Professional Documents

Culture Documents

Syme Mebasc Enme Speq 0211 b02 PDF

Uploaded by

mCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Syme Mebasc Enme Speq 0211 b02 PDF

Uploaded by

mCopyright:

Available Formats

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

:

:

Technical Specification for Liquid Burner Package

SYME-MEBASC-ENME-SPEQ-0211-B02

SHEET NO. : REV.:

1 of 9

B02

Technical Specification for Liquid Burner

Package

B02

5-Jan-2014

Issued For Comment

M.Zabihi

M.Zabihi

A.Bodaghi

B01

2-Oct-2013

Issued For Comment

M.Zabihi

M.Zabihi

A.Bodaghi

Rev.

Date

Description

Prepared

Checked

Approved

SAZ. POI :

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

IFD1

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

Technical Specification for Liquid Burner Package

SYME-MEBASC-ENME-SPEQ-0211-B02

:

:

SHEET NO. : REV.:

2 of 9

B02

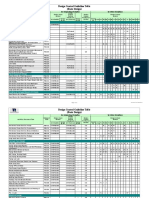

TABULATION OF REVISED PAGES

SHEET

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

REVISIONS

01 02 03 04 05 06 07

X

X

X

X

X

SHEET

REVISIONS

01 02 03 04 05 06 07

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

:

:

Technical Specification for Liquid Burner Package

SYME-MEBASC-ENME-SPEQ-0211-B02

SHEET NO. : REV.:

3 of 9

B02

Table of Contents

I.

INTRODUCTION ...................................................................................................... 4

II. Definitions ................................................................................................................. 4

III.

APPLICABLE DOCUMENTS ................................................................................. 4

IV.

CODES AND STANDARDS .................................................................................. 4

1. SITE LOCATON AND CONDITIONS ........................................................................ 5

2. SCOPE OF SUPPLY ................................................................................................ 5

3. PRIORITY OF DOCUMENTS ................................................................................... 6

4. BASIC REQUIREMENTS ......................................................................................... 6

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

GENERAL .................................................................................................................... 6

ELECTRICAL ............................................................................................................... 7

INSTRUMENTATION ................................................................................................... 7

PIPING ......................................................................................................................... 7

CIVIL ............................................................................................................................ 7

STRUCTURAL STEEL ................................................................................................. 7

EQUIPMENT ................................................................................................................ 8

PAINTING .................................................................................................................... 8

INSULATION................................................................................................................ 8

SPARE PARTS ............................................................................................................ 8

5. TESTING AND PREPARATION FOR SHIPMENT ................................................... 8

5.1

5.2

TESTING ..................................................................................................................... 8

PREPARATION FOR SHIPMENT ................................................................................ 8

6. GUARANTEE AND WARRANTY .............................................................................. 8

6.1

6.2

MECHANICAL.............................................................................................................. 8

PERFORMANCE ......................................................................................................... 9

7. TECHNICAL INFORMATION AND DATA................................................................. 9

This document is the property of OWNER. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

I.

:

:

Technical Specification for Liquid Burner Package

SYME-MEBASC-ENME-SPEQ-0211-B02

SHEET NO. : REV.:

4 of 9

B02

INTRODUCTION

South Yaran oil field is located in Kuzestan province 120KM west of Ahwaz with 20Km

length and 2.5Km width at south part of Yaran oil field.

24 No wells considered at this area consisting of 14 No Sarvak wells, 8 No Fahlian &

Gadvan wells and 2 No appraisal wells for sarvak and fahlian & Gadvan layers with total

estimated output between 50,000 to 60,000 STB/Day.

Flow of wells is transferred to the 2 phase separation unit (Cluster) for separation of gas

from liquids and dehydrating of gas.

The dehydrated gas is transferred to NGL 3200 and the liquids are transferred to Karoon

production plant for further processing.

II.

B02

Definitions

OWNER

CLIENT

CONSULTING ENGINEER

PROJECT

LOCATION

APPROVED

: NIOC

: Petroleum Engineering and development Co. (PEDEC)

: Sazeh Consultants

: South Yaran Petroleum Filed Development (Basic

Engineering)

: Khuzestan Province-120Km west of AHWAZ

: Approved by Client

III. APPLICABLE DOCUMENTS

LIQUID BURNER PACKAGE (PK-101) shall be designed in accordance with ANSI/API

STD 537 Flare Details for General Refinery and Petrochemical Service.

IV. CODES AND STANDARDS

The applicable provisions of the latest editions of the following codes, standards and

specifications that are in effect at the date of the Contract together with codes and

standards referred to in ANSI/API STD 537, Second edition, December 2008 Flare Details

for General Refinery and Petrochemical Service shall form part of this specification to the

extent specified herein.

AMERICAN PETROLEUM INSTITUTE (API)

API STD 537,

"Flare Details for General Refinery and Petrochemical Service"

API RP 520,

"Sizing, Selection and Installation of Pressure-relieving Devices

in Refineries"

API STD 521,

Part 1 "Sizing and Selection"

Part 2 "Installation"

"Guide for Pressure-relieving and De-pressuring Systems"

IRANIAN PETROLEUM STANDARDS (IPS)

IPS-E-PR-460,

"Engineering Standard For Process Design Of Flare And Blow

down Systems"

IPS-E-SF-860,

"Engineering Standard for Air Pollution Control"

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

:

:

Technical Specification for Liquid Burner Package

SYME-MEBASC-ENME-SPEQ-0211-B02

SHEET NO. : REV.:

5 of 9

B02

IPS-G-SF-860,

"General Standard for Air Pollution Control"

IPS-E-GN-100,

"Engineering Standards for Units"

ASME (AMERICAN SOCIETY OF MECHANICAL ENGINEERS)

B02

B31.3

"Process Piping"

B16.5

"Pipe Flanges and Flanged Fittings"

PROJECT SPECIFICATIONS

Following referenced specifications shall be considered as part of this specification.

SYME-PRBASC-ENPS-BSDE-9005

South Yaran Process Design Basis

SYME-MEBASC-ENME-SPEQ-0210

Technical Specification for Flare Stacks and

Flare Ignition Panel

SYME-PRBASC-ENPS-DIPF-0001

Legend And

Diagram

SYME-INBASC-ENIN-SPDE-0001

Specification For General Instrumentation

SYME-INBASC-ENIN-SPDE-0004

Specification For Instrument And Control Of

Package Unit System (PU)

SYME-ELBASC-ENEL-LILS-0001

Electrical Legend And Symbols

SYME-ELBASC-ENEL-CIDE-0001

Electrical Design Criteria

SYME-INBASC-ENIN-DWIC-0001

Instrument Installation Drawing

Symbols

Process

Flow

SYME-PIBASC-ENPI-CIDE-0001

Piping Design Criteria

B02

SYCV-CVBASC-ENCV-DCDS-0001

Civil Design Criteria

B02

SYCV-STBASC-ENSO-CIDE-0001

Job Specification for Structural design

criteria

B02

SYME-PIBASC-ENPI-SPPA-0001

Painting Specification

SYME-PIBASC-ENPI-SPDE-0001

Insulation Specification

1. SITE LOCATON AND CONDITIONS

For site location and conditions reference shall be made to SOUTH YARAN

PROCESS DESIGN BASIS Doc no.SYME-PRBASC-ENPS-BSDE-9005.

2. SCOPE OF SUPPLY

Vendor shall supply the followings:

a) Flame front generator and pilot monitoring panel

b) Self-supporting weatherproof enclosure for the panel complete with

necessary anchor bolts, nuts and washers.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

:

:

Technical Specification for Liquid Burner Package

SYME-MEBASC-ENME-SPEQ-0211-B02

SHEET NO. : REV.:

6 of 9

B02

c) Complete piping within package limit

d) Complete wiring within package limit

e) Complete instrumentation as specified in this specification and relevant

data sheets

f) Nameplate

g) Special tools required for maintenance

h) Documentation as called for in section 5 of this specification

i) Commissioning spare parts. As a minimum 10% of bolts and nuts for piping

flanges, 100% of gaskets, and one set of strainer screens.

j) List of recommended spare parts for two years of operation, price details

included.

3. PRIORITY OF DOCUMENTS

B02

The order of priority of documents is the following:

1) Purchase Order

2) Material Requisition

3) This Technical Specification

4) Data Sheet

4) Other job specifications

5) International Codes and Standards

If any difference and/or conflicts between the documents listed should occur, the most

stringent requirements shall govern. Any ambiguity or conflict shall be referred to the

Purchaser and Approved solution shall be applied.

4. BASIC REQUIREMENTS

4.1

GENERAL

4.1.1

Flame front generator shall be designed for safe and instance performance under any

condition and positive pilot ignition under adverse weather conditions.

4.1.2

Vendor shall specify, the maximum allowable distance between ignition panel and pilot

burners, and utility requirements (such as fuel gas, compressed air flow rates, and

power consumption) for ignitor package.

4.1.3

The package shall be completely shop assembled and ready for operation when

connected to Purchasers external piping and wiring gland / conduit.

4.1.4

Ignition and control panel with all associated piping, valves, instrumentation and

electrical system shall be enclosed within a self-supporting enclosure. The enclosure

shall be explosion proof housing in accordance with IP 54.

4.1.5

Numbers of pilot burners to be ignited and available utilities are specified on data sheets

& DESIGN BASIS.

4.1.6

Ignitor package shall be suitable for outdoor installation and exposed to direct sun

radiation (82 Deg. C) without loss of performance. Provision shall be made to protect the

equipment within package limits against overheating.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

:

:

Technical Specification for Liquid Burner Package

SYME-MEBASC-ENME-SPEQ-0211-B02

SHEET NO. : REV.:

7 of 9

B02

4.1.7

When compressed air is not available, self-inspiriting ignition system shall be furnished,

utilizing fuel gas to inspirited air in to a venture mixer on the ignition line.

4.1.8

The plant life time of a minimum of 30 years shall be considered by vendor.

B02

4.2

ELECTRICAL

4.2.1

External electrical connection will be by cables terminated to Vendor supplied Junction

box. The junction box shall be fitted with metric glands, suitable for accommodating

cable up to 4C-50 sq.mm, PVC/IC/SWA/PVC.

4.2.2

Purchaser will provide a 400 V, 3 Phase, 50 Hz, feeder at the delivery limits of packaged

unit. Vendors supply shall include 110 VAC and 24 VDC supply through suitable

transformer and 1 + 1 (redundant) rectifier unit with all necessary protections and

distribution for the packaged unit consumers. All components and execution indicated

above shall be performed and furnished by vendor.

4.2.3

Power supply of packaged panel instruments and solenoid valve shall be 110 VAC, 50

Hz.

4.3

INSTRUMENTATION

4.3.1

Instrument materials shall meet the requirements of the project specifications.

4.3.2

The ignition and control panel shall be equipped with temperature indicators to

continuously check the pilot state. Vendor shall provide pilot failure switch for the event

of failure of one or more pilots.

4.3.3

Provision for pilot failure display in the process control room shall be made by

providing normally closed dry contacts on the ignition and control panel, which can be

powered by 24 volts DC from Purchaser`s relay panel located in the control room.

4.3.4

All instruments within package limits shall be pre-wired, pre-assembled, and terminated

to suitable terminal strips for connection to incoming extension wires.

4.3.5

Individual pressure indicators shall be provided for compressed air and fuel gas feed

lines within package limits.

B02

4.4

PIPING

All piping required for the interconnections between the supplied equipment and the

package boundary line shall be supplied by vendor. Where preassembling is not

practicable prefabricated piping will be supplied as loose items.

B02

4.5

CIVIL

Civil materials shall meet the requirements of the project specifications.

B02

4.6

STRUCTURAL STEEL

In order to allow a complete installation and safe access to all supplied equipment,

valves and instrumentation, the supply shall include:

Piping and insulation supports

Canopy for ignition panel

In addition the supply shall include: Anchor bolts, templates, nuts, gaskets, etc.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

B02

4.7

:

:

Technical Specification for Liquid Burner Package

SYME-MEBASC-ENME-SPEQ-0211-B02

SHEET NO. : REV.:

8 of 9

B02

EQUIPMENT

Equipment materials shall meet the requirements of the project specifications and the

equipment data sheets.

B02

4.8

PAINTING

Painting including finish coat shall be in accordance with project specification SYMEPIBASC-ENPI-SPPA-0001. Vendor shall get purchasers approval for final coating

color before painting.

B02

4.9

B02

INSULATION

Insulation at shop for all skid mounted equipment, where required (if any) supply of all

material necessary for insulation for interconnecting piping (if any)

4.10

SPARE PARTS

4.10.1 Spare parts for erection, pre-commissioning, commissioning, and start up shall be

shall be recommended by vendor.

4.10.2 Vendor shall submit 2 years spare parts list with unit price during bid stage and this price

shall be valid for 6 months after purchases order.

4.10.3 Two years operational spare parts shall be ordered together with main equipment /

package.

5. TESTING AND PREPARATION FOR SHIPMENT

5.1

TESTING

Piping within package limit shall be hydrostatically tested according to ASME B 31.3

standard.

5.2

PREPARATION FOR SHIPMENT

5.2.1

The equipment shall be given a coat of the manufacturers standard paint. Exterior

machined surfaces shall be coated with a suitable rust preventive compound.

5.2.2

Flanged openings shall be provided with metal closures, rubber gaskets and four fulldiameter bolts. Threaded openings shall be provided with steel caps.

5.2.3

The equipment shall be suitably packed for overland and sea transportation and 18

months storage at site conditions. Instruments and other delicate items shall be specially

packed to ensure additional protection during transportation.

6. GUARANTEE AND WARRANTY

6.1

MECHANICAL

Supplied ignitor package shall be warranted by vendor against defective materials,

design, and workmanship for 12 months after commissioning or 18 months after

shipment.

PROJECT:

SOUTH YARAN OIL FIELD

DEVELOPMENT PROJECT

DOCUMENT TITLE

DOCUMENT NO

6.2

:

:

Technical Specification for Liquid Burner Package

SYME-MEBASC-ENME-SPEQ-0211-B02

SHEET NO. : REV.:

9 of 9

B02

PERFORMANCE

Supplied ignitor packaged shall be guaranteed for satisfactory performance under

operating conditions specified on data sheet and DESIGN BASIS.

7. TECHNICAL INFORMATION AND DATA

Detailed drawings, catalogues, manuals, certificates, etc., required from Vendor are

indicated on Vendors Drawing and Data Commitment Form.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Refrence DWG.: Yaran Oil Field Development ProjectDocument4 pagesRefrence DWG.: Yaran Oil Field Development Projectm100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- As 2601-2001 The Demolition of StructuresDocument7 pagesAs 2601-2001 The Demolition of StructuresSAI Global - APAC0% (5)

- Woodward Easygen Configuration Manual PDFDocument201 pagesWoodward Easygen Configuration Manual PDFTayyeb HassanNo ratings yet

- Goods Lifts: 300 - 2000kg CapacityDocument14 pagesGoods Lifts: 300 - 2000kg CapacityAnton LyakhovNo ratings yet

- PCD ED 451 Attachment 02Document13 pagesPCD ED 451 Attachment 02mNo ratings yet

- Wire Ropes - Bridon Rope - BAC - TechnicalDocument25 pagesWire Ropes - Bridon Rope - BAC - TechnicalJose BijoyNo ratings yet

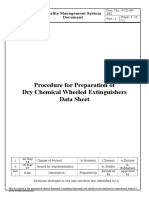

- Procedure For Preparation of Dry Chemical Wheeled Extinguishers Data SheetDocument5 pagesProcedure For Preparation of Dry Chemical Wheeled Extinguishers Data SheetmNo ratings yet

- LogicSynthesis SynopsysDocument41 pagesLogicSynthesis Synopsyslavanya rNo ratings yet

- PCD SF 191Document7 pagesPCD SF 191mNo ratings yet

- Astm A 694Document4 pagesAstm A 694Alexander MonroyNo ratings yet

- XCAL LTE Qualcomm Features v3.2 (Rev.3)Document38 pagesXCAL LTE Qualcomm Features v3.2 (Rev.3)esakNo ratings yet

- Syme Hvbasc Enhv Bsde 0001 B02Document16 pagesSyme Hvbasc Enhv Bsde 0001 B02mNo ratings yet

- Procedure For Preparation of Water/Foam Monitor Data Sheet: Quality Management System DocumentDocument7 pagesProcedure For Preparation of Water/Foam Monitor Data Sheet: Quality Management System DocumentmNo ratings yet

- PCD-SF-187-Attachment#1 Water Hose Reel Data SheetDocument4 pagesPCD-SF-187-Attachment#1 Water Hose Reel Data SheetmNo ratings yet

- Data Sheet For Dry Chemical Portable Pportable Extinguisher: ProjectDocument3 pagesData Sheet For Dry Chemical Portable Pportable Extinguisher: ProjectmNo ratings yet

- Procedure For Preparation of Water Hose Reel Data Sheet: Quality Management System DocumentDocument6 pagesProcedure For Preparation of Water Hose Reel Data Sheet: Quality Management System DocumentmNo ratings yet

- Procedure For Application of Foam Protection System: Quality Management System DocumentDocument9 pagesProcedure For Application of Foam Protection System: Quality Management System DocumentmNo ratings yet

- Procedure For Fire Water Max. Demand Calculation: Quality Management System DocumentDocument4 pagesProcedure For Fire Water Max. Demand Calculation: Quality Management System DocumentmNo ratings yet

- Syme Mebasc Enme Speq 0210 b03 PDFDocument12 pagesSyme Mebasc Enme Speq 0210 b03 PDFmNo ratings yet

- Syme Elbasc Enel Lilc 0002 b02Document6 pagesSyme Elbasc Enel Lilc 0002 b02m100% (1)

- Electrical Load List: Project: South Yaran Oil Field Development ProjectDocument8 pagesElectrical Load List: Project: South Yaran Oil Field Development ProjectmNo ratings yet

- Design Input Control Checklist: 1) Complete 2) Incomplete But Sufficient To Start 3) InsufficientDocument3 pagesDesign Input Control Checklist: 1) Complete 2) Incomplete But Sufficient To Start 3) InsufficientmNo ratings yet

- Syme Elbasc Enel Rqma 0001 b02Document16 pagesSyme Elbasc Enel Rqma 0001 b02m100% (1)

- PCD ED 451 Attachment 11Document2 pagesPCD ED 451 Attachment 11mNo ratings yet

- North Yaran Oil Field Development ClusterDocument4 pagesNorth Yaran Oil Field Development ClustermNo ratings yet

- .:f:.t:::l:. L::. (I.::,.i. .Document12 pages.:f:.t:::l:. L::. (I.::,.i. .mNo ratings yet

- Vendor Progress Report-01Document2 pagesVendor Progress Report-01mNo ratings yet

- Procedimento de Instalação de Rede Ethernet - FanucDocument33 pagesProcedimento de Instalação de Rede Ethernet - FanuctiagouebemoraisNo ratings yet

- Protocolo CD-2Document36 pagesProtocolo CD-2rccngsNo ratings yet

- Oil and Gas Industry Article On FrackingDocument2 pagesOil and Gas Industry Article On FrackingChad WhiteheadNo ratings yet

- KRBS Dtailed Index - Volume 1 To 4Document19 pagesKRBS Dtailed Index - Volume 1 To 4kushaljp8989No ratings yet

- Newtxdoc Font PackageDocument14 pagesNewtxdoc Font PackageGerardo MartinNo ratings yet

- Pan Os 7.0.3 RN - 2Document62 pagesPan Os 7.0.3 RN - 2Asus HaelNo ratings yet

- BR CB956Document29 pagesBR CB956David Eduardo Drew PerezNo ratings yet

- Ledwiz InstallDocument2 pagesLedwiz InstallProspero Araya FuentesNo ratings yet

- 511 Pressure TransmitterDocument5 pages511 Pressure TransmitterDhp CiaNo ratings yet

- Mil PRF 24139a PDFDocument13 pagesMil PRF 24139a PDFmagdita martinezNo ratings yet

- Foa 7Document1 pageFoa 7Ahmed Abo RashedNo ratings yet

- Furse Lightning Strike Counters: Features & BenefitsDocument2 pagesFurse Lightning Strike Counters: Features & BenefitsLương Quốc ThanhNo ratings yet

- C++ Programming: From Problem Analysis To Program Design: Chapter 3: Input/OutputDocument50 pagesC++ Programming: From Problem Analysis To Program Design: Chapter 3: Input/OutputAlmira SolimanNo ratings yet

- HP HP0-A01: Practice Exam: Question No: 1Document61 pagesHP HP0-A01: Practice Exam: Question No: 1Cassandra HernandezNo ratings yet

- Honeywell Sensing Smart Position Sensor Rotary Product Sheet 005948 2 enDocument6 pagesHoneywell Sensing Smart Position Sensor Rotary Product Sheet 005948 2 enRasigan KannanNo ratings yet

- Iso 7 1 Pipe ThreadsDocument11 pagesIso 7 1 Pipe ThreadsSintha AidroosNo ratings yet

- Professional Workshop Information SystemDocument6 pagesProfessional Workshop Information Systemsandro ronaldNo ratings yet

- Introduction To Computer GraphicsDocument21 pagesIntroduction To Computer Graphicssubhranildasgupta_onlineNo ratings yet

- Om MP AddsDocument78 pagesOm MP AddsIon Cezar CristianNo ratings yet

- Radiographic Examination of Weldments: Standard Test Method ForDocument5 pagesRadiographic Examination of Weldments: Standard Test Method ForphanthanhhungNo ratings yet

- Seeb Vocational College Diploma CourceDocument2 pagesSeeb Vocational College Diploma CourceSiva Agora KarthikeyanNo ratings yet

- Compact Max Lis ProtocolDocument50 pagesCompact Max Lis ProtocolRonan ColobongNo ratings yet

- Library ManagementDocument36 pagesLibrary Managementkarthik gunjaNo ratings yet