Professional Documents

Culture Documents

PGT001 In-Line Filter Training

Uploaded by

Jom BonhayagOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PGT001 In-Line Filter Training

Uploaded by

Jom BonhayagCopyright:

Available Formats

General Training Pty Ltd

Know More In An Hour!

Web Site: www.lifetime-reliability.com

The Purpose, Use and Care of In-line Liquid Filters.

Training For Operators, Maintainers, Technicians and Engineers.

Objective

This training teaches users and maintainers of in-line process liquid filters why they are used, how

they work, what causes them to go wrong and what is necessary to keep them operating properly all

the time, every time.

Training Contents

Purpose of the equipment.

The principles of how the equipment works.

Important parts and assemblies.

In-service design and operation.

How the equipment achieves its purpose and the necessary operating conditions.

Most likely failure modes, their causes and what to do about them.

On-Site, workshop or test bench observations of an equipment installation.

Compare the installation to the minimum design required.

Conduct site tests and trails on the equipment operation.

o Predict effect of changes.

o Observe actual changes.

o Identify impact of changes to the equipment operation.

Learning Assessment

o Explain purpose and use of equipment.

o Identify how the equipment achieves its purpose.

o Specify the required operating conditions for proper performance.

o List what failures are possible at the workplace and how to fix them.

o Training Supervisor review.

Outcomes of the Training

This training will make the trainee clear and knowledgeable in the proper use, care and maintenance

of in-line liquid filters. It will give them in-depth knowledge of the equipment and the factors that

affect its operation. They will use the new know-how to better operate, care-for and maintain such

equipment in future.

Time Required

The training takes one hour to complete for able people with some industry experience.

Page 1 of 9

General Training Pty Ltd

Know More In An Hour!

Web Site: www.lifetime-reliability.com

Training in the Purpose, Use and Care of In-line Liquid Filters

Purpose of Equipment

In-line liquid filters are used to trap and remove small particles of solid or soft matter from a liquid

stream. Typically a fine porous membrane or filament cartridge catches and holds the material

while letting the liquid through.

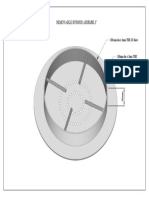

Figure 1 shows in-line filters and the typical range of filter media or filter elements placed inside

them to trap and remove fine particles from the liquid.

Figure 1 In-line Filter Housings

Filter Bags

Filter Cartridges Types

How the Equipment Works

The fabric or cartridges used in the filter have fine perforations, holes or channels in them. The

holes or channels are sized to stop particles of a larger size. The dirt or contaminant is retained on

the upstream side of the fibre or fabric element and the cleaned liquid passes through. The trapped

material builds up the surface. As the contamination material thickens it becomes a filtering screen

itself and acts to remove more and more finer material.

The method is known as surface filtration. It is the way a coffee plunger

works to separate the fine coffee grounds from the coffee liquid. The

plunger screen is coated by the first grounds that contact it. As the plunger

moves further more grounds layer over the first layer. The thicker the

layer, the harder it becomes to push the plunger.

Figure 2 shows a filter membrane collecting material on the upstream side

of the fabric while letting cleaned product through the pores. Figure 3

shows a magnified image of a filter membrane. Notice the passage ways

through the membrane twist and turn to catch and trap material.

Figure 2 Porous Filter Medium

Figure 3

Filter Membrane Pores

Page 2 of 9

General Training Pty Ltd

Know More In An Hour!

Web Site: www.lifetime-reliability.com

With continued use the unwanted material in the liquid flow builds-up and thickens on the

membrane surface. As the build-up gets thicker it gradually blocks-off the flow channels for the

liquid and less liquid passes through. To maintain the same flow through the gradually thickening

material build-up or cake requires more supply pressure. Eventually the cake becomes so thick

and dense that no matter how high the supply pressure, little flow occurs across the cake and

element.

The material build-up or cake must eventually be cleaned off so that the filter surface is again

clean. Figure 4 is a diagram of what happens to the liquid pressure and flow as the contaminant

material builds-up on the filter.

At the start, with a clean filter membrane, there is a rush of filtered liquid (the light blue area in

Figure 4). The surface of the membrane starts to build-up cake of contaminant matter (the yellow

area in Figure 4). Gradually, with continued use, the cake thickens and becomes interwoven and

compacted on the membrane. Some matter may even find its way into the membrane pores and

block them. Eventually the cake chokes the liquid flow off and a back-pressure will develop upstream of the filter (the dark blue line in Figure 4).

Filtered

Liquid

Material

build-up

Backpressure

Figure 4

Effects of Material Build-up on Back Pressure and Liquid Flow Through a Filter

When placed into a pipeline or process stream it is necessary to know if the filter is blocking. Since

the material blocking the pores causes a back-pressure in the liquid we can monitor the pressure and

see the effectiveness of the filter. By measuring the pressure change from clean to blocked

surface it is possible to watch the material build-up. Once the back-pressure is too much the filter

must be opened and cleaned or replaced.

Important Parts and Assemblies

For a filter the important parts are the housing, filter media and the seal between the filter element

and housing. The housing, seal and the filter medium need to be corrosion resistant to the liquid

and its impurities. The seal between housing and filter must to be impassable to the liquid being

filtered, otherwise the fine particles in the liquid by-pass and are not removed. If this happens the

filtered liquid becomes contaminated. Figure 5 shows the construction and fine pores in typical

filter membranes and cartridges.

Page 3 of 9

General Training Pty Ltd

Know More In An Hour!

Web Site: www.lifetime-reliability.com

Figure 5

Filter Membrane Element Section Cross-Sections

In-Service Design and Operation

Figure 6 shows how a filter is set-up in a process circuit. Included is all the necessary equipment to

insure the filter operates correctly and to permit its operation to be monitored.

Inlet

Pressure

Gauge

Inlet

Isolation

Valve

Outlet

Pressure

Gauge

Air

Vent

Filter

Housing

Outlet

Isolation

Valve

Drain

Figure 6 Minimum Filter Station and Strainer Design

Liquid enters from up-stream through the inlet valve. The upstream pressure is shown on the inlet

pressure gauge. In situations where air, gas or vapour can be trapped at the top of the filter housing

they are vented to a safe place. The liquid enters the housing and flows through the filter media.

The media traps contamination larger than the rated pore size. The clean liquid continues through

to the outlet. The outlet pressure is registered on the outlet pressure gauge.

Figure 7 show the two possible flow directions through a depending on purpose and design.

Filter

Membrane

Housing

Figure 7 Liquid Flow Down Through Screen

Liquid Flow Up Through Screen

Page 4 of 9

General Training Pty Ltd

Know More In An Hour!

Web Site: www.lifetime-reliability.com

How The Equipment Achieves Its Purpose And The Necessary Operating Conditions.

Look at first the filter station design. Liquid and contaminating particles flow under pressure to the

filter. The inlet pressure gauge shows the upstream, in-coming pressure. The outlet pressure gauge

shows the liquid pressure after passing through the filter. The outlet pressure is less than the inlet

pressure because the filter screen traps the contaminating particles and builds a cake. The

presence of the thickening cake blocks flow and creates a back-pressure. The rising back-pressure

acts to push the liquid through the built-up material and screen.

Look at the filter station drawing in Figure 8 below. Notice that the upstream pressure has risen and

the downstream pressure has fallen. The screen build-up is becoming very thick and blocking flow.

It needs to be cleaned away. It is time to de-pressurise and drain the filter. It will be necessary to

remove and clean, or replace, the membrane element to return the filter back to a clean operating

condition.

Inlet

Isolation

Valve

Filter

Housing

Outlet

Isolation

Valve

Lid O-ring Seal

Drain

Figure 8

Filter After Use

Figure 9

Filter Lid and Seal

Factors Affecting In-Line Filter Operation

There are several key factors that must be confirmed to insure successful in-line filter operation.

Pore hole size determines the size of particles that will pass through the screen and those which

will not. The pores in the filter fabric must not be so large that the filter weave prevents the

sediment bed, the cake, developing.

Filter cake thickness should develop evenly across the screen. Fortunately the nature of

creating a cake means that any preferential flow in one area builds the bed up with particulate

until the pressure is even with the rest of the bed. Provided the contaminant size is evenly

distributed in the flow stream the cake should filter equally everywhere.

Low flow velocity through the filter is needed so as to not disturb the filter cake and move it

off the membrane. This requires sufficient surface area of membrane to create the right liquid

velocities. It also means that the filter should be sized to permit a long run between cleans, else

it will require frequent, annoying cleaning.

Process chemical attack of the screen material is prevented by proper selection of fabric of

sufficient thickness to also provide the necessary mechanical strength to take the forces that

develop as the back-pressure increases during the filtration run.

Page 5 of 9

General Training Pty Ltd

Know More In An Hour!

Web Site: www.lifetime-reliability.com

Sufficient pressure is needed to force the material against the membrane and still push the

liquid through the cake and membrane. That means as the cake thickens the upstream pressure

must rise to push the liquid through the cake bed. Usually the pump speed is increased to boost

the supply pressure.

Small particulate size in the cake blocks liquid flow. Smaller than average size particle act to

seal the pathways for the liquid to flow around the larger particles.

Possible Failure Modes Causes, Prevention and Corrective Actions

Problems with Filter Membranes, Elements and Housings

Screen or fabric blinding occurs when the smaller particles to be filtered get caught in the

screen itself and block the pores. This introduces a solid obstruction to the flow. If enough

pores are blocked the flow falls and back-pressure builds quickly. If this occurs it may be

necessary to change screen or membrane design, or the shape of the pores.

Screen or fabric rupture can be a result of fair wear-and-tear over a long period of time. It

could also be the result of high local velocities across the screen; large solids impacting the

screen, water hammer pressure surges, excessively high differential pressure across the

membrane or chemical attack.

Poor fabrication or assembly of the membrane onto the frame. Do not cut or damage the filter

membranes when installing them in the housing. Replace damaged cartridges or membranes.

They must seal into the housing so that the flow cannot pass between the seal between element

and frame.

Improper cleaning of the screen due to blinding or old sediment build-up. If necessary repeat

the cleaning sequence to try and dislodge the cake. Chemical cleaning can be used if safe to do

so or use hot liquid flushing in an attempt to soften the built-up. Mechanical cleaning with water

jetting may remove surface build-up. Ultrasonic cleaning may remove deeply imbedded

materials.

Silted filtrate from the filter can be a sign of element rupture or contaminant break-through. If

sediment has got past the filter it will end up downstream and possibly ruin the product. Monitor

the pressure gauges at the filter station and change or clean the filter when the upstream

backpressure gets high. If the down stream pressure is unexpectedly near to the up-stream

pressure it a good sign that the screen has failed and needs to be replaced.

Secondary filters should be used downstream of the primary filter if it absolutely critical that

the product is not contaminated. Without a second filter there will be occasional times that the

membrane fails, or the filter will be incorrectly assembled, and contaminants will get past.

Filter lids seals must close leak-free to stop escape of product. The lid seal can become

compressed and not retain its shape with constant use. The seal material may deteriorate with

time and use and start to leak. The seal can be accidentally damaged. Inspect the seal and

replace it with a new one at regular intervals before it starts to leak. Insure the seal sits snugly in

its required position when closing the lid and does not move during the tightening down process.

Page 6 of 9

General Training Pty Ltd

Know More In An Hour!

Web Site: www.lifetime-reliability.com

On-Site Test, Workshop or Lab Test of an Installation and Learning Assessment

It is now time to do some hands-on training in the field, or with a spare, or on the test-bench. To

thoroughly understand this topic it is best to see what happens in a working situation and practice

by making and controlling changes. You will better understand what the equipment does, and how

to run it well, if you can operate it. Locate suitable equipment in your plant that you will be

allowed to adjust and inspect.

1. Locate the manufactures operating manual if available or find it on-line over the Internet. Take

the time to read it. Tag anything you dont understand and come back to it at the end of the

training to see if you come to know what they mean.

2. Hand-sketch below the equipment installation at your workplace and write the name of the

individual equipment items on the sketch.

3. Internal Inspection

3.1. Once it is safe to do so, open a filter and look inside. Name and describe below each equipment

part of the filter. The manufacturers manual and parts list can help you.

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

3.2. Remove a membrane or cartridge element and write a short description of its surface condition,

its component parts and how it is built.

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

3.3. Describe how to install the filter element into the housing and get a perfect, no-leak seal in your

installation. Describe how to insure the lid seals liquid tight on your equipment.

Page 7 of 9

General Training Pty Ltd

Know More In An Hour!

Web Site: www.lifetime-reliability.com

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

4. If at all possible, and once you have supervisor permission, operate the equipment to see what

effects happen as the operating conditions change. If you cannot operate a real item of

equipment then describe as best you can what will happen to the process due to the change.

4.1. Clean Membrane, Start-Up Conditions.

Starting with a clean filter, record the pressures upstream and downstream of the filter and

calculate the difference.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

4.2. Effect of Cake Build-up.

Describe what increasing cake build-up on the filter membrane or cartridge will do to the

upstream pressure? You can mimic the effect by gradually closing the outlet valve.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

4.3. Pressure Difference with Cake Build-up.

If there was a cake build-up on a particular in-line filter at your workplace, note below at what

pressure difference you would have to act to clean to replace the filter. How much is the change

in backpressure values between the clean condition and the blocked condition? If necessary ask

an experienced operator or see the operating manual.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

5. Describe Below How an In-Line Filter Works to Provide Clean Filtrate.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

Page 8 of 9

General Training Pty Ltd

Know More In An Hour!

Web Site: www.lifetime-reliability.com

_____________________________________________________________________________

_____________________________________________________________________________

6. Possible Modes of Failure

6.1. List the Ways That In-line Filters Have Failed to Perform Properly at Your Workplace. Talk to

the experienced operators and maintainers if necessary.

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

6.2. Getting the Equipment Back to Proper Operation.

For each failure mode listed above, describe in detail what needs to be done to correct them.

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

This is the end of this training. Please record the following details and hand your answers back to

the supervisor in charge of this training.

Trainee ________________________________ Signature _____________________________

(Print Name)

(Trainee)

Supervisor ______________________________ Signature ____________________________

(Print Name)

(Supervisor)

Assessment Result:

Pass

Repeat

Completion Date ___________________ Pass recorded in the Trainees training records

Page 9 of 9

You might also like

- Home Brewing Log Sheet PDFDocument2 pagesHome Brewing Log Sheet PDFStefanita0% (1)

- 9600 DocumentDocument174 pages9600 Documentthom38% (13)

- Leaf Filter Experimental ManualDocument12 pagesLeaf Filter Experimental ManualShoaib Pathan67% (3)

- Assignment (Plate and Frame Filter Press) Group A-8)Document22 pagesAssignment (Plate and Frame Filter Press) Group A-8)Sajjad Rasool Chaudhry0% (4)

- Lecture Filtration 1Document20 pagesLecture Filtration 1LeeGonzaLgo0% (2)

- Plate and Frame FiltrationDocument30 pagesPlate and Frame FiltrationRays Shearer100% (2)

- Field Book for Quality Control in Earthwork Operations: Project Construction Management BookFrom EverandField Book for Quality Control in Earthwork Operations: Project Construction Management BookNo ratings yet

- The Templist Scroll by :dr. Lawiy-Zodok (C) (R) TMDocument144 pagesThe Templist Scroll by :dr. Lawiy-Zodok (C) (R) TM:Lawiy-Zodok:Shamu:-El100% (5)

- (Razavi) Design of Analog Cmos Integrated CircuitsDocument21 pages(Razavi) Design of Analog Cmos Integrated CircuitsNiveditha Nivi100% (1)

- MOTTCORP - Chemical Processing - Versatility of The Multimode Porous Metal Filter in Optimizing Solids-Liquids Filtration PerformanceDocument12 pagesMOTTCORP - Chemical Processing - Versatility of The Multimode Porous Metal Filter in Optimizing Solids-Liquids Filtration PerformanceDragoslav DzolicNo ratings yet

- Unit 24: Applications of Pneumatics and HydraulicsDocument11 pagesUnit 24: Applications of Pneumatics and HydraulicsEmad ElsaidNo ratings yet

- Selection of FiltrationDocument4 pagesSelection of FiltrationAlvaro McdowellNo ratings yet

- Absolute Rating vs. Nominal Rating For FiltersDocument3 pagesAbsolute Rating vs. Nominal Rating For FiltersMukesh KangutkarNo ratings yet

- Lab Manual Separation Tech Jan 2021Document43 pagesLab Manual Separation Tech Jan 2021Abdul QayyumNo ratings yet

- Intro to FiltrationDocument3 pagesIntro to FiltrationRifka AisyahNo ratings yet

- FiltrationDocument77 pagesFiltrationmeet2abhayNo ratings yet

- Lab Manual Separation Tech Jan 2020Document48 pagesLab Manual Separation Tech Jan 2020nisasoberi0% (1)

- Experiment 4 Plate and Frame FiltrationDocument22 pagesExperiment 4 Plate and Frame FiltrationMadel Isidro100% (1)

- FiltrationDocument15 pagesFiltrationDominador Velasco jr100% (2)

- Duhok Polytechnic University: Unit Operation Laboratory of Unit OperationDocument7 pagesDuhok Polytechnic University: Unit Operation Laboratory of Unit OperationMUHAMMAD AKRAMNo ratings yet

- FILTRATION PROCESS GUIDE: FACTORS, TYPES, MEDIADocument41 pagesFILTRATION PROCESS GUIDE: FACTORS, TYPES, MEDIAKonesi RonaldNo ratings yet

- Filtration Process TypesDocument12 pagesFiltration Process Typesএম.এ লতিফNo ratings yet

- "Type of Filter and Its Applications in Detail": G H Patel College of Engineering &technologyDocument11 pages"Type of Filter and Its Applications in Detail": G H Patel College of Engineering &technologyManav PatelNo ratings yet

- Juice Extraction and Filtration: Course: Dairy and Food EngineeringDocument7 pagesJuice Extraction and Filtration: Course: Dairy and Food EngineeringAditya Shrivastava100% (1)

- Troubleshooting Filter Aids and Filtration SystemsDocument3 pagesTroubleshooting Filter Aids and Filtration SystemsRahul ChandrawarNo ratings yet

- Jose Sentmanat Filter NewsDocument8 pagesJose Sentmanat Filter NewsLeandro ChSanzNo ratings yet

- Filter Element Design FeaturesDocument10 pagesFilter Element Design Featuresman_iphNo ratings yet

- Filtration Techniques GuideDocument5 pagesFiltration Techniques GuideFamiloni LayoNo ratings yet

- Materi GravitasiDocument51 pagesMateri GravitasiImam Khoirul FajriNo ratings yet

- Filter Aid FiltrationDocument8 pagesFilter Aid FiltrationcatalinvsuNo ratings yet

- Lab Manual Separation Tech February 2023Document41 pagesLab Manual Separation Tech February 2023Nurhanis DayanaNo ratings yet

- Plate and Frame FiltrationDocument11 pagesPlate and Frame FiltrationQuenneBelocuraNo ratings yet

- Addressing Three Compressed Air Quality Problems Found in PneumaticsDocument4 pagesAddressing Three Compressed Air Quality Problems Found in PneumaticsYash DiabloNo ratings yet

- FiltersDocument11 pagesFiltersRegarz ArrowNo ratings yet

- Dust Collection MaintenanceDocument21 pagesDust Collection MaintenanceLinus RidgeNo ratings yet

- Filtration Tests: Test ProcedureDocument4 pagesFiltration Tests: Test ProcedureAbdulHameed H. AlalwanNo ratings yet

- What Is Filter, Types, Cleaning and Maintenance at Ship: Posted by Categories DateDocument8 pagesWhat Is Filter, Types, Cleaning and Maintenance at Ship: Posted by Categories DateKurupath SidharthanNo ratings yet

- Filter Press Manual for Process & PackagingDocument70 pagesFilter Press Manual for Process & PackagingNicholas Suominen100% (1)

- FiltrationDocument9 pagesFiltrationyosifNo ratings yet

- Drilling Lab Experiment on Mud Cake Thickness and Water LossDocument7 pagesDrilling Lab Experiment on Mud Cake Thickness and Water LossAbdullwahid AhmedNo ratings yet

- Filtration EquipmentDocument8 pagesFiltration EquipmentSam MalikNo ratings yet

- Principle Involved in Filtration, Types, Rates of Filtration, Pressure Drop CalculationsDocument3 pagesPrinciple Involved in Filtration, Types, Rates of Filtration, Pressure Drop CalculationsMonty KushwahaNo ratings yet

- Filtration & Centrifugation: Module-26: Fermentation Product Recovery and Purification-IIDocument13 pagesFiltration & Centrifugation: Module-26: Fermentation Product Recovery and Purification-IIHadi. MNo ratings yet

- The Basics of Hydraulic FiltrationDocument3 pagesThe Basics of Hydraulic Filtrationbee1406763181No ratings yet

- EXPERIMENT 3 Objective and IntroDocument1 pageEXPERIMENT 3 Objective and IntroLee Xiang FengNo ratings yet

- Application Note: Best Practices For Successful Filter Integrity Testing Using The Water Intrusion Test (WIT) MethodDocument8 pagesApplication Note: Best Practices For Successful Filter Integrity Testing Using The Water Intrusion Test (WIT) MethodSlavaNo ratings yet

- Plate and Frame Filtration FinalDocument18 pagesPlate and Frame Filtration FinalkprabhakarrNo ratings yet

- Breakaway Flush: Air Scouring and Cleaning For Filters and MediaDocument12 pagesBreakaway Flush: Air Scouring and Cleaning For Filters and MediaAbhishek BaneNo ratings yet

- FILTRATIONDocument4 pagesFILTRATIONFatima AminNo ratings yet

- 2010, Engineering Review, Keeping The Hydraulic System HealthyDocument3 pages2010, Engineering Review, Keeping The Hydraulic System HealthyVelibor KaranovićNo ratings yet

- Filtration Techniques for Separating Liquids and SolidsDocument18 pagesFiltration Techniques for Separating Liquids and SolidsPooja Choudhary100% (1)

- Operator's Manual For BAG FilterDocument3 pagesOperator's Manual For BAG Filterprateek_bhoir100% (1)

- Precoating: Precoating or Body-MixDocument52 pagesPrecoating: Precoating or Body-MixsreenuNo ratings yet

- Cleaning guidelines for forming fabricsDocument10 pagesCleaning guidelines for forming fabricsMr. JahirNo ratings yet

- FiltarationDocument22 pagesFiltarationAvinash GarikapatiNo ratings yet

- تقرير fiterationDocument7 pagesتقرير fiterationمحمود محمدNo ratings yet

- تقرير fiteration PDFDocument7 pagesتقرير fiteration PDFسراء حيدر كاظمNo ratings yet

- Check List:: With Increased Local and Global Attention Being Given To The Control of AirDocument5 pagesCheck List:: With Increased Local and Global Attention Being Given To The Control of Airskc3128No ratings yet

- Filtration PDFDocument34 pagesFiltration PDFmusuka gabrielNo ratings yet

- CLEANING MEMBRANES EARLY IMPROVES PLANT PERFORMANCEDocument11 pagesCLEANING MEMBRANES EARLY IMPROVES PLANT PERFORMANCENaim HossainNo ratings yet

- Chapter Eight Mechanical SeparationDocument38 pagesChapter Eight Mechanical Separationzekariyas kuneNo ratings yet

- Interacademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.From EverandInteracademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.No ratings yet

- Content: SKF Spindle Assessment Quick Start User GuideDocument10 pagesContent: SKF Spindle Assessment Quick Start User GuideJom BonhayagNo ratings yet

- FAULT NATURE DIAGNOSIS CHECKLISTDocument1 pageFAULT NATURE DIAGNOSIS CHECKLISTJom BonhayagNo ratings yet

- Coupling AlignmentDocument14 pagesCoupling Alignmentkutts76No ratings yet

- Basic Ac PowerDocument24 pagesBasic Ac PowerJom BonhayagNo ratings yet

- Position Title: NDT TechnicianDocument1 pagePosition Title: NDT TechnicianJom BonhayagNo ratings yet

- Plumbing ReviewerDocument1 pagePlumbing ReviewerJom BonhayagNo ratings yet

- HeatDocument10 pagesHeatJom BonhayagNo ratings yet

- Carina Model Renovation-Jm VallejoDocument1 pageCarina Model Renovation-Jm VallejoJom BonhayagNo ratings yet

- Removable Burner Assembly: 200 MM Dia X 2mm THK GI SheetDocument1 pageRemovable Burner Assembly: 200 MM Dia X 2mm THK GI SheetJom BonhayagNo ratings yet

- Power Plant Performance NotesDocument2 pagesPower Plant Performance NotesJom BonhayagNo ratings yet

- ASME PTC Performance Test Codes GuideDocument3 pagesASME PTC Performance Test Codes GuideVijayakumar SengottuveluNo ratings yet

- Tut DW HTML PDFDocument41 pagesTut DW HTML PDFJom BonhayagNo ratings yet

- Pump Selection Condensate Pump: Deaerator Pressure With 10% Allowance Assuming Piping Pressure DropDocument3 pagesPump Selection Condensate Pump: Deaerator Pressure With 10% Allowance Assuming Piping Pressure DropJom BonhayagNo ratings yet

- Chapters IntroDocument10 pagesChapters IntroJom BonhayagNo ratings yet

- 99 104Document1 page99 104Jom BonhayagNo ratings yet

- Company Logo: ME 198: Industrial Plant EngineeringDocument1 pageCompany Logo: ME 198: Industrial Plant EngineeringJom BonhayagNo ratings yet

- MSS SP-6 (2001)Document6 pagesMSS SP-6 (2001)Vijay KumarNo ratings yet

- DPWH Do 056 S2005Document20 pagesDPWH Do 056 S2005B R Paul FortinNo ratings yet

- Tech Sheet 128Document1 pageTech Sheet 128Sriram RamanujamNo ratings yet

- AmrDocument5 pagesAmrJom BonhayagNo ratings yet

- Master of EngineeringDocument17 pagesMaster of EngineeringMatt Bash XymNo ratings yet

- Master of Science in Mechanical EngineeringDocument9 pagesMaster of Science in Mechanical EngineeringJom Bonhayag100% (1)

- DPWH Do 056 S2005Document20 pagesDPWH Do 056 S2005B R Paul FortinNo ratings yet

- Application Form CSHprogramDocument6 pagesApplication Form CSHprogramJom Bonhayag100% (2)

- Plant Wellness Letter LRS GlobalDocument3 pagesPlant Wellness Letter LRS GlobalJom BonhayagNo ratings yet

- COL FormDocument7 pagesCOL FormelminvaldezNo ratings yet

- Comprehensive CSHPDocument15 pagesComprehensive CSHPMak ArthurNo ratings yet

- How To Use Online Trading FacilityDocument18 pagesHow To Use Online Trading FacilityJom BonhayagNo ratings yet

- Bidding Guidelines For Procurement of PowerDocument20 pagesBidding Guidelines For Procurement of PowerkannanNo ratings yet

- DP MainDocument1 pageDP MainprabhuarunkumarNo ratings yet

- Artifact and Thingamy by David MitchellDocument8 pagesArtifact and Thingamy by David MitchellPedro PriorNo ratings yet

- B. Pharmacy 2nd Year Subjects Syllabus PDF B Pharm Second Year 3 4 Semester PDF DOWNLOADDocument25 pagesB. Pharmacy 2nd Year Subjects Syllabus PDF B Pharm Second Year 3 4 Semester PDF DOWNLOADarshad alamNo ratings yet

- Clean Milk ProductionDocument19 pagesClean Milk ProductionMohammad Ashraf Paul100% (3)

- Placenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MDocument40 pagesPlacenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MMikes CastroNo ratings yet

- Helmitin R 14030Document3 pagesHelmitin R 14030katie.snapeNo ratings yet

- CP 343-1Document23 pagesCP 343-1Yahya AdamNo ratings yet

- SB Z Audio2Document2 pagesSB Z Audio2api-151773256No ratings yet

- OpenROV Digital I/O and Analog Channels GuideDocument8 pagesOpenROV Digital I/O and Analog Channels GuidehbaocrNo ratings yet

- EP - EngineDocument4 pagesEP - EngineAkhmad HasimNo ratings yet

- Evolutionary PsychologyDocument10 pagesEvolutionary PsychologyShreya MadheswaranNo ratings yet

- DK Children Nature S Deadliest Creatures Visual Encyclopedia PDFDocument210 pagesDK Children Nature S Deadliest Creatures Visual Encyclopedia PDFThu Hà100% (6)

- Hyperbaric WeldingDocument17 pagesHyperbaric WeldingRam KasturiNo ratings yet

- Are Hypomineralized Primary Molars and Canines Associated With Molar-Incisor HypomineralizationDocument5 pagesAre Hypomineralized Primary Molars and Canines Associated With Molar-Incisor HypomineralizationDr Chevyndra100% (1)

- European GMP Annex 1 - 2008 Edition - 'Pmeasuring'Document3 pagesEuropean GMP Annex 1 - 2008 Edition - 'Pmeasuring'Khairul AnwarNo ratings yet

- Organizing Small Items with Glass Bottle OrganizersDocument70 pagesOrganizing Small Items with Glass Bottle OrganizersDy SaiNo ratings yet

- Acuity Assessment in Obstetrical TriageDocument9 pagesAcuity Assessment in Obstetrical TriageFikriNo ratings yet

- Apollo TyresDocument78 pagesApollo TyresADITYA33% (3)

- GLOBAL Hydro Turbine Folder enDocument4 pagesGLOBAL Hydro Turbine Folder enGogyNo ratings yet

- O2 Orthodontic Lab Catalog PDFDocument20 pagesO2 Orthodontic Lab Catalog PDFplayer osamaNo ratings yet

- Phenomenological of in Church and TV WorshipDocument18 pagesPhenomenological of in Church and TV WorshipCindy TirtaNo ratings yet

- Fraktur Dentoalevolar (Yayun)Document22 pagesFraktur Dentoalevolar (Yayun)Gea RahmatNo ratings yet

- Asian Paints Tile Grout Cement BasedDocument2 pagesAsian Paints Tile Grout Cement Basedgirish sundarNo ratings yet

- Guidance Notes Blow Out PreventerDocument6 pagesGuidance Notes Blow Out PreventerasadqhseNo ratings yet

- Laser Surface Treatment ProcessesDocument63 pagesLaser Surface Treatment ProcessesDIPAK VINAYAK SHIRBHATENo ratings yet

- CAE The Most Comprehensive and Easy-To-Use Ultrasound SimulatorDocument2 pagesCAE The Most Comprehensive and Easy-To-Use Ultrasound Simulatorjfrías_2No ratings yet

- ADIET Digital Image Processing Question BankDocument7 pagesADIET Digital Image Processing Question BankAdarshNo ratings yet