Professional Documents

Culture Documents

DIN 7168 General tolerances for linear and angular dimensions

Uploaded by

AnwarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN 7168 General tolerances for linear and angular dimensions

Uploaded by

AnwarCopyright:

Available Formats

Page 2 DIN 7168

General tolerances for linear and angular dimensions

3 .1

Linear dimensions

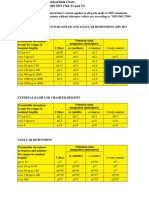

Table 1 . Permissible deviations for linear dimensions, except for external radii and chamfer heights

Permissible deviations, in mm, for nominal sizes, in mm,

Tolerance

class

from

0,5')

to

3

over

3

up to

6

over

6

up to

30

over

30

up to

120

over

120

up to

400

over

400

up to

1000

over

1000

up to

2000

over

2000

up to

4000

over

4000

up to

8000

I 0,05

over

8000

up to

12000

0,1

0,15

0 .2

0,3

0,5

0,8

over

12000

up to

16000

f (fine)

0,05

m (medium)

0,1

10,1

0,2

0,3

0,5

0,8

12

g (coarse)

0,15- 0,2

0,5

0,8

1,2

3 ~

1,5

10

12

sg (very coarse)

0,5

I .

over

16000

up to

20000

I

I

t 6

8

12

') For nominal sizes below 0,5 mm, the deviations shall be indicated adjacent to the relevant nominal size .

Table 2 . Permissible deviations for external radii, r

(cf . figure 1 for example), and chamfer heights, h

(cf . figure 2 for example)

Table 3 . Permissible deviations for angular dimensions

Permissible deviations, in mm,

for nominal sizes, in mm .

Tolerance

class

f (fine)

m (medium)

g (coarse)

sg (very coarse)

from

0,5 1 )

to

3

over

3

up to

6

over

6

up to

30

over

30

up to

120

over

120

up to

400

0,2

0,5

_2

.0,2

t4

f (fine)

Angular dimensions

General tolerances for angular dimensions apply irrespective of the actual dimensions of the lengths, i .e . the angular

deviations may occur both on workpieces with maximummaterial sizes and on workpieces with minimum-material

sizes . The upper and lower deviations do not limit the form

deviations of the legs or surfaces forming the angle .

Note . In the case of workpieces exhibiting deviations of

form, the angle is defined by the direction of the

straight lines or planes applied to the two angle legs

under the minimum material conditions (cf .

ISO 1101 for the definition of the minimum condition) .

over

10

over

10

up to

50

over over

120

50

up to up to

120

400

T 1

30'120'

g (coarse)

1 30'

50' i 25'

sg (very coarse)

= 3

m (medium)

For nominal sizes below 0 .5 mm, the deviations shall

be indicated adjacent to the relevant nominal size .

3 .2

Tolerance

class

Permissible deviations, in

units of angle, for nominal

sizes of the shorter leg, in mm,

- 1

10'

I

i

over

400

5'

I

15' 1 1 0'

30' 20'

General geometrical tolerances

4 .1 Tolerancing principle as specified in ISO 8015

General tolerances based on the tolerancing principle

specified in ISO 8015 are only to be applied when the

drawing concerned contains the reference 'Tolerancing to

ISO 8015' . Where that is the case. the general geometrical

tolerances (i .e . the tolerances of form and position) apply

independently of the actual local sizes of the workpiece

feature . Each individual tolerance requirement must be

met . The general geometrical tolerances may thus also be

applied even if the features are everywhere at their

maximum material size . For fits, the envelope requirement

must also be specified, and this shall be individually

indicated on the drawings (cf . Explanatory notes) .

4 .1 .1 General tolerances of form

4 .1 .1 .1

Straightness and flatness

The general tolerances on straightness and flatness shall

be as specified in table 4 . Tolerances on straightness shall

be selected from the table on the basis of the length of the

corresponding tine, while, for flatness tolerances, selection shall be based on the longer lateral length of the

surface, or on the diameter of the circular surface .

4 .1 .1 .2 Circularity

The general tolerance on circularity shall be equal to the

numerical value of the diameter tolerance, but in no case

shall it be greater than the respective tolerance on radial

run-out given in table 6 (cf . Explanatory notes) .

You might also like

- Us 12e pr1265 PDFDocument1 pageUs 12e pr1265 PDFAzis AbdNo ratings yet

- NutsDocument49 pagesNutsIshant JaiswalNo ratings yet

- Mechanical OPerationDocument10 pagesMechanical OPerationAnshika RajputNo ratings yet

- Wear ProtectionDocument6 pagesWear ProtectionRafael CortezNo ratings yet

- Analysis of Spiral Power SpringDocument4 pagesAnalysis of Spiral Power SpringMuhd IlhamNo ratings yet

- EU Emission Standards PDFDocument5 pagesEU Emission Standards PDFStephanie StewartNo ratings yet

- ISO 9001 Rochi Engineers profileDocument26 pagesISO 9001 Rochi Engineers profileGautamNo ratings yet

- ASTM A356 A356M - 07 Steel CastingsDocument6 pagesASTM A356 A356M - 07 Steel CastingsMacario LeyvaNo ratings yet

- Mixers and Flowakers (GB)Document24 pagesMixers and Flowakers (GB)Magin Idelfonso TorreblancaNo ratings yet

- 2405 2 PDFDocument14 pages2405 2 PDFPrasenjit DeyNo ratings yet

- Proper Bolt Tightening Force and TorqueDocument1 pageProper Bolt Tightening Force and TorqueLuisLauShNo ratings yet

- Aisi 4140Document8 pagesAisi 4140ViruzTrisnaNo ratings yet

- ChE-205 Particle Technology Screening EffectivenessDocument31 pagesChE-205 Particle Technology Screening EffectivenessInsiram NaveedNo ratings yet

- Tolerance Class Designation (Description)Document2 pagesTolerance Class Designation (Description)Cristian PopescuNo ratings yet

- Screens - TemaDocument16 pagesScreens - TemaCherezade Karine Saud SotoNo ratings yet

- Grade Chemical Composition (% by Mass - Max Unless Stated) Ferritic SteelsDocument15 pagesGrade Chemical Composition (% by Mass - Max Unless Stated) Ferritic SteelsSenthil KumarNo ratings yet

- Is 6051 1970Document15 pagesIs 6051 1970harshal161987100% (1)

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForDocument13 pagesEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method Forraulpalma93No ratings yet

- Is 8531 1986Document6 pagesIs 8531 1986Srini KumarNo ratings yet

- Basic of Forging: Types, Methods, and ProcessesDocument53 pagesBasic of Forging: Types, Methods, and ProcessesKomal TagraNo ratings yet

- Modulare Systems For Conveyor PlantsDocument36 pagesModulare Systems For Conveyor Plantsado31No ratings yet

- Chemical ChartDocument6 pagesChemical ChartAnurag SarkarNo ratings yet

- Performance Slurry PumpDocument154 pagesPerformance Slurry PumpJhonny AlvarezNo ratings yet

- H-E Parts Case Study C160 & C200 Jaw PerformanceDocument1 pageH-E Parts Case Study C160 & C200 Jaw PerformanceJorge VillalobosNo ratings yet

- General Kinematics - UncoalerDocument38 pagesGeneral Kinematics - UncoalerJogesh NarulaNo ratings yet

- HighTens EN25Document2 pagesHighTens EN25Annamali Thiayagarajan0% (1)

- Fineness Modulus of Sand - Fineness Modulus of Fine Aggregate - Fineness Modulus of Sand CalculationDocument7 pagesFineness Modulus of Sand - Fineness Modulus of Fine Aggregate - Fineness Modulus of Sand CalculationWaqas SadiqNo ratings yet

- Sand and Surki (1) (IUBAT)Document49 pagesSand and Surki (1) (IUBAT)MOIN UDDINNo ratings yet

- List - Is StandardDocument19 pagesList - Is StandardvishalNo ratings yet

- Sole PlatesDocument12 pagesSole Platesjonodo89No ratings yet

- Renold Chain CatalogueDocument24 pagesRenold Chain CatalogueThang NguyenNo ratings yet

- Spring Design 101: Ace Wire Spring & Form Co., IncDocument15 pagesSpring Design 101: Ace Wire Spring & Form Co., IncmshameliNo ratings yet

- Steel SAE O-Rings AdaptersDocument3 pagesSteel SAE O-Rings Adaptersgeav25653855No ratings yet

- How To Size A ThickenerDocument7 pagesHow To Size A ThickenerJesus Sing RoblesNo ratings yet

- E-ABRASIC P 12 To P 220: For Coated Abrasives ProductsDocument2 pagesE-ABRASIC P 12 To P 220: For Coated Abrasives ProductsBas100% (1)

- Eaton VC Clutch PDFDocument43 pagesEaton VC Clutch PDFJuan C. Gonzalez ArayaNo ratings yet

- CRS Rock Splitter PDFDocument2 pagesCRS Rock Splitter PDFHans Hans SadzNo ratings yet

- Micro-Alloyed Steels: High-Strength Steels With Yield Strengths Up To 550 MpaDocument4 pagesMicro-Alloyed Steels: High-Strength Steels With Yield Strengths Up To 550 MpacurtisvaleroNo ratings yet

- Belleville Disk Washer FormulaDocument2 pagesBelleville Disk Washer FormulajarnebergNo ratings yet

- Deepak Project On Jaw CrusherDocument96 pagesDeepak Project On Jaw CrusherAnil Kumar KnNo ratings yet

- Mechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期Document1 pageMechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期saidNo ratings yet

- HP - CONICA General-Introduction PDFDocument25 pagesHP - CONICA General-Introduction PDFluisantonio2No ratings yet

- Speed Reducer GearboxDocument14 pagesSpeed Reducer Gearboxعبد للهNo ratings yet

- Fit Selection BasicDocument1 pageFit Selection Basicapi-3848892100% (2)

- Cold Drawn Seamless Steel Tubes For Mechanical ApplicationsDocument8 pagesCold Drawn Seamless Steel Tubes For Mechanical ApplicationsAndres FlorezNo ratings yet

- E1102m PDFDocument283 pagesE1102m PDFBhawani Singh RajawatNo ratings yet

- Dynamics in Double Roll CrushersDocument7 pagesDynamics in Double Roll CrushersLê Quang Duy100% (1)

- Liner Development Process SummaryDocument3 pagesLiner Development Process SummaryJorge VillalobosNo ratings yet

- Leong Jin Product List-May 2013-Rev 10Document59 pagesLeong Jin Product List-May 2013-Rev 10EswaranNo ratings yet

- TER201 Lecture 6Document66 pagesTER201 Lecture 6lnxxNo ratings yet

- Wmd0976 Trio Tc66 Series Cone Crusher Spec SheetDocument2 pagesWmd0976 Trio Tc66 Series Cone Crusher Spec SheetYang Wan100% (1)

- QMS Jaw Crusher BrochureDocument4 pagesQMS Jaw Crusher BrochureArpit VermaNo ratings yet

- Basics RELEASE DATE: 3-12-03Document15 pagesBasics RELEASE DATE: 3-12-03Victor Ivan BarriosNo ratings yet

- PallaDocument16 pagesPallaJuan Alberto Giglio FernándezNo ratings yet

- Vibration Formula ScribDocument2 pagesVibration Formula ScribiulianstoicaNo ratings yet

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965From EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerNo ratings yet

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Permissible Deviations for Linear Dimensions TableDocument3 pagesPermissible Deviations for Linear Dimensions Tableolive_poa100% (3)

- Dried FruitsDocument11 pagesDried FruitsAnwar0% (1)

- DBMSCDocument1 pageDBMSCAnwarNo ratings yet

- ASTM Volume 02.02, September 2017 Aluminum and Magnesium AlloysDocument2 pagesASTM Volume 02.02, September 2017 Aluminum and Magnesium AlloysAnwarNo ratings yet

- AC and DC WeldingDocument18 pagesAC and DC WeldingSds Mani SNo ratings yet

- General Tolerances DIN ISO 2768Document2 pagesGeneral Tolerances DIN ISO 2768Vasil Gospodinov83% (23)

- E155-00 Aluminum & Magnesium CastingsDocument4 pagesE155-00 Aluminum & Magnesium Castingschitti409No ratings yet

- Guide to Specifying Powder Coated AluminiumDocument2 pagesGuide to Specifying Powder Coated AluminiumAnwar100% (1)

- Hot Dip Galvanizing, A Guide ToDocument14 pagesHot Dip Galvanizing, A Guide Topbharadwaj545No ratings yet

- ISO 9001 Lead Auditor TrainingDocument2 pagesISO 9001 Lead Auditor TrainingAnwarNo ratings yet

- Hot Dip Galvanized CoatingDocument28 pagesHot Dip Galvanized CoatingOci Rizal100% (6)

- Supply Chain - Logistics OfficerDocument3 pagesSupply Chain - Logistics OfficerAnwarNo ratings yet

- HAAD-Exemption Standard From ExaminationV1.2Document12 pagesHAAD-Exemption Standard From ExaminationV1.2DurgaPrasadKrishnaNo ratings yet

- Material Grade Comparison Chart PDFDocument1 pageMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

- Introduction To Iso 14001-2015Document12 pagesIntroduction To Iso 14001-2015nunukanta100% (3)

- Aalco Metals LTD Aluminium Alloy en Standards For Rolled Aluminium 51Document3 pagesAalco Metals LTD Aluminium Alloy en Standards For Rolled Aluminium 51AnwarNo ratings yet

- Specification For General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and StripDocument28 pagesSpecification For General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and StripAid Farhan Maarof100% (1)

- Audit Iso9001 2015 ChecklistDocument23 pagesAudit Iso9001 2015 ChecklistLa Metalurgica100% (5)

- ASME IX Presentation (Mode de Compatibilité)Document68 pagesASME IX Presentation (Mode de Compatibilité)AnwarNo ratings yet

- Calibration ValidationDocument12 pagesCalibration Validationdanny newmanNo ratings yet

- Mittal Steel Europe Flat Products GuideDocument24 pagesMittal Steel Europe Flat Products GuideGeorge_Wabag_2014No ratings yet

- Dasher-1 H0227-3Document101 pagesDasher-1 H0227-3Rosa María AmoneNo ratings yet

- GL Series PDFDocument2 pagesGL Series PDFcarissa putriNo ratings yet

- Principles of CalibrationDocument10 pagesPrinciples of CalibrationClark Joshua Fernandez100% (1)

- DIMENSION INSPECTION GUIDEDocument3 pagesDIMENSION INSPECTION GUIDEUmesh Sakhareliya100% (3)

- GD&T Guide: Geometric Dimensioning and Tolerancing FundamentalsDocument56 pagesGD&T Guide: Geometric Dimensioning and Tolerancing FundamentalsSyed ImranNo ratings yet

- QuickFlex Coupling CatalogDocument68 pagesQuickFlex Coupling CatalogRiaz EbrahimNo ratings yet

- On Site Buildings and Equipment 6.1. General: Bid Document Pk-4Document3 pagesOn Site Buildings and Equipment 6.1. General: Bid Document Pk-4satan007No ratings yet

- C1242Document17 pagesC1242Ana Rabiniuc100% (1)

- Adjust and correct Z and Y vibrationsDocument19 pagesAdjust and correct Z and Y vibrationsFábio HenriqueNo ratings yet

- Standard Deviation Statistics for Practical PeopleDocument4 pagesStandard Deviation Statistics for Practical PeopleRisk WisdomNo ratings yet

- Final Rear Forward Axle Housing SnorkelDocument38 pagesFinal Rear Forward Axle Housing SnorkeltarunNo ratings yet

- Hole Tolerance CalculatorDocument8 pagesHole Tolerance Calculatornick10686No ratings yet

- VW 75174 en PDFDocument59 pagesVW 75174 en PDFCindy RiveraNo ratings yet

- Proyecto Electiva PDFDocument7 pagesProyecto Electiva PDFAlf AdNo ratings yet

- Safety GratingDocument21 pagesSafety GratingAhmed IrakyNo ratings yet

- CTU Tuburan Campus Fundamentals of Electrical and Electronics Resistors ActivityDocument2 pagesCTU Tuburan Campus Fundamentals of Electrical and Electronics Resistors ActivityEngelbert RespuestoNo ratings yet

- Astm A 498 - 2004Document3 pagesAstm A 498 - 2004Teymur RegenmaisterNo ratings yet

- ~تلرانس هاي هندسي-محمد رضا عباسی 1386 PDFDocument480 pages~تلرانس هاي هندسي-محمد رضا عباسی 1386 PDFdavoodsalimiNo ratings yet

- Is 5082 1998Document11 pagesIs 5082 1998dipenkhandhediyaNo ratings yet

- Iso 8503 1 1995Document16 pagesIso 8503 1 1995Pramod WattamwarNo ratings yet

- PressFitPressureCalculator English UnitsDocument5 pagesPressFitPressureCalculator English UnitsFelipeNo ratings yet

- EN 13261-2009 EnglezaDocument57 pagesEN 13261-2009 EnglezaTanase FanelNo ratings yet

- Learning About FA Sensors and Displacement Sensors: Beginner's GuideDocument12 pagesLearning About FA Sensors and Displacement Sensors: Beginner's GuideCarlos LourençoNo ratings yet

- SAAT Module 7 Aircraft Maintenance PracticesDocument3 pagesSAAT Module 7 Aircraft Maintenance PracticesRzVaan ArfiNo ratings yet

- A10011-ASM-T61-EN-Spec-X-Serie S - DMSDocument68 pagesA10011-ASM-T61-EN-Spec-X-Serie S - DMSHigh Tech KatlaneNo ratings yet

- Standard Guide For Evaluating, Selecting and Specifying Balances and Standard Masses For Use in Soil, Rock, and Construction Materials TestingDocument5 pagesStandard Guide For Evaluating, Selecting and Specifying Balances and Standard Masses For Use in Soil, Rock, and Construction Materials TestingWillard ApengNo ratings yet

- Bentuk, Dimensi Dan Cara Pemasangan Sheet PileDocument12 pagesBentuk, Dimensi Dan Cara Pemasangan Sheet PileTeuku Rizki Muda KeulanaNo ratings yet

- A New Tolerance Analysis Method For Designers and Manufacturers - Greenwood 1987Document5 pagesA New Tolerance Analysis Method For Designers and Manufacturers - Greenwood 1987reddyNo ratings yet