Professional Documents

Culture Documents

Experimental and Computational Investigation of High-Entropy Alloys For Elevated High-Temperature Applications

Uploaded by

mykey652Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental and Computational Investigation of High-Entropy Alloys For Elevated High-Temperature Applications

Uploaded by

mykey652Copyright:

Available Formats

Pr oj e c t Fac t s

Crosscutting Research

Experimental and Computational

Investigation of High-Entropy Alloys for

Elevated High-Temperature Applications

Background

High-entropy alloys (HEAs) developed with a novel alloy design approach using multiple

principal elements in near equimolar ratios have emerged as candidate materials for

high-temperature applications in excess of 800 degrees Celsius (C). The traditional alloy

design method uses only one or two principal elements with small additions of other

alloying elements. These applications include the advanced ultrasupercritical (AUSC)

steam based power generation cycle, which uses steam at temperatures and pressures

well above its critical point. Operating a steam power plant at AUSC conditions (up to

760 C and 35 megapascals [MPa] pressure) results in fuel-to-electrical-power conversion

efficiencies that are considerably higher than in conventional subcritical or supercritical

steam power plants.

The Department of Energy (DOE) National Energy Technology Laboratory (NETL)

is partnering with The University of Tennessee to perform fundamental studies on

aluminum-chromium-copper-iron-manganese-nickel (AlXCrCuFeMnNi) HEAs for use

in boilers and steam turbines at temperatures and pressures up to 760 C and 35 MPa,

respectively, and higher. An integrated research approach that couples thermodynamic

calculations and focused experiments will be used to identify HEAs that will outperform

conventional alloys in these applications.

CONTACTS

Robert Romanosky

Crosscutting Research Technology

Manager

National Energy Technology Laboratory

3610 Collins Ferry Road

P.O. Box 880

Morgantown, WV 26507-0880

304-285-4721

robert.romanosky@netl.doe.gov

Vito Cedro

Project Manager

National Energy Technology Laboratory

626 Cochrans Mill Road

P.O. Box 10940

Pittsburgh, PA 15236-0940

412-386-7406

vito.cedro@netl.doe.gov

Peter Liaw

Principal Investigator

University of Tennessee

406 Ferris Hall

Knoxville, TN 37996-2100

865-974-6356

pliaw@utk.edu

PARTNERS

Computherm LLC

Project Description

This project will identify and develop HEAs that have the key mechanical properties for

use at elevated temperatures. Project personnel will make samples of the desired HEA

compositions and perform compositional and microstructural analyses to characterize

the structures of the developed HEAs. Researchers will perform conventional roomtemperature and elevated-temperature uniaxial tensile and creep experiments. They

will also use advanced characterization techniques, such as neutron and synchrotron

diffraction, to determine structural changes of the new HEAs under applied stresses

at high-temperatures. These advanced techniques will utilize in-situ testing of the

mechanical behavior under uniaxial tension and compression or creep loading to

identify deformation mechanisms under various stress loads at elevated temperatures.

PROJECT DURATION

Start Date

08/01/2012

End Date

07/31/2015

COST

Total Project Value

$300,000

DOE/Non-DOE Share

$300,000 / $0

Albany, OR Anchorage, AK Morgantown, WV Pittsburgh, PA Sugar Land, TX

Website: www.netl.doe.gov

Customer Service: 1-800-553-7681

Goals and Objectives

This project is to develop one or more new HEA compositions that have the required mechanical properties (ductility and

creep strength) to function in AUSC boilers. The objectives of this project are to (1) perform fundamental studies on the

AlXCrCuFeMnNi HEA system to determine its potential for use in AUSC boilers and steam turbines at 760 C and 35 MPa

and higher, and (2) develop an integrated approach to coupling thermodynamic calculations and focused experiments

to identify HEAs that outperform conventional alloys. Phase compositions that might have microstructures with the best

combined strength, ductility, and creep resistance will be identified utilizing computational thermodynamic calculations.

The computational-thermodynamic results will be verified through focused lab-scale experiments. These experiments will

be performed to confirm the phase compositions of HEAs, characterize the microstructure, and measure the key mechanical

properties of the new HEAs.

Benefits

The expected results of the project will be one or more new

HEA compositions that have the required mechanical properties

(ductility and creep strength) to function in AUSC boilers up to 760

C and a steam pressure of 35 MPa. The results will also demonstrate

a computer-aided design approach for identifying and developing

new types of alloys for advanced high-temperature fossil energy

applications. The performance of the newly-designed HEAs should

surpass that of previously-studied candidate HEA alloy systems

(e.g., Al0.5CoCrCuFeNi), achieved by identifying compositions via

computational thermodynamics that have phases providing better

mechanical properties. The proposed research will also advance

computational modeling used in the accelerated design of hightemperature alloys by enhancing the thermodynamic database for

the AlXCrCuFeMnNi HEA system and developing quantitative creep

modeling for designing a wide range of advanced precipitationstrengthened alloys.

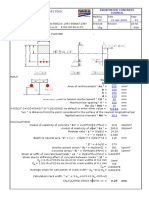

Figure 1. Calculated isopleth of the AlxCoCrCuFeNi HEA

system using thermodynamic descriptions. Similar

calculations will be performed for the AlxCrCuFeMnNi HEA

system to assist in the design of HEAs suitable for use in

high-temperature applications.

Figure 2. Compressive stress-strain curves of Al 0.5CoCrCuFeNi HEAs at (a) high strain rate (10/s) and (b) low strain rate

(10 -3/s) at elevated temperatures showing excellent strength (Tong CJ, et al. Met & Mat. Trans A, 2005, 36, 1263). Similar

AlxCrCuFeMnNi HEAs will be developed by combining the best strength and creep resistance for use in the advanced

ultrasupercritical (AUSC) steam based power generation cycle.

FE0008855, November 2012

You might also like

- Additive Manufacturing of High Entropy AlloysDocument13 pagesAdditive Manufacturing of High Entropy Alloysmykey652No ratings yet

- CatalogDocument22 pagesCatalogmykey652No ratings yet

- NRG 40C Anemometer Data SheetDocument2 pagesNRG 40C Anemometer Data Sheetmykey652No ratings yet

- CRS Solar EnergyDocument31 pagesCRS Solar Energymykey652No ratings yet

- Superalloys MarketDocument3 pagesSuperalloys Marketmykey652No ratings yet

- Microstructures and Properties of High-Entropy AlloysDocument93 pagesMicrostructures and Properties of High-Entropy Alloysmykey652No ratings yet

- Microstructures and Properties of High-Entropy AlloysDocument93 pagesMicrostructures and Properties of High-Entropy Alloysmykey652No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- (Architecture Ebook) Design of Masonry StructuresDocument23 pages(Architecture Ebook) Design of Masonry StructuresFauziah AzizNo ratings yet

- Four Point BendingDocument307 pagesFour Point BendingFathia AlkelaeNo ratings yet

- A Hybrid Material That Reversibly Switches Between Two Stable Solid StatesDocument11 pagesA Hybrid Material That Reversibly Switches Between Two Stable Solid StatesManojKumar MNo ratings yet

- Slabs (LENSCHOW and SOZEN) jl64-27Document8 pagesSlabs (LENSCHOW and SOZEN) jl64-27Pastor PachecoNo ratings yet

- Oxidation of Ternary Tizrn Hard Coatings Studied by Xps Milošev 1998 Surface and Interface Analysis Wiley Online LibraryDocument1 pageOxidation of Ternary Tizrn Hard Coatings Studied by Xps Milošev 1998 Surface and Interface Analysis Wiley Online LibraryDarshal NaharNo ratings yet

- Design Assumption and Beam Analysis PDFDocument25 pagesDesign Assumption and Beam Analysis PDFMardhika LincolnNo ratings yet

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 21-Apr-2020 33 CHG - R68Document4 pagesSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 21-Apr-2020 33 CHG - R68Vikash PeerthyNo ratings yet

- KULIAH4 EC3 Column-Kl PDFDocument27 pagesKULIAH4 EC3 Column-Kl PDFZazliana IzattiNo ratings yet

- Tirasteel Machinery SteelDocument36 pagesTirasteel Machinery SteelAndieka Cool AndieNo ratings yet

- Steel 17-4PH MmpdsDocument18 pagesSteel 17-4PH MmpdsManoj ManoharanNo ratings yet

- Warpage of Fibre Reinforced PlasticsDocument8 pagesWarpage of Fibre Reinforced PlasticsSantolashNo ratings yet

- HDD Calculation Template PDFDocument4 pagesHDD Calculation Template PDFbulituk100% (1)

- Falkner-Collapse Strength and Design of Submarine by D. FalknerDocument16 pagesFalkner-Collapse Strength and Design of Submarine by D. FalknerPiyush JainNo ratings yet

- Catálogo Greenleaf PDFDocument52 pagesCatálogo Greenleaf PDFAnonymous TqRycNChNo ratings yet

- Steel Industrial Shed:is 800 2007Document192 pagesSteel Industrial Shed:is 800 2007Gangesh Kumar ThakurNo ratings yet

- Metal - Brazing and Soldering - ProcessesDocument8 pagesMetal - Brazing and Soldering - Processeshisham_eyes100% (1)

- Polymers - A Brief Tutorial PDFDocument14 pagesPolymers - A Brief Tutorial PDFSalem GarrabNo ratings yet

- Tool Life ImportantDocument31 pagesTool Life ImportantSerajul HaqueNo ratings yet

- Effect Scale Formation in Boiler Water Wall TubesDocument7 pagesEffect Scale Formation in Boiler Water Wall TubesRishabh ChaureNo ratings yet

- Thermodynamics of Mechanical FatigueDocument164 pagesThermodynamics of Mechanical Fatiguesran1986No ratings yet

- India PCN Course Exam FeeDocument3 pagesIndia PCN Course Exam FeeJames100% (1)

- CE8394 Fluid Mechanics and Machinery (FMM) With QB - 12 by EasyEngineering - Net 6 PDFDocument91 pagesCE8394 Fluid Mechanics and Machinery (FMM) With QB - 12 by EasyEngineering - Net 6 PDFEkantha MoorthyNo ratings yet

- Second Day January 21 Structural 1Document9 pagesSecond Day January 21 Structural 1BongA.SalinasNo ratings yet

- Member Check 60x60x5 RSA (Top & Bottom Boom)Document10 pagesMember Check 60x60x5 RSA (Top & Bottom Boom)Bobor Emmanuel OfovweNo ratings yet

- Artículos Sobre SCC en Turbinas de VaporDocument349 pagesArtículos Sobre SCC en Turbinas de Vaporjuanportugal64No ratings yet

- Use of VE Dampers in Reducing Wind and Earthquake Induced Motion of Buildings-ESDocument16 pagesUse of VE Dampers in Reducing Wind and Earthquake Induced Motion of Buildings-ESkostas formulagrNo ratings yet

- Lec1 10Document205 pagesLec1 10Washim WashimmachineNo ratings yet

- Washizu Variational Methods in Elasticity and PlasticityDocument420 pagesWashizu Variational Methods in Elasticity and PlasticityMOFEEZALAM100% (1)

- Appraising Stone Column Settlement Prediction Methods Using Finite Element AnalysesDocument20 pagesAppraising Stone Column Settlement Prediction Methods Using Finite Element AnalysesZOUABINo ratings yet

- Ultrasonic Plastic Welding HornDocument5 pagesUltrasonic Plastic Welding HornAnonymous MVHeP5zNo ratings yet