Professional Documents

Culture Documents

NCR 060816

Uploaded by

David WebOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NCR 060816

Uploaded by

David WebCopyright:

Available Formats

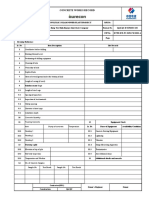

NC ANALYSIS REPORT

PROJECT : ABC

ISSUE

NC No

Issue

Month

Date of NC

Raised

Nature

Nature of

Occurrence

Category of NC

Major/

Minor/

Critical

New /

Repetitive

Workmanship /

Material /

Process

/Supervision/

Design

Trade

Area/Location

CLOSURE

Contractor to

whom NC was

given

Description of NC

Issued by

Root Cause for NC

Correction

Corrective action for closure of NC

TPQA/Site

QAQC/Co

QAQC/Site Exec

With ref. to additional 12 bore

holes and 11 PDA test geo

technical consultant has classified

the zones for design papameters.

To be filled in by

Project Head

To be filled in

by Project

Head

11 Additional PDA conducted as per

Consulatant and SEC instrcution and Additional

Design

12 Bore holes connducted for Zone

lassifiaction and design Parameters finalisation

3/6/2015

Major

New

Design

Geo technical

6/10/2015

Minor

New

Process

Drawings

Tower-3

Site Exe.

Work in progress without approved GFC drawingas and

Site QA/QC

approved Pile co-ordinate drawings

Tower-3 drawings has been revised

Approved GFC drawing has been Drawing protocol has been raised and the

and the softcopy approvals are

brought from strcutural consulatnt without approved GFC drawing no work will be Design

available.but the Hard copy not

the issued and recorded

allowed at site

been available for longtime at site

17/06/15

Minor

New

Supervision

Piling

P1-201

DPJ

immediate heavy vehicle just edge of the pile after

casting

Improper supervision

23/06/15

Minor

New

Supervision

Tools

Tower-3

DPJ

Total station used for surveying without submitting the

Site QA/QC

calibartion certificate

Surveyor(Sub Contractor) Came

with the new total station machine Calibartion certificate shared for

and started working without

approval and record

informing

24/06/15

Major

New

Material

Testing

Tower-3

DPJ

There are some cubes attain more strength than other

cubes in the same set. And there is no strength gain

Site QA/QC

after 7 days normally but in some cases there is huge

strength gain in 28 days comparing to 7 days results

For the Strength Variation - Poor

Workmanship.

For Less strength Gain- Fineness

content is more in Cement

Improper Supervision and Poor

Workmanship

Proper Steel Base fabrication done Fixed steel base in all around the fabrication

Poor Workmanship and Supervsion for Fabrication and Concrete Has yard and other places has been barricaded

been poured n the Sings zone

properly.

Mar-15

June'15

Design team

The root cause for failure has been

that because of insufficient Site

Investigations, the variations in

the strength and quality of the

rocks have not been taken into

account.

Proposed Date

of Closure

Total Re-hab

project

End bearing capacity of the Rock value is been

considered high than the rock condition.

Departmental

Responsibility

Site QA/QC

8/11/2015

Minor

New

Supervision

Process

Cube Casting yard DPJ

Cube moulds dismantled in 10 hrs. and the Gunny

bags also not used for covering until demould.

Cube found with honeycomb and aggregates visible

Site QA/QC

separate.

Out of 8 cubes 7 cubes are in improper size/shape and

edges broken

8/21/2015

Minor

New

Material

Stocking

Steel Yard

DPJ

Improper steel stocking, Poor platform, No barrication

and Rings lying on ground

Aug'15

OCPPL Site Exe.

Site QA/QC

closed

23/06/15

23/06/15

closed

Fixed 4 cubes casting team will be Team has been fixed and training will be given

used with proper training for one and the after onemonth the strength details

Site Exec.

month.the analyse the report

will be verified and procured further

7/28/2015

7/30/2015

closed

Cubes should be demoulded after

Cubes has been tested at thirdparty lab. Third

Site Exec.

24 hrs. until the time it should be

Party Govt. Lab results shows satifactory

covered with gunny bags(wet).

9/7/2015

9/8/2015

closed

Site Exec.

8/22/2015

8/22/2015

closed

Site Exec.

9/18/2015

9/18/2015

0 closed

DPJ Exec and KDS

After RNC

excavtion done

3/26/2016

Closed

PIT achived 100%

closed

P1-203 Concrete done on 26/12/15

DPJ

Concrete Cube tank with less water than required level

Site QA/QC

and Cubes are not stocked properly in the curing tank

Cubes are removed for testing so

the water level got

reduced.refilling process not

carriedout and while removal

falldown cubes not rearranged

Oct'15

10/6/2015

Minor

new

Process

Process

P3-346

DPJ

P3-346 pile concrete without collecting approval from

OCPPL Rep. for Before flushing and after flushing

parameters of bentonite and Concrete Slump

requiremnets/

Poor Workmanship and Supervsion

PIT to be conducted in that pile to Authorities has been cleraly explained to

of the Piling Engineer and

prove that is Ok

Contractor

authority issues

12/1/2015

Minor

New

Supervision

1/4/2016 Major

New

Process

11

Jan'16

Excavation

Tower-3

12

RNC

RNC

2/20/2016 Major

New

workmanship/

supervision

Concrete

Tower-1

13

Tower-3 dewatering process has not been ensured

properly.water level found always above the Pile Cutoff

Site QA/QC

level. Due to that continuous water stagnation Pile

reinforcemnet started corroded.

The Pile cap PC3H,Grid -A6 and A7 found with Too

much Honey Combs, dense less concrete patch,

Bulging and cold joints and Tope level issue(Tie beam

depth).

RNC

Feb'16

14

2/26/2016 Major

New

2/27/2016 Minor

Process/

supervision

Material

Concrete

Tower-2

RNC

The steel has found stocked in water at site. Cover is

provided at top but the water stagnated all around

bottom.

After Proper Hacking and cleaning

with approved procedure of

the MS for under casted pile has been finalised

DPJ Exec and KDS

Structural consultant Pile casted

and approved

upto Pile cutoff level

Dewatering pumbs needs to be

increased and Cement coating

needs to be applied for the

Reinforcement protection for the

Initial period

After Hacking of pile Immediate Cement Slurry

Application on pile Reinforcemnnet needs to be

Site Exec.

done. And it has to be cleaned using wire

brush before Pile Cap concrete

pile cap will be rectified with

proper grout and Non shrink grout Drawings needs to be checked before work.

packing by approved method by

Additoonal carpenter during concrete has to be

OCPPL Site Exec

External agency

ensured and Supports at bottom needs

Improper Coordination. Poor

Planning

If any issue aries contrctor has to

be rectify the total pile cap

without any additional cost with

accpetable /Approved standards

Method statemnet need to be follwoed

Poor Supervision and improper

stocking of material

Steel has to be stocked in proper

place

Steel stocked need to be done at dry area with

RNC

proper runner base

OCPPL Site Exec

Tower-1

1. Without enough equipment like additional pump car

how the Mass concrete work has been allowed to pour

at site?

Site QA/QC

2. As the Mass concrete of 180 cum was started after

the comparatively small pile cap i.e 80 m3. How the

importance has been considered?.

Poor Resourceplanning and

management

Porper Pouring plan estabilshed at Proper Resource planning needs to be ensured

OCPPL Site Exec

site

based on site condition

Cover blocks casted at site are found not as per mix

design

Lack of invovemnet and

importance on this work

Casting cover block carried out under lab

Casted cover blocks sent out from

control and cubes to casted and test needs to

site

be verified.

Poor Supervision and Not follwing

sequence of activity

Porper cleqaningn needs to be

done before comemncing

reinforecment work

15

2/27/2016

Minor

New

Supervision

Concrete

16

3/3/2016

Minor

New

Processs

Concrete

Cover block

casting yard

17

3/5/2016

Minor

New

Supervision

Formwork

pile cap 2nd lift

area Grid K, Tower RNC

- 03

RNC

Site QA/QC

The Soil stored in pile cap not cleaned even after

number of informations which is leading to corrosion

of pile cap Top reinforcement. And further yesterday it

Site QA/QC

has been noted the Beam Reinforcement work and

Dead wall shuttering works also started without

cleaning the soil stored in pile cap 2nd lift area

12/15/2015

1/6/2016

12/20/2015

1/11/2016

3/3/2016

closed

7/12/2016 Open

Method statement for rectification done by

Contrcator. SEC rejected the proposal and

asked for another material for Filling honey

comb else asked for other MS

Prof.Diaz has visited and given points for this

pile cap under review with SEC for proceeding

with closure of this issue

Reinforcement

PC2J ( Tower 2) pile

and PC3L ( Tower OCPPL

1)

Site QA/QC

Water Refilled and stocking re

Warning has been issued to the conccern

done properly.Testing will be done

engineer and process training given for the

at the cubes at Third Party Govt.

cube area

Lab.

Tie beam drawings not available

improper supports at bottom of

pile cap

Non availability additional

carpenter during concrete

Site QA/QC

PC2J Pile cap concreting from Tower-2 has been

completed without following the approved method

statement for Thermal control testing /monitoring

New

Mar'16

Site QA/QC

Improper Dewatering

Site Exec.

All new tools and equipment without apporval

Site Exec.

should not be used. informed in the survey

redords machine number should be displayed

Curing Tank

Due to presence of underground

service lines (pipes). This pile was

concreted up to casing and after

flushing concrete over the

temporary casing, it was removed.

Then the concrete may flow

through these pipes and it is

inevitable to control it.

Considering the wide variation in the rock

strata at our site location, more number of

bore hole investigations would have assisted in

identifying the constraints at an earlier point of

time

Stocking

P1-64 Pile has been found under catsed than the cutoff

Site QA/QC

level.

closed

7/18/2015

Supervision

DPJ

3/25/2016

16/07/2015

Have to accryout the PIT and PDA After 28 days from concreteing date. PDA will

to analyse the pile

be conducted to analyse the efficiency of pile

New

P1-64 and P1-203

To be filled in by Project Head if required

closed

Minor

Piling

Remarks

9/18/2015

Dec'15

NC

Status

11/6/2015

Sep'15

10

Delay

(Days)

11/6/2015

Site QA/QC

Actual Date

of Closure

Sequence of activity needs to bee followed.

3/3/2016

7/15/2016 Open

2/27/2016 27.02.16

3/1/2016

Closed

3/1/2016

closed

RNC

3/16/2016

closed

RNC

3/19/2016

closed

Mar'16

18

3/21/2016

Minor

new

Material

Reinforcement

Steelyard

19

3/29/2016

Major

new

workmanship/

supervision

Concrete

PC4L @ A/5, PC1D

A2/2 &A3/3,PC4

RNC

Grid C/5,PC3J A/4

NC - 20/ RNC

-009

Apr-16

NC - 21/ RNC

-010

RNC

The Steel yard has been closed temporarily due to

Improper maintenance, Poor Steel stocking, Mixing of

old and new steel, New steel used without

acceptance /approved test results.

Site QA/QC

Proper Segregation needs to be

Non availability of material. Delay

done. As per approved steel yard

in testing time

plan work s has to be done

28 days cube failure

Site QA/QC

Workmaship issue in cube casting

Additional cube test needed to be

Training has to be given on periodic basis

done

28-04-16

Major

New

Material

Concrete

Tower-1 @PC3H

RNC

12 @ PC3H loaction for Honeycomb, the expired

material has beem nbrough to site. Approval not taken

Site QAQC

to use the materil with OCPPL at iste after brough to

site

Material inward noot done and

Expired material has to be send

materil approval after brought to out from site. New material has to

site not taken considering this as a be brought and used with proper

additional material

approval for rectification

5/26/2016

Major

New

Supervision

Concrete

PC1B Tower-2

RNC

28 Days strength Failure

Poor Workmanship as the 28 days

strength is less sthan 7 days

strength

Site QAQC

5/27/2016

Major

New

material

Tower 2 (PC4G)

Reinforcement and Tower-1 (PC3N

& PC5)

OCPPL

steel after fabrication found inside water

Site QAQC

Heavy rain, Less no. of Pump for

Dewatering from the pile cap Pit.

And Less manpower

RNC

All materials used for constrcution needs to be

approved by OCPPL Rep. before use at site.

Failure of that the work cannot be certified as

completed

RNC QA/QC

Cube casting trainings has been given to the

Core cutting needs to be done to

Lab helpers. And Instructed to write the cube

evaluate the area

details using nail instead of marker and sticker

RNC QA/QC

May'16

NC - 22/ RNC

-011

Approved steel yard paln needs to be followed RNC

Full dewatering needs to be done

and Scaling needs to be checked

Get an inspection done by SEC team also and

take appropriate action as per the physical

conditions and relevant areas. Where the steel

is submerged have asked for immediate

evacuation of water and then remedial action

as required. Where there are elements which

are getting delayed please get the cement

slurry applied immediately to arrest

deterioration

3/24/2016

3/28/2016

closed

3/30/2016

6/29/2016

90

closed

4/30/2016

4/30/2016

7/29/2016

OCPPL Site Exec.

Closed

closed

closed Closed at site but document not yet closed

July'16

At Tower-3, Grid J - C16 has been noted with column

cover issue around 15 mm short from actual cover.As

per our Spec, Acceptable tolerance limit for this work is Site QAQC

+10mm and 0 mm.

NC - 23 /

RNC -012

6/6/2016 Major

New

workmanship/

supervision

Concrete

Tower-3, Grid J C16 Column

OCPPL

NC - 24 /

RNC -013

6/7/2016 Major

New

workmanship/

supervision

Concrete

Tower-3 Lift pile

cap

OCPPL

Due to heavy rain after concrete, before Concrete

getting hard the Top surface got damaged, Contractor

have not put the sufficient Pump to dewater this area

as well.

NC - 25 /

RNC -014

6/7/2016 Major

New

workmanship/

supervision

Concrete

Tower-3 Lift wall

OCPPL

New

workmanship/

supervision

Concrete

Tower-3 Pile cap

and Semi

basement slab

concrete at Grid (11a),(I-J),(1-5a),(H-I)

As instructed by SEC and advised

Improper fixing of Column starter

by PH-OCPPL with Structural

bars to the Pile cap top

consultant approval , Column size

mate.Movement happened during

increase y 100mm with Architect

concrete

approval

As instrcuted by SEC, MS for column cover

issue and accptable tolerance has been

created and approved by SEC and all other

parties.

OCPPL Site Exec.

Non shrik grout + penetron admix

conccrete filling on the level less

Adequate precautionary measures to be taken

area and Penetron crystalline

with monsoon preparedlness plan

coating extended up to side of pile

cap

OCPPL Site Exec.

the Extra cover (More than 25mm from clear cover) for

outside lift wall and Less cover for inside reinforcement

Site QAQC

has been noted. Which is the deviation from our actual

tolerance limit i.e. +10mm/-0mm.

Improper fixing of wall starter bars

As instrcuted by SEC, MS for RCC cover issue

to the Pile cap top mate.Movement Additional Skin R/F to be provided and accptable tolerance has been created and

happened during concrete

approved by SEC and all other parties.

OCPPL Site Exec.

OCPPL

Cube test for Tower-3 Pile cap and Semi basement slab

concrete at Grid (1-1a),(I-J),(1-5a),(H-I), 5 out of 20

Site QAQC

cubes attain less strength than characteristic

compressive strength i.e. 40 N/mm2.

cube crushing maching

repeatability issue. Machine

Exra cubes send to Third party

checked. Balce cube send to Third lab.

party lab.

Instrcution given to Re calibrate the machine

and detailed report. Contrcator Repalced the

machine

Poor Compaction at the edges.

Honey Comb Repair using Non

Damaged shutter have been used shrink grout and WP Penetron

and it lead to grout leakages

slurry coat around that lift.

Formwork regiter needs to be monitored for

repaetataions and porpre vibration needs to be OCPPL Site Exec.

done.

confined spaces, DCPT can be accpted instaed

of layer by layer compaction.

OCPPL Site Exec.

As instructed by PH, With

Guidelines has been shared with contractor to

immediate effect slurry coat needs

ensure the corrosion of steel

to be applied

OCPPL Site Exec.

Site QAQC

No adequate Dewatering pump

and It was a heavy rainy day

6/16/2016

closed

Open

6/16/2016

Externa face closed but Internal surface not yet

closed

closed

June'16

NC - 26 /

RNC -015

6/8/2016 Major

NC - 27 /

RNC -016

6/14/2016 Minor

Repetative

workmanship/

supervision

Concrete

Tower-1 PC4F and

PC3B

OCPPL

The PC4F and PC3B having a worst honey combs, and

loose concrete pockets

NC - 28 /

RNC -017

6/16/2016 Minor

New

Supervision

Backfilling

Tower-3 lift pile cap

sides

OCPPL

around lift pile cap- Backfilling carryout improper waySite QAQC

Layer by layer compaction not ensured

Shroing has been removed without Layer by layer compaction needs

doing layer by layer so side earth to be done or DCPT needs to be

collapsed

done

NC - 29 /

RNC -018

6/17/2016 Maor

New

Material

Reinforcement

600mm dia pile

reinforcemnet at

Tower-2 and Tower1

OCPPL

Pile Reinforcement found too much corroded due to

delay in pile cap casting at Tower-2 2 nos. 600 mm

dia. piles near lift pile cap and Tower-1 Rainwater tank Site QAQC

side and near Sump piles and Under casted piles near

canteen

Delay in progress

Minor

New

Material

Concrete

at C7@ (5-G),C9@

(5-F) (6-F) (7F),C8@(C-6) (C-8)

(C-9),C15@(4a-H)

OCPPL

C 50 Concrete Strength failure at C7@ (5-G),C9@ (5-F)

Site QAQC

(6-F) (7-F),C8@(C-6) (C-8) (C-9),C15@(4a-H)

Failed on initial test i.e. 34.6

N/mm2 has attained 43.7 N/mm2

strength in the Retest on the same

extra cubes to approved Third

tested cube. Which is not correct.

party lab for review and analysis

Hence the machine has to be

rechecked with the supplier for the

further use

NC - 31/ RNC

-020

7/8/2016 Minor

New

Material

Concrete

At 1-K and 5A-K

OCPPL

C50 concrete cubes of Tower-3 columns at 1-K and 5ASite QAQC

K less strength at 28 days

extra cubes to approved Third

party lab for review and analysis

NC - 32/ RNC

-021

7/8/2016 Major

New

Supervision

Concrete

Liftwall @ Tower-3

OCPPL

Large honeycomb has been noted at the Lift wall

Tower-3.this issue is in Construction joint where the

PVC water stopper also available and its visible now

and its in UG area

Site QAQC

PVC waterstopper bend during

concrete which has restrcted the

concrete flow in that area. And

improper vibration

NC - 33/ RNC

-022

7/13/2016 Major

New

Design

Concrete

PC-5 Tower-1

OCPPL

Cracks at PC5 pile cap 2nd lift

Site QAQC

Thermal Crack due to temp

As per Prof.Dias report. Epox resin

Details needs to be ensured as per Prof.Dias

difference between core and

pressure grout on crack and other

report

surface exceeded. Prof.Dias report measures

OCPPL

Column, retaining wall at Tower-1 NE corner and Pile

-600mm dia. in East side podium piles has been

covered with soil without any precautionary measures

Site QAQC

and protection. Also the Casted concrete Tie beam has

been filled with soil and access has been made for

heavy vehicle movement

Poor Supervsion

NC - 30/ RNC

-019

7/5/2016

July'16

NC - 34/ RNC

-023

7/15/2016 Minor

NC - 35/ RNC

-024

New

7/21/2016 Major

Site QAQC

Untill the confirmation on the machinery. Pls.

inform RNC to carry out the testing at Third

party lab for acceptance.

RNC QA/QC

Open

July''16

closed

Closed at site but document not yet closed

Open

Test Done.approval pending with consuuctkatnt

6/29/2016 closed

OCPPL Site Exec.

Open

Advised RNC to carryout New mixdesign due to

continuous marginal results in C50 grade

OCPPL Site Exec.

concrete

Open

PVC water stopper has to be plced rigid and

It has to be treated with approved

not to bend using U-bar before

method with presence of WP

concrete.Balance 2 lift walls has to be casted

vendor or by WP team themsself

with the same method with precautionary

for satisfaction of Engineer

measures based on Root cause Analysis report

OCPPL Site Exec.

Open

OCPPL Site Exec.

Open

Its an OPC+ Fly ash concrete casted up to 1.3

m ht. size of the Pile cap is 13.5m x 13.05m. Its

and 2nd lift. 1st has been casted with OPC only

for 600mm ht. For this heights and mixture of

OPC and OPC + Fly ash we have approval from

all parties.

closed

Document closed on 05/08/16

Its an OPC+ Fly ash concrete casted up to 1.3

m ht. size of the Pile cap is 13.5m x 13.05m. Its

and 2nd lift. 1st has been casted with OPC only

for 600mm ht. For this heights and mixture of

OPC and OPC + Fly ash we have approval from

all parties.

July'16

element shown at site needs to be

cleared with all soil coverings and Backfilling and earrth filling with necessarty

proper access to be made

care to the adjacent structure.

Supervision

Backfilling

Tower-1 NE corner

Design

Concrete

PC4G-Tower-2

OCPPL

PC4G pile cap has been found with Thermal cracks

Site QAQC

Thermal Crack due to temp

As per Prof.Dias report. Epox resin

Details needs to be ensured as per Prof.Dias

difference between core and

pressure grout on crack and other

report

surface exceeded. Prof.Dias report measures

OCPPL Site Exec.

Open

Design

Concrete

PC4K - Tower01

OCPPL

PC4K pile cap has been found with Thermal cracks

Site QAQC

Thermal Crack due to temp

As per Prof.Dias report. Epox resin

Details needs to be ensured as per Prof.Dias

difference between core and

pressure grout on crack and other

report

surface exceeded. Prof.Dias report measures

OCPPL Site Exec.

Open

New

NC - 36/ RNC

-025

7/25/2016 Major

New

Document closed on 05/08/16

You might also like

- Transmittal SampleDocument1 pageTransmittal SamplekokocdfNo ratings yet

- ITP C 006 Concrete SlipformDocument7 pagesITP C 006 Concrete SlipformAnil Pottekkat100% (1)

- CRC-CIV-ITP-000004-02 ITP For Rock Bolt InstallationDocument9 pagesCRC-CIV-ITP-000004-02 ITP For Rock Bolt Installationshahzad100% (2)

- Proposal For Outstation Trip To Kuala Lumpur 20 - 24 June 2014Document2 pagesProposal For Outstation Trip To Kuala Lumpur 20 - 24 June 2014Syamsul Qamar RosliNo ratings yet

- 5 6084543957650374717Document4 pages5 6084543957650374717ratanNo ratings yet

- Plumbing-Max FajardoDocument175 pagesPlumbing-Max Fajardoaj80% (5)

- Checklist-Structural Concrete Post PouringDocument1 pageChecklist-Structural Concrete Post Pouringajit karandikarNo ratings yet

- Internal Audit Non-Conformity ReportDocument4 pagesInternal Audit Non-Conformity ReportSparrow Green StudiosNo ratings yet

- ITP C 005 (Structural Concrete)Document4 pagesITP C 005 (Structural Concrete)segun ajibolaNo ratings yet

- Method Statement of Lateral Load Test (BHEL ANPARA)Document11 pagesMethod Statement of Lateral Load Test (BHEL ANPARA)sugurpraveenNo ratings yet

- ITP - OF - Structural Work FOR PARADEEPDocument4 pagesITP - OF - Structural Work FOR PARADEEPRajeev KumarNo ratings yet

- Italian-Thai Density Test ResultsDocument9 pagesItalian-Thai Density Test ResultsJovanni RodriguezNo ratings yet

- J910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)Document13 pagesJ910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)rudi sarifudinNo ratings yet

- PCC WorksDocument4 pagesPCC WorksRounak MaheshwariNo ratings yet

- CH - Ash Pond Lining With Geomembrane, NelloreDocument3 pagesCH - Ash Pond Lining With Geomembrane, NellorePa Dadang0% (1)

- 7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingDocument9 pages7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingMoustafa FaresNo ratings yet

- 12 Form WorkDocument7 pages12 Form WorkAkhilesh KumarNo ratings yet

- Procedure for Backfilling a PipelineDocument7 pagesProcedure for Backfilling a PipelineAjit Kumar RoutNo ratings yet

- Concrete Cube Durability Test Report SubmittalDocument13 pagesConcrete Cube Durability Test Report SubmittalNawar ZainoNo ratings yet

- Qap PDFDocument11 pagesQap PDFNirajan MarwaitNo ratings yet

- Site Visit ReportDocument15 pagesSite Visit ReportKaushal PatelNo ratings yet

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- Blockwork and Plastering - HalulDocument14 pagesBlockwork and Plastering - HalulDindo QuintanNo ratings yet

- Amendment N - I MA Y 2002 IS 1200 (PART 8) : 1993 Methods Measurement of Building and Civil Engineering WorksDocument8 pagesAmendment N - I MA Y 2002 IS 1200 (PART 8) : 1993 Methods Measurement of Building and Civil Engineering Worksraviteja036No ratings yet

- Iqwq-Cpp-Grinv-00-0001 - 0 PDFDocument91 pagesIqwq-Cpp-Grinv-00-0001 - 0 PDFவி.சுரேஷ் குமார்No ratings yet

- M.S & R.S For Soil Investigation WorksDocument14 pagesM.S & R.S For Soil Investigation WorksAL BASTAKI CONTRACTING L.L.C.100% (1)

- Typical QAPDocument4 pagesTypical QAPhemantmech09No ratings yet

- Package II Part I.1 Civil BOQ For Transit House BuildingDocument29 pagesPackage II Part I.1 Civil BOQ For Transit House Buildingdox4useNo ratings yet

- 02 Procedure For ReinforcementDocument18 pages02 Procedure For ReinforcementManas MallickNo ratings yet

- REMOVING SHUTTERSDocument8 pagesREMOVING SHUTTERSAhmet ÖzdenNo ratings yet

- Initial Pile Load Test Report - TP 3Document11 pagesInitial Pile Load Test Report - TP 3skumarsr100% (1)

- QA&QC-DT-FRMC-020 Foundation Work of Transmission LineDocument2 pagesQA&QC-DT-FRMC-020 Foundation Work of Transmission LineTariq Ali SialNo ratings yet

- External NCR MonitoringDocument7 pagesExternal NCR MonitoringGhayas JawedNo ratings yet

- 04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTADocument5 pages04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTAjay2kay5793No ratings yet

- SSTL - PRJ - Tec-Ie-581 - 749-2018 Submission of Monthly Progress Report For The Month of April 2018 (Report) .Document83 pagesSSTL - PRJ - Tec-Ie-581 - 749-2018 Submission of Monthly Progress Report For The Month of April 2018 (Report) .Harish Kumar MahavarNo ratings yet

- Authorisation For Layig GSB and WMM-Rev-R2Document1 pageAuthorisation For Layig GSB and WMM-Rev-R2Guna SekaranNo ratings yet

- 03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFDocument5 pages03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFYati R. TankNo ratings yet

- ITP - General Fill For The Roads - SampleDocument12 pagesITP - General Fill For The Roads - SamplezubairNo ratings yet

- QA For Butt FusionDocument9 pagesQA For Butt Fusionjimbox88No ratings yet

- Oman-India Fertilizer Project OIFDocument24 pagesOman-India Fertilizer Project OIFBassam Dahham83% (6)

- Cube RegisterDocument148 pagesCube RegisterShesha ShayanNo ratings yet

- ACP-EU Energy Facility LVIA Shashamene Final AuditDocument3 pagesACP-EU Energy Facility LVIA Shashamene Final AuditTesfuNo ratings yet

- Gate Installation ReportDocument3 pagesGate Installation ReportKumar AbhishekNo ratings yet

- CON 311 V00 Method Statement For Structural Steel and Pipe Support Fabrication PDFDocument22 pagesCON 311 V00 Method Statement For Structural Steel and Pipe Support Fabrication PDFfurkanNo ratings yet

- Technical Note For LimestoneDocument15 pagesTechnical Note For LimestoneAmierul MukmienNo ratings yet

- Updated Training Calendar 2021-22Document1 pageUpdated Training Calendar 2021-22supriya kumariNo ratings yet

- China National Machinery Imp. & Exp. Corp. DCM Pile Inspection PlanDocument6 pagesChina National Machinery Imp. & Exp. Corp. DCM Pile Inspection Plandimuthu lasinthaNo ratings yet

- 024 Itp For Grouting Works PDFDocument8 pages024 Itp For Grouting Works PDFHarshvardhan PathakNo ratings yet

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDocument12 pagesAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaNo ratings yet

- Dashboard C-1101 MR 2013 Fox HillsDocument10 pagesDashboard C-1101 MR 2013 Fox HillsrmdarisaNo ratings yet

- Gril Engineer URS Engineer: Manufacturer Guideline/QMS Protected Against Rain, Humidity, Dew Fall and DustDocument17 pagesGril Engineer URS Engineer: Manufacturer Guideline/QMS Protected Against Rain, Humidity, Dew Fall and Dustjitendra100% (1)

- DNERFQ-P-502 - 01 - Volume I PDFDocument199 pagesDNERFQ-P-502 - 01 - Volume I PDFAdvait Puram100% (1)

- Pullout TestDocument3 pagesPullout TestAvinash Lal100% (1)

- Hollow Bar Soil Nails Pullout TestDocument59 pagesHollow Bar Soil Nails Pullout TestTayfun ünverNo ratings yet

- QCPDocument8 pagesQCPehsan.mNo ratings yet

- SINOHYDRO CORPORATION BRT PHASE-2 PROJECT GEOTECHNICAL INVESTIGATIONDocument63 pagesSINOHYDRO CORPORATION BRT PHASE-2 PROJECT GEOTECHNICAL INVESTIGATIONSalvatory LyakurwaNo ratings yet

- 9686-CPP-NCR - 0017 - Uncontrolled BackfillingDocument3 pages9686-CPP-NCR - 0017 - Uncontrolled BackfillingANIL PLAMOOTTIL100% (1)

- Project Daily Report: Local Roads & Drainage ProgrammeDocument3 pagesProject Daily Report: Local Roads & Drainage ProgrammeMohd Naveed KhanNo ratings yet

- Inspection and Test Plan Piling: 1. Document ReviewDocument3 pagesInspection and Test Plan Piling: 1. Document ReviewZara BhaiNo ratings yet

- MS of Instrumentation Installation & MonitoringDocument32 pagesMS of Instrumentation Installation & Monitoringmbp planning100% (1)

- Insp Check List FormatDocument139 pagesInsp Check List FormatArvind Kumar SinghNo ratings yet

- Weekly QA/QC ReportDocument4 pagesWeekly QA/QC ReportJoel AlcantaraNo ratings yet

- 7 CFT MOM 29 10 14 - With Comments - 1Document2 pages7 CFT MOM 29 10 14 - With Comments - 1spdhimanNo ratings yet

- University of Wolverhampton Harward Style Reference Full GuideDocument31 pagesUniversity of Wolverhampton Harward Style Reference Full GuideDavid WebNo ratings yet

- Education Department DocumentsDocument4 pagesEducation Department DocumentsDavid WebNo ratings yet

- Branding Sri Lanka: Applying the SPBM ModelDocument82 pagesBranding Sri Lanka: Applying the SPBM ModelDavid WebNo ratings yet

- Guidelines For Interpreting A Turn It in Report (Jan 2020)Document6 pagesGuidelines For Interpreting A Turn It in Report (Jan 2020)David WebNo ratings yet

- Math test answers for Richmond College grade 11Document13 pagesMath test answers for Richmond College grade 11David WebNo ratings yet

- G9 2019-3t-Western Pro (EM)Document6 pagesG9 2019-3t-Western Pro (EM)David WebNo ratings yet

- Year End Evaluation SummaryDocument6 pagesYear End Evaluation SummaryDavid WebNo ratings yet

- Selendiva/Spmc/2021/Civil Works/Tender Doc: Page PP - 1Document7 pagesSelendiva/Spmc/2021/Civil Works/Tender Doc: Page PP - 1David WebNo ratings yet

- Maths G-6 P-II EDocument179 pagesMaths G-6 P-II EDavid WebNo ratings yet

- Year End Evaluation SummaryDocument6 pagesYear End Evaluation SummaryDavid WebNo ratings yet

- Year End Evaluation SummaryDocument6 pagesYear End Evaluation SummaryDavid WebNo ratings yet

- GR 11 Mathematics EM Paper IDocument8 pagesGR 11 Mathematics EM Paper IDavid WebNo ratings yet

- G9 2019-3t-Western Pro (EM)Document6 pagesG9 2019-3t-Western Pro (EM)David WebNo ratings yet

- Year End Evaluation SummaryDocument6 pagesYear End Evaluation SummaryDavid WebNo ratings yet

- G9 2019-3t-Western Pro (EM)Document6 pagesG9 2019-3t-Western Pro (EM)David WebNo ratings yet

- G9 2019-3t-Western Pro (EM)Document6 pagesG9 2019-3t-Western Pro (EM)David WebNo ratings yet

- Payment Gateway ProposalDocument73 pagesPayment Gateway ProposalDavid Web100% (2)

- Year End Evaluation SummaryDocument6 pagesYear End Evaluation SummaryDavid WebNo ratings yet

- 2nd Email Successfully Activated Account 2Document1 page2nd Email Successfully Activated Account 2David WebNo ratings yet

- Green Building Standards SLDocument11 pagesGreen Building Standards SLDavid WebNo ratings yet

- Save Food and Sustain LifeDocument3 pagesSave Food and Sustain LifeDavid WebNo ratings yet

- House BOQDocument36 pagesHouse BOQDavid Web100% (1)

- NTCEnglishReport2017 PDFDocument183 pagesNTCEnglishReport2017 PDFDavid WebNo ratings yet

- The A4 Paper Test Page 1 of 5 2010-10-25 (C) A4 Paper Test - R1.doc Version: R1Document5 pagesThe A4 Paper Test Page 1 of 5 2010-10-25 (C) A4 Paper Test - R1.doc Version: R1David WebNo ratings yet

- Food Wastage Directly Propotion To Climate ChangeDocument3 pagesFood Wastage Directly Propotion To Climate ChangeDavid WebNo ratings yet

- Which Countries Waste The Most FoodDocument2 pagesWhich Countries Waste The Most FoodDavid WebNo ratings yet

- Specifications For House ConstructionsDocument2 pagesSpecifications For House ConstructionsDavid WebNo ratings yet

- Coverpage of The AssignmentDocument1 pageCoverpage of The AssignmentDavid WebNo ratings yet

- Project Plan Odessa Mobile Technology ProjectDocument22 pagesProject Plan Odessa Mobile Technology Projectsan1432No ratings yet

- SOP For Payments To Contrctors Consultants by Finance WingDocument29 pagesSOP For Payments To Contrctors Consultants by Finance WingDavid WebNo ratings yet

- Channelization and Turn Bays CE 453 Lecture 31Document86 pagesChannelization and Turn Bays CE 453 Lecture 31uniqueboy60100% (1)

- Details of Indian Companies Incorporated Between 3 March 2021 To 1 April 2021Document2,846 pagesDetails of Indian Companies Incorporated Between 3 March 2021 To 1 April 2021Burzes BatliwallaNo ratings yet

- TECSYSDocument25 pagesTECSYSJenny QuachNo ratings yet

- Special Mission Aircraft Briefing: Air Ambulance Configurations for Hawker and Beechcraft ModelsDocument22 pagesSpecial Mission Aircraft Briefing: Air Ambulance Configurations for Hawker and Beechcraft ModelsBernardoNo ratings yet

- Norma Astm A1007Document9 pagesNorma Astm A1007Alfredo RangelNo ratings yet

- Structural Behaviour of Cold-Formed Thin-Walled Short Steel Channel Columns at Elevated Temperatures. Part 2 Design Calculations and Numerical AnDocument2 pagesStructural Behaviour of Cold-Formed Thin-Walled Short Steel Channel Columns at Elevated Temperatures. Part 2 Design Calculations and Numerical AnReaditReaditNo ratings yet

- Gujarat Motor Vehicles Department Learner'S Licence Computer Test The Motor Vehicles Act, 1988 & Rules Question BankDocument21 pagesGujarat Motor Vehicles Department Learner'S Licence Computer Test The Motor Vehicles Act, 1988 & Rules Question BankSantosh KumarNo ratings yet

- FevicolDocument8 pagesFevicolAkshit GuptaNo ratings yet

- Implications of Organized Retailing on Manufacturing FirmsDocument3 pagesImplications of Organized Retailing on Manufacturing Firmsvarun_nayak_1No ratings yet

- 22 11 13 - Facility Water Distribution Piping PDFDocument11 pages22 11 13 - Facility Water Distribution Piping PDFmasoodaeNo ratings yet

- Uddeholm Qro90supremeDocument12 pagesUddeholm Qro90supremeDarwin Anderson GNo ratings yet

- Alphabetical List of Pharma CompaniesDocument4 pagesAlphabetical List of Pharma Companiesvipinbhai100% (1)

- Lift Truck Operator Training ProgramDocument61 pagesLift Truck Operator Training ProgramMalathy Sekar100% (1)

- COMMITTED TO EXCELLENCE - JORAMCO'S 50 YEAR JOURNEYDocument20 pagesCOMMITTED TO EXCELLENCE - JORAMCO'S 50 YEAR JOURNEYketan SNo ratings yet

- Air Transport Fundamentals ExplainedDocument36 pagesAir Transport Fundamentals ExplainedYeow Chong TohNo ratings yet

- Om ManagementDocument5 pagesOm Managementdecoylizard92No ratings yet

- Mandal Profile-MallialDocument8 pagesMandal Profile-Mallialneravatla karunya kumarNo ratings yet

- Cold Chain Management in India: International PracticesDocument30 pagesCold Chain Management in India: International PracticesAkbar AliNo ratings yet

- 5Document248 pages5Haryadi Setiawan100% (1)

- Only Fifth Floor BOQDocument6 pagesOnly Fifth Floor BOQsabummathewNo ratings yet

- C7&C9 - Notes - S12Document64 pagesC7&C9 - Notes - S12Kareem RadwanNo ratings yet

- MillingDocument33 pagesMillingRavichandran G0% (1)

- UE-Method Statement Cables InstallationDocument13 pagesUE-Method Statement Cables InstallationshareyhouNo ratings yet

- Mmel 412-212Document50 pagesMmel 412-212LUCAS LARANo ratings yet

- Abacus Electronic TicketDocument16 pagesAbacus Electronic TicketCatherine TominNo ratings yet

- Steel Structure - CorrosionDocument10 pagesSteel Structure - CorrosionVibhor YadavNo ratings yet

- Sand Casting: How Patterns Are MadeDocument4 pagesSand Casting: How Patterns Are MadesbmmlaNo ratings yet