Professional Documents

Culture Documents

Cukurovapower

Uploaded by

Ahmed GadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cukurovapower

Uploaded by

Ahmed GadCopyright:

Available Formats

CJ720PN

Diesel Generator

CUKUROVA GENERATOR SYSTEMS

1500 Rpm, 50Hz, 400V

Perkins 2806A-E18TAG2 diesel engine

Newage/Stamford HCI544F alternator

Standard Generator Features

AMF, Automatic mains failure unit

Heavy duty type, 6 cylinder, water cooled engine

50C tropical type radiator

Starter motor

Lead acid battery

Charging alternator

Battery charge redressor

Heavy duty, brushless type alternator

Base frame with anti-vibration units

Industrial type silencers

Flexible exhaust compensator

Block water heater unit

Control panel with digital-automatic main control module

Fan, fan drive, charging alternator drive and all rotating parts

covered

Radiator matrix covered by metal mesh against the

mechanical damages

Fabricated and welded steel base frame

Anti-vibration mountings

Engine and alternator manufacturer test reports

Factory load, performance and function tests

Optional Features

Automatic load transfer panel

ISO

ISO9001:2000

9001:2000

Cukurova is a fully accrediated

ISO 9001:2000 company

Automatic syncronization and power sharing systems

Soundproof canopy

Container type enclosers

Road trailer

Job-site trailer

Protection circuit breaker

Air start

Remote type radiator

Base fuel tank

This generator is available with

CE certification

External type fuel tank

Automatic fuel transfer system

Residential silencer

Model

Cukurova is accrediated with

CJ720PN

Standby

Prime

kVA

kW

kVA

kW

720

576

670

536

Gost certification

All information in this document is substantially correct at time of printing and may be altered subsequently.

CJ720PN Technical Data Sheet 061130 - Page1

CUKUROVA Diesel Generator

engine

APPLICATION DATA

Perkins 2806A-E18TAG2 Engine

Standard Features

Model

Standby kW

Prime kW

Gross

Net

Gross

Net

628

609

584

565

Economic power

Mechanically operated unit fuel injectors with electronic control combined

2806A-E18TAG2

with carefully matched turbocharging give excellent fuel atomisation and

combustion with optimum economy

Low emissions result from electronic control of fuel injected

Lubricating System

Type

Reliable power

Developed and tested using latest engineering techniques and finite element

analysis for high reliability, low oil usage and low wear rates

Pressurized

Capacity, Liters

62

Lub oil pressure (min), bar

Wet sump with filler and dipstick

High compression ratios also ensure clean rapid starting in all conditions

Full-flow replaceable Ecoplus filter

Support comes from a worldwide network of 4000 distributors and dealers

Oil cooler integral with filter header

Fuel System

Compact and efficient power

Exceptional power to weight ratio and compact size give optimum power

density with easier installation and cost effective transportation

Designed to provide excellent service access for ease of maintenance

Clean Power

Type of injection system

MEUI

Fuel injection pump

Combined unit injector

Delivery/hour at 1500rev/min, Liters

413

Governor type

Electronic, governing to ISO 8528-5

The 2806-E18TAG2 is capable of meeting the requirements of TA luft (1986)

class G2 with isochronous capability

Mechanically actuated electronically controlled unit fuel injectors with full

authority electronic control

Standards

UK MOD, BS5750, ISO9001, BS5514/1-1982, ISO 3046/1, ISO 8528/1

Replaceable Ecoplus fuel filter elements with primary filter/water separator

Fuel cooler

Electrical System

Technical Specifications

Manufacturer

PERKINS

Alternator

Model

2806A-E18TAG2

Starter motor (DC)

24 Volt

Type

4 cycle, water-cooled, diesel engine

Starter motor power

9 kW

24 Volt with integral regulator

Number of cylinders

ECM mounted on engine with wiring looms and sensors

Cylinder arrangement

Vertical in-line

3 level engine protection system

Displacement, Liters

18.1

Bore X Stroke, mm

145 X 183

Compression Ratio

14.5:1

Fuel Consumption

Combustion System

Direct injection

Aspiration

Turbocharged, air-to-air charge cooled

Rotation

Anti-clockwise viewed on flywheel

Gross engine power, kWb

628

Fan Power, kWm

%75 Load

97 L

BMEP gross, bar

27,7

%50 Load

66 L

Combustion air flow, m / min

40

%110 Load

203 g/kWh

%100 Load

202 g/kWh

%75 Load

198 g/kWh

%50 Load

201 g/kWh

Exhaust gas temp.(after turbo), C

553

Exhaust gas flow (after turbo),m / min

114

Mean piston speed, m / s

Cooling System

liters per hour

grams per kWh

%110 Load

143 L

%100 Load

132 L

Optional Equipments

Type

Tropical, heavy duty type

Ambient temperature, C

50

Temperature and pressure sensors for gauges

Engine+Radiator coolant cap., Liters

61

Electric hours counter

Jacket coolant flow, Liters / sec

6.1

Air filter rain hood

Cooling min airflow, m / min

1170 (at 45C)

Twin starters/facility for second starter

Additional speed sensor

Gear-driven circulating pump

Mounted belt-driven pusher fan

Radiator incorporating air-to-air charge cooler, (supplied loose)

System designed for ambients up to 50C

Low coolant level switch

All information in this document is substantially correct at time of printing and may be altered subsequently.

CJ720PN Technical Data Sheet 061130 - Page2

alternator

Newage/Stamford HCI544F Alternator

Standard Features

Model

Standby

Prime

kVA

kW

kVA

kW

738

590

670

536

Winding&Electrical Performance

All generator stators are wound to 2/3 pitch.This eliminates triplen (3rd, 9th,

HCI544F

15th...) harmonics on the voltage waveform and is found to be the optimum

design for trouble-free supply of non-linear loads.The 2/3 pitch design avoids

excessive neutral currents sometimes seen with higher winding pitches,

Technical Specifications

when in parallel with the mains.A fully connected damper winding reduces

oscillations during paralelling.This winding, with the 2/3 pitch and carefully

Manufacturer

NEWAGE / STAMFORD

selected pole and tooth designs, ensures very low waveform distortion.

Model

HCI544F

Type

4-Poles, Rotating Field, Brushless

SX440 AVR

Standby power at rated voltage, kVA

738

With this self-excited system the main stator provides power via the Automatic

Efficiency, %

94.6%

Voltage Regulator (AVR) to the exciter stator. The high efficiency semi-

Power factor

0.8

conductors of the AVR ensure positive build-up from initial low levels of

Phase

residual voltage.

Frequency, Hz

50

The exciter rotor output is fed to the main rotor through a three-phase full-wave

Speed, Rpm

1500

bridge rectifier. The rectifier is protected by a surge suppressor against surges

Voltage, V

380/415

caused, for example, by short circuit or out-of-phase paralleling.

Excitation

Self excited

The SX440 will support a range of electronic accessories, including a 'droop'

Stator windings

2/3 Pitch factor

Current Transformer (CT) to permit parallel operation with other ac generators.

Regulation

AVR, Automatic Voltage Regulator

If 3-phase sensing is required with the self-excited system, the SX421 AVR

Voltage Regulator

SX440

must be used.

Voltage Regulation, %

R.F.I Suppression

BS EN 61000-6-2 & BS EN 61000-6-4

Waveform distortion

No Load <1.5% Non distorting balanced

VDE0875G, VDE 0875N

Terminals&Terminal Box

Standard generators are 3-phase reconnectable with 12 ends brought out to

linear load<5.0%

the terminals, Which are mounted on a cover at the non-drive end of the

generator. A sheet steel terminal box contains the AVR and provides ample

Rotor

Dynamic balanced

space for the customers wiring and gland arrangements.It has removable

Overspeed, Rpm

2250

panels for easy access.

Short circuit current

< 300%

TIF

Less than 50

Shaft&Keys

Insultion class

All generator rotors are dynamically balanced to better than BS6861:Part 1

Construction

Single bearing, direct coupled

Grade 2.5 for minimum vibration in operation. Two bearing generators are

Coupling

Flexible

balanced with a half key.

Stator winding

Double layer concentric

Connection

WYE

Insulation / Impregnation

Protection class

IP23

The insulation system is class 'H'

Cooling air volume,m / sec

1.035

All wound components are impregnated with materials and processes

designed specifically to provide the high build required for static windings and

the high mechanical strength required for rotating components.

Standards

Optional Equipment

Newage Stamford industrial generators meet the requirements of BS EN

60034 and the relevent section of other international standards such as

BS5000,VDE0530, NEMA MG1-32, IEC34, CSA C22.2-100, AS1359

Other standards and certifications can be considered on request

Optional Permanent Magnet Generator (PMG) provides an isolated power

supply to the excitation control system

Anti Condensation Heaters

Air Filters

Quaility Assurance

Temperature Indication RTDs

Generators are manufactured using production procedures having a quaility

Winding Protection Thermistors

assurance level to BS EN ISO 9001.

Quadrature Droop kit for Parallel Operation

SX421 AVR with 3 Phase Sensing and improved Regulation 0.5%

MX341 (PMG) 1% Regulation with 2 Phase Sensing

MX321 (PMG) with 3 Phase Sensing and improved Regulation 0.5%

All information in this document is substantially correct at time of printing and may be altered subsequently.

CJ720PN Technical Data Sheet 061130 - Page3

control panel

CJ720PN

Control Panel

Standard Equipments

Input Functions display on LCD

Generator Volts

Volts L1-N, L2-N, L3-N

Generator Volts

Volts L1-L2, L2-L3, L3-L1

Generator Amps

Amps L1, L2, L3

Generator Frequency

Hz

Mains Volts

Volts L1-N, L2-N, L3-N

Mains Volts

Volts L1-L2, L2-L3, L3-L1

Mains Frequency

Hz

Engine Speed

RPM

Plant Battery Volts

Volts

Engine Hours Run

Hour

Generator total power

kVA L1, L2, L3,total

Generator total power

kW

Generator power factor

Cos L1, L2, L3,total

Deeapse 5220 digital automatic control module

Optional Input Functions

Hourmeter

Engine Oil pressure

kPa

Voltmeter

Fuel level

Voltmeter commutator

Engine Temperature

L1, L2, L3,total

Ampermeter

Ampermeter commutator

Alarm Channels

Emergency stop button

Under/over generator voltage

Over-current

Deepsea 5220 Control Module

Under/over generator frequency

Description

Under/over speed

Charge fail

The model 5220 is an Automatic Mains Failure Control module.

Emergency stop

The modul is used to monitor a mains supply and automaticlly start a

Low oil pressure

standby generator set.

The module also provides indication of operational status and fault conditions

automaticly shutting down the genset and indicating failures by means of an

LCD display, and appropriate flashing LED on the front panel.

Selected timers and alarms can be altered by the user from the front panel.

Alterations to the system are made using the 810 interface and a PC. This

interface also provides real time diagnostic facilities

High engine temperature

Fail to start

Low/high DC battery voltage

Reverse power

Generator phase rotation error

Generator short-circuit protection

Loss of speed sensing signal

Mains out of limits

Specifications

240mm x 172mm dimensions

70mm x 40mm dimensions, 4 segment grafical LCD monitor

Environmental Testing Standards

Electromagnetic Compatibility

BS EN 50081-2:1992 and EN 61000-6-4:2000 EMC, Emission Standards for

Developed 16-bit Microprocessor design

the Industrial Environment

Easy comprehended display (Hid-Til-Lit SMD LED technology)

EN 61000-6-2:1999 EMC, Immunity Standards for the Industrial Environment

LED mimic diagram

Vibration

SMS messaging capability with suitable GSM Modem

BS EN 60068-2-6 Ten sweeps (up and back down) at 1 octave/minute in

PC software is MS Windows based and allows the operator to control the

each of the three major axes.

module from a remote location (P810 Software Kit necessary)

5Hz to @ +/-7.5mm constant displacement.

Easy pushbutton controls

8Hz to 500Hz 2gn constant acceleration.

System parameters can be adjusted manually from the front panel

Temperature

kVA,kW ve Cos measurements

Cold : BS EN 60068-2-1 to -30C

Communication with MODEM

Hot : BS EN 60068-2-2 to 70C

Humidity

BS EN 2011 part 2.1 93% RH @ 40 for 48 hours

Pushbutton Controls

Shock

BS EN 6068-2-27 Three half sine shocks in each of the three

STOP / START

major axes 15gn amplitude.11mS duration.

AUTO, TEST, MANUAL

Electrical Safety

LCD PAGE

BS EN 60950 Low Voltage Dirctive/Safety of information technology

equipments, including electrical business equipment

All information in this document is substantially correct at time of printing and may be altered subsequently.

CJ720PN Technical Data Sheet 061130 - Page4

CUKUROVA Diesel Generator

CJ720PN

Model Codes and General Information

Cukurova Diesel Generator

CJ

720

N

N Group - Alternator brand (Newage/Stamford)

P Series - Engine brand (Perkins)

Standby Power - kVA

Cukurova generator

Newage/Stamford Alternator

Perkins 2800 Series Diesel Engine

2806A-E18

HC

54

Power level

Genset engine

Core Length

Air-to-air charge cooled

Number of poles

Turbocharged

Shaft Height in cm

Electronic, 18 liters

Industrial

2800 Series, 6 cylinder

Generator type

Information

Power Ratings

Electric Formulas

Standby power rating is for the supply of emergency power at variable

load for the duration of the non-avalaibality of the mains power supply.No

overload capacity is available at this rating.A standby rated engine should be

sized for an avarage load factor of 80% based on published standby rating for

rating, incorporation of a 10% overload for 1 hour in every 12 hours of

operation which permitted

kWe

kWm X E

(U x I x 1.73 x pf) / 1000

kVA x pf

kVA

(U x I x 1.73) / 1000

kWe / pf

I (Amp)

(kWe x 1000) / (U x 1.73 x pf)

(kVA x 1000) / (U x 1.73)

in true emergency power failure conditions.

load of which the average engine load factor is 80% of the published power

Formula

kWe

500 operating hours per year.Standby ratings should never be applied except

Prime power rating is available for unlimited hours per year with a variable

Values

Frequency

( Rpm x NPole) / (2 x 60)

Rpm

(2 x 60 x Frequency) / NPole

Continuous power rating is available for continuous full load operation.No

overload is permitted.

Acc. To ISO 3046/1, BS 5514, DIN6271

All information in this document is substantially correct at time of printing and may be altered subsequently.

kWm: Mechanical Power

: Current (A)

kWe : Electrical Power

: Voltage (V)

pf

: Power factor

kVA : Power

: Alternator efficiency

Rpm: Revolutions per minute

CJ720PN Technical Data Sheet 061130 - Page5

CUKUROVA Diesel Generator

CJ720PN

General Dimensions

Standard Generator

Length, L

3,7 m

Heigth, H

2m

Width, W

1,6 m

Weight, Total

4.500 kg

Length, L

5,4 m

Heigth, H

2,9 m

Width, W

1,9 m

Weight, Total

6.500 kg

L

Generator with Soundproof Canopy

2,5 m

2m

2m

3,5 m

0,8 m

1,2 m

Generator Room Layout

7m

Above drawings dimensions and weights are only for guidence.For installation design of your specific application, necessary certified drawings, at site consultancy service as well as maintenance and installations manuals will be provided by Cukurova without any charge.

Specifications may change without notice

All information in this document is substantially correct at time of printing and may be altered subsequently.

CJ720PN Technical Data Sheet 061130 - Page6

You might also like

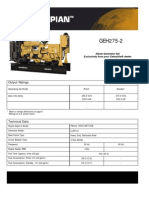

- GEH275Document4 pagesGEH275foroNo ratings yet

- Solar Energy Proposal For Anderson High SchoolDocument10 pagesSolar Energy Proposal For Anderson High Schoolapi-276217158100% (1)

- QSK60 Series 50hzDocument4 pagesQSK60 Series 50hzbacuoc.nguyen3560% (1)

- Cummins Nt855Document6 pagesCummins Nt855Luis Jesus100% (1)

- S 1514Document4 pagesS 1514bacuoc.nguyen356No ratings yet

- Analog Circuit Design Volume Three: Design Note CollectionFrom EverandAnalog Circuit Design Volume Three: Design Note CollectionRating: 3 out of 5 stars3/5 (2)

- Catalogue Newer Catepillar Engines SM NewDocument176 pagesCatalogue Newer Catepillar Engines SM NewAhmed GadNo ratings yet

- Catalogue Newer Catepillar Engines SM NewDocument176 pagesCatalogue Newer Catepillar Engines SM NewAhmed GadNo ratings yet

- DSC 1280Document11 pagesDSC 1280nhiahm nhiahmNo ratings yet

- Çukurova j1100pn Data SheetDocument6 pagesÇukurova j1100pn Data SheetibilgeNo ratings yet

- Diesel Generating Set 250 kVADocument2 pagesDiesel Generating Set 250 kVAherrtamm100% (1)

- Perkins Diesel Generator P400pub 360kwDocument4 pagesPerkins Diesel Generator P400pub 360kwTariq KoyrattyNo ratings yet

- AC250 Data SheetDocument5 pagesAC250 Data SheetAshutosh SinghNo ratings yet

- MTU20V4000DS2800 2500kW DCCP PDFDocument4 pagesMTU20V4000DS2800 2500kW DCCP PDFNestor AlbarranNo ratings yet

- Taylor Power SystemsDocument4 pagesTaylor Power SystemsTeresa CarterNo ratings yet

- Model: Model: Model: Model:: ETCG75Document7 pagesModel: Model: Model: Model:: ETCG75Jhay LopezNo ratings yet

- C1100 D5Document2 pagesC1100 D5anon_568723957100% (1)

- DFHD - Model Specification SheetDocument4 pagesDFHD - Model Specification SheetAlejandro Lagares100% (1)

- Model: Model: Model: Model:: ETCG500Document7 pagesModel: Model: Model: Model:: ETCG500HENRYNo ratings yet

- G3516 (975 Ekw 1218 kVA)Document7 pagesG3516 (975 Ekw 1218 kVA)Antwon CharlesNo ratings yet

- G3508 - 600kvaDocument7 pagesG3508 - 600kvaJim Patrick ChombaNo ratings yet

- Diesel Generator Set: Prime Model:LP90P Standby Model:LP100SDocument4 pagesDiesel Generator Set: Prime Model:LP90P Standby Model:LP100SLeonardusHSijabatNo ratings yet

- Diesel Generator Set Specifications and FeaturesDocument4 pagesDiesel Generator Set Specifications and Featuressahat100% (1)

- Rental: XQ2000 Sound Attenuated Power ModuleDocument8 pagesRental: XQ2000 Sound Attenuated Power ModuleAngel Javier NuñezNo ratings yet

- MTU10V1600DS550 550kVA Standby FuelOptDocument4 pagesMTU10V1600DS550 550kVA Standby FuelOptlcsandovalr989No ratings yet

- 90kVA PDFDocument4 pages90kVA PDFXander DelinyaNo ratings yet

- Diesel Engine MitsubishiDocument4 pagesDiesel Engine MitsubishiMarbun Benny100% (1)

- 50KVA RevDocument2 pages50KVA RevMansoor AhmadNo ratings yet

- 3412C 725 kVA Prime LowBsfc EU 50HzDocument6 pages3412C 725 kVA Prime LowBsfc EU 50Hzrbmr1No ratings yet

- Catalogo Generador Cat 3512Document6 pagesCatalogo Generador Cat 3512pamg50% (1)

- Manual BF DW550Document5 pagesManual BF DW550Luis Panti EkNo ratings yet

- 100 RDDocument4 pages100 RDMahmoud EldabahNo ratings yet

- XQ1000 Lehx0532Document6 pagesXQ1000 Lehx0532Anonymous uZJfsg819LNo ratings yet

- C150D5 - Data Sheet UKDocument2 pagesC150D5 - Data Sheet UKphonggensetNo ratings yet

- TechnicalData EMD-350 Inso PDFDocument2 pagesTechnicalData EMD-350 Inso PDFajrojas1359No ratings yet

- Perkins Diesel Generator Set - ISO Certified, 50Hz 3-Phase GeneratorDocument4 pagesPerkins Diesel Generator Set - ISO Certified, 50Hz 3-Phase GeneratorConstantyn_FrederikNo ratings yet

- Perkins P200Document4 pagesPerkins P200PaulusIwanNo ratings yet

- Diesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PDocument4 pagesDiesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PYashveer TakooryNo ratings yet

- TAD1642GE: Volvo Penta Genset EngineDocument2 pagesTAD1642GE: Volvo Penta Genset EngineroozbehxoxNo ratings yet

- Prime Model: P70 Emergency Model: P76E Diesel Generator Technical SpecificationsDocument4 pagesPrime Model: P70 Emergency Model: P76E Diesel Generator Technical SpecificationsLeonardusHSijabatNo ratings yet

- AUSGEN 100kva Perkins Silent 1006TG2ADocument5 pagesAUSGEN 100kva Perkins Silent 1006TG2AMarkqshot JaladaraNo ratings yet

- S 1644DCDocument5 pagesS 1644DCAnh NguyenNo ratings yet

- Reozjc: Standard Features Ratings RangeDocument4 pagesReozjc: Standard Features Ratings RangePapi CruzNo ratings yet

- C440 D5Document2 pagesC440 D5Thao Nguyen XuanNo ratings yet

- P1500PB (4012 46tag2a)Document4 pagesP1500PB (4012 46tag2a)astwan81No ratings yet

- P80PBDocument4 pagesP80PBastwan81No ratings yet

- 0k5093 A sd100 6 7l PDFDocument6 pages0k5093 A sd100 6 7l PDFmarpadanNo ratings yet

- Diesel Generator Set KTA19 Series Engine: 576kVA - 650kVA 50Hz 501kW 60HzDocument4 pagesDiesel Generator Set KTA19 Series Engine: 576kVA - 650kVA 50Hz 501kW 60HzSandro MunizNo ratings yet

- 1000 Kva 400v c32 Low BSFC PrimeDocument6 pages1000 Kva 400v c32 Low BSFC PrimeelipholebNo ratings yet

- PERKINS - 1306C-E87TAG3-ElectropaK - 200 KVA PDFDocument2 pagesPERKINS - 1306C-E87TAG3-ElectropaK - 200 KVA PDFYosi Darmawansyah100% (2)

- P40PB (1004G) GensetDocument4 pagesP40PB (1004G) GensetBudi WaskitoNo ratings yet

- Yanmar Brochure 02Document2 pagesYanmar Brochure 02Fabiano OnaibafNo ratings yet

- P400PB (2206C E13tag3) PDFDocument4 pagesP400PB (2206C E13tag3) PDFFirstiawanNo ratings yet

- 1010 kVADocument4 pages1010 kVAPtpNo ratings yet

- 2010.diesel Generating Set2.23 - 13.55.7 - 1169Document5 pages2010.diesel Generating Set2.23 - 13.55.7 - 1169Bechara Philip AssouadNo ratings yet

- SS10 CPGK PDFDocument4 pagesSS10 CPGK PDFvitgahiNo ratings yet

- (Maxplore Energaz Turbine) (Power Generation System Proposal)Document8 pages(Maxplore Energaz Turbine) (Power Generation System Proposal)Arthur Savero SaharsonNo ratings yet

- TB 46204 f 50 Genset without heat recovery boxDocument7 pagesTB 46204 f 50 Genset without heat recovery boxmgewaliNo ratings yet

- GTG 1636FPC PWFT4 50HzDocument24 pagesGTG 1636FPC PWFT4 50HzEmanuel CondeNo ratings yet

- Volvo Diesel Generator p150v Tad720geDocument4 pagesVolvo Diesel Generator p150v Tad720geEvany Ziñho QNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Egypt - Gridcode - For - Solar - Plant - Connection On MV and HV PDFDocument30 pagesEgypt - Gridcode - For - Solar - Plant - Connection On MV and HV PDFAhmed GadNo ratings yet

- Part B-9 PDFDocument23 pagesPart B-9 PDFFejs Za ScribdNo ratings yet

- Forced Convection Heat Transfer MechanismsDocument11 pagesForced Convection Heat Transfer Mechanismsjarek3aNo ratings yet

- Pcat1394Megadyne 11 v-BELTSDocument56 pagesPcat1394Megadyne 11 v-BELTSMykola TitovNo ratings yet

- IFC+Solar+Report Web+ 08+05Document216 pagesIFC+Solar+Report Web+ 08+05Jaikumar Pettikkattil0% (1)

- Pcat1394Megadyne 11 v-BELTSDocument56 pagesPcat1394Megadyne 11 v-BELTSMykola TitovNo ratings yet

- 6 - Johnson, K - Geotechnical Investigations For Dredging Projects PDFDocument16 pages6 - Johnson, K - Geotechnical Investigations For Dredging Projects PDFAhmed GadNo ratings yet

- Mtu 12v4000g21r1Document117 pagesMtu 12v4000g21r1RoyenNo ratings yet

- Operation and Mantenance Manual Perkins 1103 and 1104c Engines SystemsDocument92 pagesOperation and Mantenance Manual Perkins 1103 and 1104c Engines SystemsDiego Barbas83% (6)

- Deep Sea Electronics PLC: 555 Operators ManualDocument58 pagesDeep Sea Electronics PLC: 555 Operators ManualAhmed Gad100% (2)

- Perkins 2800 Series: Diagnostic ManualDocument156 pagesPerkins 2800 Series: Diagnostic ManualSajjad Hussain100% (1)

- Rukovodstvo Comap Inteligen NT Basebox PDFDocument149 pagesRukovodstvo Comap Inteligen NT Basebox PDFVERY SYAYIDINANo ratings yet

- MTU 10V1600 DS560: Diesel Generator SetDocument5 pagesMTU 10V1600 DS560: Diesel Generator SetAhmed GadNo ratings yet

- Mtu 12v4000g21r1Document117 pagesMtu 12v4000g21r1RoyenNo ratings yet

- Mtu 12v4000g21r1Document117 pagesMtu 12v4000g21r1RoyenNo ratings yet

- CH 2mmDocument8 pagesCH 2mmAhmed GadNo ratings yet

- Mtu 12v4000g21r1Document117 pagesMtu 12v4000g21r1RoyenNo ratings yet

- Solar Atlas 2018 Digital1Document277 pagesSolar Atlas 2018 Digital1Abdalla Eldeeb0% (1)

- Solar Atlas 2018 Digital1Document277 pagesSolar Atlas 2018 Digital1Abdalla Eldeeb0% (1)

- Mtu 12v4000g21r1Document117 pagesMtu 12v4000g21r1RoyenNo ratings yet

- Solar Atlas 2018 Digital1Document277 pagesSolar Atlas 2018 Digital1Abdalla Eldeeb0% (1)

- Solar Atlas 2018 Digital1Document277 pagesSolar Atlas 2018 Digital1Abdalla Eldeeb0% (1)

- TD Fault Man GB July 2009 GBDocument13 pagesTD Fault Man GB July 2009 GBAhmed GadNo ratings yet

- Cooling TowerDocument31 pagesCooling TowerAhmed GadNo ratings yet

- Solar Atlas 2018 Digital1Document277 pagesSolar Atlas 2018 Digital1Abdalla Eldeeb0% (1)

- Cooling TowerDocument31 pagesCooling TowerAhmed GadNo ratings yet

- BearingDocument23 pagesBearingAhmed Gad100% (1)

- Solv F.exam.1918Document6 pagesSolv F.exam.1918Ahmed GadNo ratings yet

- Nexsys Chargers: SolutionsDocument6 pagesNexsys Chargers: SolutionsThanh NgocNo ratings yet

- Electrical Price Schedule-R1Document6 pagesElectrical Price Schedule-R1Anu GraphicsNo ratings yet

- Company Profile 2023 PDF Version 3mbDocument12 pagesCompany Profile 2023 PDF Version 3mbmarzkiipelengaeNo ratings yet

- Thermal Power Plant Interview Questions AnswersDocument2 pagesThermal Power Plant Interview Questions Answersrajeshkumarpuvvala50% (2)

- Electrical Circuits (EEE-141)Document21 pagesElectrical Circuits (EEE-141)Sudipto Sarker SuptoNo ratings yet

- C Audio SR707 SchematicsDocument4 pagesC Audio SR707 SchematicsBNo ratings yet

- Transformer: Physics Investigatory ProjectDocument18 pagesTransformer: Physics Investigatory ProjectSonu100% (1)

- Yamamoto A08-S Amplifier Kit: Horber Steige 25 72172 Sulz Germany Tel: ++49-1755382641Document6 pagesYamamoto A08-S Amplifier Kit: Horber Steige 25 72172 Sulz Germany Tel: ++49-1755382641Kris RasNo ratings yet

- RCA - CTC177AA3 Chassis TV RCADocument16 pagesRCA - CTC177AA3 Chassis TV RCAapi-19523062No ratings yet

- ETI Green Protect 2019Document100 pagesETI Green Protect 2019123No ratings yet

- Bst100 User ManualDocument27 pagesBst100 User Manualpepsi_bozic100% (1)

- ACT30Document10 pagesACT30arao_filhoNo ratings yet

- TBoxMS Technical Specification 2.35Document157 pagesTBoxMS Technical Specification 2.35nitinsomanathanNo ratings yet

- Cem AssDocument13 pagesCem AssHarshdeep SinghNo ratings yet

- Eletronics Lab Report - Zener DiodesDocument3 pagesEletronics Lab Report - Zener DiodesThan Lwin Aung71% (7)

- User Manual: SUN2000 - (8KTL, 10KTL, 12KTL, 15KTL, 17KTL, 20KTL) - M0Document98 pagesUser Manual: SUN2000 - (8KTL, 10KTL, 12KTL, 15KTL, 17KTL, 20KTL) - M0Anh Tú NguyễnNo ratings yet

- Info Iec61869-5 (Ed1.0) BDocument15 pagesInfo Iec61869-5 (Ed1.0) Bmido211250% (2)

- Automatic Street Light ControllerDocument4 pagesAutomatic Street Light ControllerPravat SatpathyNo ratings yet

- Bts 8020 Site Specification-06-9104Document60 pagesBts 8020 Site Specification-06-9104bssvelloreNo ratings yet

- Electrical Converter: User GuideDocument73 pagesElectrical Converter: User GuideLionildo LucyNo ratings yet

- Kami Export - Thierry Keefe Kainan - Topic 5 Review WorksheetDocument6 pagesKami Export - Thierry Keefe Kainan - Topic 5 Review WorksheetHeruclolNo ratings yet

- Specifications: Portable, Explosion-Proof Wideband™ Ir Test LampDocument4 pagesSpecifications: Portable, Explosion-Proof Wideband™ Ir Test LampYonnathan Ruben Tovar FandiñoNo ratings yet

- Emmy SeminarDocument21 pagesEmmy SeminarEdul BrianNo ratings yet

- mPro-100-V2 Catalog (Standard)Document18 pagesmPro-100-V2 Catalog (Standard)bgbbNo ratings yet

- Demandnote PDFDocument2 pagesDemandnote PDFlaxmanNo ratings yet

- Directional Over CurrentDocument14 pagesDirectional Over CurrentAisah El ArinalNo ratings yet

- G81 - 2 Housing Materials PDFDocument17 pagesG81 - 2 Housing Materials PDFHassan SaeedNo ratings yet

- TR25-1 Annex DDocument2 pagesTR25-1 Annex DDarshit VyasNo ratings yet