:(a)

the annexed statement of capacity utilization and stock-in-trade are in agreement

with the books of account of the Company and exhibit true and fair view of the

Companys affairs; and

(b)

cost accounting records have been properly kept so as to give a true and fair view of

the cost of production, processing, manufacturing and marketing of the under

mentioned products of the Company, namely,

1.

2.

3.

Ordinary Portland Cement (OPC)

Sulphate Resistance Cement (SRC)

Ground Slag

The matters contained in the ANNEXED Forms are part of this report.

SIDDIQI & COMPANY

Cost & Management Accountants

Karachi : 22 OCT 2009

[1]

Attock Cement Pakistan Limited

1.

Cost Audit Report, 2009

CAPACITY (Tonne)

(a)

Clinker

Kiln-I

Kiln-II

Licensed / Installed

Capacity

720,000

990,000

1,710,000

Utilized

Capacity

750,508

928,111

1,678,619

% of Installed

Capacity

104

94

98

(b) The company's main business activity is manufacturing and sale of cement.

2.

3.

COST ACCOUNTING SYSTEM

Manufacturing of cement is a continuous process, therefore, the company uses process cost accounting

system as prescribed by SECP as per Cement Industry (Cost Accounting Records) Order, 1994.

The company has classified whole manufacturing process into six major stages / departments for the

purpose of maintaining cost accounting records.

The company is operating a fully online integrated costing system, which generates cost statements

relating to six stages / departments and allocates cost thereon.

PRODUCTION

Qty. in Tonne

(a)

Production

Increase/(Decrease)

YEARS

Clinker

Line-1

Ordinary Portland Clinker

Suplhate Resistance Clinker

Line-2

Ordinary Potland Clinker

Cement

Ordinary Portland

Sulphate Resistance

2009

2008

Tonne

479,770

270,738

750,508

464,524

234,336

698,860

15,246

36,402

51,648

3

16

7

928,111

660,906

267,205

40

1,678,619

1,359,766

318,853

23

1,436,446

285,219

1,122,020

242,491

314,426

42,728

28

18

1,721,665

1,364,511

357,154

26

(b) The plant design facilitates production of the various types of cement as per production requirements

within the installed capacity limits.

(c) There is no addition to the production capacity during the year under review.

[2]

Attock Cement Pakistan Limited

4.

Cost Audit Report, 2009

RAW MATERIAL

(a)

Major Raw Materials Consumed

ITEMS

Quantity

(Tonne)

2009

Value

Rs. in '000'

Cost per

Tonne

Quantity

(Tonne)

2008

Value

Rs. in '000'

Cost per

Tonne

Quantity

(Tonne)

2007

Value

Rs. in '000'

Cost per

Tonne

Limestone

1,074,310

190,805

178

693,707

110,484

159

680,423

99,824

147

Shale / Overburden

1,500,726

235,326

157

1,390,585

195,863

141

1,297,682

174,925

135

107,246

65,100

607

103,177

57,292

555

96,600

53,224

551

61,397

82,849

1,349

61,264

59,246

967

45,956

32,564

709

4,205

4,679

1,113

22,576

30,705

1,360

12,115

13,780

1,137

Iron Ore & Salica Sand

Gypsum

Slag

Ground Slag

578,759

453,590

[3]

374,317

Attock Cement Pakistan Limited

Cost Audit Report, 2009

(b) Major Raw Materials consumption per unit of production compared with standard requirements.

Description

Limestone

Shale / Overburden

Iron Ore / Baux. Iron

Salica Sand

TOTAL

Gypsum

Standard

Tonne

TOTAL

Gypsum

% Increase / (Decrease)

as compared to Standard

2009

2008

2007

Clinker

Clinker

Clinker

Clinker

0.240

1.328

0.032

-

0.525

1.020

0.040

0.015

0.529

1.023

0.039

0.019

0.509

1.015

0.037

0.019

119

(23)

25

100

Clinker

1.600

1.600

1.611

1.580

(0)

(1)

Cement

0.050

0.048

0.045

0.039

(4)

(9)

(22)

Description

Limestone

Shale / Overburden

Iron Ore

Salica Sand

Ordinary Portland Cement

2009

2008

2007

Tonne

Tonne

Tonne

Standard

Tonne

Sulphate Resistance Cement

2009

2008

2007

Tonne

Tonne

Tonne

121

(23)

22

100

112

(24)

16

100

% Increase / (Decrease)

as compared to Standard

2009

2008

2007

Clinker

Clinker

Clinker

Clinker

0.240

1.264

0.096

-

0.424

1.021

0.110

0.045

0.419

1.020

0.113

0.048

0.186

1.285

0.130

0.029

77

(19)

15

100

Clinker

1.600

1.600

1.600

1.630

(0)

Cement

0.050

0.036

0.043

0.038

(28)

74

(19)

18

100

(15)

(23)

2

35

100

2

(24)

(c) Explanation of Variances

The variances from standard requirements are attributed to chemical contents of raw materials.

(d) Method of Accounting

The company is maintaining raw material records using perpetual inventory system. The per unit cost for issue of

material is determined using weighted average basis.

Limestone and shale / overburden are extracted from leased mines.

Salica Sand, Iron ore, Bauxite, Gypsum and Slag are purchased from open market. The quantities and values are

recorded in the store ledger and general ledger from stores receiving report.

[4]

Attock Cement Pakistan Limited

5.

Cost Audit Report, 2009

WAGES AND SALARIES

(a) Total wages and salaries paid for all categories of employees

2009

Rs. in '000'

154,000

359,333

513,333

114,926

32,725

660,984

Direct labour cost on production

Indirect labour cost on production

Employees' cost on administration

Employees' cost on selling and distribution

Total employees cost

2008

Rs. in '000'

106,758

244,673

351,431

79,779

20,959

452,169

Increase / (Decrease)

Rs. in '000'

%

47,242

44

114,660

47

161,902

46

35,147

44

11,766

56

208,815

46

Salaries and wages increased mainly due to inflationary trend and annual increments.

(b) Salaries and perquisites of Chief Executive,Directors and Executives

The aggregate amounts charged in these financial statements for remuneration to the Chief Executive,

Directors and Executives of the Company are as follows :

2009

Rs. in `000'

Managerial remuneration

Housing Allowance

Utility Allowance

Bonus

Retirement benefits

Others

Number of person(s)

Chief

Executive

8,538

2,988

1,138

2,779

1,087

863

17,393

2008

Rs. in `000'

Directors

Executives

8,096

3,241

667

3,490

550

1,229

17,273

47,264

17,841

3,602

15,923

6,879

6,526

98,035

Chief

Executive

6,599

2,310

880

2,607

1,210

739

14,345

38

Directors

Executives

7,895

2,859

545

2,999

1,497

930

16,725

32,174

12,026

2,388

11,209

6,566

4,852

69,215

28

The chief executive, working Directors and executives are provided with free use of company maintained cars

and are also provided with medical facilities in accordance with their entitlements.

A sum of Rs. 0.92 million (2008: Rs. 0.92 million) was paid to two non-executive directors in respect of

advisory services.

(c) Total man-days of direct labour

300 days x 270 workers = 81,000

308 days x 270 workers = 83,160

Worked

Available

83,160

(d) Average number of production workers employed

(e) Direct labour cost per tonne

Direct labour cost (Rs. in '000')

Prduction in tonne

Cost per tonne (Rs. / tonne)

81,000

2009

270

2008

267

2009

154,000

1,721,665

89

2008

106,758

1,364,511

78

Per tonne direct labour cost increased due to reasons given at item 5(a) above.

[5]

% Worked

103

Increase / (Decrease)

3

% of Increase / (Decrease)

44

26

15

Attock Cement Pakistan Limited

Cost Audit Report, 2009

(f) Comments on Incentives Scheme

6.

The company awards bonus based on the profitability of the company and performance of the employees.

STORES AND SPARE PARTS

(a) Expenditure per unit of output

2009

Stores & spares consumed (Rs.in '000')

Production in tonne

Cost per tonne (Rs./tonne)

263,656

1,721,665

153

2008

% of Increase / (Decrease)

154,819

1,364,511

113

70

26

35

Stores and spares increased due to replacement of gear box of raw mill and heavy repairs of conditioning tower.

(b) System of stores

The company is using computerized perpetual inventory system for store accounting integrated with financial

accounting system. Per unit cost is calculated using weighted average basis.

All items of stores are properly coded and entered by designated staff members of the finance department

through network system, on daily basis.

(c) Proportion of closing inventory of stores representing items

which have not moved for over twenty four months.

Slow moving items amounting to Rs. 18.030 million which represents 2.92% (2008: 5.859 million: 0.94%) of

closing inventory.

7.

DEPRECIATION

(a) Method of depreciation

Upto the previous year depreciation had been charged to income applying the reducing balance method,

whereas in the current year the method for providing depreciation has been changed to straight line method in

order to better reflect the pattern in which the economic benefits of the assets are consumed by the

company.The depreciation rates have also been revised to reflect the useful lives of assets after the change in

the depreciation method.

Depreciation on acquisition is charged from the month of addition whereas no depreciation is charged on the

month of disposal.

Maintenance and normal repairs are charged to income as and when incurred. Major renewals and

improvements are capitalized and the assets so replaced, if any, are retired.

(b) Basis of allocation of depreciation on common assets to the different departments.

Depreciation on common assets is allocated as under:

(i) Cost of Sales

(ii) Administrative Expenses

(iii) Distribution Cost

2009

%

(Rs. '000)

97.710

463,580

2.120

10,040

0.170

819

100.00

474,439

(c) Basis of charging depreciation to cost of products

The depreciation is allocated to cost of production on the value of assets employed.

[6]

2008

%

(Rs. '000)

98.690

395,937

1.160

4,655

0.150

597

100.00

401,189

Attock Cement Pakistan Limited

8.

Cost Audit Report, 2009

OVERHEADS

(a) Total amounts of the overheads

(i)

(ii)

(iii)

(iv)

Factory

Administration

Selling & distribution

Financial

2009

Rs. in '000'

2008

Rs. in '000'

664,976

182,420

437,194

119,763

549,613

133,582

124,744

153,909

481,727

110,701

83,360

102,072

1,404,353

961,848

777,860

(i) Factory Overheads

Repairs and maintenance

Vehicle running & maintenance

Travelling and entertainment

Depreciation

Insurance

Others

2009

Rs.in'000'

55,619

53,037

4,369

463,580

34,594

53,777

664,976

2008

Rs. in '000'

66,139

42,229

3,186

395,937

22,196

19,926

549,613

2007

Rs. in '000'

35,255

37,230

2,201

358,029

22,140

26,872

481,727

% Increase / (Decrease)

Based on

Based on

2008

2007

(16)

58

26

42

37

99

17

29

56

56

170

100

21

38

Factory overheads increased mainly due to increase in depreciation, vehicle running & maintenance and other

overheads.

(ii) Administration Overheads

Salaries, wages and benefits

Utilities

Repairs and maintenance

Depreciation

Vehicle running & maintenance

Travelling and entertainment

Communication

Printing and stationery

Auditor's remuneration

Legal and professional charges

Advertising

Rent, rates and taxes

Donations

Insurance

Training

Subscription

Others

2007

Rs. in '000'

2009

Rs.in'000'

114,926

3,676

5,621

10,040

6,293

5,836

3,402

3,004

1,600

5,856

1,053

6,758

6,856

3,601

195

1,376

2,327

182,420

2008

Rs. in '000'

79,779

2,654

7,910

4,655

5,446

4,216

2,565

3,318

1,455

5,608

2,330

7,158

204

2,696

407

1,265

1,916

133,582

2007

Rs. in '000'

68,928

1,549

1,904

9,090

5,538

2,915

2,176

1,670

1,095

4,365

1,134

6,453

40

1,054

110

1,292

1,388

110,701

% Increase / (Decrease)

Based on

Based on

2008

2007

44

67

39

137

(29)

195

116

10

16

14

38

100

33

56

(9)

80

10

46

4

34

(55)

(7)

(6)

5

3,261

17,040

34

242

(52)

77

9

7

21

68

37

65

Administration overheads increased mainly due to increase in salaries & wages, depreciation and donations.

[7]

Attock Cement Pakistan Limited

Cost Audit Report, 2009

(iii) Selling and Distribution Overheads

2008

Rs. in '000'

2007

Rs. in '000'

32,725

20,959

19,603

56

67

819

597

72

37

1,038

PSI marking fee

27,275

3,984

2,889

585

844

Carriage outward

16,376

6,285

870

161

1,782

Advertisement and sales promotion

1,364

2,083

5,522

Travelling and entertainment

1,783

357

311,071

Salaries, wages and benefits

Depreciation

Export expenses

Commission on export sales

Miscellaneous expenses

% Increase / (Decrease)

Based on

Based on

2008

2007

2009

Rs.in'000'

(35)

(75)

745

399

139

78,947

52,478

294

493

43,548

9,899

340

100

2,233

1,633

1,181

37

89

437,194

124,744

83,360

250

424

Selling & distribution expenses increased due to increase in export expenses incurred on export of Clinker,

Cement and PSI marking fee and carriage outward.

(iv) Financial Charges

2008

Rs. in '000'

2007

Rs. in '000'

94,016

109,468

88,833

(14)

Markup on short term loan

10,270

4,161

(100)

(100)

Markup on running finance

3,557

2,985

(100)

(100)

Markup on export refinance

1,419

Finance lease charges

Markup on long term murabaha

44

430

(100)

(100)

(100)

Bank charges and commission

14,596

6,207

3,942

135

270

Exchange loss

10,957

24,312

(55)

100

194

51

302

280

(36)

119,763

153,909

102,072

(22)

17

Interest on workers' profits participation fund

% Increase / (Decrease)

Based on

Based on

2008

2007

2009

Rs.in'000'

The decrease in financial cost was due to repayment of long term murabaha and reduction in exchange loss.

(b) Reasons for any significant variances in the overheads

Reasons have already been given against items where ever necessary.

(c) Basis of allocation of overheads

The allocation was made on activity based on %age basis.

[8]

Attock Cement Pakistan Limited

Cost Audit Report, 2009

(d) Cost of Packing

1,534,581

184,581

1,719,162

Qty. in Tonne

2008

1,313,970

45,517

1,359,487

2009

Rs. in '000' Rupees/Ton

514,606

335.34

12,651

7.36

8,178

4.76

17,242

10.03

692

0.40

9,351

5.44

49,844

28.99

612,564

392.32

2008

Rs. in '000'

Rupees/Ton

344,507

262.19

9,054

6.66

5,670

4.17

19,245

14.16

444

0.33

7,919

5.82

31,204

22.95

418,043

316.28

OPC+SRC

Packed cement

Bulk cement

Total

2009

Packing material

Power

Salaries & wages

Stores / spares, repair & maint.

Insurance

Depreciation

Other administrative overheads

9.

Increase / (Decrease)

Rupees/Ton

%

73

28

1

10

1

14

(4)

(29)

0

23

(0)

(7)

6

26

76

24

ROYALTY / TECHNICAL AID PAYMENTS

Production

in Tonne

Limestone &

Shale/Overburden

2,512,273

2009

Amount

Rs. In '000

Rupees /

Tonne

Production

in Tonne

2008

Amount

Rs. In '000

75,255

29.95

2,094,610

81,178

Rupees /

Tonne

38.76

Royalty and excise duty is paid to the provincial government on the quantity of limestone, shale / overburden

extracted and transported to mill from quarries at statutory rates.

10. ABNORMAL NON-RECURRING FEATURES

(a) Features affecting production

=

NONE

(b) Special expenses

=

NONE

11. COST OF PRODUCTION

(As per Schedule-1 attached)

Qty. in

Tonne

Cement

OPC

SRC

Ground Slag

Sub-total

Clinker

OPC

2 0 0 9

Rs. in

000

Rs.

Per Ton

Qty. in

Tonne

2 0 0 8

Rs. in

000

Rs.

Per Ton

Increase /

(Decrease)

% Rs. P/Ton

1,436,446

285,219

3,629

1,725,294

4,809,664

962,269

6,773

5,778,706

3,348

3,374

1,866

3,349

1,122,020

242,491

22,718

1,387,229

3,128,697

662,322

43,350

3,834,369

2,788

2,731

1,908

2,764

20.08

23.52

(2.19)

21.18

17,990

45,857

2,549

35,000

74,898

2,140

19.12

1,743,284

5,824,563

3,341

1,422,229

3,909,267

2,749

21.55

Reasons for variances

Cost per tonne increased mainly due to increase in depreciation and fuel cost.

[9]

Attock Cement Pakistan Limited

Cost Audit Report, 2009

12. SALES

(As per Schedule-2 attached)

Qty. in

Tonne

2 0 0 9

Rs. in

000

Rs.

Per Ton

Qty. in

Tonne

2 0 0 8

Rs. in

000

Rs.

Per Ton

Increase /

(Decrease)

% P/Ton

Cement

OPC

1,437,471

6,983,224

4,858

1,119,187

3,955,848

3,535

37.44

SRC

281,691

1,423,633

5,054

240,299

859,314

3,576

41.33

Ground Slag

4,205

17,239

4,099

22,576

74,949

3,320

23.48

Sub-total

1,723,367

8,424,096

4,888

1,382,062

4,890,111

3,538

38.15

17,990

85,975

4,779

35,000

111,239

3,178

50.37

1,741,357

8,510,071

4,887

1,417,062

5,001,350

3,529

38.47

Clinker

OPC

Clinker was exported to UAE.

Cement was exported to Iraq, Qatar, UAE, Kuwait, Somalia, Tanzania, Mauritius, Sudan, Bahrain, India, Yemen,

and Djibouti.

13. PROFITABILITY

(As per Schedule-3 attached)

Qty. in

Tonne

2 0 0 9

Rs. in

000

Rs.

Per Ton

Qty. in

Tonne

2 0 0 8

Rs. in

000

Rs.

Per Ton

Increase /

(Decrease)

% Rs. P/Ton

Cement

OPC

1,437,471

1,621,842

1,128

1,119,187

497,284

444

153.93

SRC

281,691

336,371

1,194

240,299

142,054

591

102.00

Ground Slag

4,205

7,215

1,716

22,576

19,417

860

99.48

Sub-total

1,723,367

1,965,428

1,140

1,382,062

658,755

477

139.27

17,990

23,298

1,295

35,000

16,213

463

179.57

1,741,357

1,988,726

1,142

1,417,062

674,968

476

139.77

Clinker

OPC

The increase in net profit is due to the following reasons:

Overall capacity utilization increased by 18% resulting improved plant efficiencies and higher absorption of fixed

overheads.

Mainly due to improved in net retention as compared to previous year.

The decrease in financial cost was due to repayment of long term murabaha and reduction in exchange loss.

Because of significant increase in export sales.

[ 10 ]

Attock Cement Pakistan Limited

Cost Audit Report, 2009

14. COST AUDITORS' OBSERVATIONS AND CONCLUSIONS

(a) Matters which appear to him to be clearly wrong in principle or apparently unjustifiable.

No such matters have so far come to our notice during the year under review.

(b) Cases where the company funds have been used in a negligent or inefficient manner.

=

N ONE

(c) Factors which could have been controlled but have not been done resulting in increase in the cost

of production.

=

N ONE

=

(d)

(i) The Adequacy or otherwise of Budgetary Control System, if any, in vogue in the company.

The company prepares its budget on annual basis. A monthly report comparing actual results with budget is

generated alongwith the reasons for major variances. On the basis of such variances corrective measures

are initiated, implemented and followed up.

(ii) The scope and performance of Internal Audit, if any.

The Board has outsourced the internal audit function to M/s. Ernst & Young Ford Rhodes Sidat Hyder &

Co., Chartered Accountants who are involved in the internal audit function on a full time basis.

(e) Suggestion for improvements in performance.

(i) rectification of general imbalance in production facilities

Apparently, there is no general imbalance in production facilities.

(ii) fuller utilization of installed capacity

Kiln # I has achieved 104% capacity utilization where as Kiln # II achieved 94% of capacity utilization

which has yielded good production results.

(iii) Comments on areas offering scope for

(a) Cost reduction

Company is working on various projects to reduce its cost of production prominent among them is

waste heat recurring system.

(b) Increased productivity

The company has already expanded its clinker production in 2005-06 from 2400/TPD to 5700/TPD

and as a result thereof, the fixed cost per tonne decreased considerably.

(c) Key limiting factors causing production bottle necks.

=

NONE

[ 11 ]

Attock Cement Pakistan Limited

Cost Audit Report, 2009

(d) Improved inevntory policies

Present inventory policies are satisfactory.

(e) Energy conservancy

The company has already switched over to `COAL' as one of the cheapest source of energy.

(iv) State of technology

The company uses 'Dry Process' which is the latest technology in cement production.

(v) Plant

The plant was new when installed.

15. RECONCILIATIONS WITH FINANCIAL STATEMENTS

Cost accounts are in agreement with financial accounts of the company for the year ended June 30, 2009.

16. COST STATEMENTS

Copies of all cost statements on the formats prescribed by Securities and Exchange Commission of Pakistan

under clause (e) of sub-section (1) of section 230 of the Companies Ordinance, 1984, duly authenticated by the

chief executive and Chief Financial Officer of the company, and verified by us are appended to the report.

17. MISCELLANEOUS

Figures have been rounded off to nearest thousand and rupee one. Previous year's figures have been re-arranged

and regrouped where necessary to facilitate comparison.

SIDDIQI & COMPANY

Cost & Management Accountants

Karachi : 22 OCT 2009

[ 12 ]

Attock Cement Pakistan Limited

Cost Audit Report, 2009

Schedule-1

COST OF PRODUCTION

Quantitative Data

Particulars

CEMENT

OPC

Production (Tonne)

2 0 0 9

2 0 0 8

Quantity in Tonne

Quantity in Tonne

GROUND

CLINKER

1,436,446

CEMENT

TOTAL

SLAG

SRC

285,219

17,990

3,629

1,743,284

GROUND

CLINKER

SRC

OPC

1,122,020

TOTAL

SLAG

242,491

35,000

22,718

1,422,229

Cost Elements

2 0 0 9

2 0 0 8

CEMENT

Particulars

CLINKER

OPC

Rs. in '000

Cost of sales

Transferred to raw

GROUND

4,807,148

SRC

Rs./Ton

3,347

(7,342)

Rs. in '000

949,200

CEMENT

TOTAL

SLAG

Rs./Ton

3,328

Rs. in '000

45,857

Rs./Ton

2,549

Rs. in '000

7,691

OPC

Rs./Ton

2,119

(1,458)

Rs. in '000

5,809,897

Rs./Ton

3,333

(8,800)

Rs. in '000

3,111,761

GROUND

CLINKER

SRC

Rs./Ton

2,773

Rs. in '000

655,674

TOTAL

SLAG

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

3,885,204

Rs./Ton

2,704

74,898

2,140

42,871

1,887

1,598

345

1,943

2,732

-

15,338

6,303

479

22,120

2,731

74,898

2,140

material inventory

WIP Inventory adjustment

Cost of goods manufactured

9,857

4,809,664

14,527

3,348

962,269

3,374

45,857

2,549

(918)

6,773

1,866

23,466

5,824,563

[ 13 ]

3,341

3,128,697

2,788

662,322

43,350

1,908

3,909,267

2,749

Attock Cement Pakistan Limited

Cost Audit Report, 2009

Schedule-2

NET SALES REALIZATION

Quantitative Data

Particulars

CEMENT

Export

Quantity sold

2 0 0 8

Quantity in Tonne

GROUND

CLINKER

SRC

OPC

Local Sales

2 0 0 9

Quantity in Tonne

CEMENT

TOTAL

SLAG

GROUND

CLINKER

SRC

OPC

TOTAL

SLAG

1,079,181

170,831

2,205

1,252,218

1,029,365

239,799

10,623

1,279,787

358,290

110,860

17,990

2,000

489,140

89,822

500

35,000

11,953

137,275

1,437,471

281,691

17,990

4,205

1,741,357

1,119,187

240,299

35,000

22,576

1,417,062

Net Sales Value Realization

2 0 0 9

2 0 0 8

CEMENT

Particulars

CLINKER

OPC

Rs. in '000

Gross Sales

GROUND

SRC

Rs./Ton

Rs. in '000

CEMENT

TOTAL

SLAG

Rs./Ton

8,967,461

6,238

1,743,777

6,190

956,279

665

151,370

51,444

36

8,538

Rs. in '000

Rs./Ton

Rs. in '000

OPC

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

GROUND

CLINKER

Rs./Ton

Rs. in '000

TOTAL

SLAG

SRC

Rs./Ton

85,975

4,779

18,669

4,439

10,815,882

6,211

5,392,330

4,818

1,197,684

4,984

537

1,107,649

636

753,133

673

177,029

737

30

60,068

34

35,546

Rs. in '000

111,239

Rs./Ton

Rs. in '000

Rs./Ton

3,178

79,394

3,517

278

Rs. in '000

Rs./Ton

6,780,647

4,785

930,162

656

44,331

31

Less:

Excise duty

Special excise duty

Sales tax

86

20

8,507

976,514

679

160,236

569

1,344

320

1,138,094

654

647,803

579

152,834

636

4,168

185

804,805

568

1,984,237

1,380

320,144

1,137

1,430

340

2,305,811

1,324

1,436,482

1,284

338,370

1,408

4,446

197

1,779,298

1,256

6,983,224

4,858

1,423,633

5,054

85,975

4,779

17,239

4,099

8,510,071

4,887

3,955,848

3,535

859,314

3,576

3,178

74,949

3,320

5,001,350

3,529

[ 14 ]

111,239

Attock Cement Pakistan Limited

Cost Audit Report, 2009

Schedule-3

PROFITABILITY

2 0 0 9

Particulars

CEMENT

OPC

Quantity sold

Quantity in Tonne

Quantity in Tonne

LOCAL SALES

EXPORT SALES

GROUND

CLINKER

SRC

1,079,181

CEMENT

TOTAL

SLAG

170,831

OPC

2,205

1,252,218

GROUND

CLINKER

SRC

358,290

TOTAL

TOTAL

SLAG

110,860

17,990

2,000

489,140

1,741,357

Product wise Profitability

2 0 0 9

LOCAL SALES

Particulars

CEMENT

OPC

Rs. in '000

Net Sales

Less:

Cost of production

Inv. Adjust. (Finished)

Cost of goods sold

Gross profit

SRC

Rs./Ton

Rs. in '000

CEMENT

TOTAL

OPC

SLAG

Rs./Ton

Rs. in '000

5,191,500

4,811

854,715

5,003

3,613,431

3,348

576,349

3,374

(14,525)

3,603,573

3,339

561,824

1,587,927

1,471

292,891

(9,857)

EXPORT SALES

GROUND

CLINKER

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

TOTAL

GROUND

CLINKER

SRC

TOTAL

SLAG

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

Rs./Ton

8,399

3,809

6,054,614

4,835

1,791,724

5,001

568,918

5,132

85,975

4,779

8,840

4,420

2,455,457

5,020

8,510,071

4,887

4,116

1,866

4,193,896

3,349

1,196,233

3,339

385,920

3,481

45,857

2,549

2,657

1,329

1,630,668

3,334

5,824,563

3,345

918

3,289

5,034

2,283

4,170,431

3,330

1,196,233

3,339

385,920

3,481

45,857

2,549

2,657

1,329

1,630,668

3,334

5,801,099

3,331

1,715

3,365

1,526

1,884,183

1,505

595,491

1,662

182,998

1,651

40,118

2,230

6,183

3,091

824,789

1,686

2,708,972

1,556

(23,464)

(23,464)

Less:

Selling & distribution

Administrative exp.

51,175

47

8,101

47

105

47

59,380

47

16,990

47

5,257

47

853

47

95

47

23,195

47

82,575

47

113,052

105

17,896

105

231

105

131,179

105

37,533

105

11,613

105

1,885

105

210

105

51,241

105

182,420

105

69

11,749

152

69

86,122

Financial charges

74,221

Export expenses

69

-

69

-

24,642

69

7,624

69

1,237

69

138

69

33,641

69

119,763

69

259,755

725

80,372

725

13,042

725

1,450

725

354,619

725

354,619

204

Other charges

91,350

85

14,460

85

187

85

105,997

85

30,328

85

9,384

85

1,523

85

169

85

41,405

85

147,402

85

Other income

(103,206)

(96)

(16,337)

(96)

(211)

(96)

(119,755)

(96)

(34,265)

(96)

(10,602)

(96)

(1,720)

(96)

(191)

(96)

(46,778)

(96)

(166,533)

(96)

226,592

210

35,869

210

463

210

262,924

210

334,984

935

103,649

935

16,820

935

1,870

935

457,322

935

720,246

414

1,361,335

1,261

257,022

1,505

2,902

1,316

1,621,259

1,295

260,507

727

79,349

716

23,298

1,295

4,313

2,156

367,467

751

1,988,726

1,142

2 0 0 8

Quantity in Tonne

Quantity in Tonne

Particulars

LOCAL SALES

CEMENT

OPC

Quantity sold

CLINKER

SRC

1,029,365

CEMENT

TOTAL

SLAG

239,799

TOTAL

EXPORT SALES

GROUND

OPC

10,623

1,279,787

GROUND

CLINKER

SRC

89,822

TOTAL

SLAG

500

35,000

11,953

137,275

1,417,062

Product wise Profitability

2 0 0 8

LOCAL SALES

Particulars

CEMENT

OPC

Rs. in '000

Net Sales

Less:

Cost of production

Inv. Adjust. (Finished)

Cost of goods sold

Gross profit

Less:

Selling & distribution

Administrative exp.

Financial charges

Export expenses

Other charges

Other income

SRC

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

EXPORT SALES

GROUND

SLAG

CLINKER

Rs./Ton

Rs. in '000

CEMENT

TOTAL

Rs./Ton

Rs. in '000

OPC

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

TOTAL

GROUND

SLAG

CLINKER

SRC

Rs./Ton

Rs. in '000

TOTAL

Rs./Ton

Rs. in '000

Rs./Ton

Rs. in '000

Rs./Ton

3,581,612

3,479

856,980

3,574

27,722

2,610

4,466,314

3,490

370,865

4,129

2,340

4,680

113,763

3,250

48,068

4,021

535,036

3,898

5,001,350

3,529

2,877,597

(14,107)

2,863,490

2,796

2,782

660,944

(6,290)

654,654

2,756

2,730

20,398

(225)

20,173

1,920

1,899

3,558,939

(20,622)

3,538,317

2,781

2,765

251,099

(1,231)

249,868

2,796

2,782

1,378

(13)

1,365

2,756

2,730

74,898

74,898

2,140

2,140

22,952

(254)

22,698

1,920

1,899

350,327

(1,498)

348,829

2,552

2,541

3,909,266

(22,120)

3,887,146

2,759

2,743

844

7,549

711

927,997

725

120,997

1,347

975

1,950

38,865

1,110

25,369

2,122

186,207

1,356

1,114,204

26

97

111

40

(20)

254

276

1,027

1,183

422

(214)

2,693

26

97

111

40

(20)

254

33,242

123,697

142,519

50,783

(25,779)

324,461

26

97

111

40

(20)

254

2,333

8,682

10,003

58,091

3,564

(1,809)

80,863

26

97

111

647

40

(20)

900

13

48

56

324

20

(10)

450

22,652

22,652

647

647

310

1,155

1,331

7,778

474

(241)

10,809

590

4,856

457

603,537

472

[ 15 ]

40,134

447

524

16,213

463

14,561

718,122

698

26,737

99,492

114,632

40,846

(20,735)

260,972

26

97

111

40

(20)

254

457,150

444

202,326

6,229

23,178

26,704

9,515

(4,830)

60,796

141,530

26

96

112

648

40

(20)

900

1,048

26

97

111

651

40

(20)

904

1,218

786

2,656

9,885

11,390

88,845

4,058

(2,060)

114,774

19

72

83

647

30

(15)

836

35,898

133,582

153,909

88,845

54,841

(27,839)

439,236

25

94

109

63

39

(20)

310

71,432

520

674,967

476

ATTOCK CEMENT PAKISTAN LIMITED

STATEMENT OF PRODUCTION CAPACITY

under Rule 4(1)(a) of Companies

(Audit of Cost Accounts) Rule 1998

As at June 30, 2009 as compared with June 30, 2008

Machine Hours

Departments

Licensed /

Installed

Capacity

2009

Utilized Capacity

2008

% of Installed

Utilized Capacity

Capacity

% of Installed

Capacity

Kiln - I

7,200

7,375

102.43

6,972

96.83

Kiln - II

7,200

7,462

103.64

6,018

83.58

14,400

14,837

103.03

12,990

90.21

Cement Mill - I

7,200

6,097

84.68

5,147

71.49

Cement Mill - II

7,200

5,172

71.83

4,787

66.49

Cement Mill - III

7,200

5,004

69.50

4,399

61.10

Cement Mill - IV

7,200

6,041

83.90

3,925

54.51

28,800

22,314

77.48

18,258

63.40

Total

Total

Production Units (Tonne)

Departments

Licensed /

Installed

Capacity

2009

Utilized Capacity

2008

% of Installed

Utilized Capacity

Capacity

% of Installed

Capacity

Kiln - I

720,000

750,508

104.24

698,860

97.06

Kiln - II

990,000

928,111

93.75

660,906

66.76

1,710,000

1,678,619

98.16

1,359,766

79.52

Cement Mill - I

792,000

534,625

Cement Mill - II

324,000

174,216

53.77

116,755

36.04

Cement Mill - III

720,000

457,489

63.54

408,787

56.78

Cement Mill - IV

720,000

555,335

77.13

355,534

49.38

2,556,000

1,721,665

67.36

1,364,511

53.38

Total

Total

Chief Executive

Karachi: 22 OCT 2009

67.50

483,435

Chief Financial Officer

61.04

ATTOCK CEMENT PAKISTAN LIMITED

STATEMENT UNDER RULE 4(1)(b) OF COMPANIES

AUDIT OF COST ACCOUNTS RULES, 1998

STOCK IN TRADE FOR THE YEAR ENDED JUNE 30, 2009

AND COMPARED WITH JUNE 30, 2008

(Rupees in '000)

2009

Quantity

( MT )

2008

Cost in

Rupees

Quantity

( MT )

Cost in

Rupees

Stock of Raw and Packing Material :

Shale & Overburden

Lime stone

Iron ore / Bauxitic Iron

Gypsum

Slag

Salica Sand

Packing bags

Sub Total : -

2,758

59,314

15,578

40,885

8,985

3,208

2,885,495

Tonne

Tonne

Tonne

Tonne

Tonne

Tonne

Nos.

505

10,689

9,704

60,860

9,144

1,285

51,787

143,974

12,807 Tonne

16,047 Tonne

124,083 Tonne

7,839 Tonne

131,922

160,776

7,976

116,860

32,294

22,946

6,026

12,116

2,765,204

Tonne

Tonne

Tonne

Tonne

Tonne

Tonne

Nos.

510

19,484

21,919

21,678

5,611

3,727

43,583

116,511

3,325

6,624

19,009 Tonne

13,353 Tonne

4,391

4,982

337,405

21,316

181,879

23,910

368,670

82,873 Tonne

10,993 Tonne

93,866

126,228

215,162

23,223 Tonne

8,478 Tonne

31,701

73,835

27,094

100,929

24,248 Tonne

4,950 Tonne

29,198

63,978

12,569

76,547

211 Tonne

361

787 Tonne

1,279

Stock of Work-in-Process :

Stock Pile Formation

Raw Meal

Clinker :

OPC

SRC

Sub Total : -

Stock of Finished Products :

Ordinary Portland Cement

Sulphate Resisting Cement

Sub Total : Ground Slag

Grand Total : -

613,934

409,499

Notes:

01.

In terms of clause 3(2) of Companies (Audit of Cost Audit) Rules, 1998 (SRO:846/(1)/98 dt. July 24, 1998,

the Cost Auditor was appointed by the directors with the prior approval of Securities & Exchange

Commission of Pakistan within sixty days of the close of financial year of the company.

02.

In view of the above mentioned constraints appointing the Cost Auditors after the close of the financial

year; they were not present on the date of physical stock taking as of the close of the financial year. Under

the situation, the physical stock taking carried out by the management and witnessed and certified by the

statutory auditors as of June 30, 2009 was relied upon for the purpose of the above metnioned statement

of stock in trade (under clause (4)(1)(b) of Companies (Audit of Cost Accounts) Rules, 1998.

Chief Executive

Karachi: 22 OCT 2009

Chief Financial Officer

ATTOCK CEMENT PAKISTAN LIMITED

Annexure-I

NAME OF DEPARTMENT - QUARRY

FOR THE YEAR ENDED JUNE 30, 2009

A. Quantitative Data

Opening stock at quarry

Quantity quarried

Total available stock

Quantity transported to crusher

Stock adjustment (if any)

Closing stock at quarry

2009

Tonne

124,836

2,512,273

2,637,109

2,575,037

62,072

2008

Tonne

114,518

2,094,610

2,209,128

2,084,292

124,836

Increase/(Decrease)

Tonne

10,318

417,663

427,981

490,745

(62,764)

B. Cost Statement

Cost

Direct Departmental Costs:

Explosives (if any)

Royalty and duties

Labour cost

Salaries

Employee's other benefits

Contract Labour

Insurance

Stores & spares

Repairs and maintenance

Diesel-oil

Depreciation

Sub-Total :

2009

Rs. in '000'

Rs.Per Tonne

2008

Rs. in '000'

Rs.Per Tonne

25,482

75,255

29,908

7,514

9,490

4,628

2,422

4,223

2,781

3,726

18,763

184,192

10.14

29.95

11.90

2.99

3.78

1.84

0.96

1.68

1.11

1.48

7.47

73.32

17,011

81,178

20,733

5,209

6,579

3,208

1,554

3,464

2,309

4,741

18,216

164,201

8.12

38.76

9.90

2.49

3.14

1.53

0.74

1.65

1.10

2.26

8.70

78.39

35,759

14.23

23,443

11.19

35,759

14.23

23,443

11.19

219,951

87.55

187,644

89.58

19,994

18,053

Total cost of available stock :

239,945

90.99

205,697

93.11

C. Cost Distribution

Cost transferred to crusher.

Cost of closing stock.

228,751

11,194

88.83

-

185,703

19,994

89.10

-

239,945

90.99

205,697

93.11

Indirect Departmental Costs :

Compressed Air (Annexure IX)

Power (Annexure X)

Other Factory Expenses (Annexure XI)

Sub-Total :

Total cost of the period

Add : cost of opening stock

Total cost accounted for:

Chief Executive

Chief Financial Officer

ATTOCK CEMENT PAKISTAN LIMITED

Annexure-II

DEPARTMENTAL COST STATEMENT

NAME OF DEPARTMENT - TRANSPORTATION

FOR THE YEAR ENDED JUNE 30, 2009

A. Quantitative Data

2009

Tonne

Quantity transported from quarry :

(i) Shale/Overburden

(ii) Lime Stone

(iii) Gypsum

Total:

Increase/(Decrease)

Tonne

2008

Tonne

1,500,726

1,074,310

1,390,585

693,707

110,141

380,603

2,575,036

2,084,292

490,744

B. Cost Statement

Cost

Direct Departmental Costs :

(a) Outside contract costs

of transportation :

(i) Shale/Overburden

(ii) Lime Stone

(iii) Gypsum

Sub-Total (a) :

2009

2008

Rs. in '000' Rs.perTonne Rs. in '000' Rs.perTonne

102,010

95,370

197,380

67.97

88.77

76.65

71,967

48,677

120,644

Increase/(Decrease)

Rs. in '000' Rs.perTonne

51.75

70.17

57.88

30,043

46,693

76,736

16.22

18.60

18.77

(b) Own transportation costs :

Duties (if any)

Labour costs

Salaries

Employee's other benefits

Indirect materials

Insurance

Repairs and maintenance

Fuel Oil

Greases

Gas

Tyres and tubes

Depreciation

Other Overheads

Sub-Total (b) :

Indirect Departmental Costs :

Compressed Air (Annexure IX)

Power (Annexure X)

Other Factory Expenses

(Annexure XI)

Sub-Total :

Total own transportation cost:

(c) Total transportation cost

197,380

76.65

120,644

57.88

76,736

18.77

C. Cost Distribution.

Apportioned to :

(i) Shale/Overburden

(ii) Lime Stone

(iii) Gypsum

Total :

102,010

95,370

197,380

67.97

88.77

76.65

71,967

48,677

120,644

51.75

70.17

57.88

30,043

46,693

76,736

16.22

18.60

18.77

Chief Executive

Chief Financial Officer

ATTOCK CEMENT PAKISTAN LIMITED

Annexure-III

DEPARTMENTAL COST STATEMENT

NAME OF DEPARTMENT - CRUSHING

FOR THE YEAR ENDED JUNE 30, 2009

A. Quantitative Data

Opening Stock (uncrushed material).

Shale/Overb. - Tonne

Lime Stone -Tonne

2009

2009

2008

Total (Tonne)

2008

2009

2008

Add : Received from quarry

1,500,726

1,390,585

1,074,310

693,707

2,575,036

2,084,292

Total available for crushing :

1,500,726

1,390,585

1,074,310

693,707

2,575,036

2,084,293

Less : Closing Stock (uncrushed

material).

Crushed during the period

Add : Opening Stock (Crushed material).

Total Crushed Material Available :

Less : Closing Stock (Crushed material).

1,500,726

1,390,585

1,500,726

1,390,585

1,074,310

693,707

1,074,310

693,707

2,575,036

2,084,293

19,009

11,281

2,594,045

2,095,574

12,807

19,009

Transferred to raw mill.

2,581,238

2,076,565

Stock Adjustment.

Stock Reconciliation :

Total :

2,581,238

2,076,565

B. Cost Statement

2009

Increase/(Decrease)

2008

Rs. in '000'

Rs.perTonne

Rs. in '000'

Rs.perTonne

Rs. in '000'

Rs.perTonne

Labour cost.

2,050

0.80

1,421

Salaries

4,126

1.60

2,860

0.68

629

0.11

1.37

1,266

Employee's other benefits.

2,361

0.92

1,637

0.23

0.79

724

0.13

Direct Departmental Costs :

Contract Labour

Stores & spares

19,078

5,006

1.94

6,004

2.88

(998)

346

0.13

222

0.11

124

Depreciation

14,675

5.70

13,459

6.46

1,216

(0.76)

Sub-Total (a) :

47,642

18.50

42,693

20.48

4,949

(1.98)

Insurance.

1,988

17,090

Repair and maintenance.

8.20

7.41

(0.79)

(0.94)

0.03

Indirect Departmental Costs :

Compressed Air (Annexure IX).

Power (Annexure X).

22,309

8.66

16,271

7.81

6,038

0.86

Other Factory Expenses

41,380

16.07

26,490

12.71

14,890

3.36

63,689

24.73

42,761

20.52

20,928

4.22

111,331

43.23

85,454

41.00

25,877

2.24

(Annexure XI)

Sub-Total (b) :

Total Cost(a+b) :

Attock Cement Pakistan Limited

Annexure-III

Cont'd

C. Cost Distribution

(On time or other appropriate basis)

2009

2008

Increase/(Decrease)

Rs. in '000'

Rs.perTonne

Rs. in '000'

Rs.perTonne

Rs. in '000'

Rs.perTonne

Shale/Overburden

Lime Stone.

Gypsum.

Rs. in '000'

Rs.perTonne

Rs. in '000'

Rs.perTonne

Rs. in '000'

Rs.perTonne

D. Cost Transferred and Cost of

Closing Stock Cost Summary

2009

(a) Opening Stock (Uncrushed).

(b) Cost received

2008

Increase/(Decrease)

228,751

88.83

185,703

89.10

43,048

(0.26)

197,380

76.65

120,644

57.88

76,736

18.77

426,131

165.49

306,347

146.98

119,784

18.51

(during the year) - quarry

Cost received

(during the year) - transport

(c) Total Cost for uncrushed materials

(a+b)

(d) Cost applicable for closing stock

(uncrushed).

(e) Cost applicable for crushed material

(c-d).

426,131

165.49

306,347

146.98

119,784

18.51

111,331

43.23

85,454

41.00

25,877

2.24

4,391

231.00

2,428

215.23

1,963

15.77

541,854

208.88

394,229

188.12

147,625

20.76

3,325

259.62

4,391

231.00

538,529

208.63

389,838

187.73

(f) Cost of crushing process

(from above)

(g) Opening stock (crushed material).

(h) Total cost applicable to crushed

material (e + f + g).

(j) Closing stock (crushed material).

(k) Cost transferred to Raw mill (h-j).

Chief Executive

(1,066)

148,691

Chief Financial Officer

28.63

20.90

ATTOCK CEMENT PAKISTAN LIMITED

Annexure-IV

DEPARTMENTAL COST STATEMENT

NAME OF DEPARTMENT - STOCK HALL STORAGE/ISSUAGE OF RAW MATERIAL

FOR THE YEAR ENDED JUNE 30, 2009

A. Quantitative Data

Shale/Overburden

Lime Stone

Gypsum

For the year

Last year

For the year

Last year

For the year

Last year

tonne

tonne

tonne

tonne

tonne

tonne

Opening Stock.

Received from crusher.

Purchased.

Total

Issued to Mix/Slurry.

Stock Adjustment.

Closing Stock.

B. Cost Statement

For the year

Rs. 000

per tonne

Last year

Rs. 000

per tonne

Labour Costs :

Salaries.

Employees' other benefits.

Indirect materials.

Repairs and maintenance.

Insurance.

Fuel-Oil.

Gas

Depreciation

Other Overheads

Sub-Total (a) :

Indirect Departmental Costs :

Compressed Air (Annexure IX).

Power (Annexure X)

Other Expenses (Annexure XI).

Sub-Total (b) :

Total Cost (a+b) :

C: Cost Distribution

Quantity issued to

Raw Mill

(tonnes)

Cost of Stock Hall

Applicable to issues

Closing Stock

----------------------------------- ----------------------------------Rs. in '000

Shale/Overburden

Lime Stone.

Gypsum.

Cost of Applicable to

Rs. / Tonne

Rs. in '000

Rs. / Tonne

Total.

D. Cost Summary (Upto Stock Hall Stage)

Cost Transferred and Cost of closing Stock:

Shale/Overburden

Rs. in '000

Rs. / Tonne

Lime Stone

Rs. in '000

Rs. / Tonne

Gypsum

Rs. in '000

Opening Stock.

Add : Received from Crusher/

purchases.

Stock Hall

Cost.

Total :

Less: Cost of closing stock.

Cost applicable to quantities

issued to Raw Mill.

Chief Executive

Chief Financial Officer

Rs. / Tonne

ATTOCK CEMENT PAKISTAN LIMITED

Annexure-V

DEPARTMENTAL COST STATEMENT

NAME OF DEPARTMENT - RAW MILL (FOR MIX/SLURRY)

FOR THE YEAR ENDED JUNE 30, 2009

A. Quantitative Data

Opening Stock.

Received from Crushing.

Add: Iron ore

Bauxitic Iron/Slica sand

Total:

Issued for Mix/Slurry.

Total Mix/Slurry made.

Mix/Slurry transferred to clinkering.

Stock Adjustment.

Closing Stock.

Shale/Overburden

Tonne

2009

2008

1,577,137

1,394,205

1,577,137

1,394,205

-

Lime Stone

Tonne

2009

2008

1,004,101

682,359

1,004,101

682,359

-

Mix/Slurry

Tonne

2009

2008

13,353

9,236

2,581,238

2,076,564

86,484

70,640

20,762

32,537

2,701,837

2,188,978

2,701,837

2,188,978

2,701,837

2,188,978

2,685,790

2,175,626

16,047

13,353

B. Cost Statement

2009

Rs. in '000'

2008

Rs.perTonne

Rs. in '000'

Increase/(Decrease)

Rs.perTonne

Rs. in '000'

Rs.perTonne

Direct Material :

(1) Opening Stock

(2) Received from crushing

(3) Total.

(4) Closing Stock.

538,529

538,529

-

208.63

208.63

-

389,838

389,838

-

187.73

187.73

-

148,691

148,691

-

20.90

20.90

-

Cost of raw materials processed (3)-(4)

538,529

208.63

389,838

187.73

148,691

20.90

Direct Departmental Costs:

Diect material

Labour

Salaries

Employee's other benefits

Contract labour

Repairs and maintenace

Stores & spares

Linning plate

Grinding media

Water

Dereciation

Insurance.

Sub-Total (a) :

65,100

4,460

3,585

3,471

12,236

55,644

7,335

3,132

748

65,456

4,844

764,539

607.02

1.66

1.33

1.29

4.55

20.70

2.73

1.16

0.28

24.35

1.80

284.38

57,292

3,092

2,485

2,406

10,844

25,946

12,314

8,630

394

55,431

3,107

571,781

555.28

1.42

1.14

1.10

4.97

11.90

5.65

3.96

0.18

25.43

1.43

262.32

7,808

1,368

1,100

1,065

1,392

29,698

(4,979)

(5,498)

354

10,025

1,737

192,758

51.74

0.24

0.19

0.19

(0.42)

8.79

(2.92)

(2.79)

0.10

(1.08)

0.38

22.06

156,292

82,670

58.13

30.75

119,336

63,249

54.75

29.02

36,956

19,421

88.88

373.26

373.26

182,585

754,366

3,239

757,605

83.76

346.08

346.10

56,377

249,135

1,743

250,878

Indirect Departmental Costs :

Compressed Air (Annexure IX)

Power (Annexure X

Other Factory Expenses

(Annexure XI)

Sub-Total (b) :

Total Cost (a+b) :

Cost of opening stock

Total cost of slurry available

238,962

1,003,501

4,982

1,008,483

3.39

1.73

5.12

27.18

27.16

C. Cost Distribution

Transferred to Kiln

Closing stock of mix/slurry

Total :

Chief Executive

2009

Rs. in '000'

Rs.perTonne

1,001,859

373.02

6,624

1,008,483

373.26

2008

Increase/(Decrease)

Rs. in '000' Rs.perTonne Rs. in '000' Rs.perTonne

752,623

345.93

249,236

27.09

4,982

1,642

757,605

346.10

250,878

27.16

Chief Financial Officer

ATTOCK CEMENT PAKISTAN LIMITED

Annexure-VI (A)

DEPARTMENTAL COST STATEMENT

NAME OF DEPARTMENT - KILN

FOR THE YEAR ENDED JUNE 30, 2009

A. Quantitative Data - OPC

Increase/(Decrease)

Tonne

451,922

451,922

Opening Stock.

Quantity received from Raw Mill.

Total :

2009

Tonne

2,252,610

2,252,610

2008

Tonne

1,800,688

1,800,688

Quantity fed into (the) Kiln.

Stock Adjustment - Burning loss.

Closing Stock.

2,252,610

844,728

-

1,800,688

675,258

-

451,922

169,470

-

Clinker Produced.

Clinker purchased

Opening Stock of Clinker.

Total available stock :

Clinker transferred to Grinding.

Clinker sold (Local)

Clinker sold (Export)

Total clinker sold

Closing Stock of Clinker.

1,407,882

37,695

82,872

1,528,449

1,386,376

17,990

17,990

124,083

1,125,430

63,511

1,188,941

1,071,069

35,000

35,000

82,872

282,452

37,695

19,361

339,508

315,307

(17,010)

(17,010)

41,211

B: Cost Statement - OPC

2009

Rs. in '000'

Rs.perTonne

Cost received from Raw Mill :

(1) Opening Stock.

(2) Received during the year.

(3) Total

(4) Closing Stock.

Cost to be charged to the process (3) (4).

Direct Departmental Costs :

Local Clinker Purchase

Clinker handling charges

Labour.

Salaries.

Employees' other benefits.

Contract labour

Linning plate

Bricks

Coal / Gas / Oil

Water

Repairs and maintenance.

Stores & spares

Depreciation.

Insurance.

Sub-Total (a) :

2008

Rs. in '000'

Rs.perTonne

840,259

840,259

840,259

373.02

373.02

596.83

632,203

632,203

632,203

351.09

351.09

561.74

111,230

15,630

5,161

28,393

5,510

8,621

3,060

14,350

1,991,126

6,193

8,343

25,396

168,616

12,479

3,244,368

2,950.79

11.10

3.67

20.17

3.91

6.12

2.17

10.19

1,414.27

4.40

5.93

18.04

119.77

8.86

2,304.43

9,919

3,578

19,683

3,820

5,976

2,613

16,552

1,231,120

3,263

8,576

23,788

140,913

7,899

2,109,902

8.81

3.18

17.49

3.39

5.31

2.32

14.71

1,093.91

2.90

7.62

21.14

125.21

7.02

1,874.75

ATTOCK CEMENT PAKISTAN LIMITED

Cont'd

Annexure-VI (A)

Indirect Departmental Costs :

Compressed Air (Annexure IX).

Power (Annexure X)

Other Factory Expenses (Annexure XI).

411,843

88,748

292.53

63.04

270,286

55,097

240.16

48.96

Sub Total (b) :

500,591

355.56

325,383

289.12

3,744,959

2,659.99

2,435,285

2,163.87

Total Cost (a+b) :

Opening Stock - Clinker - OPC

Total cost of clinker available

Less : Cost of clinker sold (if any).

Net Cost.

181,879

108,995

3,926,838

2,569.16

2,544,280

2,139.95

46,219

2,569.16

74,898

2,139.94

3,880,618

2,569.16

2,469,381

2,139.95

C. Cost Distribution - OPC

2009

Rs. in '000'

Rs.perTonne

Cost transferred to Grinding.

Cost of closing Stock of Clinker.

Total :

Chief Executive

3,543,213

337,405

3,880,618

2,555.74

2,569.16

2008

Rs. in '000'

Rs.perTonne

2,287,502

181,879

2,469,381

Chief Financial Officer

2,135.72

2,139.95

ATTOCK CEMENT PAKISTAN LIMITED

Annexure-VI (B)

DEPARTMENTAL COST STATEMENT

NAME OF DEPARTMENT - KILN

FOR THE YEAR ENDED JUNE 30, 2009

A. Quantitative Data - SRC

2009

Tonne

2008

Tonne

Increase/(Decrease)

Tonne

Opening Stock.

Quantity received from Raw Mill.

433,181

374,938

58,243

Total :

433,181

374,938

58,243

Quantity fed into (the) Kiln.

Stock Adjustment - Burning loss.

Closing Stock.

433,181

162,443

-

374,938

140,602

-

58,243

21,841

-

Clinker Produced.

Opening Stock of Clinker.

Total available stock :

Clinker transferred to Grinding.

Clinker sold.

Stock Adjustment.

Closing Stock of Clinker.

270,738

10,993

281,731

273,892

7,839

234,336

8,835

243,171

232,178

10,993

36,402

2,158

38,560

41,714

(3,154)

Total :

281,731

243,171

38,560

B: Cost Statement - SRC

2009

Rs. in '000'

Rs.perTonne

Cost received from Raw Mill :

(1) Opening Stock.

(2) Received during the year.

(3) Total

(4) Closing Stock.

Cost to be charged to the process

(3) - (4).

Direct Departmental Costs :

Clinker handling

Salaries.

Employees' other benefits

Coal / Gas / Oil

Linning plate

Water

Repairs and maintenance.

Stores & spares

Depreciation

Insurance

Sub-Total (a) :

2008

Rs. in '000'

Rs.perTonne

161,600

161,600

161,600

373.05

373.05

596.89

120,420

120,420

120,420

321.17

321.17

513.88

3,104

6,986

2,943

391,281

607

1,289

2,781

11,129

32,429

2,400

11.46

25.80

10.87

1,445.24

2.24

4.76

10.27

41.11

119.78

8.86

2,065

4,843

2,040

256,343

544

679

2,139

8,046

29,341

1645

8.81

20.67

8.71

1,093.91

2.32

2.90

9.13

34.34

125.21

7.02

616,549

2,277.29

428,105

1,826.88

ATTOCK CEMENT PAKISTAN LIMITED

Cont'd

Annexure-VI (B)

Indirect Departmental Costs :

Compressed Air (Annexure IX).

Power (Annexure X)

Other Factory Expenses (Annexure XI).

79,206

17,626

292.56

65.10

56,279

11,472

240.16

48.96

Sub Total (b) :

96,832

357.66

67,751

289.12

713,381

2,634.95

495,856

2,115.99

Total Cost (a+b) :

Opening Stock - Clinker

Total cost of clinker available

Less : Value of clinker sold (if any).

Net Cost.

23,910

737,291

2,617.00

15,162

511,018

737,291

2,617.00

511,018

2,101.47

2,101.47

C. Cost Distribution - SRC

2009

Rs. in '000'

Rs.perTonne

Cost transferred to Grinding.

Cost of closing Stock of Clinker.

Total :

715,975

21,316

737,291

2,614.08

2,617.00

2008

Rs. in '000'

Rs.perTonne

487,108

23,910

511,018

Chief Executive

Chief Financial Officer

2,097.99

2,101.47

ATTOCK CEMENT PAKISTAN LIMITED

Annexure-VI

DEPARTMENTAL COST STATEMENT

NAME OF DEPARTMENT - KILN

FOR THE YEAR ENDED JUNE 30, 2009

A. Quantitative Data - Combined (OPC + SRC)

Increase/(Decrease)

Tonne

510,165

510,165

Opening Stock.

Quantity received from Raw Mill.

Total :

2009

Tonne

2,685,791

2,685,791

2008

Tonne

2,175,626

2,175,626

Quantity fed into (the) Kiln.

Stock Adjustment - Burning loss.

Closing Stock.

2,685,791

1,007,171

-

2,175,626

815,860

-

510,165

191,311

-

Clinker Produced.

Clinker purchased

Opening Stock of Clinker.

Total available stock :

Clinker transferred to Grinding.

Clinker sold (Local)

Clinker sold (Export)

Total clinker sold

Closing Stock of Clinker.

1,678,619

37,695

93,866

1,810,180

1,660,268

17,990

17,990

131,922

1,359,766

72,346

1,432,112

1,303,247

35,000

35,000

93,866

318,853

37,695

21,520

378,068

357,021

(17,010)

(17,010)

38,056

B: Cost Statement - Combined (OPC + SRC)

2009

Rs. in '000'

Rs.perTonne

2008

Rs. in '000'

Rs.perTonne

Cost received from Raw Mill :

(1) Opening Stock.

(2) Received during the year.

(3) Total

(4) Closing Stock.

Cost to be charged to the process (3) (4).

1,001,859

1,001,859

1,001,859

373.02

373.02

711.61

752,623

752,623

752,623

Direct Departmental Costs :

Local Clinker Purchase

Clinker handling charges

Labour.

Salaries.

Employees' other benefits.

Contract labour

Linning plate

Bricks

Coal / Gas / Oil

Water

Repairs and maintenance.

Stores & spares

Depreciation.

Insurance.

Sub-Total (a) :

111,230

18,734

5,161