Professional Documents

Culture Documents

The Best Jumper Points Design of The Sewing Machine

Uploaded by

SEP-PublisherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Best Jumper Points Design of The Sewing Machine

Uploaded by

SEP-PublisherCopyright:

Available Formats

www.seipub.

org/ie

Information Engineering (IE) Volume 4, 2015

doi: 10.14355/ie.2015.03.004

The Best Jumper Points Design

of the Sewing Machine

Shih-Yen Huang 1, Chin-Chiang Huang2, Wen-Yuan Chen*3, Chiu-Keng Lai4 and Yi-Ying Chang5

2.3

Department of Electronic Engineering, National Chin-Yi Institute of Technology

1,5

Department of Computer Science and Information Engineening, National Chin-Yi Institute of Technology

Department of Electrical Engineening, National Chin-Yi Institute of Technology

syhuang@ncut.edu.tw, 2gtmpandayo@gmail.com, 3cwy@ncut.edu.tw, chiukl@ncut.edu.tw, tony@ncut.edu.tw

Abstract

This article uses the principle of Wavelet transformation and Quad-tree structure to find the best jumper points of embroidery

machine. Embroidery want the image to be cut into four equal parts. Furthermore, to judge each part if there exist two object for

connection jumper point selection. For special case, the four parts divided will be extended until the best jumper point were

found. According to the simulation results, our method is evidently an effective and high quality method for sewing machine

for embroidering purpose.

Keywords

Sewing Machine; Quad-tree; Jumper Points; Image Processing

Introduction

The performance of the textile industry has increased steadily in recently years. For example, the total revenue are

14.158 billions, 15.123 billions, 15.866 billions and 17.91 billions in 2012, 2013, 2014 and 2015, respectively. The sales

amount is positive growth, it is expressed as an increase in garment manufacturing time. If we can reduce the

working time, the company's production capacity can improve. It can also increase the company's profit.

Path planning will be used in the sewing machine for embroidering. This technique can improve the efficiency of

sewing machines. Chen et. al. [1] published an article Image-Based Obstacle Avoidance and Path-Planning System

and Rigasova [2] proposed the Path planning algorithm based on search algorithm, edge detector and GPS

data/Satellite image for outdoor mobile systems are offer the information about the path planning studies. Other

related path algorithm can refer to [3-4]. According to the [5-8], it can be found these sewing techniques, but they

did not discuss about the best connection points. In order to improve sewing techniques, we proposed the Quadtree technique to accelerate the search time for searching the best connection jumper point of the sewing machine.

The Best Jump Point Algorithm

In this paper, we focus on the best connection jump point design for sewing machines. It is a part of the picture of

sewing techniques. Figure 1 shows the flow chart of the best jump point design. At beginning, the color picture is

entering to the system. And then the color segmentation was used to separate the picture into several parts which

are the same color. In practical, the same color parts will be processed at the same time. Due to the fact that

greyscale is suitable for the image processing. Therefore, we use the color to greyscale mapping to transfer the

color picture into greyscale picture. Next, edge detection was used to obtain the edge of the picture. Once we get

the edge and each color parts, we use the quad-tree technique to get the best jump point information. The sewing

machine can achieve best efficient and best quality on the picture embroidering.

Input

Image

CS

C2GP

ED

BCJPA

Results

Output

CS : Color Segmentation

ED : Edge Detection

BCJPA : Best Connection Jamp Point Algorithm

C2GP : Color to Grayscale Maping

FIG.1 THE BEST JUMP POINT ALGORITHM

18

Information Engineering (IE) Volume 4, 2015

www.seipub.org/ie

Color Segmentation

Color segmentation was used to divide several same color parts from a picture. Figure 2 shows a test example.

Figure 2(a) shows the test picture and figure 2(b) is the histogram which is corresponding to figure 2(a) in

greyscale.

FIG. 3 displays the classified results. Figure 3(a) shows the class that the pixel value is 17 and figure 3(b) shows the

pixel value is 55. Similarly the pixel value is 105, 112, 123 and 202 are the values correspond to figure 3(c), 3(d), 3(e)

and 3(f) respectively.

In the paper, we use the concept of the wavelet techniques and Quad-tree structure to design a best connection

jump point design.

According to the [9-10], the sewing step and sewing jumper points are on the edge, so to find the side track is

important. In edge detection, we put the original picture and erosion operation to produce a good performance

edge image. From the simulation result, it is superior to the Sobel operation or Canny edge detection.

(a)

(b)

FIG.2 COLOUR SEGMENTATION; (A) THE TEST IMAGE (B) THE HISTOGRAM OF CLUSTERING

(a)

(d)

(b)

(c)

(e)

(f)

FIG. 3 THE CLASSIFIED RESULTS; ( A ) THE PIXEL VALUE IS 17, (B) THE PIXEL VALUE IS 55, (C) THE PIXEL VALUE IS 105, (D) THE

PIXEL VALUE IS 112, (E)A THE PIXEL VALUE IS 123, (F) THE PIXEL VALUE IS 202

The Best Jump Point Search Method

A picture can be divided into several independent objects. When the sewing machine do embroider action,

jumping to the other object is necessary. Thus search the best jump point is important. Figure 5 shows the best

jump point situation for a picture. In the figure, the green points are the best jump points.

The wavelet concept divides the picture into four parts first. And then check each part if it includes two objects. If

the answer is yes, then search the best jump points. If the part only has one object then the part can be discarded

because there is no jump exists. FIG. 5 shows the process of dividing the picture into several parts for searching the

19

www.seipub.org/ie

Information Engineering (IE) Volume 4, 2015

best jump points. Figure 5(a) is the original test picture. Figure 5(b) and figure 5(c) are the parts include two objects.

Similarly, Figure 5(d) and figure 5(e) are the parts only have one object, it means no jump point needed.

FIG. 4 THE SCHEMATIC OF THE BEST CONNECTION JUMP POINTS

(b)

(a)

(c)

(d)

(e)

FIG. 5 THE PROCESS OF DIVIDING THE PICTURE INTO SEVERAL PARTS FOR SEARCHING THE BEST JUMP POINTS; (A) THE

ORIGINAL PICTURE, (B) THE PART INCLUDE TWO OBJECTS, (C) THE PART INCLUDE TWO OBJECTS, (D) THE PART ONLY HAS ONE

OBJECT, (E) THE PART ONLY HAS ONE OBJECT

(a)

(c)

(b)

(d)

FIG.6 THE SUCCESSFUL TEST RESULTS; (A)CASE-1, (B) CASE-2, (C)CASE-3, (D)CASE-4

Experimental Results

In order to demonstrate that our method is effective and of high quality, several image are used to simulation.

20

Information Engineering (IE) Volume 4, 2015

www.seipub.org/ie

From the simulation results it is evident that the wavelet based quad-tree structure is suitable for the sewing

machine to find the best jump point search.

Figure 6 shows the successful test results of the best jump point design for the picture. Figure 6(a) is the best jump

point design of the case-1 picture. Figure 6(b) shows another best jump design of the case two picture.

Simultaneously, Figure 6(c) and figure 6(d) are the successful jump point design case of different pictures.

Conclusion

In this paper we use the shortest distance technique, the wavelet concept and Quad-tree structure to search the best

jump points for sewing machine.

We use the wavelet concept to obtain a suitable jump point search. Besides, we use the Quad-tree structure to

obtain a computation complicate. From the simulation results, it is demonstrated that our method obtain 29.9% ~

55.6% computation reduce time

ACKNOWLEDGMENT

This work was partly supported by the National Science Council, Taiwan (R.O.C.) under contract NSC 101 - 2221

E - 167 034-MY2. References

REFERENCES

[1] Chen.Y. H , Chen. M. C, Li. I, Wang. W. Y, and Su. S. F ,"Image-Based Obstacle Avoidance and Path-Planning

System", IEEE International Conference on System Science and Engineering, 2013, pp. 205 209

[2] Zidek, K, Rigasova, E"Path planning algorithm based on search algorithm, edge detector and GPS

data/Satellite image for outdoor mobile systems", Applied Machine Intelligence and Informatics (SAMI), 2012,

pp.349 354

[3] Lin. Z. D. Covering the whole field of home cleaning robot's path planning and implementation.[D],

Taiwan,National Cheng Kung University Department of Engineering Science, 2005

[4] Zhang. J. A * algorithm to improve the planning of a better guide paths[D], Taiwan, Tatung University

Information Engineering Institute,2009

[5] Li. J. Y. Development of an Automatic Sewing Machine by Embedded Controller[D], Taiwan, Konkuk

University of Science and Technology, Institute of Electrical and Automation Engineering-cum-light system,

2008

[6] Lin. C. Y. Development of Sewing Path Design Software for Broidery[D], Taiwan, Konkuk University of

Science and Technology, Electrical Engineering, 2005

[7] Tsai. T. R. Machine vision based servo control of a robotic sewing system[D].Taiwan, National Yunlin

University of Science and Technology, Mechanical Engineering, 2012:5-8.

[8] Chen. C. N. Analysis & Design Practice of the industrial design development for the OBM household sewing

machineCase study of RICCAR[D]. Taiwan, Chaoyang University of Technology, Master of Design in

Industrial Technology R&D, 2011.

[9] Yang. Z. Y A Fast Inter Residual Quad-Tree Construction Construction Method in HEVC [D].Taiwan,

National Cheng Kung University institute of Computer and Communication Engineering

[10] Tan. Y. H, Yeo .C, Tan .H .L, and Li. Z ,On residual quad-tree codingin hevc in Multimedia Signal

Processing(MMSP),2011 IEEE 13th

[11] Cheng, S.C, Yang ,C.K, A fast and novel technique for color quantization using reduction of color space

dimensionality[C] Pattern Recognition Letters(Volume 22, Issue 8)2001,pp. 845856

21

www.seipub.org/ie

Information Engineering (IE) Volume 4, 2015

Chih-Chiang Huang was born in Taichung, Taiwan, in 1992. He received the B.S. degree in Department of

Electronic Engineering from National Chin-Yi Institute of Technology in 2010 and 2014. Currently, he is

studying for his master degree on Department of Electronic Engineering from National Chin-Yi Institute of

Technology. His research interests include image analysis, wind energy, Electromagnetic Compatibility.

Shih-Yen Huang received the PhD Degree in Electrical Engineering in 2005 from National Cheng Kung

University, Tainan, Taiwan. Currently, he is an associate professor at the National Chin-Yi University of

Technology, Taichung, Taiwan. His research interests include image processing, object recognition, object

tracking, and application of micron processor.

Wen-Yuan Chen was born in Taichung, Taiwan, in 1957. He received the B.S. and M. S. degrees in Electronic Engineering from

National Taiwan University of Science and Technology in 1982 and 1984, respectively, and the Ph.D. degree in Electrical

Engineering from National Cheng Kung University at Tainan Taiwan, in 2003. Since 2007, he has been a Professor in the

Department of Electronic Engineering at National Chin-Yi University of Technology. His research interests include digital

signal processing, image compression, pattern recognition and watermarking.

Chiu-Keng Lai received the B.S. degree in Electronic Engineering from National Taiwan University of

Science and Technology, Taipei, Taiwan in 1989, and the M.S. and Ph.D. degrees in Electrical Engineering

from National Central University, Chung-Li, Taiwan in 1991 and 2001 respectively. In 1992, he joined the

National Chin-Yi Institute of Technology (NCIT), Taiping City, Taiwan. In 2003, he was an Associate

Professor in the Institute of Information and Electrical Energy in NCIT. In 2006, he joined the department

of Electrical Engineering in National Chin-Yi University of Technology, and he is now the Director of the

department. His teaching and research interests include variable-structure system applications for motor

control, PC-based control system design, DSP-based control system and motor drive design, and digital

circuit design with FPGAs for motor drives.

Yi-Ying Chang, he received his college graduate in Electronics Engineering (1982), and Master degree in Computer Information

Science (1997) in the Department of Computer Information & Science Engineering in Knowledge System Institute, Skokie,

Illinois USA. He received the Ph. D degree in Electrical Engineering Department of National Cheng Kung University, Tainan,

Taiwan. His research interests include image enhancement, segmentation and application of Internet of Things. He joined the

National Chin-Yi University of Technology in 1982 and he is an Associate Professor of Department of Computer Science and

Information Engineering of National Chin-Yi university of Technology.

22

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Barking Abbey Basketball AcademyDocument11 pagesBarking Abbey Basketball AcademyAbbeyBasketballNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Grade 6: Student BookletDocument14 pagesGrade 6: Student BookletEjaz Rashid100% (1)

- Veena Das Ed., Michael D. Jackson Ed., Arthur Kleinman Ed., Bhrigupati Singh Ed. The Ground Between Anthropologists Engage PhilosophyDocument360 pagesVeena Das Ed., Michael D. Jackson Ed., Arthur Kleinman Ed., Bhrigupati Singh Ed. The Ground Between Anthropologists Engage PhilosophyGuillermo García ParraNo ratings yet

- University of Asmara Graduation - July 1996Document80 pagesUniversity of Asmara Graduation - July 1996Ibrahim Ali100% (2)

- Mill's Critique of Bentham's UtilitarianismDocument9 pagesMill's Critique of Bentham's UtilitarianismSEP-PublisherNo ratings yet

- Cognitive Domains Taxonomy ChartDocument1 pageCognitive Domains Taxonomy ChartNorila Mat ZanNo ratings yet

- Brahmavidya Breathing SummeryDocument13 pagesBrahmavidya Breathing Summerysudhir vaidya100% (1)

- Arnis Traning Matrix 2023Document6 pagesArnis Traning Matrix 2023RA CastroNo ratings yet

- Curriculum and the Teacher's RoleDocument11 pagesCurriculum and the Teacher's RoleAudremie DuratoNo ratings yet

- Concept PaperDocument5 pagesConcept PaperFernie Villanueva BucangNo ratings yet

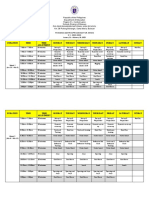

- Division of Misamis Occidental Training Design Action Research Seminar Workshop Venue: TBA Date: TBA Time: 8:00 AM - 4:30 PM A. RationaleDocument6 pagesDivision of Misamis Occidental Training Design Action Research Seminar Workshop Venue: TBA Date: TBA Time: 8:00 AM - 4:30 PM A. RationaleDENMARK100% (1)

- Casta Painting Art Race and Identity in ColoniaDocument8 pagesCasta Painting Art Race and Identity in ColoniaalbagonezNo ratings yet

- LAC PLAN 2023 2024.newDocument3 pagesLAC PLAN 2023 2024.newrosemarie lozada78% (9)

- Contact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentDocument7 pagesContact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentSEP-PublisherNo ratings yet

- Delightful: The Saturation Spirit Energy DistributionDocument4 pagesDelightful: The Saturation Spirit Energy DistributionSEP-PublisherNo ratings yet

- Influence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearDocument13 pagesInfluence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearSEP-PublisherNo ratings yet

- Enhanced Causation For DesignDocument14 pagesEnhanced Causation For DesignSEP-PublisherNo ratings yet

- Reaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesDocument9 pagesReaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesSEP-PublisherNo ratings yet

- Experimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesDocument8 pagesExperimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesSEP-PublisherNo ratings yet

- Improving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesDocument5 pagesImproving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesSEP-PublisherNo ratings yet

- Effect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesDocument11 pagesEffect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesSEP-PublisherNo ratings yet

- Device For Checking The Surface Finish of Substrates by Tribometry MethodDocument5 pagesDevice For Checking The Surface Finish of Substrates by Tribometry MethodSEP-PublisherNo ratings yet

- FWR008Document5 pagesFWR008sreejith2786No ratings yet

- Mindfulness and Happiness: The Empirical FoundationDocument7 pagesMindfulness and Happiness: The Empirical FoundationSEP-PublisherNo ratings yet

- Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingDocument5 pagesMicrostructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingSEP-PublisherNo ratings yet

- Microstructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesDocument7 pagesMicrostructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesSEP-PublisherNo ratings yet

- Enhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentDocument6 pagesEnhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentSEP-PublisherNo ratings yet

- Isage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophyDocument8 pagesIsage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophySEP-PublisherNo ratings yet

- Quantum Meditation: The Self-Spirit ProjectionDocument8 pagesQuantum Meditation: The Self-Spirit ProjectionSEP-PublisherNo ratings yet

- Metaphysics of AdvertisingDocument10 pagesMetaphysics of AdvertisingSEP-PublisherNo ratings yet

- Technological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsDocument9 pagesTechnological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsSEP-PublisherNo ratings yet

- Cold Mind: The Released Suffering StabilityDocument3 pagesCold Mind: The Released Suffering StabilitySEP-PublisherNo ratings yet

- Social Conflicts in Virtual Reality of Computer GamesDocument5 pagesSocial Conflicts in Virtual Reality of Computer GamesSEP-PublisherNo ratings yet

- Architectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldDocument5 pagesArchitectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldSEP-PublisherNo ratings yet

- Ontology-Based Testing System For Evaluation of Student's KnowledgeDocument8 pagesOntology-Based Testing System For Evaluation of Student's KnowledgeSEP-PublisherNo ratings yet

- A Tentative Study On The View of Marxist Philosophy of Human NatureDocument4 pagesA Tentative Study On The View of Marxist Philosophy of Human NatureSEP-PublisherNo ratings yet

- Legal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialDocument4 pagesLegal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialSEP-PublisherNo ratings yet

- The Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateDocument8 pagesThe Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateSEP-PublisherNo ratings yet

- Computational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpDocument6 pagesComputational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpSEP-PublisherNo ratings yet

- Damage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationDocument10 pagesDamage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationSEP-PublisherNo ratings yet

- Educational Services Post Secondary Education Award Ma000075 Pay GuideDocument34 pagesEducational Services Post Secondary Education Award Ma000075 Pay Guiderabi1973No ratings yet

- Houran - Do Online Matchmaking Tests WorkDocument21 pagesHouran - Do Online Matchmaking Tests Workyasirzaidi1No ratings yet

- KBSM 2019 English Scheme of Work Term 1Document5 pagesKBSM 2019 English Scheme of Work Term 1ilangoven100% (7)

- Weebly Burgardquaranta Asd Network ResumeDocument5 pagesWeebly Burgardquaranta Asd Network Resumeapi-297920664No ratings yet

- SPED 425-001: Educational Achievement Report Towson University Leah Gruber Dr. Fewster 4/30/15Document12 pagesSPED 425-001: Educational Achievement Report Towson University Leah Gruber Dr. Fewster 4/30/15api-297261081No ratings yet

- Tie Preparation (Investigation & News)Document4 pagesTie Preparation (Investigation & News)Joanna GuoNo ratings yet

- Self Certification With Matatag LogoDocument2 pagesSelf Certification With Matatag LogoGerardBalosbalosNo ratings yet

- Shahzad Zar Bio DataDocument2 pagesShahzad Zar Bio DatanoureenNo ratings yet

- Anna University Literature Review FormatDocument4 pagesAnna University Literature Review Formatea844bbv100% (1)

- Andrew Burton Resume1Document2 pagesAndrew Burton Resume1api-113889454No ratings yet

- Organizational Behavior: Stephen P. RobbinsDocument35 pagesOrganizational Behavior: Stephen P. RobbinsPariManiyarNo ratings yet

- Reporting Test Scores: Unit 9Document22 pagesReporting Test Scores: Unit 9Waqas AhmadNo ratings yet

- Cps in FypDocument4 pagesCps in FypMuhammadHafiziNo ratings yet

- Capitol University Medical Center PoliciesDocument5 pagesCapitol University Medical Center PoliciesCharles CagaananNo ratings yet

- School Dental Health Programme Pedo 2Document25 pagesSchool Dental Health Programme Pedo 2misdduaaNo ratings yet

- Primera Lengua Extranjera II - Inglés Examen ResueltoDocument4 pagesPrimera Lengua Extranjera II - Inglés Examen ResueltoAlbaNo ratings yet

- Assessing Agricultural Innovation SystemsDocument106 pagesAssessing Agricultural Innovation SystemsAndre RDNo ratings yet

- 221 Meeting Minutes FinalDocument157 pages221 Meeting Minutes FinalKrishna Kumar MishraNo ratings yet