Professional Documents

Culture Documents

Us 3233334

Uploaded by

cvkkkk1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 3233334

Uploaded by

cvkkkk1Copyright:

Available Formats

Feb.

8, 1966

w. H. HAMILTON

3,233,334

FLASH DRYING APPARATUS AND METHOD UTILIZING INTERMITTENT

PULSES OF DRYING GAS

Feb. 8, 1966

w.` H. HAMILTON

3,233,334

FLASH DRYING APPARATUS AND METHOD UTILIZING' INTERMITTENT

PULSES OF DRYING GAS

Filed Sept. 28, 1962

2 Sheets-Sheet 2

40

/2

7.2

H7D"I/PVMSEN.'6

.46.80

3.6

2.4

/50

/30

/0

.90

30

70

/2

Q

Q

$507 H9/JM

INVENTOR

WILL/AM H. HAMILTON

ATTORNEY

United States Patent

CC

3,233,334

Patented Feb. 8, 1966

3,233,334

for rehydration whereas the identical product dried in

accordance with the present invention may require only

two to three minutes for rehydration.

William H. Hamilton, Philadelphia, Pa., assigner, by

It is an object of the present invention to provide a

novel vacuum drying apparatus and method.

It is another object of the present invention to pro

vide a novel apparatus and method for ash drying

FLASH DRYING APPARATUS AND METHOD UTI

LlZlNG INTERMITTENT PULSES 0F DRYING

GAS

mesne assignments, to Pennsalt Chemicals Corporation,

Philadelphia, Pa., a corporation of Pennsylvania

Filed Sept. 28, 1962, Ser. No. 226,961

10 Claims. (CI. 34-15)

products.

It is another object of the present invention to provide

a novel apparatus and method which reduces the amount

of shrinkage of the product during the drying process.

It is another object of the present invention to provide

This .application is a continuation-in-part of my co

pending application Serial No. 148,126 filed on October

27, 1961 and entitled Drying Apparatus and Method.

a novel apparatus and method for drying products so

that the products may be rehydrated quicker than those

This invention relates to an apparatus and method for

fiash drying products.

15 products which have been dried in accordance with con

ventional methods.

The most common methods of removing moisture from

products are freeze drying and vacuum drying. The

present invention is a substantial improvement over the

apparatus and methods >used heretofore for vacuum dry

It is another object of the present invention to provide

a novel apparatus and method which substantially reduces

the time cycle for eifecting the drying of a product.

It is another object of the present invention to provide

a novel apparatus and method for drying products faster

with less shrinkage without sacrificing color or avor.

Other objects will appear hereinafter.

ing. Vacuum drying apparatus and methods include the

provision of a means to evacuate a chamber within which

the product is to be disposed and means to apply heat to

the product while the product is subjected to the reduced

pressure. Depending upon the nature of the product

For the purpose of illustrating ' the invention there

is shown in the drawings forms which are presently pre

and the amount of residual moisture desired, the time re

quired to vacuum dry a product generally ranges between

eight and sixteen hours.

The flash drying apparatus and method of the present

invention is a novel departure from the apparatus and

methods proposed heretofore for vacuum drying. In 30

accordance with the present invention, the product to be

dried is periodically and sequentially subjected to hot

gases at atmospheric pressure and an evacuated atmos

phere wherein the moisture is dashed off. Actual com

ferred; it being understood, however, that this invention

is not limited to the precise arrangements and instrumen

talities shown.

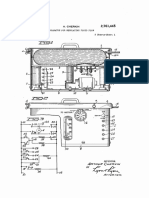

FIGURE 1 is a schematic illustration of the apparatus

of the present invention.

FIGURE 2 is a graph illustrating moisture removed,

pressure and temperature of the product versus drying

time in accordance with the present invention.

FIGURE 3 is a graph similar to FIGURE 2 but illus

parison tests have indicated that the present invention 35 trating the same characteristics as associated with con

ventional apparatus and methods.

reduces the time cycle by more than fifty percent (50%).

FIGURE 4 is a cross sectional view of another em

The reasons why the present invention reduces the time

bodiment of the present invention.

cycle to such an unexpected amount has not been deli

Referring to the drawing in detail, wherein like nu

Vnitely ascertained. However, it is believed that the

substantial decrease in the time cycle results from the 40 merals indicate like elements, there is shown in FIGURE

l a drying apparatus designated generally as 10.

fact that the product is periodically subjected to hot

Theapparatus 10 includes a housing 12 within which

gases at atmospheric pressure thereby enabling heat of

the-product 28 is to be Hash dried. The housing 12 may

the gases to impregnate the voids in the product, such

have one or more shelves 14 adapted to be heated in any

voids being created by prior steps wherein the moisture

was flashed olf. The hot gases are preferably super 45 conventional manner. As illustrated, the shelf 14 is hol

low and will be heated by means of a dowable medium in

heated steam which by its very nature does have some

conduit 16. Conduit 16 is provided with a pump 18

moisture. Other gases which may be utilized include

and a portion of the conduit passes through a heat ex

hot inert gases such as nitrogen or the like. The alter

nating sequence of the steps wherein the product is sub

jected to hot gases at atmospheric pressure and then an

evacuated atmosphere is preferably responsive to the tern

perature of the product.

The products which may be flash dried in accordance

with the present invention include foods such as meats

changer V2).

The temperature of the heat exchanger 20 is regulated

by a controlling uid such as steam which is circulated

theretlnough by means of a conduit containing a steam

generator 21, a pump 22, and a solenoid operated control

valve 24. Suitable automatic temperature responsive con

and vegetables, bones, blood, pharmaceuticals, etc. If

55 trols may be provided to operate the pump 22 and valve

color and flavor are an important factor such as where

2d. As will be made clear hereinafter, use of the shelf

1d as a source of heat is optional and may be used only

the product is food, the product may be subjected to a

tumbling action or otherwise moved during the iiash dry

ing process when the trays for the product are made of

during a portion of the cycle since the temperature of the

product will be primarily increased by introducing a hot

thermally conductive material.

therwise, the product 60 gas into the housing.

The products to be dried are preferably supported

will not have uniform color. Products which have

within the housing 12 by means of a tray 216. Tray 26

been dash dried in accordance with the present invention

is preferably made from a thermally non~conductive mate

have been found to shrink only about ten percent as

rial such as a high temperature lightweight plastic. For

compared to conventional vacuum drying methods where

in the shrinkage of the product is fifty percent (50%) or 65 example, tray 25 may be made of polypropylene. In this

manner, discoloration and overheating of the product are

greater. As a result of this substantially smaller amount

avoided. The tray 26 is spaced from the shelf 14 by

of shrinkage, the products which have been ashd in

means of a wire spacer or the like.

accordance with the present inventionwill rehydrate sub

In order that the operating cycle for the apparatus

of shrinkage, the products which have been ash dried in

and method of the present invention to be responsive to

accordance with conventional methods, for example, a

product which has been dried in accordance with a con

ventional vacuum drying process may require ten minutes

the temperature of the product, at least one of the prod

ucts 2S will have a temperature responsive coil 29 or the

3,233,334

3

like embedded therein and in series with an amplifier 32

and a weight recorder and controller 3Q across the source

of potential 34. The controller 3i) may be provided with

an alarm 36 which may be audible and/or visible. The

alarm 35 is primarily designed to give a signal indicative

of the fact that the product is being overheated thereby

indicating that the apparatus is not functioning properly.

Since the weight of the product is a function of the

amount of moisture therein, and the amount of moisture

therein is indicative of the strength of the signal received 10

The identical product was vacuum dried in accordance

with conventional methods as shown in FIGURE 3 where

in the pressure of the chamber was maintained uniform

at approximately 35 mm. of mercury and the product tem

perature varied between about 32 C. and 55 C.

It will

be noted that the time cycle required approximately

eleven hours to obtain the residual moisture of eleven per

cent. Hence, the time cycle to effect a predetermined

amount of residual moisture is three times as long when

using conventional equipment when compared with the

by the controller 30, a permanent record may be ascer

present invention.

tained 0f the change in weigh-t of the product 2S. The

controller 30 is preferably electrically coupled to a tem

perature recorder and controller 33. Controller 38 will

Notwithstanding the substantial decrease in the length

of `the time cycle, the present invention substantially re

duced the shrinkage of the product. In conventional

methods, the product normally shrinks more than fifty

percent. In accordance with the present invention, the

maintain a permanent record of the temperature of the

product as a function of the strength of the signal received

and will alternatively operate the Valves 42 and 48 as a

product generally has a shrinkage of less than ten percent.

function of the strength of the signal indicative of the pre

determined high and low temperature limits for the prod

Accordingly, the product which has been dried in accord

uct 28.

Valve 42 is in a conduit 4t).

ance lwith the present invention may be rehy-:lrated at a

20 much faster rate.

While a conventionally dried product

may require between eight and ltwelve minutes to be re

One end of conduit 40

communicates with the interior of housing 12.

The other

nydrated, `the present invention enables the identical prod

end of conduit 40 is connected to a source of hot gas 4i.

uct to be rehydrated within three minutes.

Valve 48 is disposed in a conduit 46. One end of conduit

46 is in communication with the interior of housing 12.

standing the decrease inthe period for rehydraticn .and the

time cycle -for effecting a drying of the product, color and

rlhe other end of conduit 46 is coupled to a vacuum

pump 44 which is adapted to evacuate the housing l2.

The operation of the apparatus and method of the

present invention is as follows:

The product to be dried is placed on the tray 26- which

is disposed within the housing 12. Preferably, the prod

L)

Notwith

flavor or" the product has not been sacriced. Uniform

color and llavor may be obtained by tumbling or other

wise agitating the products during the drying cycle when

thermally conductive tray-s are used. Drying -chambers

having apparatus for tumbling the product during the dry

ing cycle is commercially available. Such tumbling ap

uct 28 is comprised of a plurality of small articles of uni

paratus is not necessary if the color of the product is not

form size. The graphs in FIGURES 2 and 3 are based

important. Generally, the color of the product is only

on three-eighths of an inch diced turnip cubes. A tem

impor-tant with those products which are intended to be

perature sensing coil or the like will be embedded in one

' consumed by humans immediately upon rehydration.

or more of the products 28. While the products 28 are

In FIGURE 4, there is illustrated another embodiment

at atmospheric pressure, a-hot gas such as superheated

of `the present invention which is identical with apparatus

steam will be introduced into the chamber to increase the

di) except as will be made clear hereinafter. Hence, like

temperature of the products 2d. As indicated in FIG

elements of apparatus 10 and 10 are provided with primed

URE 2, the temperature of the product was raised up to 40 numerals in FIGUiRE 4. Also, it is not deemed necessary

approximately 80 C. When the products 28 reach this

to illustrate the circuitry of FIGURE 1 in lFIGURE 4

temperature, valve 42 was closed and valve 43 opened in

since the identical circuitry is used.

response to a signal from controller 33.

Apparatus 10' includes a housing 12 which is open

The valves 42 and 4S remain in this position until the

at its top .and bottom. A lid 70 having a handle '7l is

pressure in the housing 12 is reduced down to a pressure

hingedly connected to housing 12 to selectively permit

between the range of approximately 5 to 50 mm. or mer

access into the interior of housing 12. A bottom outlet

cury. As illustrated in FIGURE 2, the pressure was re

door 72 having a handle 74 is hingedly connected to hous

duced to approximately 30 to 40 mm. of mercury. While

ing 12 to selectively permit discharge from housing 12',

the pressure within the housing 12 is being reduced, mois

Perforated plates 7d and '78 of a .thermally non-conductive

ture in the products 2S is being flashed oft, As soon as 50 m-aterial are each juxtaposed to and spaced from one of

the predetermined low level for the pressure within the

the upright .side walls of housing 12 to deline a chamber

housing i2 is reached, the temperature of the products

80 therebetween for receiving the products to be dried.

28 will have decreased to the predetermined low tempera

It will be noted that door 72 constitutes the bottom of

ture cut off point. At this point, valve 48 is closed and

chamber 80 and therefore is made from la thermally non

valve 42 opened in response to a signal from controller 38. 55 conduct-ive material. 'If desired, only the inner face of

As soon as valve 42 is opened, hot gases such as super

door 72 may be provided with a layer of thermally non

heated steam will be introduced into the housing I2 to

conductive material.

Pipe `40 communicates with the space between plate

reheat the products 28 and raise the pressure therein to

78 and the juxtaposed upright wall of housing l2. Pipe

atmospheric pressure. The introduced hot gases impreg

nate the voids in the products 28 created by the removal 60 46 communicates wi-th the space between plate 76 and

the juxtaposed upright wall of housing 12. The upper

of moisture. As soon as the temperature of the product

end of housing '12 may be dared outwardly to facilitate

again reaches the predetermined high temperature of ap

introduction of the product into chamber 80 such as by

proximately 80, the valve 42 is closed and valve 48 is

pouring. At the end of the cycle, door 72 is opened and

opened in response to a signal from controller 3S. The

above process is repeated until the amount of predeter 65 the product is discharged into a hopper, container, or

the like. Apparatus I0 eliminates the necessity for

mined residual moisture in the product is attained. As

separate

discrete trays for each batch of products, elimi

indicated in FIGURE 2, the products 23 reached dryness

nates the heaters such as heated shelf 14, and materially

in a time cycle of four hours. During this time cycle,

reduces handling of the product. Otherwise, apparatus

the product temperature varied between approximately 70 10 operates as described above.

80 C. and 32 C. while the pressure in the chamber

varied between atmospheric pressure and 35 mm. of mer

cury.

As will be evident from FIGURE 2, the above

process was repeated approximately fourteen times during

the three hour drying cycle.

The present invention may be embodied in other spe

cie forms without departing from the spirit or essential

attributes thereof and, accordingly, reference should be

made to the appended claims, rather than to the foregoing

75 specification as indicating the scope of the invention.

3,233,334

high temperature, dashing oli moisture from the product

said control means being coupled to and responsive to

the temperature detecting means so that heating is initiated

when the >product temperature reaches a set minimum

and the subliming step is initiated when the product tem

perature reaches a given maximum.

7. Apparatus in accordance with claim 5 wherein said

by reducing the pressure in the chamber to about 5-50

second means includes a sour-ce of heated inert gas.

I claim:

. A method of drying a frozen product comprising in~

troducing a product into a chamber, heating the product

by introducing a heated gas into said chamber closed to

exit of a gas until the product reaches a predetermined

millimeters of mercury and until the temperature of Ithe

product reaches a predetermined low temperature, then

8. Apparatus in accordance with claim 5 wherein said

until the product contains a predetermined amount of re

sidual moisture.

2. A method in accordance with claim 1 wherein said

gas is at atmospheric pressure when it is introduced into

the chamber.

abling a product t-o be introduced into the chamber, and

selectively movable door means at the bottom of said

housing for enabling a product to ybe removed from said

chamber.

9. Apparatus in accordance with claim S including rst

housing is constructed and arranged in a manner so as to

repeating said steps of heating and flashing in that order 10 have a selectively movable lid means at the top for en

and second upright spaced plates disposed in said housing

3. A method of drying products comprising placing a

and having apertures therethrough, the products to be

plurality of frozen products of substantially uniform size

>dried being disposable on said supporting means 4between

in a chamber, alternatively and sequentially heating the

said plates, said rst plate -being constructed and arranged

products and subliming moisture from the products, said

heating step including heating the products and siinul 20 `with respect to said iirst means in a manner so that the

rst means communicates with that portion of the cham

taneously increasing the pressure in said chamber by

ber ybetween said plates by way of the apertures in said

introducing a heated gas into the chamber until the prod

rst plate, and said second plate being constructed and

ucts reach a predetermined high temperature, said sub

arranged with respect to said second means so that said

liming -step including subliming moisture from the products

second means -communicates with that portion of the

by reducing pressure in the chamber until the temperature

chamber ybetween said plates by way of the apertures in

of the products reaches a predetermined low t mperature,

said second plate.

removing sublimed moisture from said chamber simul

10. A drying apparatus comprising a housing, means

taneously with the step of reducing pressure in the cham

for supporting a product to -be dried within the housing,

ber, then repeating said steps in that order until the

product contains a predetermined amount of residual 30 means for radiantly heating products on said supporting

moisture.

means, means for detecting the temperature of pnoducts

4. A method in accordance with claim 3 including the

step of detecting the temperature of the products and con

ybeing dried, a yrst means including a valved conduit cou

pled to lsaid housing for selectively reducing the pressure

in said housing, a second means including a valved con

trolling the sequence of said steps of heating and sub

liming in response to the desired minimum and maximum 35 duit kfor introducing a hot gas into the housing to heat

said product, circuitry coupling said detecting means to

temperature of the products so that heating is initiated

said valves for alternatively and repetitively placing said

when the product temperature reaches a set minimum

housing in communication with said trst and second

and the subliming step is initiated when the product tem

means -in response to the temperature of the product,

perature reaches a given maximum.

5. A drying apparatus comprising a housing, means 40 whereby products to be dried will be alternatively and

in said housing for supporting a product to be dried within

the housing, means in said housing for heating products

repetitively subjected to increasing and decreasing tem

perature.

to be dnied in the housing, rst means coupled to said

References Cited by the Examiner

UNITED STATES PATENTS

housing for selectively evacuating the housing to decrease

the temperature and pressure within said housing, second

means coupled to said housing for heating a Igas and in

troducing said heated gas int-o the housing to heat the

products to be dried and increase the pressure Within

said housing, said second means being without said hous

ing, and control means for alternatively and repetitively 50

placing the housing, in communication with the first and

second means, whereby products to be dried will `alterna

tively and repetitively be subjected to an atmosphere of in

creased pressure and temperature and then decreased tem

perature and pressure.

6. Apparatus in .accordance with claim 5 including

means for detecting the temperature of the product, and

942,150

1,050,151

1,866,346

2,023,536

12/1909

1/1913

7/1932

>12/1935

Tiemann __________ __ =34---13.4

Loomis __________ __ 'S4-134

Clark ____________ __ 34-15 X

Moore _____________ __ 34-15

2,344,754

3/ 1944 Vang.

2,435,503

2,586,818

2,994,132

3,020,645

2/1948

2/1952

8/1961

2/19'62

Levinson ____________ __ 34-5

Harms ___________ __ 34-10 X

Neuman ____________ __ 34-5

Copson _____________ __ 34--5

ROBERT A. OLEARY, Primary Examiner.

NORMAN YUDKOFF, Examiner.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 47 Instrumentation Interview Questions and AnswersDocument8 pages47 Instrumentation Interview Questions and AnswersKalidass BackNo ratings yet

- Predictive Astro M N KedarDocument388 pagesPredictive Astro M N KedarPrasan Nanda71% (7)

- Elektor PPP 2001.májusDocument11 pagesElektor PPP 2001.májussoyagurt100% (1)

- Case Study: Iim-Indore Pgpmx-Mumbai Team A Mandar Risbud Sanmeet Dhokay Michelle D'Souza Vinod Maliyekal Amit JaitlyDocument23 pagesCase Study: Iim-Indore Pgpmx-Mumbai Team A Mandar Risbud Sanmeet Dhokay Michelle D'Souza Vinod Maliyekal Amit Jaitlypriyam dixitNo ratings yet

- Dry DockDocument10 pagesDry Dockmoonspellanarchy8810100% (1)

- TWT Twta HandbookDocument133 pagesTWT Twta HandbookMudassar RafiqNo ratings yet

- Residual Life Assessment and Failure of The BoilerDocument21 pagesResidual Life Assessment and Failure of The BoilernagasureshNo ratings yet

- Optima MS: Technical ManualDocument112 pagesOptima MS: Technical ManualFrancesco Frizz MengozziNo ratings yet

- Coating Supply Machine PDFDocument26 pagesCoating Supply Machine PDFDeniMestiWidianto100% (1)

- Plazmax Servicio PDFDocument109 pagesPlazmax Servicio PDFLeonel Losada Cardozo0% (1)

- Feb. 8, 1966 L.. H. Smith 3,233,345: Filed July Lí 1964 2 Sheets-Sheet LDocument6 pagesFeb. 8, 1966 L.. H. Smith 3,233,345: Filed July Lí 1964 2 Sheets-Sheet Lcvkkkk1No ratings yet

- United States Patent 1191: Davies Et A1Document4 pagesUnited States Patent 1191: Davies Et A1cvkkkk1No ratings yet

- Sept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1Document5 pagesSept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1cvkkkk1No ratings yet

- Gli55 User ManualDocument126 pagesGli55 User Manualcvkkkk1No ratings yet

- Jlpga S 07Document16 pagesJlpga S 07hopkhtnNo ratings yet

- Design of A Heat Exchanger: K. SHERWIN and M. MAVROMIHALES, School of EngineeringDocument8 pagesDesign of A Heat Exchanger: K. SHERWIN and M. MAVROMIHALES, School of EngineeringGaurav SavaleNo ratings yet

- 20F650Document50 pages20F650Neto GarciaNo ratings yet

- TACO Products 2007 r1Document174 pagesTACO Products 2007 r1yennyoj100% (1)

- D V 5-l C o C: Service ManualDocument44 pagesD V 5-l C o C: Service Manualwillycoyote1990-1No ratings yet

- Wall Mounted Bed Head UnitDocument2 pagesWall Mounted Bed Head UnitTauhid RahmanNo ratings yet

- Ac MatlsDocument16 pagesAc MatlsEugene M. VillegasNo ratings yet

- Chapter-3-Lesson-1-Information AgeDocument58 pagesChapter-3-Lesson-1-Information AgeEfrilMae AljasNo ratings yet

- MEC322 Chapter 1Document47 pagesMEC322 Chapter 1HaFiy HaZimNo ratings yet

- The First Fully-Digital C-Arm. 21 Century Mobile X-Ray ImagingDocument9 pagesThe First Fully-Digital C-Arm. 21 Century Mobile X-Ray Imagingاحمد زغارىNo ratings yet

- Cold Shrink Technology For CablesDocument8 pagesCold Shrink Technology For Cablesnitin369No ratings yet

- FMDS0603Document24 pagesFMDS0603Alex AlmeidaNo ratings yet

- Wireless World 1946 06Document76 pagesWireless World 1946 06Matheus OliveiraNo ratings yet

- Structure of Atom For Class 9 Solved Summative AssesmentDocument23 pagesStructure of Atom For Class 9 Solved Summative AssesmentSabu VincentNo ratings yet

- 38CKC 8PDDocument36 pages38CKC 8PDjean_carlos_abreu_rNo ratings yet

- LG 50pt250na-Pd13kDocument72 pagesLG 50pt250na-Pd13kCarlos AzañedoNo ratings yet

- eALOM Chemistry Practical HandbookDocument148 pageseALOM Chemistry Practical HandbookElizabeth GeorgeNo ratings yet

- Effective Layouts - Superior Radiant ProductsDocument6 pagesEffective Layouts - Superior Radiant ProductsAllan GomezNo ratings yet

- A Novel Parabolic Trough Solar Collector Model - Validation With Experimental Data and Comparison To Engineering Equation Solver (EES) (2015)Document14 pagesA Novel Parabolic Trough Solar Collector Model - Validation With Experimental Data and Comparison To Engineering Equation Solver (EES) (2015)AnikilatorBoy100% (1)

- Bluebox Tetris - 2 80-900Document50 pagesBluebox Tetris - 2 80-900Montassar BouslamaNo ratings yet

- NRGT 26-1 NRGT 26-1S For Marine Applications: Level MonitoringDocument3 pagesNRGT 26-1 NRGT 26-1S For Marine Applications: Level MonitoringNgũ Văn SỹNo ratings yet