Professional Documents

Culture Documents

Page 164-166 Recommendations

Uploaded by

Sahil GrgCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Page 164-166 Recommendations

Uploaded by

Sahil GrgCopyright:

Available Formats

RECOMMENDATIONS

164

RECOMMENDATIONS

6

6.1. Flexible Pavement

After calculating the pavement thickness from various types of

formulae and charts, we observe that the pavement thickness

according to the IRC 37 2001 is the safest and maximum. So provide

the flexible pavement with following specifications:

1. Provide Soil Sub Grade well compacted at OMC as calculated in

laboratory upto a depth of 500 mm.

2. Provide Granular Sub Base of thickness 200 mm consisting of

Coarse Aggregates of grading given in the detail in next chapter.

3. Provide Wet Mix Macadam as base course of thickness 250 mm

consisting of Coarse Aggregates of grading given in the detail in

next chapter.

4. Provide one coat of Bituminous Primer on the surface of Wet Mix

Macadam.

5. Provide one coat of low viscosity bituminous material also called

as Tack Coat over Prime Coat.

6. Provide Dense Bituminous Macadam as pre surface course over

the Tack Coating of thickness 80 mm.

7. Provide Bituminous Concrete as surface course over the Dense

Bituminous Macadam of thickness 40 mm.

8. Provide a layer of surface dressing is to be provided according the

specifications.

9. Provide the width of carriageway as 7.0 m and the combined

width of paved shoulder and brick on edge shoulder as 2.0. So,

the total Roadway Width is 9.0 m.

10.

Provide the camber or side slope provided is 2.5%

RECOMMENDATIONS

165

11.

Provide Drains of base width 0.3 m and height of 0.3 m with

a side slope of 1:1 is to be provided both sides.

Detail specifications and detailed Estimate of all of the above

items are given in the next chapters.

6.2. Rigid Pavement

Various components of Rigid Pavement are calculated using IRC

58 2000. So provide the rigid pavement with following specifications:

1. Provide Soil Sub Grade well compacted at OMC as calculated in

laboratory upto a depth of 500 mm.

2. Provide Granular Sub Base of thickness 200 mm consisting of

Coarse Aggregates of grading given in the detail in next chapter.

3. Provide Dry Lean Concrete of thickness 100 mm having a

Cement/Aggregate as 1:4:8 with the aggregate grading as

described in detail later.

4. Provide 125 Polythene Sheet over the Dry Lean Concrete

surface.

5. Provide Cement Concrete pavement of thickness 250 mm having

1

a Cement/Aggregate as 1:1 2 :3 with the aggregate grading as

described in detail later.

6. Provide Contraction or Construction Joint after every 4.5 m.

7. Provide 40 mm dia Dowel Bars of plain type of length 500 mm

having a c/c spacing of 200 mm. in Contraction Joint. The first bar

is to be placed at 150 mm from pavement edge. Keep one end

fixed and other free by providing emulsion on the dowel bar

surface.

8. Provide Expansion Joint after every 45 m or 10 Contraction Joints.

RECOMMENDATIONS

166

9. Provide Dowel Bars with caping on one side in Expansion Joint

keeping all the specifications as stated above.

10.

Provide Longitudinal Joint all along the length of the road at

the center of Carriage Way.

11.

Provide 12 mm dia TOR Tie Bars of length 650 mm having a

c/c spacing of 700 mm in Longitudinal Joint. Both ends of tie Bars

should be kept fixed.

12.

Provide the width of carriageway as 7.0 m and the

combined width of paved shoulder and brick on edge shoulder as

2.0. So, the total Roadway Width is 9.0 m.

13.

Provide the camber or side slope provided is 2.5%

14.

Provide Drains of base width 0.3 m and height of 0.3 m with

a side slope of 1:1 is to be provided both sides.

Detail specifications and detailed Estimate of all of the above

items are given in the next chapters.

You might also like

- VEC CE6601 Design of RCC and Brick Masonry Question BankDocument12 pagesVEC CE6601 Design of RCC and Brick Masonry Question BankSabarinath MuruganNo ratings yet

- Detailed Technical Specification For Civil WorkDocument8 pagesDetailed Technical Specification For Civil WorkShivhar Menkudle100% (2)

- Guide: Mrs. P. Chithra (Lecturer)Document25 pagesGuide: Mrs. P. Chithra (Lecturer)Vicky RockNo ratings yet

- RC Water Tank Design Question BankDocument12 pagesRC Water Tank Design Question BankJaga NathNo ratings yet

- Football GroundDocument2 pagesFootball GroundRahul RajasekharanNo ratings yet

- Description of Item Unit Qty Supply Rate: Sl. NoDocument50 pagesDescription of Item Unit Qty Supply Rate: Sl. NoKrishan PandyaNo ratings yet

- AdvancedConcrete Structures 062110013957 23Document7 pagesAdvancedConcrete Structures 062110013957 23sdg0808No ratings yet

- Bedele HallDocument57 pagesBedele Hallfayisamamo126No ratings yet

- Method Statement Bundwall GSUT Spare Unit 3Document4 pagesMethod Statement Bundwall GSUT Spare Unit 3MarhendraNo ratings yet

- Question Bank of RCC 601Document3 pagesQuestion Bank of RCC 601somesh dubeyNo ratings yet

- Appendix A - 1 - 27 PDFDocument1 pageAppendix A - 1 - 27 PDFAhmad Ramin AbasyNo ratings yet

- Office NoteDocument6 pagesOffice NoteS N satyanarayanaNo ratings yet

- Section VII. Technical SpecificationDocument10 pagesSection VII. Technical SpecificationBalkrishna PangeniNo ratings yet

- Design of RC & Masonry StructuresDocument5 pagesDesign of RC & Masonry Structuresdraj1875977No ratings yet

- Buldg Specifications v1Document9 pagesBuldg Specifications v1Adel JaNo ratings yet

- 2700 Wearings Coat and AppurtenancesDocument5 pages2700 Wearings Coat and Appurtenancesdhamu_i4uNo ratings yet

- Field Training at Gaiban Builders and Developers, IchalkarajiDocument30 pagesField Training at Gaiban Builders and Developers, IchalkarajiSameer Satpute100% (1)

- Ce6601 Drcbms Rejinpaul Iq April May 2018Document3 pagesCe6601 Drcbms Rejinpaul Iq April May 2018Anonymous NoLC1bXCNo ratings yet

- CE302 BDocument3 pagesCE302 BsahilkaushikNo ratings yet

- Concrete Strip Roads For The FarmDocument4 pagesConcrete Strip Roads For The FarmRoshanNo ratings yet

- Drbms TutorialsDocument4 pagesDrbms TutorialsUmar Saba100% (1)

- F) 50 M3 Masonry RCC Sandwich Clean Water Reservoir: Earth WorkDocument4 pagesF) 50 M3 Masonry RCC Sandwich Clean Water Reservoir: Earth WorkEng GaaxeelNo ratings yet

- Question Bank of DRCBMDocument11 pagesQuestion Bank of DRCBMrishinathnehruNo ratings yet

- UP PWD WP Spec (1)Document9 pagesUP PWD WP Spec (1)sanjay kumarNo ratings yet

- A SITE VISIT To Hollow ClaypotDocument9 pagesA SITE VISIT To Hollow ClaypotAyodele Oluwaseyi Dina100% (1)

- Revathy Madam AggrementDocument7 pagesRevathy Madam Aggrementsas cadNo ratings yet

- Design Philosophy and Special RC Elements Question BankDocument8 pagesDesign Philosophy and Special RC Elements Question BanklavanyaNo ratings yet

- Question Bank: Cem701 Design of Reinforced Concrete Structures Ii Unit 1Document7 pagesQuestion Bank: Cem701 Design of Reinforced Concrete Structures Ii Unit 1RaNo ratings yet

- Question Bank - 8 MarksDocument2 pagesQuestion Bank - 8 MarksSyed K INo ratings yet

- Mumbai Monorail ProjectDocument61 pagesMumbai Monorail ProjectAmit GargNo ratings yet

- Method Statement For Drainage SystemDocument2 pagesMethod Statement For Drainage SystemElson Jesu Dass Ejd97% (39)

- 5 Question BankDocument11 pages5 Question Bankapi-297121029No ratings yet

- Enquiry No. E-1444/Psnr/Scp/Opr Annexure-IDocument6 pagesEnquiry No. E-1444/Psnr/Scp/Opr Annexure-Isreedevi gummadiNo ratings yet

- Animal Feed EFFORTDocument16 pagesAnimal Feed EFFORTHaftamu Tekle100% (1)

- MS For MasonryDocument23 pagesMS For MasonryThimira Bandara EkanayakeNo ratings yet

- West Omo Meinit Goldia Woreda Bani Kebele Water SupplyDocument60 pagesWest Omo Meinit Goldia Woreda Bani Kebele Water SupplyReffisa JiruNo ratings yet

- Papa Document 8Document10 pagesPapa Document 8krishansoni1965No ratings yet

- Wearing CoatDocument5 pagesWearing Coatnandi_scrNo ratings yet

- Reinforced EarthDocument4 pagesReinforced EarthAnonymous g1LSaANo ratings yet

- Outline Specifications (One 1 Storey Residential)Document5 pagesOutline Specifications (One 1 Storey Residential)mark manalang100% (1)

- Muffakham Jah College of Engineering and TechnologyDocument15 pagesMuffakham Jah College of Engineering and TechnologyKimz IbrahimNo ratings yet

- Section VII. Technical Specification: Telescopic Steel PoleDocument10 pagesSection VII. Technical Specification: Telescopic Steel PoleBalkrishna PangeniNo ratings yet

- Method Statement Slab & Beam ConcretingDocument3 pagesMethod Statement Slab & Beam Concretingudithairesha100% (6)

- Tutorial: Rectangle Singly Reinforced BeamDocument7 pagesTutorial: Rectangle Singly Reinforced BeamSaket ThakkarNo ratings yet

- Rubble WallDocument3 pagesRubble WallLynn Mail100% (2)

- Morth 2700 Wearing Coat and AppurtenancesDocument7 pagesMorth 2700 Wearing Coat and AppurtenancesRamesh100% (1)

- GodownDocument7 pagesGodownShashank TiwariNo ratings yet

- LMRC PROJECT REPORTDocument12 pagesLMRC PROJECT REPORTApoorv DixitNo ratings yet

- Bill of Quantities for Bituminous Road Work at Suzlon GeneratorsDocument8 pagesBill of Quantities for Bituminous Road Work at Suzlon GeneratorsEr. Naseem SayyedNo ratings yet

- Construction SpecificationDocument9 pagesConstruction SpecificationYeth SantosNo ratings yet

- 1.-BTCVC601 DCS-I UpdatedDocument4 pages1.-BTCVC601 DCS-I UpdatedAmaan ShaikhNo ratings yet

- Steel Wire Cable Tray SpecificationDocument2 pagesSteel Wire Cable Tray Specificationsubidubi99No ratings yet

- Design of cantilever retaining walls and water tanksDocument3 pagesDesign of cantilever retaining walls and water tanksgobinathdpiNo ratings yet

- Building Works Specification: Two Storey HouseDocument12 pagesBuilding Works Specification: Two Storey HouseKhalid AwanNo ratings yet

- RCC QB - 030410041238 - 1Document4 pagesRCC QB - 030410041238 - 1dsureshcivilNo ratings yet

- Core & Shell BOQ - ArchDocument58 pagesCore & Shell BOQ - ArchashokNo ratings yet

- Supreme Beam and Block FloorDocument8 pagesSupreme Beam and Block FloorDoralba V NolanNo ratings yet

- Control Sys Nov-2015Document40 pagesControl Sys Nov-2015krkpanduNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Dir FDocument50 pagesDir FSahil GrgNo ratings yet

- Phone BookDocument3 pagesPhone BookSahil GrgNo ratings yet

- Delhi PincodeDocument5 pagesDelhi Pincodeharshil12No ratings yet

- Page 164-166 RecommendationsDocument3 pagesPage 164-166 RecommendationsSahil GrgNo ratings yet

- Hungama 15Document1 pageHungama 15Sahil GrgNo ratings yet

- Transportation Engineering Lab ManualDocument42 pagesTransportation Engineering Lab Manualउमेश गावंडे89% (9)

- HJHJBHBJKDocument97 pagesHJHJBHBJKSahil GrgNo ratings yet

- Wefewf 103-109Document8 pagesWefewf 103-109Sahil GrgNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- HCGHVJ1 - 13Document16 pagesHCGHVJ1 - 13Sahil GrgNo ratings yet

- Page 265-271 MeasurementDocument9 pagesPage 265-271 MeasurementSahil GrgNo ratings yet

- UPPCL Pay Bill Excel 2003Document3 pagesUPPCL Pay Bill Excel 2003Sahil GrgNo ratings yet

- WritDocument1 pageWritSahil GrgNo ratings yet

- Page 257-264 Schedule of RatesDocument11 pagesPage 257-264 Schedule of RatesSahil GrgNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- CPWD Books and Specifications ListingDocument8 pagesCPWD Books and Specifications ListingSahil GrgNo ratings yet

- Classified List of Sale of Publication 30-11-2008Document29 pagesClassified List of Sale of Publication 30-11-2008Sahil GrgNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- CPWD Books and Specifications ListingDocument8 pagesCPWD Books and Specifications ListingSahil GrgNo ratings yet

- Paper1 East ABCFGHI PDFDocument17 pagesPaper1 East ABCFGHI PDFSatyajitMannaNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- Fci Key 2015Document18 pagesFci Key 2015Prakash JpNo ratings yet

- CPWD Books and Specifications ListingDocument8 pagesCPWD Books and Specifications ListingSahil GrgNo ratings yet

- FAQsadDocument15 pagesFAQsadSahil GrgNo ratings yet

- TB 1 Fly Ash Types & BenefitsDocument1 pageTB 1 Fly Ash Types & BenefitsSahil GrgNo ratings yet

- Annex 10 (Radio Navigation Aids)Document189 pagesAnnex 10 (Radio Navigation Aids)olivirus1007100% (1)

- Parts Catalogue: '19 ER300 AKF/AKFA (CL) (Z300)Document87 pagesParts Catalogue: '19 ER300 AKF/AKFA (CL) (Z300)Yeison Cartagena BedoyaNo ratings yet

- Smart Steps Book 3 WebDocument86 pagesSmart Steps Book 3 WebNgaire TaylorNo ratings yet

- Nice Form: Lewis Builds Corp. - Trump International Hotel & TowerDocument1 pageNice Form: Lewis Builds Corp. - Trump International Hotel & Towerkeath71No ratings yet

- STPO Wo. DELDocument9 pagesSTPO Wo. DELDurgesh KadamNo ratings yet

- Road Qty - S-R-SH-10-Total Project ECL - PCL OffsetDocument1 pageRoad Qty - S-R-SH-10-Total Project ECL - PCL OffsetStephen Rajkumar JayakumarNo ratings yet

- CARGO RATES FOR CITILINK DOMESTIC FLIGHTSDocument2 pagesCARGO RATES FOR CITILINK DOMESTIC FLIGHTSAsyh SlsblNo ratings yet

- These Worksheets Can Be Uploaded On Any School Website WWW - Cbse.onlineDocument4 pagesThese Worksheets Can Be Uploaded On Any School Website WWW - Cbse.onlineAnn Mariya T MNo ratings yet

- TBW Transport VocabularyDocument1 pageTBW Transport VocabularyZoe78No ratings yet

- CX302Document11 pagesCX302josua1234554321No ratings yet

- National Drilling Company: Journey Management Plan (JMP)Document2 pagesNational Drilling Company: Journey Management Plan (JMP)Alaa AttalahNo ratings yet

- Maintenance Manual For AC LHB CoachesDocument729 pagesMaintenance Manual For AC LHB Coachesdiiiiips100% (14)

- Backmap eDocument3 pagesBackmap ealexstevenson01No ratings yet

- Survey Report SummaryDocument9 pagesSurvey Report SummaryM Rizwan ShahabNo ratings yet

- List PDFDocument29 pagesList PDFSahil AhmedNo ratings yet

- Automotive Design Course IndiaDocument17 pagesAutomotive Design Course Indiamq23No ratings yet

- SCM Chapter 6Document17 pagesSCM Chapter 6Dito Eri BasyasyaNo ratings yet

- Oarr 10000310 1 PDFDocument520 pagesOarr 10000310 1 PDFyoussefNo ratings yet

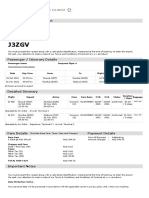

- Air India Web Booking ETicket (J3ZGV) - ThangarajuDocument2 pagesAir India Web Booking ETicket (J3ZGV) - ThangarajuKannan MurugesanNo ratings yet

- VW - DSG Component AgungDocument4 pagesVW - DSG Component AgungAgung PurnamaNo ratings yet

- Safe Motorcycle Riding TipsDocument8 pagesSafe Motorcycle Riding TipsRista Nya DendiNo ratings yet

- The Naughty BusDocument2 pagesThe Naughty BusSITI ELINA BINTI MD ZIN MoeNo ratings yet

- Volvo-FH-Series Specifications Chassis UKDocument5 pagesVolvo-FH-Series Specifications Chassis UKVacutza NebunaNo ratings yet

- A Comparative Study of Effect of Motorcycle Volume On Capacity of Four Lane Urban Roads in India and ThailandDocument11 pagesA Comparative Study of Effect of Motorcycle Volume On Capacity of Four Lane Urban Roads in India and ThailandManu BkNo ratings yet

- Global Logistics - New Directions in Supply Chain Management, 6th EditionDocument28 pagesGlobal Logistics - New Directions in Supply Chain Management, 6th EditionChanchal SharmaNo ratings yet

- Bus & Cable Car Simulator – San Francisco Gameplay GuideDocument39 pagesBus & Cable Car Simulator – San Francisco Gameplay GuideDanialNo ratings yet

- Boeing 747-400 White Cockpit TourDocument5 pagesBoeing 747-400 White Cockpit ToursakiNo ratings yet

- Flagging-Off of BH205E BY CMD BEML and CMD NCLDocument3 pagesFlagging-Off of BH205E BY CMD BEML and CMD NCLJackson PhinniNo ratings yet

- InTraDE Newsletter Jul-Dec 2012Document4 pagesInTraDE Newsletter Jul-Dec 2012Mohamed BenmerikhiNo ratings yet

- Evo7 GtaDocument9 pagesEvo7 GtaBhirawich PholpokeNo ratings yet