Professional Documents

Culture Documents

Drying Temperature and Water Content-Strength Correlations - Brendan O'Kelly - Academia

Uploaded by

Shelly Theresse Catian NovoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drying Temperature and Water Content-Strength Correlations - Brendan O'Kelly - Academia

Uploaded by

Shelly Theresse Catian NovoCopyright:

Available Formats

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

Search...

LO G I N

SIGN UP

We're trying Google Ads to subsidize server costs. If you are logged in, you won't see ads. Hover to learn more.

{KeyWord:Sand Dryer} Manufacturer

High Drying Efciency. Factory Price,Short Delivery Time. Get Free Quotes Now!

Dryingtemperatureandwatercontentstrength

correlations

Dryingtemperatureandwater

contentstrengthcorrelations

UPLOADED BY

VIEWS

Brendan O'Kelly

263

CONNECT TO DOWNLOAD

GETPDF

15 Pages

READ PAPER

Environmental Geotechnics

Volume 1 Issue EG2

Drying temperature and water content

strength correlations

OKelly

Environmental Geotechnics 1 May 2014 Issue EG2

Pages 8195 http://dx.doi.org/10.1680/envgeo.13.00016

Paper 13.00016

Received 24/04/2013; accepted 13/08/2013

Published online 19/12/2013

Keywords: codes of practice & standards/strength and testing of materials/

thermal effects

ICE Publishing: All rights reserved

Drying temperature and water

contentstrength correlations

Brendan C. OKelly PhD, FTCD, CEng, CEnv, MICE

Associate Professor, Department of Civil, Structural and Environmental

Engineering, Museum Building, Trinity College Dublin, Dublin, Ireland

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

1/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

For water content determinations on organic soils, several researchers have adopted lower oven-drying temperatures

in the range 3590C (instead of the standardised range for mineral soils of 100110C) in order to prevent possible

charring, oxidation and (or) vaporisation of substances other than water. However, at too low a temperature, not all

of the relevant water is driven off. One major consequence of using such a wide range of drying temperatures for

more sensitive materials is to produce considerable disparity in interpolated index values and in deduced correlations

between water content and other engineering properties. This paper discusses the pros and cons regarding the ovendrying temperature adopted for routine water content determinations on organic sludges and residues. It concludes

by recommending a standardised oven temperature of 105110C or 105 5C, a 24-h drying period and a suggested

minimum wet specimen mass of 50 g.

Notation

AMC

ILN

LL

LOI

PL

WTR

a

b

mrefand mtC

sur

sur

and

(LL)

s ur

(PL)

w

w105Cand wtC

105Cand 110C

105Cand 110C

Apparent moisture content ratio after

Skempton and Petley (1970)

Modied liquidity index

Liquid limit

Loss on ignition

Plastic limit

Water-treatment residue material

Water content (as %) for sur= 1 kPa

Gradient of log wlog sur correlation

Equilibrium dry masses for a reference oven

temperature and a lower drying temperature

oftC, respectively

Saturated remoulded undrained shear strength

Saturated remoulded undrained strengths at

LL and PL, respectively

Gravimetric water content (as %)

Dimensionless water content values for

temperatures of 105C and tC, respectively

Water content parameter

Water content parameter values for reference

temperatures of 105C and 110C, respectively

Gradient of parameter against drying

temperature trend line

Gradients of parameter against drying

temperature trend lines based on equilibrium

dry masses at 105C and 110C, respectively

Introduction

Municipal sludges and residues generally have very or extremely

high values of water content. It is widely accepted that water

content alone is an inadequate and often unreliable measure in

assessing, from a geotechnical standpoint, that satisfactory levels

of dewatering have been achieved for organic sludges and residues.

This is necessary, for example, in order to reduce associated

transportation and landfill disposal costs and to achieve adequate

shear strength for efficient handling, trafficability and geotechnical

stability of landfill slopes (OKelly and Quille, 2010). There has

also been a trend toward adopting the fall-cone and shear-vane

test methods as quick means of determining the shear strength

in order to assess whether such materials have been adequately

dewatered before leaving municipal or industrial works and,

again, for example, by the landfill operator before accepting the

dewatered material for disposal (OKelly, 2014). However, as

illustrated in Figure 1, for a given value of water content, the

mobilised remoulded undrained shear strength (sur) depends on the

material (its grading, composition and mineralogical properties,

particularly those of the clay fraction (Trauner et al

1990), organic content along with type of chemical and biological

treatments applied and level of bioactivity); physical state (degree of

compaction and saturation); and method of strength measurement,

including the test-specimen size, stress and boundary conditions,

shearing mode and rate (OKelly, 2013a, 2013b, 2014). Where

liquid limit and plastic limit data are available, liquidity index is

often determined and used instead of water content for correlation

Environmental Geotechnics

Volume 1 Issue EG2

Drying temperature and water content

strength correlations

OKelly

1000

8

4

2

m100

/

N

k

:

h

t

g

n

e

r

t

s

r

a

e

h 10

S

1, Alum WTR

2, Alum WTR

3, Alum WTR

4, Alum WTR

5, Iron WTR

6, Iron WTR

7, Iron WTR

8, Sewage sludge

9, WTRs and sewage sludge

3

2

5

9

1

not considered as pore water either. For mineral soils, the removal

of pore water is achieved by oven drying representative specimens

at temperatures of 105 5C (ASTM D2974; ASTM, 2007) or

105110C (BS1377-2; BSI, 1990a) for a period of at least 16 h, or

longer as necessary, until there is no change in the specimen mass

after further drying periods in excess of 1 h. Apart from gypsum,

and some tropical clays, water of crystallisation is generally not

removable by oven drying at temperatures of up to 105110C

(Head, 1997).

However, in the case of organic sludges and residues, some solid

organic matter may potentially char or oxidise (decompose) and

vaporisation of substances other than pore water (e.g., organic

solvents, alcohols, greases, oils, aromatic components) may also

occur at these elevated temperatures. This would result in the

measurement of apparently higher values of water content (OKelly

2005b, 2005d). By contrast, at too low a temperature, not all of the

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

2/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

1

30

300

Water content: %

3000

2005b, 2005d). By contrast, at too low a temperature, not all of the

pore water would be driven off (OKelly, 2004a, 2005c).

The aims of the present study are:

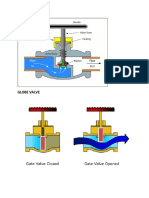

Figure 1. Undrained strength against water content correlations

for water-treatment residue (WTR) and sewage sludge materials.

(a) For different temperatures, investigate the drying rate and

Dryingtemperatureandwatercontentstrengthcorrelations

Nos. 1 and 5, Novak and Calkins (1975); nos. 2, 3 and 6, Wang

period required for oven drying of municipal sewage sludge

et al. (1992); nos. 4 and 7, Wichmann and Riehl (1997); no. 8,

and WTR material;

OKelly (2006); no. 9, Geuzens and Dieltjens (1991).

(b) Study the impact of oven-drying temperature on correlations

with shear strength. However, the data in Figure 1 are presented in

terms of water content since the values of these consistency limits

were reported for only two of the five studies considered. Included

in the figure are undrained strength data deduced from fall-cone,

miniature vane and triaxial compression apparatus for alum and

iron water-treatment residues (WTRs) and municipal sewage

sludge materials. The premise of this paper is that the wide range of

oven temperature values adopted by different researchers for water

content determinations can significantly impact on water content

strength correlations.

In geotechnical literature, water content ( w) is defined as the mass

ratio of pore water to solids, expressed as a percentage. The definitive

procedure for the laboratory determination of water content is the

oven-drying method. Oven temperature and drying period are of

great importance, influencing the measurement result, whereas

atmospheric pressure and humidity are of secondary importance.

For some materials, such as highly organic soils, soils in which the

pore water contains dissolved solids, or those containing significant

amounts of halloysite, mica, montmorillonite, gypsum or other

hydrated materials, the oven-drying method may not yield reliable

water content values.

For industry-standard water content determinations, the removal of

pore water is required and excludes adsorbed water on the surface

of the solids and any water of crystallisation. Other phenomena,

such as the permanent removal of inter-sheet water in, for instance,

halloysite 10 (Mitchell, 1993), may also occur, although this is

D O W N LO A D

between water content and undrained strength;

(c) Recommend a suitable combination of oven tempera

drying period for routine water content determinations on

organic sludges and residues.

In the present investigation, oven-drying tests were performed over

the temperature range 80110C. Testing commenced at 80C since

MacFarlane and Allen (1965) reported that charring and oxidation

of some organic matter, specifically coarse fibres in a fibrous peat

material, became increasingly evident for temperatures in excess of

~85C. OKelly (2005b, 2005d) also reported that for eight

soils having loss on ignition (LOI) values of 393%, some slight

charring and oxidation of susceptible organic matter commenced

YUTONG Concrete Mixer Truck.

within the temperature range 8090C. Gravity-convection and

Export To 128 Countries.Ask Now!

forced-draft type ovens are both used in the present investigation

in order to investigate whether the method of air circulation

within

yutonghi.com/Concrete_Mixer_Truck

the oven chamber has any significant effect on measured values of

water content. Finally, the significance of adopting different ovendrying temperatures for routine water content determinations is

considered in terms of its impact on interpolated index values and

correlations between water content and undrained strength. To the

authors knowledge, this is the first study to investigate such effects.

Concrete Mixer Truck

Test materials

Oven-drying tests were performed on moderately degraded

municipal sewage sludge material obtained from the Tullamore

Municipal Wastewater Works (County Offaly, Ireland) and on

alum WTR material derived from the production of potable water

at Ballymore Eustace Water Treatment Works (County Dublin,

82

Environmental Geotechnics

Volume 1 Issue EG2

Drying temperature and water content

strength correlations

OKelly

Ireland). Comprehensive descriptions of the geotechnical and

hydraulic properties of these materials have been reported for the

sewage sludge by OKelly (2004b, 2005a, 2006, 2008a, 2013b) and

the WTR material by OKelly (2008b, 2014) and OKelly and Quille

(2009, 2010). The oven-drying characteristics of the fraction of the

sewage sludge material passing the 425-m sieve, which had an LOI

of 70%, have been reported previously by OKelly (2004a, 2005b,

2005c), employing the same convection oven as that used in the

present investigation. The oven-drying characteristics of the coarse

fibrous fraction (~10% of the materials total dry mass) retained after

wet sieving the bulk material on the 425-m sieve are investigated in

the present study. This fraction was mainly composed of cellulose,

hemicellulose and lignin plant fibres, with any Magnafloc LT22S

additive that had been added for chemical conditioning of the sludge

at the municipal works substantially diluted during the laboratory

wet-sieving process. Scanning electron micrographs reported

by OKelly (2005a) indicated that the solids phase comprised

aggregate flocs of clay mineral particles, coarse and fine organic

fibres, colloidal organic matter (carbohydrates, proteins and lipids;

Raunkjaer et al., 1994) and pathogenic organisms. High-intensity

peaks from X-ray diffraction analysis for the mineral solids were

interpreted as quartz, calcite and kaolinite, although there was also

the likelihood of other trace minerals at concentrations of less than

12% by mass. The pore fluid had a viscous gel-like nature, caused

by the high concentration of dissolved solids, high bonding or

adsorption of the liquid phase within and around the aggregate flocs,

and some form of biological coagulation between the pore fluid and

organic solids (OKelly, 2013b). Comparisons in the present study

between the oven-drying characteristics of the two fractions of the

sewage sludge material would enable the effect of the coarse organic

fibres on the drying response to be determined.

Experimental method

For the two study materials, samples were thoroughly remoulded

and sub-divided to obtain homogeneous specimens of nominally

50 g in wet mass for oven-drying tests. These specimens were

placed in tarred aluminium cups within a 14-L chamber

gravity-convection oven (Memmert Universal model UNB 100)

which provided thermostatic control of the chamber temperature

to 15C of the set temperature value. The equilibrium dry masses

of the specimens were determined for set oven temperatures,

commencing with 80C and increasing in six steps up to a

maximum of 110C. In this manner, the effects of increasing oven

temperature could be investigated for specific values of temperature

and drying period within this temperature range. During the course

of these tests, the specimens were periodically removed from the

oven, cooled in desiccators to ambient laboratory temperature and

the dry masses of the specimens recorded to 001 g. The use of

desiccators is important since considerable systematic errors may

arise if the test material were hygroscopic and absorbed water from

surrounding air after drying, but before it could be weighed. The

oven-drying process was then continued by replacing the specimens

in the same locations within the oven chamber. Note that repeated

sequences of heating and cooling may affect the samples struc

Although this was not apparent in the present study, in other

instances, unavoidable, simultaneous decomposition

may occasionally occur; for example, following removal from

water of crystallisation. Over the course of the drying process, the

chamber temperature was set and maintained for different periods

at 80C, 90C, 100C, 105C and 110C, with the temperature

increasing from one step to the next. A similar sequence of 60C,

85C, 100C, 105C and 110C was used in oven-drying

various organic soils by Skempton and Petley (1970). In

investigation, drying tests commenced at 80C, below the reported

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

3/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

investigation, drying tests commenced at 80C, below the reported

For the WTR material, the source water under treatment was

value of ~85C for which some charring of organic matter became

obtained from an upland catchment of saturated peat overlying

increasingly evident for a fibrous peat studied by MacFarlane and

granite bedrock in the Dublin and Wicklow mountains, Ireland.

Allen (1965). OKelly (2005b, 2005d) also reported that, for eight

The solids phase of the WTR material was almost exclusively

organic soils investigated, some slight charring and oxidation had

composed of aggregate flocs of colloidal organic matter, clay

commenced in the range 8090C. Full evaporation of the pore

D O W N LO A D

Dryingtemperatureandwatercontentstrengthcorrelations

mineral particles and included alum Chemifloc 4140 coagulant

water occurs at 100C. The standardised oven-drying temperature

and Magnafloc LT25 polyelectrolyte. These chemicals had been

is 105C, with 110C specified as the upper limit, for water

added during the purification processes and also to achieve better

content determinations on mineral soils (BS1377-2: BSI, 1990a;

dewatering efficiency of the WTR slurry at the treatment works. In

ASTM D2974: ASTM, 2007). Hence it follows that the specimen

terms of chemical composition, the WTR material was composed

equilibrium dry mass would comprise the following:

of 2428% aluminium and ~35% Magnafloc by dry solids mass.

Refer to OKelly (2008b, 2010, 2014) and OKelly and Quille

At 80C, the mass of solids, any residual pore water less any

(2009, 2010) for further details.

vaporisation of volatile substances;

At 90C, the mass of solids, less any reduction that may

LOI values of 57% and ~100% were determined for the WTR

have occurred due to charring, oxidation and vaporisation

material and coarse fibrous fraction of the sewage sludge,

of volatile substances and a potentially reduced amount

respectively, by igniting test specimens of the powdered materials

residual pore water;

(previously oven dried to achieve equilibrium mass at 105C) in a

At 100C, 105C and 110C, the mass of solids, less any

muffle furnace at 440C over an 18-h period, in accordance with

reduction due to charring, oxidation and vaporisation of

BS1377-3 (BSI, 1990b). Respective fibre contents (percentage of

volatile substances.

material by dry mass retained on the 150-m sieve) were measured

YUTONG

In

a

second series of drying tests, a larger forced-draft

oven was Concrete Mixer Truck.

at 0% and 100%, in accordance with ASTM D1997-91 (ASTM,

Export

To 128 Countries.Ask Now!

used to investigate whether the method of air circulation

within

2008).

Concrete Mixer Truck

yutonghi.com/Concrete_Mixer_Truck

Environmental Geotechnics

Volume 1 Issue EG2

0

1

1

r

e

t

e

m

a

r

a

p

t

n

e

t

n

o

c

r

e

t

a

W

e

c

n

e

r

e

f

e

R

f

o

e

u

l

a

V

5

0

1

f

o

e

u

l

a

V

Drying temperature and water content

strength correlations

OKelly

5

8

t

A

7

0

9

.

0

0

8

t

A

5

2

9

.

0

0

9

8

.

0

6

6

9

.

0

0

6

t

A

6

3

9

.

0

223

489

9

. 9

. 9

.

000

5

8

t

A

2

3

9

.

0

76

99

9

. 9

.

00

9753

8888

9

. 9

. 9

. 9

.

0000

8

8

9

.

0

0

8

t

A

97

38

9

. 9

.

00

5

1

9

.

0

3995

7779

9

. 9

. 9

. 9

.

0000

0

6

t

A

5

7

9

.

0

6501

5769

9

. 9

. 9

. 9

.

0000

92

88

9

. 9

.

00

6620

6545

9

. 9

. 9

. 9

.

0000

3

5

9

.

0

a

y

d

u

t

s

t

n

e

s

e

r

P

a

)

b

5

0

0

2

(

y

l

l

e

K

d a

n)

a

5

6

e9

n

a1

l

(

r

a

n

F

e

l

c

al

A

M

b

)

0

9

9

1

(

t

r

e

b

l

i

G

8

.

6

9

7

.

2

8

6

. 6

. 5

.

745

61

9756

. 4

. 5

. 0

.

1

1112

%

:

I

O

L

70

50

1

c y

t

i

i

v

c

e a

p r

S g

65

8

. 4

.

11

8

3

.

1

8

4

2

055

6

4

114

c %

i

t

:

s t

ai

l

m

Pl

i

c

i

t

8 s

6 n

ol

a

2N

p

d%

i

:

ut

qi

i

m

L i

l

6

1

5

y

t

i

c x

e

i

t

d

s

n

ai

l

P

e

g

d

t

a

e

7

. 9

. 0

. 7

.

7209

8972

a

d)

n

a0

7

n9

o1

(

t

p y

e

l

m

et

e

k

SP

61

1

6542

2478

9

9

0020

9565

522

c

- i

nt

3

s 0

13

o a

64

Nl

p3

0530

1853

34 1

0

1

8

0550

0318

9731

088

52

428

y

a

l

t

a

e

e

pt g

c

i

n

a

s

u

o

r y

bl

e

t

y a

r

l

e

t

y

l

e

t

a

r

e

d

o

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

.

C

0

1

1

b

r

o

C

5

0

1

a

f

o

e

r

u

t

a

r

e

p

m

e

t

g

n

i

y

r

d

n

e

v

o

n

a

f

o

s

i

s

a

b

e

h

t

n

o

d

e

n

i

m

r

e

t

e

d

e

r

e

w

s

e

u

l

a

4/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

y r

e

e

n

t

g

l

o

a

a

a

t e

pt g

l

t

d

e

c d

g

hd

d

m

a

u

r

l

a

p

g o t

,

u

e t

a e u d

i

s n

e

l

o

e

l

e

p

s

a

n m d p

s m a

t

f

e o

p a

ad e

e

at

,

, t

n

o

w

y

g

r

c

e

i

p

g

a

a

ad

s

g

w k

r

a

t

c

p a

e

r B

e

e e a

e

n

o l

w

a u

n e t

l

r

c

y e

dd

wl

p p

a e

ei

w

a s

a

b bH o

r

r

a v O

i

c l

r t e

y

t

s

o

y

n

n

r

s

a

g

s

t

e

f

r

d dki

al

t el m

ei

a

u

e o r

,

w

w

s

c

b

t

e

n

n

n n hd a

o

y

y

c

Dryingtemperatureandwatercontentstrengthcorrelations

o

o

a nl

r

p

o

o

a

g

al

a r

pi

c l

r r s h

a

i

i

a

y

y

m

b

i

P

P

l

s s

B

l

l

y

mi

o r

r

c c e et bb ui

c n

s t i

u

s i

s t

t t

e t y hk

i

a

y

k r

R

s F

ok

o

y

c

e

v

v

r

r h

g

e y

et

n

T c

g n

g r

u r

al

al

a a5

ab

i

r

r

i

n

a

a e a

a r

abl

2 i

e

l

r

WF m4 F

D DWS VSMO GG mCSDDB

l

a

v

t

n

e

t

n

o

c

r

e

t

a

w

d

e

t

r

o

p

e

R

D O W N LO A D

84

Environmental Geotechnics

Volume 1 Issue EG2

Drying temperature and water content

strength correlations

OKelly

Concrete Mixer Truck

YUTONG Concrete Mixer Truck.

Export To 128 Countries.Ask Now!

the oven chamber had any significant effect on the specimen dry

mass and required drying period, and, hence, on measured values of

water content, for 105C. The 133-L chamber capacity forced-draft

oven used (ELE International model N150CF, with a rated power of

1500 W) provided thermostatic control of the chamber temperature

to 1C of the set temperature value, which was calibrated using an

alcohol thermometer.

The WTR material was found to have unusual oven-drying

behaviour in that the test-specimen mass did not show any signs

of equilibrating after a 48-h drying period. WTR test specimens of

nominally 20, 50 and 100 g in wet mass were oven dried at 105C

over an extended period of 34 days using the forced-draft oven in

order to investigate this behaviour further.

Correlations were also established between water content

determined on the basis of different oven temperatures and

remoulded undrained strength for the WTR material. Undrained

strength data extending well beyond the plastic range were

determined using three approaches: the 80 g30 fall-cone liquid

limit apparatus (BS1377-2; BSI, 1990a), miniature vane and

triaxial compression tests. In the vane tests, a 25-mm-by-25-mm

cruciform vane was torqued under a vane-head rotation of 9/

min. In the triaxial tests, 38-mm-diameter-by-76-mm-long test

specimens were compressed at an axial strain rate of 2%/min

under an applied cell pressure of 100 kPa. Batches of the WTR

material were prepared to different values of water content by

allowing wet material to air dry for different periods at ambient

laboratory temperature of 21C, with frequent mixing to maintain

a uniform paste. Once air-dried sufficiently, the batches were

stored in separate airtight containers for a period of at least 48 h

to achieve uniformity of water content. The test specimens were

prepared by pressing the freshly remoulded material into moulds

of the same dimensions using the kneading technique, taking

care to minimise air voids. Although the water content of most of

the triaxial specimens (w= 215285%) was below the measured

plastic limit value of 268% (Table 1), nevertheless, the material

was readily remoulded at these lower values of water content.

This behaviour will be examined later in the Discussion section

of this paper. The British standard method for determination of the

undrained shear strength in triaxial compression (BS1377-7; BSI,

1990c) specifies a rate of axial deformation to produce specimen

failure with a period of 515 min. Hence a strain rate of 2%/min

was used in these triaxial tests since peak deviatoric stress was

generally mobilised at between 20% and 30% axial strain. Further

details on strength testing of sludges and residues using these test

methods are reported by OKelly (2013a, 2013b, 2014).

Experimental results

Figure 2 shows the recorded dry masses of four WTR test specimens

plotted against the cumulative drying period. Over the course of the

oven-drying process, the chamber temperature had been maintained

for different periods at 80C, 90C, 100C, 105C and 110C, with

the temperature increasing from one step to the next. The data in

11

First measurements taken after 3 days

Specimen 1

Specimen 2

Specimen 3

Specimen 4

10

g

:

s

s

a

m

y

r

D

yutonghi.com/Concrete_Mixer_Truck

80

90

100

105

110

Set oven temperature (C)

7

10

20

Cumulative drying period: day

Figure 2. Drying of WTR material in a gravity-convection oven for

step increases in drying temperature

the figure indicate a trend of decreasing specimen dry mass with

both increasing oven temperature and drying period. According to

BS1377-2 (BSI, 1990a), after the initial 24-h drying period, all of

the test specimens would have been deemed to have achieved a dry

state. This is deemed satisfied where the difference in successive

weighing of a test specimen over a 4-h interval does not exceed

01% of its initial wet mass. It was also observed that the WTR

material had rather unusual drying behaviour in that it became

brittle and disintegrated into irregular angular fragments. OKelly

(2008b, 2014) also reported this behaviour for oven drying of the

same WTR material.

Figure 3 compares the drying response of the WTR material

in gravity-convection and forced-draft ovens at 105C for

test specimens having initial wet masses of nominally 100

Experimental data for specimens nominally 50 g in initial wet

are presented in Supplementary Figures A and B. As expected,

Figure 3(a) shows that the evaporation rate achieved using the

forced-draft oven was initially significantly greater. The rate of

mass loss over the 1- to 3-day oven-drying period was slightly

greater for the gravity-convection oven (Figure 3(b)). The latter

presumably occurred since marginal amounts of residual pore

were still present in material dried using the gravity-convection

oven on account of its slower drying rate and also because of the

colloidal nature and hence slower drying rate of the material itself.

After the initial 3-day drying period, the rates of mass loss for

the gravity-convection and forced-draft ovens were very similar.

Hence the method of air circulation (either by gravity-convection

or forced-draft) within the oven chamber appears to significantly

affect the pore-water evaporation rate only, with similar levels of

charring and oxidation occurring. However, it should be noted

that, as set out in BS1377-2 (BSI, 1990a), the specimen dry mass

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

5/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

Dryingtemperatureandwatercontentstrengthcorrelations

D O W N LO A D

Concrete Mixer Truck

YUTONG Concrete Mixer Truck.

Export To 128 Countries.Ask Now!

yutonghi.com/Concrete_Mixer_Truck

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

6/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

Dryingtemperatureandwatercontentstrengthcorrelations

D O W N LO A D

Concrete Mixer Truck

YUTONG Concrete Mixer Truck.

Export To 128 Countries.Ask Now!

yutonghi.com/Concrete_Mixer_Truck

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

7/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

Dryingtemperatureandwatercontentstrengthcorrelations

D O W N LO A D

Concrete Mixer Truck

YUTONG Concrete Mixer Truck.

Export To 128 Countries.Ask Now!

yutonghi.com/Concrete_Mixer_Truck

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

8/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

Dryingtemperatureandwatercontentstrengthcorrelations

D O W N LO A D

Concrete Mixer Truck

YUTONG Concrete Mixer Truck.

Export To 128 Countries.Ask Now!

yutonghi.com/Concrete_Mixer_Truck

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

9/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

Dryingtemperatureandwatercontentstrengthcorrelations

D O W N LO A D

Concrete Mixer Truck

YUTONG Concrete Mixer Truck.

Export To 128 Countries.Ask Now!

yutonghi.com/Concrete_Mixer_Truck

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

10/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

Dryingtemperatureandwatercontentstrengthcorrelations

D O W N LO A D

Concrete Mixer Truck

YUTONG Concrete Mixer Truck.

Export To 128 Countries.Ask Now!

yutonghi.com/Concrete_Mixer_Truck

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

11/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

Dryingtemperatureandwatercontentstrengthcorrelations

D O W N LO A D

Concrete Mixer Truck

YUTONG Concrete Mixer Truck.

Export To 128 Countries.Ask Now!

yutonghi.com/Concrete_Mixer_Truck

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

12/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

Dryingtemperatureandwatercontentstrengthcorrelations

D O W N LO A D

Concrete Mixer Truck

YUTONG Concrete Mixer Truck.

Export To 128 Countries.Ask Now!

yutonghi.com/Concrete_Mixer_Truck

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

13/14

8/27/2016

Dryingtemperatureandwatercontentstrengthcorrelations|BrendanO'KellyAcademia.edu

Dryingtemperatureandwatercontentstrengthcorrelations

Job Board

About

Press

Blog

People

Papers

Terms

D O W N LO A D

Privacy

Copyright

Concrete

Mixer Truck

We're Hiring!

Help Center

Find new research papers in: Physics Chemistry Biology Health Sciences Ecology Earth Sciences Cognitive Science Mathematics Computer Science

Academia 2016

YUTONG Concrete Mixer Truck.

Export To 128 Countries.Ask Now!

yutonghi.com/Concrete_Mixer_Truck

http://www.academia.edu/10847495/Drying_temperature_and_water_content_strength_correlations

14/14

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Linear Programming Part IIDocument1 pageLinear Programming Part IIShelly Theresse Catian NovoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Present Worth Analysis PDFDocument24 pagesPresent Worth Analysis PDFShelly Theresse Catian NovoNo ratings yet

- HazardsDocument3 pagesHazardsShelly Theresse Catian NovoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Linear Programming ProblemsDocument2 pagesLinear Programming ProblemsShelly Theresse Catian Novo100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Exam 1 SolutionDocument5 pagesExam 1 SolutionShelly Theresse Catian NovoNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Binary Distillation in A Bubble Cap Tray ColumnDocument3 pagesBinary Distillation in A Bubble Cap Tray ColumnShelly Theresse Catian NovoNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Fluid Motive DevicesDocument31 pagesFluid Motive DevicesShelly Theresse Catian NovoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Sludge-To-Cement ConversionDocument4 pagesSludge-To-Cement ConversionShelly Theresse Catian NovoNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Take Home Quiz - Higher OrderDocument1 pageTake Home Quiz - Higher OrderShelly Theresse Catian NovoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Valves Fittings Von Karman From FoustDocument9 pagesValves Fittings Von Karman From FoustShelly Theresse Catian NovoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Flow Meter Charts and Assignments On Flow Meters PDFDocument3 pagesFlow Meter Charts and Assignments On Flow Meters PDFMona BreyNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 28 Psychrometric ProcessesDocument19 pages28 Psychrometric ProcessesPRASAD326100% (7)

- Estimation of Friction Loss FROM FOUSTDocument18 pagesEstimation of Friction Loss FROM FOUSTShelly Theresse Catian NovoNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Project ProposalDocument1 pageProject ProposalShelly Theresse Catian NovoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- SocioDocument3 pagesSocioShelly Theresse Catian NovoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Project ProposalDocument1 pageProject ProposalShelly Theresse Catian NovoNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Department of The NavyDocument29 pagesDepartment of The Navymrgoniea100% (1)

- Commercial Office Space - Cyber CityDocument8 pagesCommercial Office Space - Cyber CityankurNo ratings yet

- Dennis Eagle OlympusDocument104 pagesDennis Eagle OlympusPamela CastroNo ratings yet

- Ammonia Slide Blok Diagram CV Nghjyujkm BNMC NDFHG NVBNBMGHDocument22 pagesAmmonia Slide Blok Diagram CV Nghjyujkm BNMC NDFHG NVBNBMGHR Kibik Sht100% (1)

- ISO 14001 Ver 2015Document12 pagesISO 14001 Ver 2015Resya Andita PutriNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Nuclear Waste DisposalDocument24 pagesNuclear Waste DisposalSainath ReddyNo ratings yet

- Freshkills FinalDocument13 pagesFreshkills FinalJyotee RayNo ratings yet

- Recycled Plastic Used in Concrete Paver BlockDocument3 pagesRecycled Plastic Used in Concrete Paver BlockInternational Journal of Research in Engineering and TechnologyNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Smaka Kincl 1996 Allium CepaDocument9 pagesSmaka Kincl 1996 Allium Cepalean coronelNo ratings yet

- Building Study (Evan Hospital)Document36 pagesBuilding Study (Evan Hospital)Abhishek Kadian67% (3)

- Plastic PlanetDocument3 pagesPlastic PlanetpiaNo ratings yet

- Do Not Stare at Me University of HungerDocument3 pagesDo Not Stare at Me University of HungerJosh BissoonNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Abattoir 1Document128 pagesAbattoir 1Sanjay Kumar0% (1)

- POSIVA 2003 04 - Working Report - Web PDFDocument186 pagesPOSIVA 2003 04 - Working Report - Web PDFFaqih SultonNo ratings yet

- Workplace HousekeepingDocument9 pagesWorkplace HousekeepingKeith Tanaka MagakaNo ratings yet

- Use of Industrial Wastes in The Construction of Flexible PavementsDocument6 pagesUse of Industrial Wastes in The Construction of Flexible Pavementssai venkateshNo ratings yet

- Syllabus OcDocument2 pagesSyllabus OcAlok AhujaNo ratings yet

- Water DesalinationDocument19 pagesWater Desalinationravi_patidar_6No ratings yet

- Cim Best Practice Guidelines For Mineral ProcessingDocument12 pagesCim Best Practice Guidelines For Mineral ProcessingJose ValdesNo ratings yet

- A Compendium of Concrete Aggregates Used in SW EnglandDocument136 pagesA Compendium of Concrete Aggregates Used in SW EnglandPetrolabNo ratings yet

- Technical Description: Extended MTU Lube Oil SystemDocument22 pagesTechnical Description: Extended MTU Lube Oil SystemDenNo ratings yet

- Iteh Standard Preview (Standards - Iteh.ai) : SIST-TP CEN/TR 12566-2:2005 Slovenski StandardDocument15 pagesIteh Standard Preview (Standards - Iteh.ai) : SIST-TP CEN/TR 12566-2:2005 Slovenski StandardRoberto CecchinatoNo ratings yet

- Material Safety Data Sheet Material Name: Mineral Wool InsulationDocument7 pagesMaterial Safety Data Sheet Material Name: Mineral Wool InsulationEndang Reta LazuardiNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lag Atta 1997Document9 pagesLag Atta 1997linoficNo ratings yet

- Waste ManagementDocument2 pagesWaste ManagementMohammad Nazmin Syamsul BahriNo ratings yet

- MST Act 3Document3 pagesMST Act 3Mary Joyce UngsodNo ratings yet

- Detection of Abnormal Conditions in Wastewater Treatment Plant Using Image Processing and AnalysisDocument37 pagesDetection of Abnormal Conditions in Wastewater Treatment Plant Using Image Processing and AnalysishorasiusNo ratings yet

- IPA 5 LPD Monhas-ModelDocument3 pagesIPA 5 LPD Monhas-ModelinfocvpjsNo ratings yet

- Manual Midea M-Thermal Split Outdoor UnitDocument48 pagesManual Midea M-Thermal Split Outdoor UnitpanoiuNo ratings yet

- PerugudidumpyardpaperDocument14 pagesPerugudidumpyardpaperShakthiVelNo ratings yet