Professional Documents

Culture Documents

Manual For HA31-80

Uploaded by

rpshvjuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual For HA31-80

Uploaded by

rpshvjuCopyright:

Available Formats

1 HDU 05003-YN Rev.

Manual Operating Mechanism

Type HA31-80

Instruction Manual

1 HDU 05003-YN Rev. C

2/12

For High-Voltage Disconnectors and

Earthing Switches

for Outdoor Installation

Table of Contents

Sr. Description

No.

Page

No.

General Remarks

Design

Optional Extras

Method of Operation

Technical Data

Transportation and Storage

Installation

Commissioning

Maintenance

10

Spare Parts

11

List of Components

1 HDU 05003-YN Rev. C

3/12

General remarks

Practical experience has shown that strict adherence to the recommendation of this instruction manual

will ensure the best possible safe performance of the equipment.

In an instruction manual it is not possible to cover every possible eventuality that might occur when using

technical apparatus. It is, therefore, requested that all incidences, in particular, those for which the

instruction manual provides no plausible explanation, be reported to us directly or through our local

representatives.

These instructions are based on the present technical design. We reserve the right to make any technical

changes without prior notice.

We cannot accept any responsibility for damage resulting directly from incorrect handling or operation

irrespective of whether specific reference is to be found in the instructions for erection and operation or

not.

With respect to this document we reserve all rights also in the event of a patent being issued and

registration being made under other commercial rights. Misuse, in particular copying and handling over to

third parties is prohibited and offenders can be prosecuted under civil and criminal law.

2.

Design

Manual Operating mechanism type HA31-80 are designed for outdoor installation and used for operation

of high-voltage disconnectors and earth switches.

All components of the operating mechanism are installed in a polyurethane painted aluminium housing

(12) with a door (12a) at the front.

The Control components are attached to a mounting plate (4) and wired to the Terminal Strip (5).The

length of the Terminal strip support is designed to accommodate the Maximum equipment configuration. A

clearance of about 10 cm is provided for connecting the control cables to the Terminal Strip.

The Basic Version includes the following:

-

An Auxiliary Switch with 4NO + 4NC contacts, Switching capacity of each contact is 2A at 220V DC, at

T=20 ms.

An Anti-condensation Heater with Switch.

All internal Wiring connections are done using 1.5 sqmm Flexible wires. Gray wires are used for DC

Circuit, Black Wires are used for AC circuit, and Green wire for Earthing Circuit.

All Auxiliary switch contacts are wired upto Terminals. The door and the housing are connected with Cable

(26) to earth connection and Angle for Earthing.

The Incoming and outgoing cables are passed from through a removable Gland Plate (9). An Angle for

Earthing (23) with 13 mm dia. Holes are provided for earthing. Cable Glands are not included in the

standard scope of delivery and must be provided by the customer.

2.1

Blocking magnet

Optionally a Blocking Magnet (19) can be installed. The blocking magnet de-energised prevents the

operating mechanism from being operated.

3.

Optional Extras (depending on the Customers order)

3.1

Blocking Magnet (19) for preventing mal-operation during manual emergency operation.

1 HDU 05003-YN Rev. C

4/12

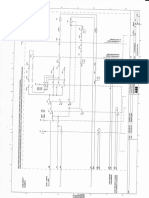

Fig. 1 Manual operating mechanism type HA31-80

54

56

19

13

4

51

52

3

12

12a

11

5

21

26

9

16

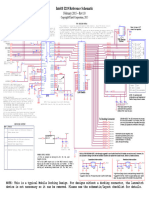

Fig. 2 Manual operating mechanism type HA31-80 inside view

(additionally with wiring of auxiliary switches to the terminal strip,

blocking magnet and automatic equipments)

23

1 HDU 05003-YN Rev. C

5/12

Caution :

Ensure auxiliary switch elements positions are not

be altered if removed for any maintenance. When

they are to be replaced, ensure that any two

elements of the same colour are not placed next to

each other. It is necessary to place elements of blue

and black colours alternatively. The same has been

shown in the figure.

Blue Blue

Wrong

Black Black

Wrong

Blue Black

Right

3.2

Adjustable thermostat for Heater (11).

3.3

Additional Auxiliary switch Contacts upto Max. 24 Contacts in Any combination can be provided. Please

refer to Schematic drawing submitted against order for details.

4.

Method of Operation

The manual operating mechanism is actuated by an operating lever (53), which can be blocked in both end

positions by a padlock as shown in Figure 1 ( to put a padlock, bolt shown in figure to be removed and

same hole can be used for padlocking)

The switching angle of the operating mechanism is 190. Pilot switches (3) are actuated by the control disc

(13) fitted to the operating shaft (10). The position signal meets the requirement of IEC Publication

IEC-62271-102, third edition and VDE standard 0670, Part 2.

The Optional blocking magnet (19) when de-energised prevents the manual operating mechanism from

being operated. In this case the manual lever (53) is not allowed to rotate.

Unauthorised opening of the door (12a) can be prevented by padlock on the door.

5.

Technical data

5.1

Technical data of manual operating mechanisms

-

Rated torque on the operating shaft

500 Nm

Length of operating handle

1000 mm

Switching angle of the hand lever

1900

Heating capacity

approx. 25W

Heating voltage

110/125/230 VAC

Degree of protection against contact with live or moving part, ingress of foreign

bodies and water

IP 54

Cross-section of internal wiring

1.5 mm

Max. cross-section of supply leads solid

4 mm

Stranded (with end sleeve)

2.5 mm2

Weight

20 kg approx.

1 HDU 05003-YN Rev. C

6/12

9.50...17.50

9.5 ...17.5

NC contact

NO contact

00

Off

1900

On

Main contact of

disconnector

Fig. 4 Auxiliary switch, functional diagram

5.2

Technical data of the blocking magnets

Operating Voltage

48, 110, 125, 220 or 250V DC

Admissible deviation from the operating voltage

+ 10 % / -15 %

Rated power consumption of blocking magnet coil

approx. 6 W

Duration factor

100 %

Note : Due to continuous efforts to improve our products, the details given in this publication may be

changed without notice.

5.3

Technical data of the auxiliary switches

-

Switching capacity of each contact = 2A at 220 VDC, T = 20 ms

Current carrying capacity = 10 A

Transportation and storage

Each operating mechanism is specially packed before shipment.

As soon as the equipment arrives at destination, an inspection for damage in transit should be carried out

to find out the extent of damage, the cause of damage and if necessary, its originator. The damage report,

if any, should immediatelly be sent to the appropriate forwarding agency to be passed on to the

transportation insurance company.

The operating mechanism should be stored indoors. To maintain corrosion protection provided by the

special packing as long as possible the operating mechanism should be left in this packing until

installation is started.

In dry climate the duration for transportation and storage of the operating mechanisms must not exceed 6

months without heating. For longer times of storage or if there is danger of moisture condensation, the

heater has to be connected unless precautions was taken by appropriate packing or storage to prevent

moisture condensation.

7.

Installation

Every operating mechanism should be mounted in accordance with the mounting instructions for the unit

for which it is intended and relevant order bound drawings.

For direct attachment of the operating mechanisms to disconnectors or earthing switches designed for

wall mounting, special instructions, if supplied along with the unit, have to be observed. If the customer

decides at a later date to mount the equipments in this way, he should contact our sales department for

these instructions.

The interior parts of the operating mechanisms (e.g. auxiliary switches, blocking magnet, etc.) are not

resistant to the atmospheric conditions prevailing outdoors; therefore, care must be taken to ensure that

parts are not exposed to humidity during installation.

To avoid condensation, it is absolutely necessary to connect the heater (11). After installation the heater is

to be commissioned immediately even if the associated disconnectors and earthing switches have not yet

been commissioned.

1 HDU 05003-YN Rev. C

8.

7/12

Commissioning

Check the disconnectors or earthing switches for proper engagement according to the corresponding

service instructions.

Also check the auxiliary switch(es), (3) for proper contact make in the two end positions. Adjustments of

the auxiliary switches are to be made by specialised personnel only.

check blocking magnet (19) to make sure that its locking pin properly locks the click-stop pin (56), which

engages into the interlocking disc (54) when the magnet de-energised, and prevents rotation of the

manual operating lever (53). Check for correct functioning of the interlocking switch (51), i.e. the circuit

must be interrupted when the blocking magnet is de-energised.

Make sure that ventilating holes within the filter mesh (16) provided on supply lead plate are not plugged. If

the units are painted, keep the ventilating hole with filter, fee from paint.

Maintenance

The manual operating mechanism hardly needs any maintenance.

It is recommended to have an inspection carried out together with the inspection of the corresponding

disconnector or earthing switch after the first 5 years of operation, at the latest, however, after 1,000

make and break operations. The inspection intervals mentioned above apply to normal ambient

conditions. For extraordinary conditions (e.g. use in tropical climate or at excessively low temperatures or

heavy pollution) these intervals should be reduced by 50%.

The following details should be observed during inspection or random test :

a)

Stop electrical supply to disconnector and earthing switch. Care should be taken that heating circuit

and control voltage of the blocking magnet are disconnected.

b)

Observe IEC and national safety regulations.

c)

Carry out several test operations by hand.

d)

Check heating resistor (11) and thermostat (22) for proper functioning.

e)

Check auxiliary switch(es) (3) for proper contact make in both switching positions. Adjustments of

the auxiliary switch, if required, should only be made by specialists.

f)

Check proper functioning of blocking magnet (19) and interlock switch (51). For details see section 8.

g)

Check whether the control and signalling cable are properly fitted to all terminals.

h)

Check whether the movement is properly transmitted from the operating shaft (10) to auxiliary

switch (3) via control disc (13). If necessary, clean and grease the guides and running surfaces.

i)

Check for inadmissible ingress of foreign bodies and moisture.

k)

Clean filter insert of cable gland (16) in supply lead plate (9).

l)

Check gasket (21) of the door (12a) and replace, if necessary.

m)

After inspection, reconnect the heating circuit and the blocking magnet to the power supply.

Caution :-

Ensure that auxiliary switch elements position or orientation is not altered if it is removed for any

maintenance work. This is because it has built-in blow out magnet.

Ensure blocking magnet (if provided) is in disengaged position.

Cleaning of any plastic parts must be done with dry cloth only.

1 HDU 05003-YN Rev. C

10

8/12

Spare parts

It is recommended to keep the following parts in stock so that, in case of disturbances, prolonged, periods

of interruption are avoided by rapidly replacing the individual parts. When ordering spare parts, indicate

the following details :

a)

Type and serial number according to the rating plate of the specific unit.

b)

Designation of spare part, item no. and order no. in accordance with this instructions.

c)

Control, heating and blocking magnet voltage.

Designation

Identification Item

Fig. Quantity

letter

Sr. No.

per

operating

mechanism

Miniature circuit breaker

for heating

3 A AC

Auxiliary switch elements

with roller

Blue

Black

Auxiliary switch elements

without roller (required for

double decker switch)

Blue

Black

Blocking magnet

52

1HYN450102P20

As per specific

Scheme and

order

1HYN450103R2

1HYN450103R3

Y1

19

1HYN350027P20

1HYN350027P15

1HYN350027P13

1HYN450039P11

1HYN450039P18

Anticondensation heater

R1

11

MT430162P20

Thermostat

23T

11

1HYN450182P1

1 Piece.

1HYN450193P1

Door Sealing Gasket

48 V DC

110 V DC

125 V DC

220 V DC

250 V DC

90

Order No.

21

aprox. 2 m

Sealing Ring

1HYN450038P1

Molycote Longterm 2 Plus

1 can 250 gm

GON598000P521

Dowty Seal

1HYN450042P111

Retaing ring

1HYN450107P1

Cylindrical Pin f

12

1HYN450095P1

1 HDU 05003-YN Rev. C

11

List of Components

Item no.

3

4

5

9

10

11

12

13

16

19

21

23

24

26

37

42

43

47

51

52

53

54

55

56

Designation

Auxiliary switch

Mounting plate

Terminal strip

Supply lead plate (with earthing connection angle 23 and ventilating hole 16)

Operating shaft

Anticondensation heater

Housing (with door 12a)

Control disc

Filter mesh for ventilation

Blocking magnet

Door sealing gasket

Earthing connection angle

Mounting holes of operating mechanism (thread M16)

Flexible earthing connection

Rectifier

Compartment for instructions and wiring diagrams

Rating plate

Hole for fixing padlock

Inter-lock switch at blocking magnet 19

Miniature circuit breaker

Manual operating lever

Inter-locking disk

End position locking plate

Click-stop pin

Fig.

2

2

2

2

1

2

1,2

2

2

2

2

2

2

2

2

1

2

1

2

Typical Schematic Diagram

48 / 110 / 125 / 220 / 250 VDC

12

9/12

Typical schematic diagram of HA31-80 drive with Heater, 4NO+4NC Aux. Switch and optional Blocking Magnet coil.

1 HDU 05003-YN Rev. C

Note :

10/12

1 HDU 05003-YN Rev. C 2008-03

"ABB is woking continuously to improve the products.

We therefore reserve the right to change designs, dimensions data without prior notice."

ABB Limited

Business Area : Disconnectors

Maneja, Vadodara 390 013 India

India

Tel. : +91-265-2604080

+91-265-2604082/2604261

Fax : +91-265-2638927

www.abb.co.in

You might also like

- Motor Ope. Mech. Type MT 50-100-17!03!08Document16 pagesMotor Ope. Mech. Type MT 50-100-17!03!08rpshvjuNo ratings yet

- NARI - PCS-9611 - X - Instruction Manual - EN - Overseas General PDFDocument290 pagesNARI - PCS-9611 - X - Instruction Manual - EN - Overseas General PDFKAREEM OLAWALE0% (1)

- PCS-9611 - X - Instruction Manual - EN - Overseas General - X - R2.10 - (EN - DYBH5321.0086.0003) PDFDocument300 pagesPCS-9611 - X - Instruction Manual - EN - Overseas General - X - R2.10 - (EN - DYBH5321.0086.0003) PDFRobert MihayoNo ratings yet

- Test Guide Current Line Diff Nari Pcs-931Document9 pagesTest Guide Current Line Diff Nari Pcs-931JNo ratings yet

- PCS-9611 - X - Instruction Manual - EN - Overseas General - X - R3.01 PDFDocument316 pagesPCS-9611 - X - Instruction Manual - EN - Overseas General - X - R3.01 PDFjayofo8363No ratings yet

- Ltbe1 With Blk222Document12 pagesLtbe1 With Blk222rpshvjuNo ratings yet

- 6MB5515 Catalogue SheetDocument16 pages6MB5515 Catalogue SheetSalvador Fayssal100% (2)

- Département Télécommunications - Document Technique: Alspa PLC 1790/B Technical Manual InstallationDocument26 pagesDépartement Télécommunications - Document Technique: Alspa PLC 1790/B Technical Manual Installationjrsk638742No ratings yet

- 220kv Phu Tho v6Document712 pages220kv Phu Tho v6Thanh Tâm100% (1)

- PCS-985GE - X - Instruction Manual - EN - Overseas General - X - R1.02 PDFDocument464 pagesPCS-985GE - X - Instruction Manual - EN - Overseas General - X - R1.02 PDFarulsethuNo ratings yet

- PCS 9705Document3 pagesPCS 9705elkhalfi50% (2)

- MVTP R6023iDocument8 pagesMVTP R6023idik_pngNo ratings yet

- Flyer - PCS-9691E Overcurrent RelayDocument2 pagesFlyer - PCS-9691E Overcurrent RelayRendieRamadhan100% (2)

- Instruction Manual - SGF36 To 362kVDocument116 pagesInstruction Manual - SGF36 To 362kVrpshvjuNo ratings yet

- Technical Specification for 17.5kV Metal-Clad SwitchgearDocument5 pagesTechnical Specification for 17.5kV Metal-Clad Switchgeardaniel.cabasa2577No ratings yet

- 1) 145kV Disconnecting Switch (DS) and Earthing Switch (ES)Document17 pages1) 145kV Disconnecting Switch (DS) and Earthing Switch (ES)Alaa ZoraNo ratings yet

- Design Brief For 300kV CT & VTDocument43 pagesDesign Brief For 300kV CT & VTSantoshNo ratings yet

- GE document operating mechanism diagramDocument12 pagesGE document operating mechanism diagramtuantz206No ratings yet

- NARI PCS 9611 X Instruction Manual EN Overseas General PDFDocument290 pagesNARI PCS 9611 X Instruction Manual EN Overseas General PDFKhoirin NidaNo ratings yet

- Regulador de Voltage KVGC 202Document168 pagesRegulador de Voltage KVGC 202mimiii36No ratings yet

- 220kV Sicam Panel 2 (BOP) PDFDocument23 pages220kV Sicam Panel 2 (BOP) PDFAnonymous SWz3bgcUNo ratings yet

- PCS-902S - X - DataSheet - EN - Overseas General - X - R1.00Document52 pagesPCS-902S - X - DataSheet - EN - Overseas General - X - R1.00Marcio BonfimNo ratings yet

- Synchroteq® Plus: Installation and WiringDocument38 pagesSynchroteq® Plus: Installation and WiringCô Nàng Song TửNo ratings yet

- Config Upload and Download PCS-ExplorerDocument10 pagesConfig Upload and Download PCS-ExplorerBarry79x100% (1)

- Jin Kwang-Recloser-Mold Recloser (With R200C) Catalouge PDFDocument15 pagesJin Kwang-Recloser-Mold Recloser (With R200C) Catalouge PDFMd. zahidul IslamNo ratings yet

- PCS-9611 Feeder Relay V1.01 PDFDocument46 pagesPCS-9611 Feeder Relay V1.01 PDFMuhammad Burhanuddin Fadhli RobbiNo ratings yet

- MVTP Manual GB PDFDocument22 pagesMVTP Manual GB PDFVikash Kumar PrasadNo ratings yet

- PCS-9611S X Communication Protocol Manual en Overseas General X R1.20Document211 pagesPCS-9611S X Communication Protocol Manual en Overseas General X R1.20parveen115No ratings yet

- Circuit Diagram - 1HSB543200-ADLDocument11 pagesCircuit Diagram - 1HSB543200-ADLRenzo GutillaNo ratings yet

- t390 en TG b23 GlobalDocument598 pagest390 en TG b23 GlobalPlamenNo ratings yet

- High Voltage SF6 Circuit Breaker InstructionDocument24 pagesHigh Voltage SF6 Circuit Breaker InstructionHusein Okhonov100% (1)

- PCS-9655S X Instruction Manual en Domestic General X R1.01Document106 pagesPCS-9655S X Instruction Manual en Domestic General X R1.01parveen115No ratings yet

- Management and Safe Handling Procedures For (Sf6) GasDocument21 pagesManagement and Safe Handling Procedures For (Sf6) GasKhaled KhaledNo ratings yet

- PCS 931SDocument773 pagesPCS 931SMuhamad YasrinNo ratings yet

- Manual DS +dse 150 KV PDFDocument116 pagesManual DS +dse 150 KV PDFerfin1No ratings yet

- GE Grid Solutions B90 system commissioning reportDocument18 pagesGE Grid Solutions B90 system commissioning reportNgigiDanielNo ratings yet

- Brosur Voksel Hv-70kvDocument2 pagesBrosur Voksel Hv-70kvSyahrul MakkuassangNo ratings yet

- KRT V3.5 EngDocument103 pagesKRT V3.5 EngJavier CuzcoNo ratings yet

- PCS-9611S Feeder RelayDocument197 pagesPCS-9611S Feeder RelayMarkusKunNo ratings yet

- LTB D1 - B With FSA1 For 3 - Pole OperatedDocument17 pagesLTB D1 - B With FSA1 For 3 - Pole Operateddwas1314No ratings yet

- PCS-9611 X Instruction Manual en Overseas General X R1.01 (En DYBH5301.0086.0002)Document286 pagesPCS-9611 X Instruction Manual en Overseas General X R1.01 (En DYBH5301.0086.0002)Doan Bao100% (9)

- PCS-924 PCS-9611 - Setting Calculation - EN - GW1200249 - India Mylapor Substation 230kV Inter Connection Line - R1.00 - SUBQ00383520Document11 pagesPCS-924 PCS-9611 - Setting Calculation - EN - GW1200249 - India Mylapor Substation 230kV Inter Connection Line - R1.00 - SUBQ00383520prabhu_natarajan_nNo ratings yet

- Instruction Manual PLC Line TrapsDocument47 pagesInstruction Manual PLC Line Trapsshabbireee84@gmail.comNo ratings yet

- Technical Data Fluokit m24 LengkapDocument20 pagesTechnical Data Fluokit m24 LengkapAbdulhakk Agai100% (1)

- L6-PDS-01-H-5215-S-40218-B - 220kV PRTN SCH DRG D15+R1 TG72Document66 pagesL6-PDS-01-H-5215-S-40218-B - 220kV PRTN SCH DRG D15+R1 TG72Satish KumarNo ratings yet

- p345 Technical ManualDocument1 pagep345 Technical ManualabhayambujNo ratings yet

- NR PCS-9655 (Fast Changeover Device) - ManualDocument53 pagesNR PCS-9655 (Fast Changeover Device) - ManualAbdul MoizNo ratings yet

- GRB200C (6F2S1923 G2A Replica) 0.02Document72 pagesGRB200C (6F2S1923 G2A Replica) 0.02Khánh Vũ HoàngNo ratings yet

- 7PA22 - Lockout RelayDocument6 pages7PA22 - Lockout RelayJack JohnsonNo ratings yet

- CT Trench PDFDocument17 pagesCT Trench PDFradinalNo ratings yet

- PCS Explorer Auxiliary Software Instruct PDFDocument190 pagesPCS Explorer Auxiliary Software Instruct PDFTram E29No ratings yet

- Wiring Internal PMT ABB Single Pole LTB 170D1 B - 01 PDFDocument9 pagesWiring Internal PMT ABB Single Pole LTB 170D1 B - 01 PDFTragi Kisaran100% (1)

- PCS-9691 - X - Instruction Manual - EN - Overseas General - X - R1.03 PDFDocument292 pagesPCS-9691 - X - Instruction Manual - EN - Overseas General - X - R1.03 PDFBarry79x100% (2)

- PCS-9611 X Instruction Manual en Overseas General X R3.08Document330 pagesPCS-9611 X Instruction Manual en Overseas General X R3.08khaledonaNo ratings yet

- BFT Mizar 6Document5 pagesBFT Mizar 6CésarSá100% (1)

- GF92 Installation, Operation and Troubleshooting Guide: 24 Hour Factory Service Hot Line: 1 (800) 854-1993Document8 pagesGF92 Installation, Operation and Troubleshooting Guide: 24 Hour Factory Service Hot Line: 1 (800) 854-1993eodogy5No ratings yet

- Hitachi Ras Rac-7!9!14gh4Document68 pagesHitachi Ras Rac-7!9!14gh4cristiangodeanuNo ratings yet

- 36kV GISDocument19 pages36kV GISNiket GuptaNo ratings yet

- BFT TIR 120 BrochureDocument9 pagesBFT TIR 120 BrochureRibeiroLuisNo ratings yet

- Libra MarDocument11 pagesLibra MarLiz FabiolaNo ratings yet

- NISMDocument18 pagesNISMAbhinav PratapNo ratings yet

- Chapter PDFDocument9 pagesChapter PDFVenkatramana Reddy KNo ratings yet

- Nse Options Strategies Explanation With ExamplesDocument60 pagesNse Options Strategies Explanation With ExamplesVatsal ShahNo ratings yet

- Bank Nifty Option Strategy For November Series - 09112020-1604902911Document2 pagesBank Nifty Option Strategy For November Series - 09112020-1604902911rpshvjuNo ratings yet

- Website Details Password and Id's: Website Address: 1. Domain Registrar and Hosting Company: HostingrajaDocument1 pageWebsite Details Password and Id's: Website Address: 1. Domain Registrar and Hosting Company: HostingrajarpshvjuNo ratings yet

- Budget Fin Year Department - Em-OphDocument10 pagesBudget Fin Year Department - Em-OphrpshvjuNo ratings yet

- Option StrategyDocument59 pagesOption StrategyTarkeshwar MahatoNo ratings yet

- Strategy Guide: Bull Call SpreadDocument14 pagesStrategy Guide: Bull Call SpreadworkNo ratings yet

- Option Trading StrategiesDocument0 pagesOption Trading StrategiesGarvit Garg100% (1)

- Purchase Requistion: Sagardighi Thermal Power ProjectDocument3 pagesPurchase Requistion: Sagardighi Thermal Power ProjectrpshvjuNo ratings yet

- Motor protection relay user manualDocument13 pagesMotor protection relay user manualrpshvjuNo ratings yet

- Post No 6 - How To Move Your Website From Localhost To Online ServerDocument7 pagesPost No 6 - How To Move Your Website From Localhost To Online ServerrpshvjuNo ratings yet

- Cooking TipsDocument1 pageCooking TipsrpshvjuNo ratings yet

- Agency Blacklisting RulesDocument10 pagesAgency Blacklisting Rulesrpshvju100% (1)

- ZnO Gapless Lightning Arrester or Surge ArresterDocument8 pagesZnO Gapless Lightning Arrester or Surge ArresterrpshvjuNo ratings yet

- Welcome To: Cooling Water Treatment in Power Plants Recent Trends & Case StudyDocument17 pagesWelcome To: Cooling Water Treatment in Power Plants Recent Trends & Case StudyrpshvjuNo ratings yet

- Raw water 6.6Kv switchgear and DM Plant 415V MCC single line diagramsDocument2 pagesRaw water 6.6Kv switchgear and DM Plant 415V MCC single line diagramsrpshvjuNo ratings yet

- Intake To Filter Water SystemDocument3 pagesIntake To Filter Water SystemrpshvjuNo ratings yet

- Adhikary Plant CycleDocument19 pagesAdhikary Plant CyclerpshvjuNo ratings yet

- Common HmiDocument7 pagesCommon HmirpshvjuNo ratings yet

- Total power failure restoration and cold start up proceduresDocument8 pagesTotal power failure restoration and cold start up proceduresrpshvjuNo ratings yet

- EXIDEDocument27 pagesEXIDErpshvjuNo ratings yet

- RHH and LTSH links overviewDocument4 pagesRHH and LTSH links overviewrpshvjuNo ratings yet

- Adhikary Plant CycleDocument19 pagesAdhikary Plant CyclerpshvjuNo ratings yet

- Resource 2: Three-Phase AC MachinesDocument11 pagesResource 2: Three-Phase AC MachinesrpshvjuNo ratings yet

- PLC Unity Pro Software Quantum Hot StandbyDocument28 pagesPLC Unity Pro Software Quantum Hot StandbyrpshvjuNo ratings yet

- Esld R07 ..Document1 pageEsld R07 ..rpshvjuNo ratings yet

- Intake Switchgear Layout Phase 2Document1 pageIntake Switchgear Layout Phase 2rpshvjuNo ratings yet

- Spam Relay Setting Guide PDFDocument28 pagesSpam Relay Setting Guide PDFrpshvju100% (1)

- Pseudo CodesDocument6 pagesPseudo CodesVinti PandeyNo ratings yet

- Covid Full Catalog 2016Document96 pagesCovid Full Catalog 2016Camilo Alejandro PalaciosNo ratings yet

- Interline 1012+ds+eng PDFDocument4 pagesInterline 1012+ds+eng PDFSUBHOMOY100% (1)

- CIS Microsoft SQL Server 2019 Benchmark v1.0.0 PDFDocument100 pagesCIS Microsoft SQL Server 2019 Benchmark v1.0.0 PDFConciencia ImmortalNo ratings yet

- Mechanical Component ToleranceDocument2 pagesMechanical Component ToleranceOmkar Kumar JhaNo ratings yet

- Fund Mech Eng SiemensDocument150 pagesFund Mech Eng SiemensRafael Pacheco100% (2)

- Johan Holmberg-Train Communication Networks PDFDocument35 pagesJohan Holmberg-Train Communication Networks PDFVaibhav DhinganiNo ratings yet

- Quick Setup Guide for Panasonic SIP Cordless PhonesDocument26 pagesQuick Setup Guide for Panasonic SIP Cordless PhonesputegrainNo ratings yet

- Call 800-DIESELS (343-7357) : Natural Gas EngineDocument10 pagesCall 800-DIESELS (343-7357) : Natural Gas EnginereycoeleNo ratings yet

- Material Handling Flow PatternDocument20 pagesMaterial Handling Flow PatternAli WarsiNo ratings yet

- How To Simplify Compliance With The New ISO 13485 2016 Final PDFDocument63 pagesHow To Simplify Compliance With The New ISO 13485 2016 Final PDFAymen Bekir100% (3)

- Fanuc 30i Ethernet SettingsDocument60 pagesFanuc 30i Ethernet SettingsChen Yi ChangNo ratings yet

- Intel Ethernet Connection I219 Reference Schematic Rev1 0Document1 pageIntel Ethernet Connection I219 Reference Schematic Rev1 0Смартфон СигмаNo ratings yet

- Network Design ToolsDocument13 pagesNetwork Design ToolsUmang SomeshwarNo ratings yet

- TSG PRD TS 11 V17 Cover - Device Field and Lab Test GuidelinesDocument18 pagesTSG PRD TS 11 V17 Cover - Device Field and Lab Test GuidelinesAlberto Martín JiménezNo ratings yet

- It8501 Web Technology SyllabusDocument3 pagesIt8501 Web Technology SyllabusJaya Lakshmi0% (2)

- Double-Jacketed Gaskets For Heat Exchangers Sealabilty Behavior in Flanges With and Without Nubbin (PVP2005-71023) PDFDocument10 pagesDouble-Jacketed Gaskets For Heat Exchangers Sealabilty Behavior in Flanges With and Without Nubbin (PVP2005-71023) PDFAngel Sanchez GarciaNo ratings yet

- Pipe Handling EquipmentDocument4 pagesPipe Handling EquipmentJohn RongNo ratings yet

- Introduction To Networks, Reference ModelsDocument38 pagesIntroduction To Networks, Reference ModelsMukesh100% (2)

- Elective III E CommerceDocument6 pagesElective III E CommercepocketoxyNo ratings yet

- Vroom-Yetton-Jago: Deciding How To DecideDocument11 pagesVroom-Yetton-Jago: Deciding How To DecideJean Paula MercadoNo ratings yet

- Bus Enquiry SystemDocument29 pagesBus Enquiry SystemMäjîd KhâñNo ratings yet

- BIS Licence DocumentDocument4 pagesBIS Licence DocumentbsdygswdywNo ratings yet

- Epson TM-L90 POS Label Printer BrochureDocument2 pagesEpson TM-L90 POS Label Printer BrochureJohnny BarcodeNo ratings yet

- Dual Stack Ip-Mpls and MPLS-TPDocument6 pagesDual Stack Ip-Mpls and MPLS-TPFelipe A. PérezNo ratings yet

- PL/SQL Program UnitsDocument67 pagesPL/SQL Program Unitsdeeps21No ratings yet

- Drive Lines, Differentials, and Power TrainsDocument44 pagesDrive Lines, Differentials, and Power TrainsAnonymous QiMB2lBCJLNo ratings yet

- Es 211Document50 pagesEs 211Jr BongabongNo ratings yet

- NAV Analyzer for Air Traffic ManagementDocument2 pagesNAV Analyzer for Air Traffic ManagementnemyaNo ratings yet

- InterClean Hybrid Transit Bus Wash With RecyclingDocument21 pagesInterClean Hybrid Transit Bus Wash With Recyclingmelgarcia829100% (1)