Professional Documents

Culture Documents

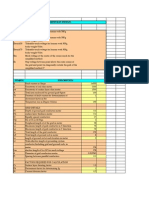

SEO-Optimized Title for Power Plant Layout Map

Uploaded by

jacs127Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEO-Optimized Title for Power Plant Layout Map

Uploaded by

jacs127Copyright:

Available Formats

8

R

U

P

N

A

K

(T

3400 N

58

SCALE

SPEED CALM

17.30 Hrs

1

3300 N

3300 N

3200 N

11

19

>19 Km/hr

LIST OF BUILDINGS & STRUCTURES

SR.NO.

3200 N

58

DESCRIPTION.

TG. BUILDING

STEAM GENERATOR

ESP

ESP CONTROL ROOM

CHIMNEY

TRANSFORMER YARD AREA

765kV/400kV/132kV SWITCHYARD & CONTROL ROOM

3100 N

R

/K

A

N

ha

ta

mp

ur

58

3000 N

IR

P

U

To

G

3000 N

P

U

3100 N

A

M

TOWNSHIP

2900 N

58

2800 N

G

EXISTING NALLAH

2700 N

58

2500 N

2400 N

2400 N

C

H

R

=

4

5

0

m

2500 N

2200 N

2100 N

56

2000 N

ASH POND

MAKEUP WATER FROM

RIVER WATER SYSTEM

1800 N

E

N

OV

ER UPP

RA L

PH IL

BR

-I

I

ID

G

1400 N

35

0

RAW WATER RESERVOIR

R=

58

1770.0M (W)

HW

BAFFLE

AY

1100 N

58

d

n

o

P

d

n

o

P

1000 N

V

l

au

dh

id

S

ge

la

il

e

g

a

ill

V

RAW WATER RESERVOIR

900 N

800 N

d

n

o

P

COMPARTMENT-II

m

ri

Pr

P

-N

0

0

6

2

7

8

2

800 N

54

58

PE

I

LYP

UPP

ER S

WAT

RAW

a

ri

a

g

a

B

1200 N

1100 N

1000 N

900 N

1300 N

y

ar

ly

R

LLA

NA

ng

si

ros

C

58

RL.133.00M

NALLA

58

RL.133.00M

RAIN WATER

PU

T.B.M.-20

765kV/400kV/132kV SWITCHYARD

LA

11

CLARIFIER (FOR ASH WATER SYSTEM)

12

INTERMEDIATE SURGE HOPPER (ISH)

13

FGD PLANT (FUTURE)

14

CONDENSATE STORAGE TANK & HOT WELL MAKE-UP AND BOILER FILL PUMPS

15

A.C.EQUPMENT AND GAS ROOM

16

SERVICE BUILDING

17

DRY ASH SILO

18

SILO UTILITY ROOM

19

SILO MCC ROOM

20

FUEL OIL TANK FARM AREA & LDO & HFO UNLOADING & TRANSFER PUMP HOUSE

21

NATURAL DRAFT COOLING TOWERS

22

CW PUMP HOUSE & FOREBAY

23

CHLORINATION ROOM FOR CW SYSTEM, CHEMICAL HOUSE & ACID STORAGE

24

EFFLUENT TREATMENT PLANT, GUARD POND

25

DM PLANT , BULK ACID/ ALKALI STORAGE

25a

NEUTRALIZATION PIT

26

PARKING AREA

27

CANTEEN

28

DISPENSARY

29

ADMINISTRATION BUILDING

30

FIRE STATION

31

TIME OFFICE

32

SECURITY OFFICE

33

MAIN ENTRANCE ARCH. AND GATE COMPLEX

34

WORK SHOP

35

PERMANENT STORE SHEDS (6 NOS FOR MECH.,ELECT.,C&I AND CIVIL )

36

WEIGH BRIDGE AND CONTROL ROOM FOR HEAVY VEHICLE

37

GATE #2(FOR HEAVY VEHICLES ENTRY)

38

AUXILIARY BOILER

39

CIRCULATING WATER INLET AND OUTLET PIPES

40

PERIPHERAL ROAD

41

SPACE FOR LAYDOWN AREA

42

RECLAIMER MACHINE

LINE BAY-2

LINE BAY-1

BUSCOUPLER

ICT-1

LINE BAY-3

43

MARSHALLING YARD/RAILWAY SIDING

44

WAGON TIPPLER (FOUR NUMBERS)

45

PENT HOUSE FOR CONVEYORS FROM WT (PH-1)

46

CRUSHER HOUSE

BUS TRANSFER

LINE BAY-4

ICT-2

LINE BAY-5

LINE BAY-6

ICT-3

LINE BAY-7

ST # 1

ST # 2

400 N

47

COAL PILES

ST # 3

LA

CVT

RAIL TRACK

TOWER

ROAD

3014

CT

CB

TOWER

3000

ISO

RAIL TRACK

ISO

CRP

CRP

80

400KV GIS ROOM

CRP

CRP

CRP

CRP

CRP

CRP

CRP

CRP

LINE

CRP

CRP

CRP

CRP

LINE

CRP

CRP

5000

CRP

CRP

RAI

L TRA CK

ICT

CRP

ICT

CRP

CRP

CRP

CRP

3.5M WIDE ROAD

RAI

L TRA CK

ICT

CRP

RAIL TRACK

CRP

CRP

CRP

60

CRP

CRP

CRP

CRP

CRP

CRP

RA I

L TRA CK

CRP

CRP

CRP

CRP

CRP

TRAFO.

CRP

CRP

CRP

CRP

CRP

400KV GIS ROOM

CRP

ROLLING SHUTTER

TRAFO.

RAIL TRACK

765KV GIS ROOM

132KV ROOM

RAIL TRACK

200 N

CH

RAIL TRACK

RAIL TRACK

BOUNDARY WALL

24

C 109.5 (N) OF 7.0M WIDE ROAD

L

C 7.0M WIDE ROAD

L

C CW RETURN HDR (UNIT#1)

L

FROM

0.00M

3.0M.WIDE PIPE RACK

STAIRCASE FROM

0.0M TO 33.0M (TYP.)

FROM

0.00M

3.0M.WIDE PIPE RACK

CPV

EL.3.5M

TG MAINTENANCE

BUILDING

(40M X 20M)

UNLOADING BAY

PAVED AREA

RS

REMOVABLE PLATFORM

CPV

CPV

PL.EL.5.0M

REMOVABLE PLATFORM

& HAND RAILING

FROM

0.00M

RS

3.0M.WIDE PIPE RACK

RS 5.0MWx5.0MH

LOUVERS

BATTERIES

LOUVERS

BATTERIES

BATTERIES

TOILET

EL.2.0M

LOUVERS

CPV

LIFT

C.P.U. UNIT

LUBE OIL SKID

TDBFP

FROM

0.00M

RS 5.0MWx5.0MH

LOUVERS

BATTERIES

DUPLEX LUBE

OIL COOLER

PAVED AREA

RS 3.0MWx5.0MH

TDBFP HANDLING

AREA

EL.0.0M

DOSING UNIT

EL.3.5M

OIL TANK

OIL TANK

T.B.M.-17

3.0M.WIDE PIPE RACK

C 7.0M WIDE ROAD

L

RS

23

75

28

UP

STAIRCASE FROM 0.00M

TO ROOF LEVEL

27

26

22

21

20

12

65

15

I

FROM 0.0M

UP

STAIRCASE FROM 0.00M

TO ROOF LEVEL

10

73

65

38

63

PMH-4

FD FAN

C

L

C

L

64(II)

JT-6

BC-6A/6B

136.85[S]

PA FAN

C

L

C

L

FD FAN

C

L

RL.133.00M

12

JT-8

JT-7

12

41

47.2[W ]

267.3[W ]

JT-9

8

59

9

19

FA W ATER PUM PS (4 Nos.

)

PIPE RACK

129.3[W ]

JT-10

12

185.2[W ]

JT-11

BAHP W ATER PUM PS (3 Nos.

)

LP W ATER PUM PS (4 Nos.

)

10

BOUNDARY WALL

59

18

d

n

o

P

LIME

CH-1

13

LIMESTONE

GRINDING

AREA

RL.133.00M

PMH-3B

RL.135.750M

73

DH-1B

C

LERH-1

71

50

58

51

RC-1

587.0[S]

47

SR-1B

RYBC-1B

659.0[S]

PERMANENT STORE SHEDS

BC-4A/4B

42

DH-1A

SR-1A

48

RYBC-1A

CU

T

LI

NE

3rd

C

L 7M W IDE OF ROAD

47

CRUSHED COAL STOCKPILE# CCS-2

SEMI STORE SHEDS

CHP MAINTENANCE

77

BUILDING

BUILDING

793.0[S]

RL.135.750M

49

990.0[W ]

JT-3

CRUSHED COAL STOCKPILE# CCS-1

47

RL.135.750M

58

975 S

JT-2

BC-1A/1B

42

THCR-1

ER-4

44

ER-3

ER-2

52

44

SAC-2

OUT HAUL

C

L

52WT-2

OUT HAUL

C

L

C

L HOPPER

# WT-2

44

C

L HOPPER

# WT-1

OUT HAUL

C

L

SAC-1

WT-1

RL.140.00M

MSL- 142.850

OUT HAUL

C

L

WT-4

C

L HOPPER

# WT-4

C

L HOPPER

# WT-3

SAC-3

WT-3

IN HAUL

C

L

TRACK (WT-1)

58

SAC-4

44

IN HAUL

C

L

TRACK (WT-3)

IN HAUL

C

L

TRACK (WT-2)

R

CS

ER-1

PENT HOUSE ERH (PH-2)

52

CHP CONTROL ROOM & MCC ROOM

53

HYDROGEN GENERATION PLANT

54

RAW WATER RESERVOIR

55

RAW WATER PUMP HOUSE

56

ASH POND

57

COAL PILE RUN OFF PIT

58

WATCH TOWERS

59

COMPRESSOR CUM VACUUM PUMP HOUSE FOR ASH HANDLING

(COMMON CONTROL ROOM FOR ALL THE THREE UNITS AT 2nd FLOOR IN UNIT#1 BUILDING)

60

SEWAGE TREATMENT PLANT

1200 S

530 E

N - 2872279.00

Ch

.:

20

0.

0

T.B.M. -7

Ch

.:

30

0.

0

T.

B

R

.

l

. M.

14

No.

3.

12 1

GUM

Vi

TI

l

l

.

A

ha

T

rc

hh

ua

HP

1300 S

Lahurimau

To Vill.

TO

Ch

.:

50

0.

0

1500 S

Ch

.:

60

0.

0

58

RL

Y

CH

L:K

XI

M

CL NG

13

N

AS

74

S( O.

50

UN S4

0

/

M) 5 '

C'

1600 S

Ch

.:

70

0.

0

Ch

.:

80

0.

0

1700 S

1400 S

1500 S

EX

I

S

T

I

NG

RLY.TR

ACK

SURVEY BOUNDARY

DG SET BUILDING

62

CPU REGENERATION BUILDING

63

COMPRESSOR HOUSE

iM

ar

h

La

64

BOILER MAINTENANCE BUILDING

65

PASSENGER CUM GOODS ELEVATOR

66

COMPOUND WALL

67

FENCING

68

ASH WATER RECOVERY AND RECOVERY PUMP HOUSE

69

FILTRATION PLANT, FILTER WATER RESERVOIR, FILTER WATER & FIRE WATER PUMP HOUSE

70

PIPE RACK/CABLE RACK

71

DOZER SHED

72

LOCO SHED

73

PUMP HOUSE FOR DUST SUPRESSION SYSTEM (DSS)

74

AIR WASHER UNIT

75

PASSENGER ELEVATOR

76

TG MAINTENANCE BUILDING

77

CHP MAINTENANCE BUILDING

78

SIMULATOR TRAINING CENTER

79

LABOUR COLONY

80

RAIN HARVESTING

1300 S

RLY.LA

ND

BO UND

ARY

58

1400 S

.

l

l

i

oV

T

a

hhu

c

r

ha

Dh

Cr ar

os ch

si hu

ng a

Ch

.:

40

0.

0

58

61

1100 S

UR

P

HE

AT

OF

T

52CLTUNNEL

E - 419203.00

m

718

M)

oF

rt

e

ppl

Ti

(

1000 S

e

g

a

ill

V

IN HAUL

TRACK (WT-4)

Ch

.:

10

0.

0

.

No

2.

.

82 2

C

L

RL.140.00M

43

34m

R8

CS

T.B.M.-12

OUT HAUL

C

L

WBCR-1A

52

GATE

73

JT-1

BC-1C/1D

T.

B

Rl .M

.

14

WBCR-1B

ACH-1

MSL-141.310

E - 420030

N - 2873197

M)

oF

rt

e

ppl

Ti

(

Ch

.:

0.

0

a

u

h

rc

a

h

73

1100 S

1200 S

51

PMH-2

PMH1

60 E

CRH

Kanp

ur

152 E

JT-2A

900 S

To

46

T.B.M.-13

3

1

.-

58

C

LTUNNEL

PH-1 45

BC-2A/2B

975 S

1000 S

.M

.B

T

BC2C/

2D

JT-2B

800 S

HA

M

923.00M(S)

RL.140.00M

RL.140.00M

MSL -141.785

E - 419937

N - 2873469

Vi

l

l

age

73

RL.135.750M

Li

ne

BC-3A/3B

PMH-3A

RL.135.750M

52

Rai

l

wa

y

RL.135.750M

5

ER-

900 S

700 S

INSPECTION SHED

CHP MAINTENANCE

Dh

arc

hua

793.0[S]

41

STORE SHED

JT-4

CRUSHED COAL STOCKPILE# CCS-3

EMERGENCY RECLAIM HOPPER

STORE SHED

(FOR OIL DRUMS)

(FOR GAS CYLINDER)

RL.135.750M

600 S

2nd

PERMANENT STORE SHEDS

48

800 S

35

1st

49

58

50

500 S

JT-5

PH-2

CRUSHED COAL STOCKPILE# CCS-4

659.0[S]

587.0[S]

CU

T

LI

NE

EX

IS

T

RL ING

.1

41 TRA

.0

0M CK

57

T.B.M. -2

530.00M(S)

KA

NP

UR

N -2871992.12

20

C LDO

L

TANK #1

RL.133.00M

BC-5A/5B

e

g

a

ill

V

RL.135.750M

990.0[W ]

u

a

MSL-135.685

E - 418207.56

190.0[W ]

(55Mx40M)

PUMP HOUSE

C LDO

L

TANK #2

DOW N

m

ri

u

h

a

L

CRUSHED LINE

STORAGE SILO

LO

CO

34

RL.133.00M

HFO/LDO

13

ABSORBER

SYSTEM

(70Mx60M)

400 S

IR

PU

R/

KA

NP

UR

58

ABSORBER

SYSTEM

(70Mx60M)

36

C HFO TANK #1

L

DA

PS

UR

A

C HFO TANK #2

L

G A TE

29

GATE #2

DOWN

:

13

75

.

59

7

ST

AB

LI

NG

37

LIME STONE

UNLOADING

HOPPER

ABSORBER

SYSTEM

(70Mx60M)

700 S

FOR HEAVY VEHICLES ENTRY

C391(S)

OF 7M WIDE ROAD

L

C

L 7M W IDE OF ROAD

28

78

(1

50

M

TIM E OFFICE

27

T.B.M.-16

SECURITY

C

L OF 7M WIDE ROAD

6

1

.-

30

E - 419330

N - 2873589

KM

LI

NE

BC-5A/5B

11

C

L DUCT

226.250M (W)

MSL -136.241

17

530 E

SECURITY OFFICE

64(I)

343.0M (S)

.M

.B

T

31

C CHIMNEY

L

DRIVE HOUSE

300 S

RL.133.00M

58

400 S

200 S

e

g

a

ill

V

405.3[W ]

JT-12

59

323.2[W ]

21

49

100 S

ER-6

MI

LL

(TYP)

FD FAN

REJECT SI

LO

MI

LL

(TYP)

BC-6A/6B

PA FAN

C

L

14

PA FAN

C

L

r

u

jp

ra

u

S

15

BC-7A/7B

REJECT SI

LO

FD FAN

C

L

C

L

75

MI

LL

(TYP)

PA FAN

FD FAN

REJECT SI

LO

BC-7A/7B

PA FAN

C

L

11

13

(FOR ALL THREE UNITS)

NEXT FLOOR AT EL. 8.5M

MI

LL

(TYP)

BC-8A/8B

REJECT SI

LO

MI

LL

(TYP)

REJECT SI

LO

MI

LL

(TYP)

REJECT SI

LO

PA FAN

C

L

13a

E

A/C EQUIPMENT ROOM FL.EL.0.0M

16

BC-8A/8B

FD FAN

C

L

58

17

18

19

60.0[E]

C

L

FROM 0.0M

TBC-1A/1B

24

(FOR ALL THREE UNITS)

NEXT FLOOR AT EL. 8.5M

C OF M ILL BAY

L

BOILER

25

25a

INERT GAS ROOM FL.EL.0.0M

15

BOILER

29

C

L

30

65

TBC-1C/1D

31

C OF M ILL BAY

L

C OF M ILL BAY

L

14

32

TBC-2A/2B

33

C OF M ILL BAY

L

34

TBC-3C/3D

35

75

C OF M ILL BAY

L

36

STACKER CUM RECLAIMER MACHINE

OIL TANK

COMMON

CHIMNEY

5M WIDE

37

48

COMMON

OIL TANK

OIL TANK

21

300 S

0.00 NS

DG SET ROOM

R.S.

C 7.0M WIDE ROAD

L

25a

226.94M (S)

58

600 S

MSL -135.225

E - 419024

N - 2873821

C 7.0M WIDE ROAD

L

61

PANEL ROOM

FOR CPU

M AINTENANCE BAY

W ITHDRAW L

SPACE FOR TUBE

M DBFP

DC SEAL OIL M OTOR

STARTER CABINET FOR

SPACE FOR HP PARTS

LAYDOWN

CABLE VAULT AT FL.EL.0.0M

HT SWITCHGEAR AT FL.EL.3.5M

DRAIN COOLER

GRATED FLOOR

LUBE OIL SKID

TDBFP

TDBFP

C 88 (E) OF 7.0M W IDE ROAD

L

76

NGR

EL0.0M

CEP

BALL COLL

STRAINER

TDBFP

TOILET

R.S.

GSC

EL. 3.1M

ELECTRICAL ROOM

UNIT

AIR RECEIVER

EL.2.5M

M AINTENANCE BAY

EL.2.0M

CPV

BALL COLL

STRAINER

DMCW PUMPS (SG)

SEAL OIL UNIT

RESISTANCE BOX

OIL COOLER

MOTOR FOR DC SEAL OIL

DUPLEX W ORKING

PW INST.

CABINET

STAIR FROM CEP PIT

TO 2.2M PLATFORM

C PUM P

C CW SUPPLY HDR (UNIT# 1)

L

C CW RETURN HDR (UNIT# 1)

L

M ANHOLE

M ANHOLE

SCF-B

SCF-A

W ATER BOX HANDELING

UNLOADING BAY

FOR DMCW PUMP

C.P.U. UNIT

REMOVABLE PLATFORM

& HAND RAILING

RS

GAS ANALYSER

CONTROL CABINET

FROM

CPV

PL.EL.5.0M

CW SUPPLY

CW SUPPLY

REMOVABLE PLATFORM

LUBE OIL SKID

TDBFP

FROM

0.00M

DM CW PUM PS (T.G.)

W ITHDRAW L

SPACE FOR TUBE

SEAL OIL UNIT

OIL COOLER

DUPLEX W ORKING

DC SEAL OIL M OTOR

STARTER CABINET FOR

M DBFP

TDBFP HANDLING

AREA

EL.0.0M

DOSING UNIT

TOILET

R.S.

HANDLING SPACE

PHE-A(SG)

EQUIPMENT HANDLING

HYD. & SEAL CABINET

OIL INSTRUMENT CABINET

VACUUM PUMP

LP DF/T

FROM

0.

0M

EL.3.5M

NGR

RS

TURBINE

PHE-B(SG)

PANEL ROOM

FOR CPU

FROM

CPV

CABLE VAULT AT FL.EL.0.0M

HT SWITCHGEAR AT FL.EL.3.5M

DRAIN COOLER

UAT#1B

EL3.5M

SPACE FOR

VACUUM PUMP

MAIN PLC

HP DF/T

C T.G.SET

L

C STEAM DRAIN

GRATED FLOOR

LUBE OIL SKID

TDBFP

TDBFP

FROM

0.

0M

REMOVABLE PLATFORM

& HAND RAILING

RS

EL0.0M

CEP

BALL COLL

STRAINER

TDBFP

UAT#1A

AIR WASHER

UNIT#1

(15X12M)

FROM

MONORAIL

PANEL-2

EL.2.2M

C CONDENSER

L

C CW SUPPLY HDR (UNIT# 2)

L

C CW RETURN HDR (UNIT# 2)

L

M ANHOLE

SCF-B

SCF-A

DM CW PUM PS (T.G.)

OIL COOLER

EL.2.0M

CPV

C.P.U. UNIT

PL.EL.5.0M

M ONORAIL CAP.5T

W ITHDRAW L

SPACE FOR TUBE

SEAL OIL UNIT

OIL COOLER

DC SEAL OIL M OTOR

STARTER CABINET FOR

M DBFP

CPV

LUBE OIL SKID

TDBFP

FROM

0.00M

FROM

0.

0M

FROM

REMOVABLE PLATFORM

DOSING UNIT

BALL COLL

STRAINER

UNIT

AIR RECEIVER

74

ROOF AT EL. 5.0 M

HPSU JB

LPBV

HPSU OF

EL. 2.2M

HP PIPING BAY

a

rs

Si

TOILET

FOR DMCW PUMP

DMCW PUMPS (SG)

UT#1A

STATOR HANDLING

BALL COLLECTION SKID

PHE-A(TG)

SPACE FOR HP PARTS

LAYDOWN

U1

LADIES

HANDLING SPACE

PHE-A(SG)

BALL COLLECTION SKID

PANEL-2

GAS UNIT

GSC

EL. 3.1M

U1

TDBFP HANDLING

AREA

EL.0.0M

STAIRCASE FROM

0.0M TO 33.0M (TYP.)

PHE-B(SG)

PANEL ROOM

FOR CPU

NGR

JACK PADS SUPPORT FOR

GAS CYLINDER ROOM

FROM

PHE-C(TG)

PHE-B(TG)

EL.2.5M

U2

LUBE OIL SKID

TDBFP

TDBFP

U2

25

U3

170.00M (S)

U3

735.00M (W)

MONORAIL FOR HANDLING

BUTTERFLY VALVES (TYP.)

TDBFP

FROM

CR

S

CABLE VAULT AT FL.EL.0.0M

HT SWITCHGEAR AT FL.EL.3.5M

GRATED FLOOR

BALL COLL

STRAINER

MONORAIL FOR HANDLING

BUTTERFLY VALVES (TYP.)

MOTOR FOR DC SEAL OIL

RESISTANCE BOX

STAIR FROM CEP PIT

TO 2.2M PLATFORM

M ONORAIL CAP.5T

UNLOADING BAY

W ATER BOX HANDELING

M ANHOLE

890.564M (W)

UNIT

AIR RECEIVER

TBC-3A/3B

EL0.0M

DRAIN COOLER

BALL COLL

STRAINER

DMCW PUMPS (SG)

UT#1B

C CW SUPPLY HDR

L

RS

C UNIT.F/T

SPACE FOR

EQUIPMENT HANDLING

PW INST.

CABINET

GAS ANALYSER

CONTROL CABINET

LP DF/T

GT#1A

C CW RETURN HDR

L

NGR

EL3.5M

HYD. & SEAL CABINET

OIL INSTRUMENT CABINET

VACUUM PUMP

GAS UNIT

0.00M EW [418788M-(E)]

1U

2U2

NGR

UAT#2B

(15X12M)

VACUUM PUMP

MAIN PLC

HP DF/T

2U1

UAT#2A

AIR WASHER

UNIT#2

PANEL-2

C T.G.SET

L

TURBINE

1V

2V2

GT#1B

NGR

74

FROM

MONORAIL

BALL COLLECTION SKID

EL.2.2M

C STEAM DRAIN

2V1

STATION TRANSFORMER#1

UT#2A

ROOF AT EL. 5.0 M

HPSU JB

LPBV

HPSU OF

EL. 2.2M

HP PIPING BAY

1W

2W2

GT#1C

STATOR HANDLING

RS

BALL COLLECTION SKID

PANEL-2

PHE-A(TG)

SPACE FOR HP PARTS

LAYDOWN

2W1

JACK PADS SUPPORT FOR

GAS CYLINDER ROOM

FROM

PHE-C(TG)

PHE-B(TG)

GSC

EL. 3.1M

C OF M ILL BAY

L

LOG

C

L 1090.50 (W ) OF 4M W IDE ROAD

RESISTANCE BOX

DUPLEX LUBE

C CONDENSER

L

DM CW PUM PS (T.G.)

M ONORAIL CAP.5T

PORTICO

OP

T

S

LIFT

62

BOUNDARY WALL

CW SUPPLY

CW SUPPLY

CW SUPPLY

M ANHOLE

SCF-B

SCF-A

PUMP

GATE

TOILET

R.S.

947.504M (W)

T.B.M.-28

MOTOR FOR DC SEAL OIL

EL.2.5M

CEP

3.0M.WIDE PIPE RACK

N - 2872339.11

PW INST.

CABINET

STAIR FROM CEP PIT

TO 2.2M PLATFORM

DUPLEX W ORKING

GAS ANALYSER

CONTROL CABINET

LP DF/T

HANDLING SPACE

PHE-A(SG)

NGR

C CW SUPPLY HDR

L

RS

C UNIT.F/T

HYD. & SEAL CABINET

OIL INSTRUMENT CABINET

VACUUM PUMP

C T.G.SET

L

TURBINE

UT#2B

C CW RETURN HDR

L

LUBE OIL

SYSTEM

NGR

EL3.5M

SPACE FOR

VACUUM PUMP

MAIN PLC

HP DF/T

EL.2.2M

C STEAM DRAIN

OIL COOLER

PUMP

PUMP

OF

EL. 2.2M

HP PIPING BAY

PHE-B(SG)

16

(F.F.L.)

EL.(+) 0.5M.

14.436M (S)

C GANTRY

L

GT#2A

CENTRAL

NGR

UAT#3B

(15X12M)

FROM

MONORAIL

OF

CE

N

T

AREEN

AI

N

EEN

22

1U

2U2

2U1

1U

2U2

UAT#3A

AIR WASHER

UNIT#3

ROOF AT EL. 5.0 M

HPSU JB

LPBV

HPSU OF

EQUIPMENT HANDLING

PHE-A(TG)

2U1

GT#2B

NGR

74

STAIRCASE FROM

0.0M TO 17.0M (TYP.)

STATOR HANDLING

GAS UNIT

5000

200 S

UT#3A

JACK PADS SUPPORT FOR

RS

BALL COLLECTION SKID

PANEL-2

PANEL-2

PHE-B(TG)

(42M X 33.5M)

1V

2V2

STATION TRANSFORMER#2

GAS CYLINDER ROOM

FIRE EXIT

DOOR (TYP.)

BALL COLLECTION SKID

2V1

GT#2C

DUPLEX LUBE

NGR

C CW RETURN HDR

L

C CW SUPPLY HDR

L

MONORAIL FOR HANDLING

BUTTERFLY VALVES (TYP.)

C UNIT.F/T

FROM

FIRE EXIT

STAIRCASE FROM

0.0M TO 17.0M (TYP.)

PHE-C(TG)

SERVICE BUILDING

1W

2W2

2W1

CW SUPPLY

UT#3B

OF

PUMP

OF

CW

P

UM

PUMP

OF

FOR DMCW PUMP

MSL -138.152

E - 418025.80

GT#3A

M ANHOLE

NGR

70

PUMP

OF

2U2

21

T.B.M.-25

100 S

1U

AREA

PUMP

2U1

GT#3B

STATION TRANSFORMER#3

OF

1V

2V2

W ATER BOX HANDELING

PARKING AREA

2V1

GT#3C

C CONDENSER

L

26

PUMP

OF

MSL-139.697

E - 418062

N - 2872862

C GANTRY

L

TRANSFORMERS

1W

2W2

30000

C GANTRY

L

2W1

BOILER

OF

0.00M NS [2873567M-(N)]

C CW SUPPLY HDR (UNIT#3)

L

C

L

PUMP

TBC-2C/2D

OF

C CW RETURN HDR (UNIT#3)

L

C CW SUPPLY HDR (UNIT# 3)

L

PUMP

ACW

PU

PS

OF

C 501.5(W ) OF 7.

0M W IDE ROAD

L

39

SYSTEM PIPING

520.

0M (W )

C CW SUPPLY HDR (UNIT#3)

L

TP-FOR CW & ACW

IN

T

E

AREA

C CW SUPPLY HDR (UNIT#2)

L

C CW RETURN HDR (UNIT#3)

L

C PUM P

C CW SUPPLY HDR (UNIT#2)

L

100 N

750

C CW SUPPLY HDR (UNIT#1)

L

C CW RETURN HDR (UNIT#2)

L

C CW RETURN HDR (UNIT#2)

L

67.00M(N)

62.00M(N)

NANCE

PUMP

0.00 NS

C

L OF 7M WIDE ROAD

C CW RETURN HDR (UNIT#1)

L

C CW SUPPLY HDR (UNIT#1)

L

77.00M(N)

72.00M(N)

C CW RETURN HDR (UNIT# 3)

L

82.00M(N)

23

200 N

138000

138000

ACW SUPPLY UNIT#1,2 & 3

87.00M(N)

13

76

.

22

5

DI

SP

AT

CH

94.50M(N)

92.50M(N)

90.50M(N)

RL.133.00M

C OF TG

L

UNIT# 1

C OF TG

L

UNIT# 2

C OF TG

L

UNIT# 3

100 N

:

KM

300 N

YA

RD

58

58

58

TOWER & WT

CT

150X150M

58

12000

69

500 S

ASH WATER PUMP HOUSE AND MCC ROOM

CVT

4.

0M WI

DE ROAD

300 N

HARVESTING POND

MSL -137.782

E - 418508

N - 2873970

67

e

g

lae

ilg

Vlla

aVi

rs

i

sa

S

ir

S

-E

0

0

2

7

1

4

KA

N

NALLA

10

500 N

TO

RL.133.00M

LA

NALLA

58

MCC CONTROL ROOM (FOR ASH SLURRY PUMP HOUSE)

LA

53

C

L 436.5 (W ) OF 7.0M W IDE ROAD

400 N

600 N

66

AR

EA

55

-E

0

0

0

7 CULVERT

1

4

NO

58

M

AI

NT

EN

AN

CE

500 N

RL

Y

13 .:

LKM

76

XI

.6

'

C' NG

00

N

CL

AS O -S

S(

-4

6

M

)

SLO PE

40

PE

58

700 N

58

O

SL

-N

0

0

4

2

7

8

2

600 N

58

TE

:-

l

o

o

ho

ch

S

700 N

EX

IS

TI

NG

PR

W

OP

OR

OS

K

SH

E

PR

D

OW

NU

OP

N

PP

OS

IN

L

ED

SI

-DI

NU

--N

PP

G

BL

L/

W

RA

AC

OR

IL

K

K

W

SH

AY

OW

PR

N

OP

IN

OS

-AL

--AT

RE

TH

D

E

TI

M

E

OF

DO

35

0

d

n

o

P

1315.0M (N)

PR

OP

SI

.N

DI

N G UP

P

PH L

-I

COMPARTMENT-I

58

AG

54

H IG

1200 N

1500 N

RA

IL

58

NALLA

1300 N

1600 N

R=

NALL

A

AM

1400 N

68

1700 N

60

PUR

M IR

HA

TO

AD

RO

BAFFLE

1500 N

58

H

AC

RO

APP

TO

ps

o

h

S

am

i

rp

ur

s

op

Sh

s

op

h

S

1700 N

58

To

H

IR

PU

R

1800 N

RA

IL

W

1900 N

EX

IS

TI

NG

1900 N

AY

300 acres

----

2000 N

127 acres

TA

ASH POND

SH

O

U

C

E

S

58

2100 N

ASH SLURRY PUMP HOUSE

OFF

56

Y

IT

R

E

IC

MAIN ENTRY

TO PLANT

32

EN

3

3

GATE #1

UB

LI

N

2200 N

2300 N

EX

I

LA STI

NG

ND

TR

RA

BO

AC

IL

UN

K

DA W A

RY Y

2300 N

RL

Y.

KM

LXI

13

N

'

78

C'

G

.3

NO

CL

20

AS

-S

S(

-4

7

M

)

A

LL

NA

2600 N

C

S

R

2600 N

7

5

6

m

2700 N

:

K

M

A

M

S

1

T

3

I

R

A

7

T

9

P

IO

.0

U

R

4

N

0

R

LY

.

2800 N

E

X

IS

T

IN

E

G

X

IS

L

O

T

O

IN

P

G

L

IN

M

E

A

IN

L

IN

167 acres

R

L

(U Y.

P

L

R

LO O O

L

P

O

(U Y M

P

L

P

A

LI IN

IN

M

E

N

A

E

LI

IN

) AT

N

T

LI

E

H

N

E

A

E

T

T

)

IM

T

H

E

E

O

T

F

IM

D

E

O

U

O

B

F

LI

D

N

O

G

U

B

LN

G

2900 N

1600 N

ANNUAL

ANNUAL

08.30 Hrs

NRUE)

3500 N

3400 N

48

2300 E

2200 E

2100 E

2000 E

1900 E

1800 E

1700 E

1600 E

1500 E

1400 E

1300 E

1200 E

1100 E

1000 E

900 E

800 E

700 E

600 E

500 E

400 E

300 E

200 E

100 E

0.00 EW

100 W

200 W

300 W

400 W

500 W

600 W

700 W

800 W

900 W

1000 W

1100 W

1200 W

1300 W

1400 W

1500 W

1600 W

1700 W

1800 W

1900 W

2000 W

2100 W

2200 W

2300 W

2400 W

3500 N

N (CONST.)

48

48

O

T

CO NS.

NO RTH

10

11

CO NS.

NORTH

12

1600 S

1700 S

au

Ch

.:

90

0.

0

43

1800 S

72

RECEPTION YARD

GATE

RL

Y

M)

150

(

NE

I

L

NG

I

ABL

T

OS

C

O

L

1800 S

:

KM

13

73

.

71

0

1900 S

1900 S

LOCO WORKSHOP

B

2000 S

58

FOR TENDER PURPOSE ONLY

2300 E

2200 E

2100 E

2000 E

1900 E

1800 E

1700 E

1600 E

1500 E

1400 E

1300 E

1200 E

1100 E

2200 S

1000 E

700 E

1

5

00

.0

600 E

C

h

.

:-

500 E

400 E

58

300 E

200 E

100 E

0.00 EW

100 W

58

200 W

300 W

400 W

500 W

600 W

700 W

800 W

900 W

1000 W

1100 W

1200 W

1300 W

1400 W

1500 W

1600 W

1700 W

1800 W

1900 W

2000 W

2100 W

2200 W

2300 W

2200 S

2100 S

900 E

DA

PS

UR

A

o.

83 3

LABOUR COLONY

Cu

lv

er

t

T.

B

R

.

l

. M.

142. N

2100 S

800 E

79

2400 W

2000 S

sw

A

NEYVELI UTTAR PRADESH POWER LIMITED

M

ar

au

10

11

REFERENCE DRAWINGS.

NOTICE

NOTES

10

1. PLOT PLAN (PROJECT REPORT)

2. LAYOUT PLAN(PROPOSAL-3)

DWG.NO. 00-1111113-G-001 REV.H

DWG.NO. RITES/RPO-DELHI/NEYVELI/GHATAMPUR/03 REV.0

1.

DO NOT SCALE, ASK WHEN IN DOUBT.

2.

ALL DIMENSIONS ARE IN MILIMETRES UNLESS NOTED OTHERWISE.

3.

RAILWAY MARSHALLING YARD SHOWN IS TENTATIVE ONLY.

THIS

DRAWING IS THE PROPERTY OF

C

H

:

K

M

1

DESEIN

PRIVATE LIMITED, NEW DELHI,

3

7

2

.

8

4

0

A

U

R

A

S

T

A

T

IO

N

5.

FINISHED FLOOR LEVEL OF BUILDING AND DIFFERENT AREA ARE AS FOLLOWS-

b. AREA FROM A- ROW TO C- ROW-RL.133.50M

FURNISH ANY INFORMATION FOR THE

c. BOILER AREA -RL.133.30M

MAKING OF DRAWINGS, APPARATUS,

d. FINISHED GRADE LEVELS -RL.133.0M ,RL.135.750 & RL.140.0M

e. ALL OTHER BUILDINGS -RL.500MM ABOVE,ADJACENT FINISHED GRADE LEVEL.

LENT OR OTHERWISE DISPOSED OF, DIRECTLY

OR INDIRECTLY. IT SHALL NOT BE USED TO

a. TRANSFORMER YARD-RL.133.40M

REVISED AS PER NLC MAIL DATED 11.11.2015

12.11.15

REVISED AS PER Lr.No PSE/NUPPL/CIVIL/1222/2015 DTD 25.07.2015

12.08.15

REVISED FOR RAILWAY SIDING AND WAGON TIPLLER LOACTION

08.07.15

REVISED FOR INDCATING TOWNSHIP AND APPROACH ROAD

12.06.15

REVISED AS PER NLC MAIL DATED.12.05.2015

LF

SE

ZONE

NAME

DESEIN

DES EI

N

NEW DELHI - INDIA

18.04.15

GENERALLY REVISED

16.01.15

REVISED AS PER MOM DATED-16.07.14 TO 19.07.14

22.08.14

REVISED AS PER NUPPL COMMENTS DATED-05.04.14

14.05.14

PARTICULARS

DATE

PROJECT:- 3 x 660MW GHATAMPUR THERMAL POWER PROJECT GHATAMPUR TEHSIL (U.P)

TITLE:-

CIVIL

MECH.

ELEC.

C&I

CAD/DRAWN

RAKESH

18.01.14

DESIGNED

KM.RAO

18.01.14

CHECKED

KM.RAO

23.01.14

SCALE

1:9000 (A0)

JOB. No.

D-4033

DWG.No.

H.O.D.

REV.

111-21-0100

CONTRACT AGREEMENT WITH DESEIN.

SR. No.

DATE

CLIENT:- NEYVELI UTTAR PRADESH POWER LIMITED

PLOT PLAN

MARK

SIGN.

CONSULTING ENGINEERS

18.05.15

REVISED AS PER NLC LR.N0. PSE/NUPPL/GENERAL/CIVIL/628/2015 DATED.17.04.2015

N ENGI

ANCE I

NEE

RELI

RI

NG

OR PARTS THEREOF EXCEPT FOR THE

PROJECT SPECIFICALLY PROVIDED FOR BY

6. ROAD LEVELS SHALL BE 250MM ABOVE FINISH GRADE LEVELS.

THAT IT SHALLRLYNOT

BE REPRODUCED, COPIED,

.

19.01.16

D

AND IS LENT

SUBJECT TO THE CONDITION

A

PS

4. FINISHED FLOOR LEVEL OF POWER HOUSE IS 133.50M WHICH

REVISED AS PER DISCUSSION WITH NUPPL/ RITES ON 06.01.2016 AT GURGAON

PARTY

REVISIONS

PRINT DISTRIBUTION

12

11

10

10

APPROVED

5

You might also like

- Boiler Erection 2Document51 pagesBoiler Erection 2Sam100% (7)

- Construction of Nayagav Fa S Anicut, Bhat:, P.S. Dungarpur, Dist. Dun ArpurDocument98 pagesConstruction of Nayagav Fa S Anicut, Bhat:, P.S. Dungarpur, Dist. Dun ArpurRajendra BadjatyaNo ratings yet

- 3VYN191246 - Busdesign CalculationsDocument9 pages3VYN191246 - Busdesign CalculationsManiKantNo ratings yet

- Semiconductor KRC101M KRC106M: Technical DataDocument7 pagesSemiconductor KRC101M KRC106M: Technical DataMisión ItuscolNo ratings yet

- 33000V Substation Main LT PanelDocument22 pages33000V Substation Main LT PanelAnonymous 2yMUwsNo ratings yet

- Denah Power House PLTMDocument1 pageDenah Power House PLTMWardhana ZolliNo ratings yet

- Costing For SwroDocument1,021 pagesCosting For Swroganesh100% (2)

- Et Zc341 Ec-3r Solution Second Sem 2013-2014Document9 pagesEt Zc341 Ec-3r Solution Second Sem 2013-2014mubashkNo ratings yet

- GE Industrial Motor Data SheetsDocument8 pagesGE Industrial Motor Data SheetsEdgar CanelasNo ratings yet

- SG3524 SMPS Control Circuit: Description Pin ConfigurationDocument5 pagesSG3524 SMPS Control Circuit: Description Pin ConfigurationNiko OlnicasaNo ratings yet

- Design of Drains - SubmissionDocument12 pagesDesign of Drains - SubmissionjnmanivannanNo ratings yet

- 3.earth MatDocument9 pages3.earth MatPrabhash Verma100% (1)

- Semiconductor KRA101S KRA106S: Technical DataDocument7 pagesSemiconductor KRA101S KRA106S: Technical Datapromatis5746No ratings yet

- 03145calibracio Sistema de Inyeccion John DeereDocument3 pages03145calibracio Sistema de Inyeccion John DeereAndres ContrerasNo ratings yet

- Electrical Technical Detail MainDocument50 pagesElectrical Technical Detail MaineshanrastogiNo ratings yet

- SAIKAT252Document30 pagesSAIKAT252nikcsitNo ratings yet

- Switchboard power monitoring and efficiency reportDocument2 pagesSwitchboard power monitoring and efficiency reportJyothisrikanth100% (1)

- Semiconductor KRC110M KRC114M: Technical DataDocument4 pagesSemiconductor KRC110M KRC114M: Technical Dataelita04No ratings yet

- RAB MDP 1 and COS 1250A panel material and lighting installation needsDocument4 pagesRAB MDP 1 and COS 1250A panel material and lighting installation needskikputririzNo ratings yet

- Powering CalculationDocument11 pagesPowering CalculationIbrahim SameirNo ratings yet

- Ec 1 Part-1Document25 pagesEc 1 Part-1Joshua DuffyNo ratings yet

- Conduit Selection On CB SizesDocument2 pagesConduit Selection On CB SizesSri NathNo ratings yet

- Halton TsaDocument9 pagesHalton TsaNetri KrisztiánNo ratings yet

- Techanicaldiary 490 MW PDFDocument13 pagesTechanicaldiary 490 MW PDFsauravyadav33No ratings yet

- 60EPFxx PDFDocument8 pages60EPFxx PDFRogerio E. SantoNo ratings yet

- Generator DataDocument8 pagesGenerator DataMohammad Ibnul HossainNo ratings yet

- Tabel Short CircuitDocument64 pagesTabel Short CircuitqhecilNo ratings yet

- Part1 ModelDocument1 pagePart1 Modelderk casNo ratings yet

- DJS BRGBC TR8Document11 pagesDJS BRGBC TR8Greg SchwartzogNo ratings yet

- Encoder HEDL 5540 500 CPT, 3 Channels, With Line Driver RS 422Document4 pagesEncoder HEDL 5540 500 CPT, 3 Channels, With Line Driver RS 422danhhongNo ratings yet

- LTBF UcuyorumDocument7 pagesLTBF UcuyorumYigit Omer CiftciNo ratings yet

- Simulation of A Ac Voltage Controller With Various Loads: G T T X yDocument3 pagesSimulation of A Ac Voltage Controller With Various Loads: G T T X yKarthik SsnongoleNo ratings yet

- 2260 110 03TR Pve y 002 01 PDFDocument10 pages2260 110 03TR Pve y 002 01 PDFAnand K. MouryaNo ratings yet

- ComputationDocument13 pagesComputationLester MuscaNo ratings yet

- Chapter 9 Solutions for Resonant CircuitsDocument23 pagesChapter 9 Solutions for Resonant CircuitsCarolina de Melo100% (3)

- 20 Induction Motor DesignDocument20 pages20 Induction Motor DesignRavikumar GogulamandaNo ratings yet

- Rexroth A10vso Variable Axial Piston PumpDocument18 pagesRexroth A10vso Variable Axial Piston PumpJairoHernanLopera100% (6)

- DC Load FBDDocument5 pagesDC Load FBDAbu Monsur AliNo ratings yet

- NAD 3020 ServiceManualDocument6 pagesNAD 3020 ServiceManualmartin-d-johnsonNo ratings yet

- IRG4PH40K: Features Features Features Features FeaturesDocument9 pagesIRG4PH40K: Features Features Features Features FeaturesJesus GuillermoNo ratings yet

- Injection Pump Specification and SettingsDocument1 pageInjection Pump Specification and Settingsjohnny sabinNo ratings yet

- Hydac SCADocument6 pagesHydac SCADenis JimenezNo ratings yet

- MR758Document7 pagesMR758Bruno NascimentoNo ratings yet

- KIA 6213S Marshall 1 WDocument4 pagesKIA 6213S Marshall 1 WMika ForicNo ratings yet

- IRG4BC30K-S: Features Features Features Features FeaturesDocument8 pagesIRG4BC30K-S: Features Features Features Features FeaturesRafael MonzonNo ratings yet

- Hydro Electric Project-Basic Layout For Francis, As Per Is, USBR and Other StandardsDocument15 pagesHydro Electric Project-Basic Layout For Francis, As Per Is, USBR and Other Standardsबिपन गुलेरियाNo ratings yet

- Project Electrical Boq Feb 10-1Document40 pagesProject Electrical Boq Feb 10-1Vijaya Sarathi RaviNo ratings yet

- 30CPQ080 30CPQ100: Schottky Rectifier 30 AmpDocument6 pages30CPQ080 30CPQ100: Schottky Rectifier 30 AmpBruno NascimentoNo ratings yet

- lm555 DatasheetDocument11 pageslm555 DatasheetKhu GhingNo ratings yet

- Pipeline Design Calculations PDFDocument21 pagesPipeline Design Calculations PDFjimallen21281% (21)

- ALARKO CirculationPump PDFDocument8 pagesALARKO CirculationPump PDFAlienshowNo ratings yet

- Aerodrome Elev 728Ft. Instrument Approach Chart - ,: KhajurahoDocument1 pageAerodrome Elev 728Ft. Instrument Approach Chart - ,: KhajurahoShibin JohneyNo ratings yet

- IRG4PC50S: Features Features Features Features FeaturesDocument8 pagesIRG4PC50S: Features Features Features Features FeaturesPerica RakićNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1From EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Rating: 4.5 out of 5 stars4.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- 14) Webinar Content - Stone Columns For Improving Weak GroundsDocument110 pages14) Webinar Content - Stone Columns For Improving Weak GroundsEswara PrasadNo ratings yet

- Abrahamson and SilvaDocument31 pagesAbrahamson and Silvajacs127No ratings yet

- RIM-cell Testing in Australia (Perth)Document2 pagesRIM-cell Testing in Australia (Perth)jacs127No ratings yet

- O-Cells in QatarDocument4 pagesO-Cells in Qatarjacs127No ratings yet

- E 146Document7 pagesE 146jacs127No ratings yet

- 03 McVay FinalDocument47 pages03 McVay Finaljacs127No ratings yet

- A Unified Procedure For Earth Pressure CalculationsDocument5 pagesA Unified Procedure For Earth Pressure Calculationsjacs127No ratings yet

- O CellsDocument7 pagesO Cellsjacs127No ratings yet

- Ocell Test in IndaiDocument3 pagesOcell Test in IndaiSushanta TakhellambamNo ratings yet

- Hussien 2016Document54 pagesHussien 2016jacs127No ratings yet

- AICTE Tentetive 2017-18Document9 pagesAICTE Tentetive 2017-18jacs127No ratings yet

- ISGTI BrochureDocument2 pagesISGTI Brochurejacs127No ratings yet

- Anderson 2001Document6 pagesAnderson 2001jacs127No ratings yet

- Https WWW - Irctc.co - in Eticketing PrintsdfTicketDocument2 pagesHttps WWW - Irctc.co - in Eticketing PrintsdfTicketJayamkondanNo ratings yet

- Challenges to Quality Control in Bored Cast-In-Situ Piling in Growing Urban EnvironmentsDocument17 pagesChallenges to Quality Control in Bored Cast-In-Situ Piling in Growing Urban Environmentsjacs127No ratings yet

- BRC Ju Jcs Bhavin 22102017Document2 pagesBRC Ju Jcs Bhavin 22102017jacs127No ratings yet

- Indigo TKT of MR Jaykumar Shukla 18 Oct Ccu Del BDQDocument4 pagesIndigo TKT of MR Jaykumar Shukla 18 Oct Ccu Del BDQjacs127No ratings yet

- Industry Academia Brochure 18-11-2017Document2 pagesIndustry Academia Brochure 18-11-2017jacs127No ratings yet

- Haripur River Water Intake GA, SectionDocument1 pageHaripur River Water Intake GA, Sectionjacs127No ratings yet

- Stability of Steel Oil Storage Tanks Duncan OrazioDocument20 pagesStability of Steel Oil Storage Tanks Duncan Oraziojacs127No ratings yet

- Brown 1969Document6 pagesBrown 1969jacs127No ratings yet

- Mou With DD Ws DR Do Bio DigesterDocument15 pagesMou With DD Ws DR Do Bio Digesterjacs127No ratings yet

- Chapter 2Document42 pagesChapter 2Manoj SinghNo ratings yet

- Code of Practice For Oil Storage Installations 1992Document22 pagesCode of Practice For Oil Storage Installations 1992Hassan SleemNo ratings yet

- Vopak BHDocument1 pageVopak BHjacs127No ratings yet

- Mesotech MS1000 PDFDocument2 pagesMesotech MS1000 PDFArnoldo López MéndezNo ratings yet

- Code of Practice For Oil Storage Installations 1992Document22 pagesCode of Practice For Oil Storage Installations 1992Hassan SleemNo ratings yet

- Bio DigesterBrochureDocument2 pagesBio DigesterBrochurejacs127No ratings yet

- Shaking Table Tests and Stability Analysis of Steep Nailed SlopesDocument16 pagesShaking Table Tests and Stability Analysis of Steep Nailed Slopesjacs127No ratings yet

- Co-Ordinates in UTM and Degree MinuteDocument2 pagesCo-Ordinates in UTM and Degree Minutejacs127No ratings yet

- Models - Acdc.pm Motor 3dDocument52 pagesModels - Acdc.pm Motor 3dAmadou KonfeNo ratings yet

- JavaScript ArraysDocument5 pagesJavaScript Arraysursu_padure_scrNo ratings yet

- Reflection Paper About Educational Administration (Ivy M. Peralta)Document1 pageReflection Paper About Educational Administration (Ivy M. Peralta)Ivy peraltaNo ratings yet

- Test Booklet Primary-1 PDFDocument53 pagesTest Booklet Primary-1 PDFReynold Morales Libato100% (1)

- Fiitjee Two Year Crp-2013-2015 Reshuffling Test - II Marks Test Date 30.03.2014Document35 pagesFiitjee Two Year Crp-2013-2015 Reshuffling Test - II Marks Test Date 30.03.2014Prateek__ManochaNo ratings yet

- Experiment 1 Tensile Testing (Universal Tester) : RD THDocument23 pagesExperiment 1 Tensile Testing (Universal Tester) : RD THShangkaran RadakrishnanNo ratings yet

- Week Three Lesson Plan Bread and Jam For FrancesDocument2 pagesWeek Three Lesson Plan Bread and Jam For Francesapi-29831576No ratings yet

- BlockStack Top 21 Trends in Web3 1676290935Document9 pagesBlockStack Top 21 Trends in Web3 1676290935Ahmed BachaNo ratings yet

- Solid Waste Management Center RevisedDocument44 pagesSolid Waste Management Center RevisedPrimo Ernesto CanoyNo ratings yet

- Electrical Power System FundamentalsDocument4 pagesElectrical Power System FundamentalsArnab BanerjeeNo ratings yet

- Dealing in Doubt 2013 - Greenpeace Report On Climate Change Denial Machine PDFDocument66 pagesDealing in Doubt 2013 - Greenpeace Report On Climate Change Denial Machine PDFŦee BartonNo ratings yet

- Agriculture DisciplineDocument3 pagesAgriculture DisciplineUmair FaheemNo ratings yet

- Case Study: The Chinese Fireworks IndustryDocument37 pagesCase Study: The Chinese Fireworks IndustryPham Xuan Son100% (1)

- Research On Water Distribution NetworkDocument9 pagesResearch On Water Distribution NetworkVikas PathakNo ratings yet

- Standardized Nursing LanguageDocument8 pagesStandardized Nursing LanguageLiiza G-GsprNo ratings yet

- Pe Unit2Document2 pagesPe Unit2srikaanth06No ratings yet

- Significance of Six SigmaDocument2 pagesSignificance of Six SigmaShankar RajkumarNo ratings yet

- Reviews On IC R 20Document5 pagesReviews On IC R 20javie_65No ratings yet

- Real Estate Development Business PlanDocument5 pagesReal Estate Development Business PlanA. FranciscoNo ratings yet

- Neotextil 8: Installation and Activation GuideDocument21 pagesNeotextil 8: Installation and Activation GuideRamesh PrajapatiNo ratings yet

- Using Accelerometers in A Data Acquisition SystemDocument10 pagesUsing Accelerometers in A Data Acquisition SystemueidaqNo ratings yet

- 12soal Uas - K.99 - Raditya - Bahasa Inggris Hukum (1) - 1Document3 pages12soal Uas - K.99 - Raditya - Bahasa Inggris Hukum (1) - 1Brielle LavanyaNo ratings yet

- The Retired Adventurer - Six Cultures of PlayDocument14 pagesThe Retired Adventurer - Six Cultures of Playfernando_jesus_58No ratings yet

- Baseline Switch 2226 Plus: User GuideDocument92 pagesBaseline Switch 2226 Plus: User GuideOswaldoNo ratings yet

- Teaching Arts in ElementaryDocument21 pagesTeaching Arts in ElementaryJackaii Waniwan IINo ratings yet

- Lesson 4 - Learning AssessmentDocument2 pagesLesson 4 - Learning AssessmentBane LazoNo ratings yet

- CNS - Types of CiphersDocument47 pagesCNS - Types of Ciphersmahesh palemNo ratings yet

- The Grand Landscape - Ian PlantDocument145 pagesThe Grand Landscape - Ian PlantJohanny Bravo100% (1)

- Paul of Aegina LaminectomyDocument9 pagesPaul of Aegina LaminectomypepepartaolaNo ratings yet

- Study Guide For Kawabata's "Of Birds and Beasts"Document3 pagesStudy Guide For Kawabata's "Of Birds and Beasts"BeholdmyswarthyfaceNo ratings yet