Professional Documents

Culture Documents

Biores 04-3-1178 Shen SQLhi Acid Tol PCC Dip Onp 607

Uploaded by

AnujKumarVermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biores 04-3-1178 Shen SQLhi Acid Tol PCC Dip Onp 607

Uploaded by

AnujKumarVermaCopyright:

Available Formats

PEER-REVIEWED ARTICLE

bioresources.com

A PRELIMINARY INVESTIGATION INTO THE USE OF ACIDTOLERANT PRECIPITATED CALCIUM CARBONATE FILLERS IN

PAPERMAKING OF DEINKED PULP DERIVED FROM RECYCLED

NEWSPAPER

Jing Shen,a Zhanqian Song,b Xueren Qian,a* and Wenxia Liu c

The use of acid-tolerant precipitated calcium carbonate fillers, including

phosphoric acid/sodium hexametaphosphate modified precipitated

CaCO3 filler, and sodium silicate/phosphoric acid/sodium hexametaphosphate modified precipitated CaCO3 filler in papermaking of deinked pulp

derived from recycled newspaper was explored. These two acid-tolerant

fillers provided considerably more brightness improvement in papers in

comparison the unmodified filler, presumably indicating alleviated pulp

darkening achieved as a result of better acid-resistant properties. The

addition of acid-tolerant fillers into the furnish slurries gave lower system

pH as compared with unmodified filler. Among the three fillers used in

this work, the effect on retention of modification of the filler with sodium

silicate/phosphoric acid/sodium hexametaphosphate was probably the

best, as evaluated from ash content measurements. For air permeability

of the paper, the use of acid-tolerant fillers provided slightly more

improvement in comparison to the unmodified filler. For tensile and burst

strength of the paper, the use of sodium silicate/phosphoric acid/sodium

hexameta-phosphate modified precipitated calcium carbonate filler gave

better results as compared with the other two fillers. Additionally, the

improving effect of acid-tolerant fillers on furnish static drainage was

found to be slightly weaker than that of unmodified filler.

Keywords: Acid-tolerant precipitated calcium carbonate filler; Papermaking; Deinked pulp; Optical

properties; pH profile; Strength properties; Air permeability; Ash content; Furnish static drainage

Contact information: a: Laboratory of Pulp and Paper Engineering Subject, Key Laboratory of Bio-based

Material Science and Technology of Ministry of Education, Material Science and Engineering College,

Northeast Forestry University, Harbin 150040, China; b: Institute of Chemical Industry of Forest

Products, Chinese Academy of Forestry; Key and Open Lab. on Forest Chemical Engineering, State

Forestry Administration, Nanjing 210042, China; c: Key Laboratory of Paper Science & Technology of

Ministry of Education, Shandong Institute of Light Industry, University Park of Science and Technology,

Jinan 250353, China. *Corresponding author: qianxueren@yahoo.com.cn

INTRODUCTION

Calcium carbonate fillers have been widely used in woodfree paper grades since

the 1980s to improve the optical properties of paper products and to reduce

manufacturing costs. In woodfree paper grades, the alkaline nature of calcium carbonate

is an additional benefit because it creates a stable buffered system and provides some

paper strength improvement (Evans and Slozer 2003), and paper products filled with

calcium carbonate usually have better aging resistance as compared with other fillers

(Gill and Scott 1987). In the manufacture of paper there is also an economic incentive to

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1178

PEER-REVIEWED ARTICLE

bioresources.com

use calcium carbonate fillers because of the ability to produce cheap precipitated calcium

carbonate on-site at the paper mill (Pang 2001). However, the use of calcium carbonate

fillers in wood-containing paper is generally considered as not industrially feasible

because of pulp darkening at alkaline pH and dissolution below pH 7 (Ain and Laleg

1997; Evans and Drummond 1991), and their use in rosin-sized paper has also many

limitations due to saponification reaction of rosin sizes under alkaline conditions (Shen et

al. 2007). The alkaline nature of calcium carbonate fillers and their poor acid-resistant

properties make them unsuitable for use in acid and pseudo-neutral papermaking.

Titanium dioxide and calcined clay have often been used as fillers in acid and pseudoneutral papermaking. However, these materials, and titanium dioxide in particular, are

expensive, thus adding to the cost of the paper. Talc fillers can also be used in acid and

pseudo-neutral papermaking, and the price of talc is generally equivalent to calcium

carbonate, but calcium carbonate is much superior to talc in many respects, such as the

optical properties of the filled paper. Therefore, there is a need to enable the use of

calcium carbonate fillers in acid and pseudo-neutral papermaking.

The methods now available for making calcium carbonate fillers suitable for use

in acid and pseudo-neutral papermaking can be divided into the following two categories:

z Addition of a dissolution inhibitor such as carbon dioxide or phosphoric acid

(or a combination of various inhibitors) to the filler-containing papermaking

wet-end system to inhibit filler dissolution

z Modification of calcium carbonate fillers before use to inhibit filler dissolution

and to improve their acid-resistant properties

These two categories of methods have been used in the past few years to obtain

acid-tolerant calcium carbonate fillers. From a worldwide perspective, the use of acidtolerant calcium carbonate fillers in wood-containing paper grades has already been

commercialized to a certain degree. In specific industrial applications the use of acidtolerant calcium carbonate fillers can involve the separate addition of calcium carbonate

and dissolution inhibitor or weak acid to furnish. This allows much more effective and

efficient pH control of the wet end. It should be mentioned that the use of carbon dioxide

to adjust the pH and to inhibit the dissolution of calcium carbonate fillers in papermaking

has been a hot topic (Pakarinen and Leino 2001). It has been claimed that the effect of the

carbon dioxide is due to the increased amount of carbonate ions which result from the

dissolution of carbon dioxide in the aqueous medium, and these carbonate ions affect the

balance of the dissociation equation of calcium carbonate in such a way that calcium

carbonate has a lower tendency for dissolving and dissociating (Laurila-Lumme et al.

2003).

For filler modification to improve acid-tolerant properties and lower dissolution

tendency, there have been considerable reports in the literature, and the modifiers that

have been found to be effective can include aluminum salt (Wu 1997a), calciumchelating agent/weak acid (Passaretti 1991), weak base/weak acid (Wu 1997b) , calciumsalt-based modifiers (Drummond 2001), phosphoric acid (Pang et al. 1998, 2001, 2003;

Pang and Englezos 2003), sodium silicate/weak acid (Snowden et al. 2000), zinc

compound/silica-containing substance (Tokarz et al. 1991), sodium silicate/zinc

chloride/carbon dioxide (Chapnerkar et al. 1992), and anionic starch derivative/cationic

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1179

PEER-REVIEWED ARTICLE

bioresources.com

starch derivative (Lambert and Lowes 1975). The available filler modification methods

can generally be classified into two categories. One is only suitable for use in the

production of filler slurries, whereas the other one is capable of producing modified

fillers in power form. For example, The calcium-chelating agent/weak acid, and weak

base/weak acid systems have been demonstrated as effective in the production of acidtolerant filler slurries, and the buffering actions of the modifiers can play a decisive role

in suppressing the dissolution of calcium carbonate fillers. However, for the use of

modifiers such as zinc compound/silica-containing substance in filler modification, the

formation of acid-resistant coatings on the filler surfaces contributes significantly to the

suppressed dissolution of the modified fillers in acidic mediums, and the modified fillers

can exist in powder form.

Phosphoric acid can be used as a modifier of calcium carbonate fillers to inhibit

filler dissolution, and its combined use with other modifiers has been shown to be highly

effective. Although the use of phosphoric acid in modification of calcium carbonate

fillers has certain disadvantages, such as formation of calcium phosphate (scaling), and

release of unwanted phosphorus to waste water, it can possibly be used under certain

controlled papermaking conditions to enhance the properties of paper and paperboard

products. Our previous work has shown that the use of phosphoric acid/sodium

hexametaphosphate, or sodium silicate/phosphoric acid/sodium hexametaphosphate in

modification of papermaking grade precipitated calcium carbonate filler can inhibit the

dissolution of filler in various water solutions with different pH values, and its acidresistant property can be significantly enhanced (Shen et al. 2008a,b).

In this work, the use of acid-tolerant precipitated calcium carbonate fillers

including phosphoric acid/sodium hexametaphosphate modified filler, and sodium

silicate/phosphoric acid/sodium hexametaphosphate modified filler in papermaking of

deinked pulp derived from recycled newspaper was explored.

EXPERIMENTAL

Materials

Papermaking grade precipitated calcium carbonate filler was obtained from

Guangxi Guilin Wuhuan Co., Ltd., China. Deinked pulp derived from recycled

newspaper was supplied by Jilin Chenming Paper Co., Ltd., China, and was slightly

refined to a beating degree of 57.0 oSR using a ZQS2 valley beater made in China.

Cationic polyacrylamide with the trademark of Percol 47 used as retention aid was

obtained from Ciba Specialty Chemicals Co., Ltd., Germany. Phosphoric acid, sodium

hexametaphosphate, sodium silicate, and alum were all analytical reagents produced in

China.

Acid-tolerant precipitated calcium carbonate fillers were prepared by filler

modification. Precipitated calcium carbonate filler slurries with concentration of 10 wt%

were initially prepared, and the water solutions of modifiers were then added. The

resulting mixtures with PCC concentration of 5 wt% were sufficiently mixed, and were

then aged for 24 h before use. The modifiers used for the preparation of the two acidtolerant fillers were phosphoric acid/sodium hexametaphosphate, and sodium

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1180

PEER-REVIEWED ARTICLE

bioresources.com

silicate/phosphoric acid/sodium hexameta-phosphate, respectively. The dosages of

sodium silicate, phosphoric acid, and sodium hexameta-phosphate were 1 wt%, 4 wt%

and 1 wt%, respectively, based on the dry mass of PCC.

EDAX Analysis and SEM Observations of Fillers

EDAX analysis and SEM observations of acid-tolerant precipitated calcium

carbonate fillers and unmodified precipitated calcium carbonate filler were performed

with a scanning electron microscope with elemental distribution analysis (QUANTA 200).

Evaluation of Influence of Filler Addition on the pH of Furnish Slurry

Filler was added to the pulp slurry to form a suspension with concentration of 0.5

wt/%, and the target filler loading level was controlled to be 15 wt%. The slurry pH as a

function of time was measured using a PHS-3C pH meter made in China.

Evaluation of Static Furnish Drainage

The pulp with dry weight of 2 g was mixed with 0.5 g filler to form a 1000 ml

suspension, and the freeness (oSR) was measured to evaluate the static drainage property

of the filler-containing furnish. The apparatus used was a ZDJ-100 beating degree tester

made in China.

Handsheets Preparation

The mixture of pulp and filler was diluted to 0.5 wt%, and the target filler loading

level was controlled to be 15 wt%. Cationic polyacrylamide solution was added, and the

slurry was stirred for 1 min. Diluted alum solution was then added dropwise to adjust the

slurry pH to 6.50, and the pH-adjusting time was controlled to be 1 min. Handsheets with

target basis weight of 60 g/m2 were then prepared using the sheet former (ZQJ1-B200mm)

produced in China. The handsheets were further pressed and flattened for 24 h using the

apparatus called Pingyatuo equipped with the sheet former. The conditions for

handsheets preparation were kept consistent for all of the samples.

Measurement of Strength Properties, Optical Properties and Air

Permeability of Handsheets

The tensile index values of handsheets were measured using a L&W CE062

tensile strength tester made in Sweden. The burst index values of handsheets were

measured using ZDNP-1 burst strength tester made in China. The brightness, opacity and

light scattering coefficient of handsheets were measured using a YQ-Z-48A brightness &

color tester made in China. The air permeability values of handsheets were measured

using YG461E permeability tester made in China.

Measurement of Ash Content of Handsheets

The handsheets were dried at 105 oC for 6 h, and the dry weight values of

handsheets were measured. The dried handsheets were then incinerated at 575 oC for 6 h,

the ash weight values were measured, and the ash content values of handsheets (%) were

calculated.

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1181

bioresources.com

PEER-REVIEWED ARTICLE

RESULTS AND DISCUSSION

Element Compositions and Surface Morphologies of Acid-Tolerant Fillers

Elemental compositions and SEM images of acid-tolerant fillers and unmodified

precipitated calcium carbonate fillers are shown in Table 1 and Fig. 1. It can be seen from

Table 1 that the use of phosphoric acid/sodium hexametaphosphate in filler modification

might have initiated the precipitation of Ca-P overgrowths on the filler surfaces, and the

use of sodium silicate/phosphoric acid/sodium hexametaphosphate in filler modification

might have initiated the precipitation of both Ca-P overgrowths and silica coatings. The

presence of Ca-P overgrowths and silica coatings on the filler surfaces might act as

barriers and block the dissolution sites, which might contribute to the improved acidresistant properties. It can be seen from Fig. 1 that the morphologies and elemental

compositions of acid-tolerant precipitated calcium carbonate fillers were different from

that of unmodified precipitated calcium carbonate filler, indicating a change in surface

characteristics of filler when modified using the respective modifiers.

Table 1. Elemental Compositions of Acid-Tolerant Precipitated Calcium

Carbonate Fillers and Unmodified Precipitated Calcium Carbonate Filler

Measured by EDAX.

Element

Carbon

Oxygen

Calcium

Magnesium

Phosphorus

Silicon

Unmodified

Precipitated

calcium

carbonate filler

28.57

54.24

16.65

0.54

-

Elemental Content (Molar percent, Atomic)

Phosphoric acid/sodium sodium silicate/phosphoric

hexametaphosphate

acid/sodium hexametaphosphate

modified precipitated

modified precipitated calcium

calcium carbonate filler carbonate filler

25.55

25.08

52.75

52.40

19.57

19.15

0.65

0.79

1.48

1.95

0.63

(a).

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1182

bioresources.com

PEER-REVIEWED ARTICLE

(b)

(c)

Fig. 1. SEM images of different fillers: (a) unmodified precipitated calcium carbonate filler, (b)

phosphoric acid/sodium hexametaphosphate modified precipitated calcium carbonate filler, and (c)

sodium silicate/phosphoric acid/sodium hexametaphosphate modified precipitated calcium

carbonate filler

Influence of Filler Addition on the pH Profile of Furnish Slurry

The influence of addition of different fillers on the pH profile of furnish slurry is

shown in Fig. 2. When unmodified precipitated calcium carbonate filler was incorporated

into the slurry, the system pH rose to above 9 within 30 minutes. However, the pH values

of furnish slurries containing the acid-tolerant precipitated calcium carbonate fillers were

quite low (around 7.5). The pH-reducing effect of the modifiers used in filler

modification on the pH of furnish slurry might be mainly attributed to the pH-buffering

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1183

bioresources.com

PEER-REVIEWED ARTICLE

action, and the formation of Ca-P overgrowths on the filler surfaces as a result of addition

of phosphoric acid might also contribute to the lowered system pH (Pang et al. 2003).

10

pH

Phosphoric acid/sodium hexametaphosphate

modified filler

Sodium silicate/phosphoric acid/sodium

hexametaphosphate modified filler

6

Unmodified filler

5

0

8 10 12 14 16 18 20 22 24 26 28 30

t/min

Fig. 2. Influence of filler addition on the pH profile of furnish slurry

Static Drainage Properties of the Filler-Containing Furnishes

Freeness values of the filler-containing furnishes are shown in Table 2. The

freeness values of the filler-containing furnishes were all lower than that of furnish with

no filler added, showing the positive effects of unmodified filler and acid-tolerant

precipitated calcium carbonate fillers on furnish static drainage. Compared with the

furnish containing unmodified precipitated calcium carbonate filler, the freeness values

of furnishes containing acid-tolerant fillers were slightly higher. Also, these two acidtolerant precipitated calcium carbonate fillers exhibited almost the same effects on

furnish freeness. Therefore, the acid-tolerant precipitated calcium fillers could improve

the static drainage property of deinked pulp derived from recycled newspaper, but their

effects were slightly weaker in comparison to the unmodified precipitated calcium

carbonate filler.

Table 2. Freeness Values of the Furnishes.

Sample

Furnish with no filler added

Furnish containing unmodified precipitated calcium carbonate filler

Furnish containing phosphoric acid/sodium hexametaphosphate modified

precipitated calcium carbonate filler

Furnish containing sodium silicate/phosphoric acid/sodium

hexametaphosphate modified precipitated calcium carbonate filler

Freeness

(oSR)

57.0

48.2

52.0

51.8

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1184

bioresources.com

PEER-REVIEWED ARTICLE

Ash Content of the Filled Papers

Ash content values of the filled handsheets are shown in Table 3. The ash content

of handsheets with no filler added was as low as 4.0 wt%. For the filled handsheets, the

handsheets filled with sodium silicate/phosphoric acid/sodium hexametaphosphate

modified precipitated calcium carbonate filler gave the highest ash content, and the

handsheets filled with phosphoric acid/sodium hexametaphosphate modified precipitated

calcium carbonate filler gave the lowest ash content. Thus, the retention property of

sodium silicate/phosphoric acid/sodium hexametaphosphate modified precipitated

calcium carbonate filler was better than phosphoric acid/sodium hexametaphosphate

modified precipitated calcium carbonate filler and unmodified precipitated calcium

carbonate filler.

Table 3. Ash Content Values of the Filled Handsheets.

Sample

Handsheets without filler

Handsheets filled with unmodified precipitated calcium carbonate filler

Handsheets filled with phosphoric acid/sodium hexametaphosphate modified

precipitated calcium carbonate filler

Handsheets filled with sodium silicate/phosphoric acid/sodium

hexametaphosphate modified precipitated calcium carbonate filler

Ash content

(wt%)

4.0

16.0

12.7

16.6

Optical Properties of the Filled Papers

Optical properties of the filled handsheets are shown in Table 4. The use of

unmodified precipitated calcium carbonate filler and acid-tolerant precipitated calcium

carbonate fillers all strikingly improved the brightness of handsheets. The brightness of

handsheets filled with acid-tolerant precipitated calcium carbonate fillers was higher as

compared with the handsheets filled with the unmodified precipitated calcium carbonate

filler. After modification, the brightness of handsheets increased by more than 2 %ISO,

presumably indicating the alleviation of pulp darkening, achieved by enhanced acidresistant property of the filler. For phosphoric acid/sodium hexametaphosphate modified

precipitated calcium carbonate filler, its retention in the handsheets was lower than the

unmodified precipitated calcium carbonate filler (see Table 3), whereas the brightness of

handsheets filled with the acid-tolerant filler was higher than that of handsheets filled

with the unmodified filler, further confirming the alleviation of pulp darkening associated

with the use of acid-tolerant filler. Thus, under the controlled experimental conditions,

the acid-tolerant precipitated calcium carbonate fillers were more efficient in brightness

improvement of the filled papers in comparison to the unmodified precipitated calcium

carbonate filler.

The opacity of filled handsheets was slightly lower than that of unfilled

handsheets, and the opacity of handsheets filled with phosphoric acid/sodium hexametaphosphate modified filler was slightly higher than handsheets filled with unmodified

filler.

The light scattering coefficient of filled handsheets was much higher than that of

unfilled handsheets. Compared with the handsheets filled with unmodified precipitated

calcium carbonate filler, the light scattering coefficient of handsheets filled with sodium

silicate/phosphoric acid/sodium hexametaphosphate modified filler was slightly higher,

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1185

bioresources.com

PEER-REVIEWED ARTICLE

but the light scattering coefficient of handsheets filled with phosphoric acid/sodium

hexametaphosphate modified filler was much lower.

Table 4. Optical Properties of the Filled Handsheets

Sample

Brightness

(%ISO)

Opacity

(%)

Handsheets without filler

Handsheets filled with unmodified

precipitated calcium carbonate filler

Handsheets filled with phosphoric

acid/sodium hexametaphosphate modified

precipitated calcium carbonate filler

Handsheets filled with sodium

silicate/phosphoric acid/sodium

hexametaphosphate modified precipitated

calcium carbonate filler

61.7

97.3

Light scattering

coefficient

(m2kg-1)

52.7

67.8

96.4

69.0

69.9

97.0

61.6

70.5

95.7

69.4

Air Permeability of the Filled Papers

Air permeability values of the filled handsheets are shown in Table 5. The use of

acid-tolerant precipitated calcium carbonate fillers and unmodified precipitated calcium

carbonate filler strikingly increased the air permeability of handsheets. Compared with

the handsheets filled with unmodified precipitated calcium carbonate filler, the air

permeability of handsheets filled with acid-tolerant precipitated calcium carbonate fillers

was slightly higher. Thus, the air-permeability-increasing effect of acid-tolerant

precipitated calcium carbonate fillers was slightly greater than that of unmodified

precipitated calcium carbonate filler.

Table 5. Air Permeability Values of the Filled Handsheets

Sample

Handsheets without filler

Handsheets filled with unmodified precipitated calcium carbonate filler

Handsheets filled with phosphoric acid/sodium hexametaphosphate

modified precipitated calcium carbonate filler

Handsheets filled with sodium silicate/phosphoric acid/sodium

hexametaphosphate modified precipitated calcium carbonate filler

Air permeability

(Lm-2s-1)

18.5

28.5

34.8

30.1

Strength Properties of the Filled Papers

Tensile indices and burst indices of the filled handsheets are shown in Table 6.

The use of modified precipitated calcium carbonate fillers and unmodified precipitated

calcium carbonate filler all impaired the strength properties of filled handsheets to a

certain degree. For the three fillers used in this work, the handsheets filled with sodium

silicate/phosphoric acid/sodium hexametaphosphate modified precipitated calcium

carbonate filler gave comparatively good tensile and burst strength properties. As the

retention of sodium silicate/phosphoric acid/sodium hexametaphosphate modified precipitated calcium carbonate filler was comparatively high, filler modification with sodium

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1186

PEER-REVIEWED ARTICLE

bioresources.com

silicate/phosphoric acid/sodium hexametaphosphate can possibly alleviate the negative

effect of filler loading on paper strength.

Table 6. Tensile and Burst Index Values of the Filled Handsheets

Sample

Tensile index

(Nmg-1)

Handsheets without filler

Handsheets filled with unmodified precipitated

calcium carbonate filler

Handsheets filled with phosphoric acid/sodium

hexametaphosphate modified precipitated

calcium carbonate filler

Handsheets filled with sodium

silicate/phosphoric acid/sodium

hexametaphosphate modified precipitated

calcium carbonate filler

17.02

Burst index

(KPam2g1)

1.22

11.14

0.66

9.93

0.59

13.28

0.65

CONCLUSIONS

1. The use of acid-tolerant precipitated calcium carbonate fillers, including phosphoric

acid/sodium hexametaphosphate modified precipitated calcium carbonate, and

sodium silicate/phosphoric acid/sodium hexametaphosphate modified precipitated

calcium carbonate, in papermaking of deinked pulp derived from recycled newspaper

provided considerably more brightness improvement as compared with unmodified

filler.

2. The pH values of the furnish slurries containing acid-tolerant precipitated calcium

carbonate fillers were much lower than that of unmodified filler.

3. The use of acid-tolerant precipitated calcium carbonate fillers and unmodified filler

all improved furnish static drainage, and the improving effect of acid-tolerant

precipitated calcium carbonate fillers was slightly weaker as compared with

unmodified filler.

4. Compared with the unmodified filler, the acid-tolerant precipitated calcium carbonate

fillers gave slightly more increase in air permeability of the papers.

5. For tensile and burst strength of filled paper, the use of sodium silicate/phosphoric

acid/sodium hexametaphosphate modified precipitated calcium carbonate filler gave

better results as compared with the other two fillers.

6. Among the three fillers, the use of sodium silicate/phosphoric acid/sodium

hexametaphosphate modified precipitated calcium carbonate filler gave the highest

ash content of the filled paper, indicating the best retention performance.

7. Further work concerning the important issues such as comparisons of acid-tolerant

precipitated calcium carbonate fillers with the use of carbon dioxide as a dissolution

inhibitor, alkaline darkening properties of the deinked pulp, more complete statistics

of the experimental data, overall characterization and evaluation of fillers, and the

relevant mechanisms, is still needed in the future.

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1187

PEER-REVIEWED ARTICLE

bioresources.com

ACKNOWLEDGMENTS

Support from the Foundation (No.0802) of Key Laboratory of Paper Science &

Technology of Ministry of Education (Shandong Institute of Light Industry), P. R. China,

is gratefully acknowledged. The authors wish to express their thanks for a grant

(No.07007) from Northeast Forestry University, P. R. China, which has provided vital

support. The authors also wish to thank K.C. Wang, an undergraduate student who started

his higher education in 2005 in Material Science and Engineering College, Northeast

Forestry University, China, for conducting the relevant experimental work.

REFERENCES CITED

Ain, R. L., and Laleg, M. (1997). Mill experiences with AT precipitated calcium

carbonate (PCC) in papers containing mechanical pulp: New technology stabilizes

carbonate and pH at neutral, Pulp Paper Canada 98(12), 172-176.

Chapnerkar, V. D., Lasmarias, V. B., and Mathur, V. K. (1992). Method for preparing

acid resistant calcium carbonate pigments, U.S. Patent 5,164,006, Nov. 17.

Drummond, D. K. (2001). Use of calcium carbonate in acidic aqueous medium, U.S.

Patent 6,228,161, May. 8.

Evans, D. B., Drummond, D. K., and Koppelman, M. H. (1991). PCC fillers for

groundwood papers, Proceedings from 1991 Papermakers Conference, 321-330.

Evans, B., and Slozer, M. (2003). Neutral groundwood papers: Practical and chemical

aspects, Proceedings from 2003 Paper & Coating Symposium, 43-46.

Lambert, B. P., and Lowes, J. (1975). A method for treating calcium carbonate paper

filler, U.S. Patent 3,873,336, Mar. 26.

Laurila-Lumme, A., Pakarinen, H., and Leino, H. J. (2003). Process for substantially

retarding dissolution of calcium carbonate in a papermaking system, U.S. Patent

6,540,870, Apr. 1.

Gill, R. A., and Scott, W. (1987). The relative effects of different calcium carbonate

filler pigments on optical properties, Tappi J. 70(1), 93-99.

Pakarinen, H., Leino, H. (2001). Benefits of using carbon dioxide in the production of

DIP containing newsprint, Wochenblatt fr Papierfabrikation 129, 953-958.

Pang, P. (2001). Optimization of the use of polyethylene oxide and calcium carbonate in

papermaking, Ph.D Thesis of the University of British Columbia.

Pang, P., Deslandes, Y., Raymond, S., Pleizier, G., and Englezos, P. (2001). Surface

analysis of ground calcium carbonate filler treated with dissolution inhibitor, Ind.

Eng. Chem. Res. 40, 2445-2451.

Pang, P., and Englezos, P. (2003). Application of pretreated ground calcium carbonate

in mechanical pulp suspension, Pulp Paper Canada 104(6), 152-154.

Pang, P., Khoultchaev, K. K., and Englezos, P. (1998). Inhibition of the dissolution of

papermaking grade precipitated calcium carbonate filler, Tappi J. 81(4), 188-192.

Pang, P., Modgi, S. B., and Englezos, P. (2003). Optimisation of the use of calcium

carbonate as filler in mechanical pulp, Appita J. 56(2), 122-126.

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1188

PEER-REVIEWED ARTICLE

bioresources.com

Passaretti, J. D. (1991). Acid-stabilized calcium carbonate, process for its production

and method for its use in the manufacture of acidic paper, U.S. Patent 5, 043, 017,

Aug. 27.

Shen, J., Song, Z.Q., and Qian, X.R. (2007). Acid-stabilization modification of calcium

carbonate filler, China Pulp & Paper 26, 49-51.

Shen, J., Song, Z. Q., Qian, X. R., Zhang, Y., and Wang, K. C. (2008a). Dissolutioninhibiting effects of phosphoric acid and phosphoric acid/cofactor on papermaking

grade PCC filler, China Pulp & Paper 27(8), 23-27.

Shen, J., Song, Z. Q., Qian, X. R., Wang, K. C., and Zhang, Y. (2008b). Dissolutioninhibiting effect of silicate-based inhibitors on precipitated calcium carbonate filler,

China Pulp & Paper 27(10), 13-17.

Snowden, K. J., Wu, K. T., and Rodriguez, J. M. (2000). Stabilized calcium carbonate

composition using sodium silicate and one or more weak acids or alum and uses

therefor, U.S. Patent 6,083,317, Jul. 4.

Tokarz, M., Jaras, S., and Sikkar, R. (1991). Process for the preparation of an acidresistant coating on filler particles, U.S. Patent 5,000,791, Mar. 19.

Wu, K. T. (1997a). Acid resistant calcium carbonate composition containing an

aluminum salt, uses therefor and processes for its production, U.S. Patent 5,599,388,

Feb. 4.

Wu, K. T. (1997b). Acid resistant calcium carbonate composition and uses therefor,

U.S. Patent 5,593,488, Jan. 14.

Article submitted: June 23, 2009; Peer review completed: July 17, 2009; Revised version

received and accepted: July 25, 2009; Published July 27, 2009.

Shen et al. (2009). Acid-tolerant PCC in papermaking, BioResources 4(3), 1178-1189.

1189

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Graphene-Based Antibacterial PaperDocument7 pagesGraphene-Based Antibacterial PaperAnujKumarVermaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Dental Biomedical Waste Management: Review ArticleDocument3 pagesDental Biomedical Waste Management: Review ArticleAnujKumarVermaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Acschemneuro 0c00609Document3 pagesAcschemneuro 0c00609AnujKumarVermaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Kandi - 502 285, Sangareddy, Telangana, INDIA: Indian Institute of Technology HyderabadDocument1 pageKandi - 502 285, Sangareddy, Telangana, INDIA: Indian Institute of Technology HyderabadAnujKumarVermaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Der Pharmacia Lettre 2018Document14 pagesDer Pharmacia Lettre 2018AnujKumarVermaNo ratings yet

- A Review On Utilization of Coconut Shell As Coarse Aggregate in ConcreteDocument3 pagesA Review On Utilization of Coconut Shell As Coarse Aggregate in ConcreteAnujKumarVermaNo ratings yet

- B Tech C T - III toVIIIDocument54 pagesB Tech C T - III toVIIIAnujKumarVermaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- PGP July 2020 Batch Fee Structure Wef 11 05Document1 pagePGP July 2020 Batch Fee Structure Wef 11 05AnujKumarVermaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Lecture 2. Portland Cement: CIV-E2020 Concrete Technology (5 CR)Document31 pagesLecture 2. Portland Cement: CIV-E2020 Concrete Technology (5 CR)AnujKumarVermaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Bentonite Adsorption Coagulation Treatment of RecyDocument7 pagesBentonite Adsorption Coagulation Treatment of RecyAnujKumarVermaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Ordinance and Syllabus: M.Sc. Biomedical ScienceDocument26 pagesOrdinance and Syllabus: M.Sc. Biomedical ScienceAnujKumarVermaNo ratings yet

- 110820final Combine Brochure With List of ExpertsDocument4 pages110820final Combine Brochure With List of ExpertsAnujKumarVermaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

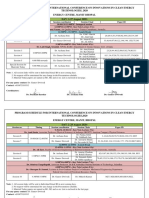

- Program Schedule For International Conference On Innovations in Clean Energy Technologies, 2020 Energy Centre, Manit Bhopal DAY 1 (27 August 2020)Document3 pagesProgram Schedule For International Conference On Innovations in Clean Energy Technologies, 2020 Energy Centre, Manit Bhopal DAY 1 (27 August 2020)AnujKumarVermaNo ratings yet

- Havan,: F - E - 2 ST IDocument3 pagesHavan,: F - E - 2 ST IAnujKumarVermaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- NTHU - Spring 2021 - Application Guideline - v2Document104 pagesNTHU - Spring 2021 - Application Guideline - v2AnujKumarVermaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Winnefeld-2016-Phase Equilibria in The System - (Published Version)Document7 pagesWinnefeld-2016-Phase Equilibria in The System - (Published Version)AnujKumarVermaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Problems in The Cement Industry PDFDocument35 pagesProblems in The Cement Industry PDFAnujKumarVermaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- HARCOURT BUTLER TECHNICAL UNIVERSITY (HBTU) Job 6Document2 pagesHARCOURT BUTLER TECHNICAL UNIVERSITY (HBTU) Job 6AnujKumarVermaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 100820NOTICE For MMVY ScholarshipDocument4 pages100820NOTICE For MMVY ScholarshipAnujKumarVermaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- All Physical & Financial Information of Incubation SchemeDocument24 pagesAll Physical & Financial Information of Incubation SchemeAnujKumarVermaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Program Schedule For International Conference On Innovations in Clean Energy Technologies, 2020 Energy Centre, Manit Bhopal DAY 1 (27 August 2020)Document3 pagesProgram Schedule For International Conference On Innovations in Clean Energy Technologies, 2020 Energy Centre, Manit Bhopal DAY 1 (27 August 2020)AnujKumarVermaNo ratings yet

- White Cane Sugar ProductionDocument16 pagesWhite Cane Sugar ProductionAnujKumarVermaNo ratings yet

- 12 THDocument2 pages12 THAnujKumarVermaNo ratings yet

- ASTM D5954-98 (2014) E1 Standard Test Method For Mercury Sampling and Measurement in Natural Gas by Atomic Absorption SpectrosDocument5 pagesASTM D5954-98 (2014) E1 Standard Test Method For Mercury Sampling and Measurement in Natural Gas by Atomic Absorption SpectrosLuisEduardoRomeroNo ratings yet

- Bio P and D and Implementation J.SinclairDocument6 pagesBio P and D and Implementation J.SinclairJowayne Sinclair100% (1)

- Jsa Jis R 1701-4Document17 pagesJsa Jis R 1701-4farhad pashaeimehrNo ratings yet

- Porg Lec MidtermsDocument37 pagesPorg Lec MidtermsVincent BustamanteNo ratings yet

- Comparative StudiesDocument8 pagesComparative StudiesJames UgbesNo ratings yet

- Bisphenol A Imprinted Polymer Adsorbents With Selective Recognition and Binding CharacteristicsDocument8 pagesBisphenol A Imprinted Polymer Adsorbents With Selective Recognition and Binding CharacteristicsAndrija ĆirićNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Cone Penetrometer For SoilDocument7 pagesCone Penetrometer For SoilOkello StevenNo ratings yet

- Water Adsorption Ion On Mica SurfaceDocument13 pagesWater Adsorption Ion On Mica SurfaceRajdeep GhoshNo ratings yet

- 1 s2.0 S0360319915012975 MainDocument22 pages1 s2.0 S0360319915012975 MainAblaqNo ratings yet

- Metronidazole AssyDocument2 pagesMetronidazole AssysaiNo ratings yet

- SN-QC-SAPP-106 Ebotux 2g InjDocument6 pagesSN-QC-SAPP-106 Ebotux 2g Injdaizhussain004No ratings yet

- Astm D7066Document9 pagesAstm D7066Nawawi Khalimi100% (2)

- 3340 and 3345 Bench Ion MetersDocument5 pages3340 and 3345 Bench Ion MetersAmir MohammedNo ratings yet

- 10.3 Using Materials QPDocument37 pages10.3 Using Materials QPRNo ratings yet

- SRL Catalogue 20 21 Excel Version 27-05-2020Document315 pagesSRL Catalogue 20 21 Excel Version 27-05-2020Vanshika JainNo ratings yet

- Interpreting Mass SpectraDocument7 pagesInterpreting Mass SpectraManzNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Stepanfoam Ri 9912Document2 pagesStepanfoam Ri 9912A MahmoodNo ratings yet

- Functional Propieties of Lupin Seed (Lupinus Mutabilis) Protein... (Sathe Et Al.)Document7 pagesFunctional Propieties of Lupin Seed (Lupinus Mutabilis) Protein... (Sathe Et Al.)Lenna TrujilloNo ratings yet

- Potential of Lemongrass Leaves Extract Cymbopogon Citratus As Prevention For Oil OxidationDocument6 pagesPotential of Lemongrass Leaves Extract Cymbopogon Citratus As Prevention For Oil OxidationAdriana Lucia MerchanNo ratings yet

- Analysis of ToothpasteDocument29 pagesAnalysis of Toothpasteanushka chadha100% (1)

- Lab 5Document2 pagesLab 5Leighton WilliamsNo ratings yet

- 9Document2 pages9Christine TrinidadNo ratings yet

- PHP RFZ KBVDocument11 pagesPHP RFZ KBVpranavmmistry210% (1)

- Biological Tools TechniquesDocument10 pagesBiological Tools Techniquesayushi75086No ratings yet

- 46 PondSetUp PDFDocument0 pages46 PondSetUp PDFBoyko IzoffNo ratings yet

- Adhesive Systems Important Aspects Related To TheiDocument8 pagesAdhesive Systems Important Aspects Related To TheiHachko GiragosyanNo ratings yet

- Melilotus ElegansDocument3 pagesMelilotus ElegansBiniam PaulosNo ratings yet

- Material Data Sheet: Duplex Stainless Steel, Cd4McuDocument3 pagesMaterial Data Sheet: Duplex Stainless Steel, Cd4McufendixNo ratings yet

- 5 - EDTA Titrations 20130815Document12 pages5 - EDTA Titrations 20130815Husna Hafiza Bt. R.AzamiNo ratings yet

- Water 14 02549Document17 pagesWater 14 02549Boris KazoiNo ratings yet

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Piping Engineering Leadership for Process Plant ProjectsFrom EverandPiping Engineering Leadership for Process Plant ProjectsRating: 5 out of 5 stars5/5 (1)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)