Professional Documents

Culture Documents

A Probe Into Failure of Selected Plumbing Parts: Alloy Composition, Microstructural Condition and Aqueous Exposure

Uploaded by

SEP-PublisherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Probe Into Failure of Selected Plumbing Parts: Alloy Composition, Microstructural Condition and Aqueous Exposure

Uploaded by

SEP-PublisherCopyright:

Available Formats

Journal of Metallurgical Engineering (ME) Volume 3 Issue 2, April 2014

doi: 10.14355/me.2014.0302.02

www.me-journal.org

A Probe into Failure of Selected Plumbing

Parts: Alloy Composition, Microstructural

Condition and Aqueous Exposure

Iyiola O. OTUNNIYI*, Oluwayimika O. OLUOKUN

Metallurgical and Materials Engineering, Federal University of Technology Akure, Nigeria

*iootunniyi@futa.edu.ng; drolatunji@gmail.com

Abstract

A probe into the metallurgical integrity of selected plumbing

parts was carried out for an informed evaluation of the

failures observes in service. Faucets and sink drainer were

focused on. Alloy compositions and microstructures were

assessed, and test exposures to normal service conditions

were simulated. Alloys were found with off-specification

compositions, with residual stresses in the microstructures

providing energy to initiate degradation early in service.

Hence, plumbing parts corrodes freely in ordinary neutral

water, with metal overload in water. The materials choice

and production design predisposes the units to short service

life. Conformity to basic material and manufacturing

standards is still lacking in some operations.

Keywords

Plumbing Parts; Metallurgical Integrity; Materials Selection;

Alloy Compositions; Residual Stress; Corrosion

Introduction

Instances of very short service lives are very common

experiences in using many consumer items in Nigeria

in recent years. Plumbing fittings have been found to

fail and had to be replaced within months. Service

lives of electric bulbs have been found to average less

than four weeks. Wall electrical outlets commonly heat

up under household amperage, melt and burn the

plastic housing. Electric stoves, water heaters, pressing

iron, rechargeable lamps, ceiling lamp holders and IT

products, often pack up in few months of use. The list

is longer and there have been officially statements

about the trend (Agboola, 2011). Since many of these

items were imported into the country, such

experiences can be expected in many parts of the globe.

For this work, plumbing parts that have been found to

fail in service after remarkably short service lives were

focused. Shower sprinklers and drainers (sieves in

kitchen sink hole) produced to appear like stainless

steel have been found to rust to dirty brown within

less than 24 weeks of fitting. Drainers rust and crumble

into pipe work. Taps not used for a few days have

been found to first dispense a burst of brownish

globule before clear flow. Such tap heads often cease to

hold flow after about four months. The tap continues

to drip and must be replaced. Whereas, a plumbing

part is expected to be noncorrosive, and durable

enough to equal or exceed the expected life of the

building in which it is installed (Encyclopedia B., 2010)

When a consumer item fails after a short service life, it

can be a case of abuse by the user, or a single defective

product out of many other good ones. When this

observation is in all instances of use, the logical

thinking is that these items are not made to safe and

durable standards from source. No position will be

final without an empirical basis for its conclusion.

Selected plumbing parts were therefore investigated

and reported herein. The alloy compositions were

determined and compared to standard material

specifications for such units (BSI, 1991; CDA, 1991;

Ramesh, 2011; Malekith, 2013), and the microstructural

conditions of the alloys as-used were studied. Test

exposure to the service condition (neutral water) was

simulated. It was also found necessary to assess

possible metal load of water dispensed by such faucets.

The results were discussed from different viewpoints.

Methodology

For a documentary, visual inspection of striking

instances of faucets and drainer failure, as found in

service were carried out. From a survey of the varieties

of these items available in the plumbing stores, four

most common faucets found in the shops and a drainer,

were obtained. For reference, Table 1 gives designations and summary description of the items. The

samples were dissembled, scratched, sawn, and cut

apart, as necessary, to visually assess surface and bulk

body material make up.

69

www.me-journal.org

Journal of Metallurgical Engineering (ME) Volume 3 Issue 2, April 2014

Spark spectrometric analysis of separate alloys making

up the units was done. For the faucets, the alloys used

in the central control rods in F1 F3, being the major

moving part, and the housing alloys, being the bulk

material, were analyzed. Since mechanical and heat

treatments affect microstructural condition, which in

turn affects service performance, metallographic

samples of the alloys analyzed were obtained. Optical

microstructures of the alloys were obtained.

Microstructure and compositional analysis were

similarly done for the drainer.

TABLE 1 DESIGNATION AND DESCRIPTION OF FOUR COMMON FAUCETS

AND THE DRAINER STUDIED

Designation

F1

F2

Features and description

A circular indentation around the valve control rod

of the faucet reads ENGLAND EURO UK. On the

faucet housing (the gland), on one side, letters SF

and on the other side BS 10102 and were boldly

embossed as-cast. Uses screw control mechanism.

Similar to F1 expect with no indentation or

embossed, and the stem appears to be of steel luster.

water above another set of samples using a small

impeller attached to the thin shaft of a small DC motor.

The motor was powered for four hours in a day; since

the tap in a typical household will not dispense water

round the clock, while in a typical public utility the tap

can be expected to run cumulatively for about four

hours a day. Measurement of any changes in the

samples mass was done weekly for six weeks, with

the water above the samples replaced with every

measurement.

From the corrosion test (results below), possible level

of pollution of water dispensed by such faucets was

also assessed. Sample was taken from the water in

which the component alloys were placed, and

analyzed for metal load using atomic absorption

spectroscopy (Haswell, 1991; Welz, 1999). With the

respective lamps, the water sample was analyzed for

iron, copper, sodium, lead, potassium, and zinc.

F3

Similar to F1 in stem, and embossed letters but with

different structural design.

Results and Discussion

F4

Stainless steel appearance; flow control mechanism

by aperture opening and closing in 90O turn.

Exhibits

A sample drainer; the sieve covering drain hole in a

kitchen sink.

From the visual inspections, Figure 1 presents exhibits

of sample faucets as found in service. Corrosion stains

and rusts to different extents on the stem (the central

control rod) and towards the supporting threaded nut

can be seen on the faucets. For plumbing fittings to

corrode visibly in this manner in service, the material

selection and the production design are strongly

suspects. The faucets shown in Figure 1 are of the type

designated as F1.

For a quantitative check on the performance in the

service environment, test exposure to the service medium

was simulated. The disassembled components were

left undisturbed to simulate the static condition of a

tap that is not dispensing water. Since in service, water

is not static but actually runs in the tap, the dynamic

flow service condition was simulated by stirring the

FIGURE 1 INSTANCES OF TAP1 AS FOUND IN SERVICE SHOWING DETERIORATION LEVELS AND EMBOSSED PRODUCTION

STAMP SHOWING SUPPOSED STANDARD SPECIFICATION KEPT.

70

Journal of Metallurgical Engineering (ME) Volume 3 Issue 2, April 2014

www.me-journal.org

(c)

(a)

(b)

FIGURE 2 TAP SAMPLES AS OBTAINED FROM THE PLUMBING SHOP

Figures 2a c show new samples of F2, F3 and F4 as

obtained from the plumbing shop. Examining the

samples, the stem in F2 shows steely luster, and it is

presumably machined from rolled bars. The main

faucet body is apparently made of brass, with as-cast

surface texture. It is notable that the stem and the

valve housing are not of the same alloy. This portends

a dissimilar metal violation for a unit that will be

susceptible to wet aqueous exposure in service. In F1

(new one is not shown), the stem has the same brass

coloration as the housing. On this basis, F1 in new

form appears to be of better material selection in its

design and production, compared to F2, since the

possibility of dissimilar metal galvanic effect appears

to be removed. However, while holding F1 around in

the course of observation, the stem started showing

discoloration (due to inadvertent rubbing by fingers),

exposing portions with steel luster. Portions showing

steel and brass coloration like this were found in

service also (Figure 1). The stem obviously has a thin

(possibly submicron) coating, with poor adhesion. In

F3 the stem is also coated as in F1, but the coating did

not rub off so readily.

F4 is a different design, with covered stem and the

housing of stainless steel luster. The housing surface

when scratched with a pin indented deep and softly,

unlike stainless steel but rather more like an organic

coating. With a hand saw and file, a thin undercoat

showing reddish brown on a bulk body of dull white

luster was revealed. The bulk material of the housing

thus appears to be of steel, with a faint first coat of

copper, and a final tenacious surface coat that can be

organic.

F1, F2 and F3 are similar in working mechanism: the

threaded stem is turned downward to block flow by

closing against a polymeric o-ring. The valves will

continue to block flow as long as the polymeric disc

remains resilient and the stem maintain its length. In

F4, a turn through 90O allows or stops flow when

holes in two polymeric components align or not,

respectively. One of the polymeric components sits on

a stem that appears as cast brass. The stem turns the

polymeric piece in and out of alignment with the other

piece that is fixed in the flow channel. The unit will

continue to regulate flow effectively as long as the

aligning polymeric components do not degrade but

maintain tight tolerance. Based on visual inspection,

production of F4 appears of a best material selection

and design.

Figure 3 shows a sample drainer in service that has

corroded and crumbled, and a new sample. The new

sieve appears of stainless steel, but this surely cannot

be if the new is of the same material as the one

observed in service, which corroded so badly that part

of it crumbled into the pipe works. The fitting bolt

gave way and can no longer hold it in place. The

results of analysis are presented following.

FIGURE 3 DRAINER SIEVE AS FOUND IN SERVICE INSIDE A

DRAINER AND A NEW ONE.

71

www.me-journal.org

Journal of Metallurgical Engineering (ME) Volume 3 Issue 2, April 2014

Compositions of Component Alloys

Table 2 shows the elemental compositions of different

alloys in the study. Columns R1 to R3, gives the

compositions for the control rods in F1, F2 and F3

respectively, while H1 to H4 are for the housing alloys

of F1 to F4. Column D is for the drainer, ST is for the

generic BS 1400 brass alloy recommended for fresh

water faucets, and column SD is for AISI-SAE Grade

304 stainless steel recommended of the drainers (CDA,

1991; MatWeb, 2013). Among many equivalents,

specifications BS 5154: 1991, BS 12288: 2010, BS EN

12163: 2011, BS EN 1982: 2008 cover specific brass

alloys for components of fresh water valves, while BS

EN 10088-1: 2005 number 1.4301 or 1.4401 covers

stainless steels for screens (BSI, 1991; ASD, 2012).

According to the compositions in Table 2, the housings

of F1, F2 and F3 were confirmed to be brass alloys,

while that of F4 is a zinc-aluminum alloy. The central

control rods in F1, F2, and F3 were found to be of

medium to low carbon steels (MatWeb, 2013). The

drainer was also of low carbon steel and not stainless

steel according to the standard in column SD.

Compared to the standard specifications, there are

random elements in the alloys compositions. This can

be traced to recycling charge. More than half of metal

productions in the world are now sustained by scrap

recycling (Papp, 2001). Production of finished parts

using only ingots smelted from primary ores is

increasingly rare. Different copper alloys in the

BS2870/5, BS3072/6, BS1400 specifications (the PB10x,

CN10x, AB10x, CA10x, ABx series) contains definite

amounts of Al, Si, Mn, Fe, Pb (Higgins, 1999; Callister,

2001). There are precipitation hardened copper alloys

containing Cr and Be. For steels and irons, the existing

alloys are more (MatWeb, 2013). Such assorted alloys

get into scrap feed in recycling, and the charge

calculation settles for the closest optimum. If a heat

produces off-specification composition, the product

becomes new scrap (Papp, 2001). If an operation

weighs economics too high, compositions such as

obtained herein will be the result.

For the control rods and the drainer, the compositions

cannot be classed as stainless steel based on the Ni and

Cr, nor as Mn-Si steel; all the elements were not up to

requisite levels (Callister, 2001; MatWeb, 2013). Trace

Al and Cu were also detected. Based on the carbon

levels, the alloys can be said to have been produced

from assorted ferrous scraps charge, roughly targeted

toward mild steel but turned out off-specification.

Compositions that are roughly mild steel are

inadequate for plumbing applications for which they

have been employed (Blower, 2006; Ramesh, 2011;

Malekith, 2013).

TABLE 2 ELEMENTAL COMPOSITION (%) OF ALLOYS USED IN THE DRAINER (D), THE CONTROL RODS (R) AND HOUSING (H) OF THE SAMPLE FAUCETS, AND

THE STANDARD SPECIFICATIONS OF SUCH PARTS.

72

R1

R2

R3

H1

H2

H3

H4

ST

SD

Al

0.023

0.149

0.003

0.0088

0.245

0.087

83.3

0.1-0.8

0.031

0.100

As

0.034

0.032

0.016

0.014

0.014

--

0.193

0.244

0.195

--

--

--

--

0.142

0.080

Cr

0.532

0.313

0.0042

0.0068

0.02

0.069

0.070

0.084

20.000

Cu

0.037

0.04

0.0033

58.2

67.5

54.2

1.86

58-63

0.081

Fe

97.7

97.35

99.3

0.74

0.95

0.7

0.5

0.7

99.2

68.995

Mn

0.79

1.02

0.369

0.009

0.005

0.003

1.18

0.5

0.108

2.000

Ni

0.009

0.015

0.021

0.306

0.281

0.281

--

0.053

8.000

0.036

0.037

0.047

0.0079

0.005

0.005

--

0.02

0.045

0.045

Pb

0.003

0.001

0.002

2.61

5.63

6.22

0.05

0.5 - 2.5

0.024

0.03

0.020

0.0061

0.011

0.007

--

--

0.048

0.750

Si

0.58

0.71

0.021

0.013

0.066

0.14

1.3

0.05

0.188

0.030

Sn

0.026

0.027

0.0012

0.81

2.44

1.6

0.146

0.0043

Zn

--

--

0.013

37.17

22.68

36.65

11.40

30.43 38.13

0.01

--

Journal of Metallurgical Engineering (ME) Volume 3 Issue 2, April 2014

For the housing alloys, reference to column ST in Table

2, a plumbing faucet will be made of brass alloy. All

the components of the unit the housing, the turning

knob, the control rod are mandated to be of the same

brass alloy (CDA, 1991). The brass alloys used in the

housings deviated with respect to different elements.

The Pb levels in H1 (F1 housing) is close enough to be

acceptable, while that in F2 and F3 exceeded this level.

Lead level of 2.5 maximum is the standard, while F2

and F3 contained 5.63% and 6.22%. Pb is notably

carcinogenic for humans and strict restrictions apply to

the presence and use of this element according to the

RoHS directive (Directive, 2003). Permitted levels may

therefore not be exceeded. Chromium is another

element not expected but found in trace proportion. It

may not be a threat in this context, but can rather

improve corrosion resistance of the alloy. More so that

these housings did not fail in service instances

inspected, or show any dissolution during the

corrosion testing (see below), the brass alloys used in

the manufacture of the faucet heads can be considered

www.me-journal.org

acceptable.

The bulk body alloy used in F4 housing found to be of

aluminum alloy is a good alternative to the brass

alloys. The composition shows an Al-Zn alloy that can

come under the BS 1475:7000 series. Aluminum is

known for its tenacious thin surface oxide which

makes aluminum alloys naturally corrosion resistant

(Snodgrass, 2003). The surface of this faucet was also

treated to a tenacious coating, and the material can be

considered acceptable.

Microstructures of Component Alloys

The housings of the various faucets generally show

different as cast microstructures. Since the housings

actually did not give any problem in service or in the

corrosion test, the micrographs are inconsequential in

further analysis of the performance problem. Figures

4a and b, micrographs obtained for H1 and H3, were

therefore shown only as representative micrographs of

the brass housings.

FIGURE 4 OPTICAL MICROGRAPH OF THE BRASS HOUSING OF (A: LEFT) TAP1, SHOWING A GRANULAR AS-CAST +

STRUCTURE (EXPECTED AT 37 % Zn, X 400), AND (B: RIGHT) H3, SHOWING A PREDOMINANTLY -BRASS MATRIX (AT 22 % Zn, X 200)

WITH EQUIAXED AS CAST STRUCTURE.

FIGURE 5 OPTICAL MICROGRAPHS OF THE VALVE CONTROL RODS OF (A: LEFT) TAP1 SHOWING AS-ROLLED DIRECTIONAL

GRAIN (X 400) AND (B: RIGHT) TAP2 SHOWING RECRYSTALLISED GRAINS POSSIBLY FROM FULL ANNEAL (X 400).

73

www.me-journal.org

Journal of Metallurgical Engineering (ME) Volume 3 Issue 2, April 2014

FIGURE 6 OPTICAL MICROGRAPHS OF (A: LEFT) THE VALVE CONTROL ROD OF TAP3 SHOWING THE AS ROLLED STRUCTURE

LARGELY RELIEVED, THOUGH LITTLE FLOW IS STILL RESIDUAL (X 400), AND (B: RIGHT) THE DRAINER SIEVE WITH CLEARLY

FLOWED PEARLITE MORPHOLOGY IN A FERRITE MAIN MATRIX (X 400).

Considering the microstructure from R1 (Table 2)

shown in Figure 5(a), it can be inferred that the stem

was machined to size from the rod in as-rolled condition.

The microstructure shows grains with preferred

orientation ascribable to the rolling direction (Tatsuya

and Kenji, 2010). In this state, this rod was used asworked, and with the strain energy not relieved. It was

therefore more corrosion active than if some stress

relief annealing had been performed on it (Van Boven

et al., 2007). Here is another insight into why the stem

was, as it were, dissolving in ordinary water at room

temperature. The micrograph of R2 shows rather

recrystallised grains, possibly from full anneal of the

as-rolled rod used in the production of the stem. For

F3, as Figure 6 indicates, the stem can be said to have

been turned from an alloy that was worked and then

treated only to stress relief anneal. From Figure 6b, the

drainer is in a slightly worked state, with the residual

stress unrelieved. This could have been from the little

deformation during press forming. A fully relieved

structure is a better condition for reducing corrosivity

(Higgins, 1999). In the production design of F1, F3 and

the drainer, this fact was disregarded. Production

design in F2 is mindful of this, but the bulk alloy is

essentially not corrosion resistant.

The highpoint thus far is that the central valve control

rod in F1, F2 and F3 were of alloys that are clearly

unsuitable, of mild and low carbon steels and not

brasses. The drainer alloy was also not of stainless

steel according to specification. These alloys are

inappropriate and are not expected in applications for

aqueous exposure. Some are also in worked states. To

have used such alloys for these applications in the first

place is bad enough; to keep the alloys in a worked

state, with residual energy in the microstructure, is

worse. This predisposed the items to such poor

performance as found in service. The results of the test

74

exposures track the degradation in service with time.

Corrosion Behavior of the Faucet and the Drainer Alloys

Of the various components of the faucets exposed to

static and flowing water, all the component parts of F4

did not show any degradation. No noticeable

corrosion was observable. The mass measurements

remained constant. In the other faucets, the central

valve control rod corroded glaringly, turning rusty

brown on the surface, while the water also turned

brownish. The mass measurements showed mass loss

in the rods. Figure 7 shows the cumulative mass loss in

the different control rods under the two conditions

over the 42 days of exposure. From the figure, the

material used for the control rods in F1, F2 and F3

cannot survive exposure to ordinary water at room

temperature. Even under static exposure, corrosion of

the rods was progressing. Under the dynamic

condition, the rate increased, indicating erosioncorrosion (Rabald, 1991). These central control rods are

the very component of the valve that blocks the flow.

This implies that, in the locked condition, the faucets

will continue to degrade. Related to service performance, the corrosion observed under static condition

accounts for the first globule of brownish water that

burst from these faucets after some days of inactivity.

On a closer study of the data in Figure 7, in the first

week of exposure, the mass loss rate was relatively

highest for control rod of F3. This latter slowed down,

relatively, before the corrosion continued steadily. This

can be a passivation - transpassive behavior (Kruger,

2003), but the imperfect coating on the surface of the

rod could be more responsible. With imperfect coating,

coating breakdown, surface corrosion, local galvanic

action with the substrate, exfoliation, peeling, and

blistering to different extents can occur (Roberge, 1999).

Journal of Metallurgical Engineering (ME) Volume 3 Issue 2, April 2014

Mass loss rate can therefore reduce after the coating is

fully consumed, and some modes of corrosion cease.

However, the corrosion did not passivate. There is also

such coating on F1. Corrosion commences right from

the very first week of exposures and continued

steadily. Cummulatively, F3 gave lower mass loss, and

F1 the higher. In both cases, the manufacturers would

know that the coatings do not offer short or long term

protection to the substrate. These coatings must have

been for sale cosmetics only. Overall, the control rod of

F2 recorded the highest mass loss over the time

interval, while F1 and F3 were in the trail. All the

dissolution is continuous, and will not passivate. The

faucets will cease to control flow after short service life.

The drainer also was found to corrode under water.

Figure 8 shows the drainer response over the period

under dynamic exposure. It was noted that the

response was initially slow. The coating first tended to

resist degradation, but later tarnished and gradually

gave way. The rate of corrosion then aggravated. As

the sample corrodes in this manner under neutral

water, more profuse corrosion till failure as found in

service (Figure 3), can be expected. When exposed to

the real kitchen waste water streams, with pH shocks

above and below 7, depending on what is cooking, and

thermal fluctuations, the product is surely a failure.

R1-Static

R1-Dynamic

R2-Static

R2-Dynamic

R3-Static

R3-Dynamic

12

Cumulative mass loss per unit area

(mg/cm2)

www.me-journal.org

10

8

6

4

2

Time (days)

0

0

10

20

30

40

Cummulative mass loss per unit area

(mg/cm2)

FIGURE 7 CUMULATIVE MASS LOSS PER UNIT AREA UNDER STATIC AND DYNAMIC EXPOSURES OF CONTROL RODS IN F1, F2

AND F3, DENOTED AS R1, R2 AND R3 RESPECTIVELY.

6

5

4

3

2

1

0

0

10

20

30

Time (days)

40

FIGURE 8 CUMULATIVE MASS LOSS PER UNIT AREA OVER TIME OF EXPOSURE OF THE DRAINER SIEVE TO ORDINARY WATER

UNDER DYNAMIC CONDITION, WITH VIEWS OF THE CORRODED TEST SAMPLE INSET.

75

www.me-journal.org

Journal of Metallurgical Engineering (ME) Volume 3 Issue 2, April 2014

Obviously, the alloys used for the different

components are unsuitable for these applications,

virtually dissolving under exposure to ordinary water,

only with the exception components of F4. These types

of products will only put the consumer in a vicious

cycle of replacing the plumbing fittings forever.

Metal Load in Water

With the dissolution of the faucet control rods in

presence of ordinary water, expect for F4, metal load in

water dispensed by such faucets raises concern. The

AAS analysis shows various metallic elements in the

water sample (Table 3). The allowable levels for safe

drinking water for these elements by some standard

bodies (United Nations WHO, USAs EPA and

Nigerias NSDWR) are also shown in the table (NIS

2007; EPA, 2010; WHO, 2011). It may be needed to

restate that the water sample analysed was taken

above the corroding control rods, and the analysis is

indicative of possible contaminations that this rods can

contribute to water dispensed by the faucets. It does

not account for many other possible source of

contamination of pipe borne water. It may be needed

also to state that the water has become faint brown due

to the corrosion dissolution. This analysis may

therefore represent the first brownish globule observed

in service when the faucets have not been used for

some days. Clear flow normally follows after such first

brownish burst, although how clean such clear flow

can be is clearly debatable.

TABLE 3 METAL LOAD IN WATER SAMPLE FROM CORRODED PARTS

Elements

Chromium (Cr)

Copper (Cu)

Iron (Fe)

Lead (Pb)

Manganese(Mn)

Nickel (Ni)

Zinc (Zn)

Tested Water

Sample (mg/L)

0.074

0.186

130.8

1.039

0.027

28.833

NSDWR WHO EPA

(mg/L) (mg/L) (mg/L)

0.05

0.05

0.1

1

2

1.3

0.3

-0.3

0.01

0.01

0

0.2

-0.05

-0.07

-3

3

5

Definite information from this analysis is that six

metallic elements can leach from these control rods

into household cup of drinking water. The list includes

chromium, known to serve no biological function in

the body, but rather a cumulative poison (Chowdury

and Chanda, 1987. Chromium can also exist in the

hexavalent state, which is particularly listed as

hazardous. Elements such as iron and zinc that are

dietary elements can be loaded beyond limits from

these units, as the data show. Iron overload disturbs

pH balance, predisposing patient to permanent coma

in the worst case. Human exposure to metals from tap

76

water is known for a long time, with lead plumbing

being notorious. From the data herein, excessive

dosage of many other metals may soon add to the

global health concerns from different vulnerable

regions where these substandard parts still enjoy sales.

Conclusion

Study of alloys used in production of sample

plumbing parts faucets and drainer shows cases of

bad material selection and production design. The

composition analyses show the alloys as off

specification compositions, but close to mild steel. The

alloys are actually from assorted scraps charged not to

a strict composition target. The microstructures show

that some of the alloys are in stressed states, providing

internal energy to hasten degradation. There are

dissimilar metal coupling too. Active surface corrosion

of the critical moving parts triggers on exposure to

service condition (drinking water). Coatings were only

for sale cosmetics. Corrosion was sustained in erosioncorrosion mode by fluid current so that passivation

will not occur. The short service life as found in service

is expected. Metal load in the water dispensed from

such taps can be far above safe portable water

threshold. The products were produced to a gross

substandard. It is an indication that conformity to

basic materials and manufacturing standards is still

lacking in some operations.

REFERENCES

Agboola, T. Nigeria loses over 50 billion annually to fake

products. The Nation Newspaper, November 21, 2011.

ASD

Architectural

Services

Department.

General

specifications for plumbing and drainage installations in

government buildings in the Hong Kong Special

Administrative Region, 2012 edition. Hong Kong SAR,

2012.

Blower, G. J. Plumbing mechanical services, 5th ed.,

Edinburgh Gate, Essex, UK: Pearson Education Limited,

2006.

BSI. B. S. 5154:1991 Specification for copper alloy globe,

globe stop and check, check and gate valves. British

Standards Board: Piping System Components Standard

Committee; 1991.

Callister, W. D. Fundamentals of materials science and

engineering, 5th ed. New York: John Wiley, 2001.

Chowdhury, B. A. and Chanda, R. K. Biological and health

implications of toxic heavy metals and essential trace

Journal of Metallurgical Engineering (ME) Volume 3 Issue 2, April 2014

www.me-journal.org

element interactions. Progress in Food and Nutrition

plumbing fixtures on drinking water quality a review.

Science 11(1) (1987): 55-113.

International Journal of Environmental Studies 56 (5)

CDA - Copper Development Association, Grovelands

Hempstead. Copper and copper alloy castings properties

and applications. Publication TN42. 1991.

Directive 2002/95/EC of the European parliament and of the

(1999): 717-743.

Triantafyllidou, S. Simoni, C. and Edwards M. Lead (Pb) in

tap water and in blood: implications for lead exposure in

the United States. Critical Reviews in Environmental

council on the restriction of the use of certain hazardous

Science and Technology, Vol. 42 (13) (2012): 1297-1352.

substances in electrical and electronic equipment; Official

Tatsuya, M. Kenji, H. Deformation microstructure and

Journal of the European Union l37/19 EN 13.2.2003.

EPA - U.S. Environmental Protection Agency, Washington,

DC. . 2010-06-02. Accessed July 2013.

Haswell, S. J. Atomic absorption spectrometry: theory,

design and applications. Amsterdam: Elsevier, 1991.

Higgins, R. A. Engineering Metallurgy - Part I: Applied

Physical Metallurgy, 6th ed. New York: Arnold, 1999.

Kruger, J. Passivity. In Corrosion: Fundamentals, Testing,

and Protection, ASM Handbook 13A, edited by Stephen

D. Cramer and Bernard S. Covino, Jr., 6167. ASM

International: 2003.

Malekith, A. Ball Valves for Plumbing Needs. ; Accessed,

July 2013.

MatWeb: Overview of Materials for Medium Carbon Steels.

www.matweb.com. Accessed, July 2013.

NIS - Nigeria Industrial Standard, Nigerian standard for

drinking water, NIS 554. Lagos: Standard Organization of

Nigeria, 2007.

Rabald, E. Corrosion Guide. 2nd ed. Hempstead: Copper

Development Association; 1991.

Ramesh R. G. Stainless India. Vol. 16 (2). Gurgaon: Indian

Stainless Steel Development Association; 2011.

Roberge, P. R. Handbook of Corrosion Engineering, McGraw

Hill, USA, 1999.

Snodgrass, J. Corrosion Resistance of Aluminum Alloys. In

Corrosion: Fundamentals, Testing, and Protection, ASM

Handbook 13A, edited by Stephen D. Cramer and

Bernard S. Covino, Jr., 6167. ASM International: 2003.

texture in a cold-rolled austenitic steel with low stackingfault energy, Materials Transactions, 51 (4)(2010): 620

624.

Van Boven, G., Chena, W. and Rogge, R. The role of residual

stress in neutral pH stress corrosion cracking of pipeline

steels Part I: Pitting and cracking occurrence, Acta

Materialia, (2007): 2942.

Papp, J. F. Introduction, in Recycling-Metals, 2001:

http://minerals.usgs.gov/minerals/pubs/commodity/recycle/r

ecymyb01.pdf Accessed July 2013.

Plumbing. In: Encyclopdia Britannica, Student and Home

Edition. Chicago: 2010.

Welz, B. and Sperling, M. Atomic Absorption Spectrometry.

Germany: Weinheim, 1999.

WHO World Health Organization, Guidelines for drinkingwater quality, 4th ed. Switzerland: WHO, 2011.

Wikipedia. Drug Overdose. . Accessed July 2013.

Iyiola Olatunji OTUNNIYI is a

Metallurgical Engineering academic.

He studied at Obafemi Awolowo

University

Ile-Ife,

Nigeria

and

University of Pretoria, South Africa.

He holds a PhD degree and has more

than ten years of teaching and research

experiences in Universities and Institutes.

Oluwayimika O OLUOKUN is a notably bright upcoming

Metallurgical Engineer. He studied at Federal University of

Technology, Akure and took interest in materials quality and

integrity in service, metallurgical plant and process design.

Subramanian, T.K.S. and Venkata R. B. Impact of household

77

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Electrical WorkDocument16 pagesElectrical WorkGalip KuyukNo ratings yet

- Astm B443 PDFDocument8 pagesAstm B443 PDFMohammad ShamimNo ratings yet

- Mill's Critique of Bentham's UtilitarianismDocument9 pagesMill's Critique of Bentham's UtilitarianismSEP-PublisherNo ratings yet

- Composite in Marine ApplicationsDocument12 pagesComposite in Marine ApplicationsJithin Devan PadincharayilNo ratings yet

- Memorize Architect's Review Notes SummaryDocument59 pagesMemorize Architect's Review Notes SummaryInah Quiniquini Manalese100% (2)

- TN NewDocument6,322 pagesTN Newdeva nesan83% (6)

- VSL - Multistrand Post TensioningDocument15 pagesVSL - Multistrand Post TensioningkmabdNo ratings yet

- Contact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentDocument7 pagesContact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentSEP-PublisherNo ratings yet

- Delightful: The Saturation Spirit Energy DistributionDocument4 pagesDelightful: The Saturation Spirit Energy DistributionSEP-PublisherNo ratings yet

- Influence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearDocument13 pagesInfluence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearSEP-PublisherNo ratings yet

- Enhanced Causation For DesignDocument14 pagesEnhanced Causation For DesignSEP-PublisherNo ratings yet

- Reaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesDocument9 pagesReaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesSEP-PublisherNo ratings yet

- Experimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesDocument8 pagesExperimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesSEP-PublisherNo ratings yet

- Improving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesDocument5 pagesImproving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesSEP-PublisherNo ratings yet

- Effect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesDocument11 pagesEffect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesSEP-PublisherNo ratings yet

- Device For Checking The Surface Finish of Substrates by Tribometry MethodDocument5 pagesDevice For Checking The Surface Finish of Substrates by Tribometry MethodSEP-PublisherNo ratings yet

- FWR008Document5 pagesFWR008sreejith2786No ratings yet

- Mindfulness and Happiness: The Empirical FoundationDocument7 pagesMindfulness and Happiness: The Empirical FoundationSEP-PublisherNo ratings yet

- Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingDocument5 pagesMicrostructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingSEP-PublisherNo ratings yet

- Microstructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesDocument7 pagesMicrostructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesSEP-PublisherNo ratings yet

- Enhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentDocument6 pagesEnhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentSEP-PublisherNo ratings yet

- Isage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophyDocument8 pagesIsage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophySEP-PublisherNo ratings yet

- Quantum Meditation: The Self-Spirit ProjectionDocument8 pagesQuantum Meditation: The Self-Spirit ProjectionSEP-PublisherNo ratings yet

- Metaphysics of AdvertisingDocument10 pagesMetaphysics of AdvertisingSEP-PublisherNo ratings yet

- Technological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsDocument9 pagesTechnological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsSEP-PublisherNo ratings yet

- Cold Mind: The Released Suffering StabilityDocument3 pagesCold Mind: The Released Suffering StabilitySEP-PublisherNo ratings yet

- Social Conflicts in Virtual Reality of Computer GamesDocument5 pagesSocial Conflicts in Virtual Reality of Computer GamesSEP-PublisherNo ratings yet

- Architectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldDocument5 pagesArchitectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldSEP-PublisherNo ratings yet

- Ontology-Based Testing System For Evaluation of Student's KnowledgeDocument8 pagesOntology-Based Testing System For Evaluation of Student's KnowledgeSEP-PublisherNo ratings yet

- A Tentative Study On The View of Marxist Philosophy of Human NatureDocument4 pagesA Tentative Study On The View of Marxist Philosophy of Human NatureSEP-PublisherNo ratings yet

- Legal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialDocument4 pagesLegal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialSEP-PublisherNo ratings yet

- The Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateDocument8 pagesThe Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateSEP-PublisherNo ratings yet

- Computational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpDocument6 pagesComputational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpSEP-PublisherNo ratings yet

- Damage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationDocument10 pagesDamage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationSEP-PublisherNo ratings yet

- Fatigue Crack Growth Behavior of 4340 Steels: P. K. Liaw and T. R. LeaxDocument18 pagesFatigue Crack Growth Behavior of 4340 Steels: P. K. Liaw and T. R. LeaxSWAPNIL PATILNo ratings yet

- St37 2Document4 pagesSt37 2Brio LevNo ratings yet

- Engineering Design Calculations for Ductwork ElbowsDocument25 pagesEngineering Design Calculations for Ductwork ElbowsJosifNo ratings yet

- TR 60Document3 pagesTR 60Narayanan MoorthyNo ratings yet

- Agreement Readymix With PAF 2ndDocument2 pagesAgreement Readymix With PAF 2ndNoni100% (1)

- Acoustic Materials GuideDocument110 pagesAcoustic Materials GuideMOHD AZHAR NUMANINo ratings yet

- ME - 312, HMT-week 11Document21 pagesME - 312, HMT-week 11Qazi MaazNo ratings yet

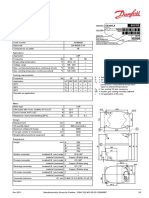

- Gs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralDocument2 pagesGs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralmustafaNo ratings yet

- Soil Mech and Foundation by XYZDocument73 pagesSoil Mech and Foundation by XYZParamveer SharmaNo ratings yet

- Cat Filtrazione 2017 enDocument80 pagesCat Filtrazione 2017 enTed ThomsonNo ratings yet

- Performance Evaluation of The Bending Strength of Larch CLTDocument12 pagesPerformance Evaluation of The Bending Strength of Larch CLTSỹ PhạmNo ratings yet

- A Case Study On The Lighting Condition, Both Natural and Artificial, of The USTP CafeteriaDocument8 pagesA Case Study On The Lighting Condition, Both Natural and Artificial, of The USTP Cafeteriaclark yooowNo ratings yet

- Mechanical - Vendor ListDocument1 pageMechanical - Vendor ListImythNo ratings yet

- Spur Gears Component GeneratorDocument4 pagesSpur Gears Component GeneratorRodrigo NavarreteNo ratings yet

- Wainscoting - Catalogue (New)Document4 pagesWainscoting - Catalogue (New)IfKitchen ConceptNo ratings yet

- Materials System SpecificationDocument21 pagesMaterials System SpecificationPrasanna UmapathyNo ratings yet

- Ventilation CowlsDocument12 pagesVentilation CowlsShahadatuliskandar RosliNo ratings yet

- Sushant School of Art and ArchitectureDocument6 pagesSushant School of Art and Architectureankushsingla.barch21No ratings yet

- Sikadur®-732: Product Data SheetDocument2 pagesSikadur®-732: Product Data SheetFaisal FaizNo ratings yet

- Grade 9 PHYSICS Syllabus For Annual Examination Portion 2019 1 General PhysicsDocument2 pagesGrade 9 PHYSICS Syllabus For Annual Examination Portion 2019 1 General PhysicsAnonymous TyJqkvOFNo ratings yet

- Horse Stable VentilationDocument16 pagesHorse Stable VentilationRenata C CalfatNo ratings yet

- Current Composites Testing ReportDocument4 pagesCurrent Composites Testing ReportMohamed RamzanNo ratings yet

- Avida Centralis PVC Technical EvaluationDocument2 pagesAvida Centralis PVC Technical EvaluationJovenal TuplanoNo ratings yet

- ASTM E 139-06 Standard Test Methods For Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials1Document14 pagesASTM E 139-06 Standard Test Methods For Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials1Angel RamirezNo ratings yet