Professional Documents

Culture Documents

Standard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1

Uploaded by

Lupita RamirezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1

Uploaded by

Lupita RamirezCopyright:

Available Formats

Designation: C 496/C 496M 04e1

Standard Test Method for

Splitting Tensile Strength of Cylindrical Concrete

Specimens1

This standard is issued under the fixed designation C 496/C 496M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e1 NOTEFootnote 3 was reinserted editorially to correct a typo in December 2006.

3. Summary of Test Method

3.1 This test method consists of applying a diametral

compressive force along the length of a cylindrical concrete

specimen at a rate that is within a prescribed range until failure

occurs. This loading induces tensile stresses on the plane

containing the applied load and relatively high compressive

stresses in the area immediately around the applied load.

Tensile failure occurs rather than compressive failure because

the areas of load application are in a state of triaxial compression, thereby allowing them to withstand much higher compressive stresses than would be indicated by a uniaxial compressive strength test result.

3.2 Thin, plywood bearing strips are used to distribute the

load applied along the length of the cylinder.

3.3 The maximum load sustained by the specimen is divided

by appropriate geometrical factors to obtain the splitting tensile

strength.

1. Scope*

1.1 This test method covers the determination of the splitting tensile strength of cylindrical concrete specimens, such as

molded cylinders and drilled cores.

1.2 The values stated in either inch-pound or SI units are to

be regarded separately as standard. The SI units are shown in

brackets. The values stated in each system may not be exact

equivalents; therefore, each system shall be used independently

of the other. Combining values from the two systems may

result in nonconformance with the standard.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The text of this standard references notes that provide

explanatory material. These notes shall not be considered as

requirements of the standard.

4. Significance and Use

4.1 Splitting tensile strength is generally greater than direct

tensile strength and lower than flexural strength (modulus of

rupture).

4.2 Splitting tensile strength is used in the design of

structural lightweight concrete members to evaluate the shear

resistance provided by concrete and to determine the development length of reinforcement.

2. Referenced Documents

2.1 ASTM Standards: 2

C 31/C 31M Practice for Making and Curing Concrete Test

Specimens in the Field

C 39/C 39M Test Method for Compressive Strength of Cylindrical Concrete Specimens

C 42/C 42M Test Method for Obtaining and Testing Drilled

Cores and Sawed Beams of Concrete

C 192/C 192M Practice for Making and Curing Concrete

Test Specimens in the Laboratory

C 670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

5. Apparatus

5.1 Testing MachineThe testing machine shall conform to

the requirements of Test Method C 39/C 39M and be of a type

with sufficient capacity that will provide the rate of loading

prescribed in 7.5.

5.2 Supplementary Bearing Bar or PlateIf the diameter or

the largest dimension of the upper bearing face or the lower

bearing block is less than the length of the cylinder to be tested,

a supplementary bearing bar or plate of machined steel shall be

used. The surfaces of the bar or plate shall be machined to

within 6 0.001 in. [0.025 mm] of planeness, as measured on

any line of contact of the bearing area. It shall have a width of

at least 2 in. [50 mm], and a thickness not less than the distance

1

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee

C09.61 on Testing for Strength.

Current edition approved Feb. 1, 2004. Published March 2004. Originally

approved in 1962. Last previous edition approved in 1996 as C 496 96.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 496/C 496M 04e1

from the edge of the spherical or rectangular bearing block to

the end of the cylinder. The bar or plate shall be used in such

manner that the load will be applied over the entire length of

the specimen.

5.3 Bearing StripsTwo bearing strips of nominal 18 in.

[3.2 mm] thick plywood, free of imperfections, approximately

1 in. [25 mm] wide, and of a length equal to, or slightly longer

than, that of the specimen shall be provided for each specimen.

The bearing strips shall be placed between the specimen and

both the upper and lower bearing blocks of the testing machine

or between the specimen and supplemental bars or plates, when

used (see 5.2). Bearing strips shall not be reused.

NOTE 1Figs. 1 and 2 show a suitable device for drawing diametral

lines on each end of a 6 in. by 12 in. [150 mm by 300 mm] cylinder in the

same axial plane. The device consists of three parts as follows:

(1) A length of 4-in. [100-mm] steel channel, the flanges of which have

been machined flat,

(2) A section, part a, that is grooved to fit smoothly over the flanges of

the channel and that includes cap screws for positioning the vertical

member of the assembly, and

(3) A vertical bar, part b, for guiding a pencil or marker,

The assembly (part a and part b) is not fastened to the channel and is

positioned at either end of the cylinder without disturbing the position of

the specimen when marking the diametral lines.

NOTE 2Fig. 4 is a detailed drawing of the aligning jig shown in Fig.

3 for achieving the same purpose as marking the diametral lines. The

device consists of:

(1) A base for holding the lower bearing strip and cylinder,

(2) A supplementary bearing bar conforming to the requirements in

Section 5 as to critical dimensions and planeness, and

(3) Two uprights to serve for positioning the test cylinder, bearing

strips, and supplementary bearing bar.

6. Test Specimens

6.1 The test specimens shall conform to the size, molding,

and curing requirements set forth in either Practice C 31/

C 31M (field specimens) or Practice C 192/C 192M (laboratory specimens). Drilled cores shall conform to the size and

moisture-conditioning requirements set forth in Test Method

C 42/C 42M. Moist-cured specimens, during the period between their removal from the curing environment and testing,

shall be kept moist by a wet burlap or blanket covering, and

shall be tested in a moist condition as soon as practicable.

6.2 The following curing procedure shall be used for evaluations of light-weight concrete: specimens tested at 28 days

shall be in an air-dry condition after 7 days moist curing

followed by 21 days drying at 73.5 6 3.5F [23.0 6 2.0C] and

50 6 5 % relative humidity.

7.2 MeasurementsDetermine the diameter of the test

specimen to the nearest 0.01 in. [0.25 mm] by averaging three

diameters measured near the ends and the middle of the

specimen and lying in the plane containing the lines marked on

the two ends. Determine the length of the specimen to the

nearest 0.1 in. [2 mm] by averaging at least two length

measurements taken in the plane containing the lines marked

on the two ends.

7.3 Positioning Using Marked Diametral LinesCenter

one of the plywood strips along the center of the lower bearing

block. Place the specimen on the plywood strip and align so

that the lines marked on the ends of the specimen are vertical

and centered over the plywood strip. Place a second plywood

strip lengthwise on the cylinder, centered on the lines marked

on the ends of the cylinder. Position the assembly to ensure the

following conditions:

7. Procedure

7.1 MarkingDraw diametral lines on each end of the

specimen using a suitable device that will ensure that they are

in the same axial plane (see Fig. 1, Fig. 2 and Note 1), or as an

alternative, use the aligning jig shown in Fig. 3 (Note 2).

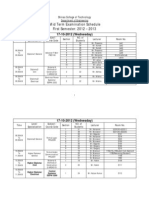

FIG. 1

General Views of a Suitable Apparatus for Marking End Diameters Used for Alignment of Specimen in Testing Machine

C 496/C 496M 04e1

FIG. 2

FIG. 3

Detailed Plans for a Suitable Apparatus for Marking End Diameters Used for Aligning the Specimen

7.3.2 The supplementary bearing bar or plate, when used,

and the center of the specimen are directly beneath the center

of thrust of the spherical bearing block (see Fig. 5).

7.4 Positioning by Use of Aligning JigPosition the bearing strips, test cylinder, and supplementary bearing bar by

means of the aligning jig as illustrated in Fig. 3 and center the

jig so that the supplementary bearing bar and the center of the

specimen are directly beneath the center of thrust of the

spherical bearing block.

7.5 Rate of LoadingApply the load continuously and

without shock, at a constant rate within the range 100 to 200

psi/min [0.7 to 1.4 MPa/min] splitting tensile stress until failure

of the specimen (Note 3). Record the maximum applied load

indicated by the testing machine at failure. Note the type of

failure and the appearance of the concrete.

Jig for Aligning Concrete Cylinder and Bearing Strips

NOTE 3The relationship between splitting tensile stress and applied

load is shown in Section 8. The required loading range in splitting tensile

stress corresponds to applied total load in the range of 11 300 to 22 600

lbf [50 to 100 kN]/min for 6 by 12-in. [150 by 300-mm] cylinders.

7.3.1 The projection of the plane of the two lines marked on

the ends of the specimen intersects the center of the upper

bearing plate, and

C 496/C 496M 04e1

FIG. 4

FIG. 5

Detailed Plans for a Suitable Aligning Jig for 6 by 12 in. [150 by 300 mm] Specimen

Specimen Positioned in a Testing Machine for Determination of Splitting Tensile Strength

8. Calculation

8.1 Calculate the splitting tensile strength of the specimen

as follows:

T 5 2P/pld

P = maximum applied load indicated by the testing machine, lbf [N],

l = length, in. [mm], and

d = diameter, in. [mm].

(1)

where:

T = splitting tensile strength, psi [MPa],

C 496/C 496M 04e1

9. Report

9.1 Report the following information:

9.1.1 Identification number,

9.1.2 Diameter and length, in. [mm],

9.1.3 Maximum load, lbf [N],

9.1.4 Splitting tensile strength calculated to the nearest 5 psi

[0.05 MPa],

9.1.5 Estimated proportion of coarse aggregate fractured

during test,

9.1.6 Age of specimen,

9.1.7 Curing history,

9.1.8 Defects in specimen,

9.1.9 Type of fracture, and

9.1.10 Type of specimen.

however, suggests that the within batch coefficient of variation

is 5 % (see Note 4) for 6 3 12-in. [150 3 300-mm] cylindrical

specimens with an average splitting tensile strength of 405 psi

[2.8 MPa]. Results of two properly conducted tests on the same

material, therefore, should not differ by more than 14 % (see

Note 4) of their average for splitting tensile strengths of about

400 psi [2.8 MPa].

NOTE 4These numbers represent, respectively, the (1s %) and

(d2s %) limits as defined in Practice C 670.

10.2 BiasThe test method has no bias because the splitting tensile strength can be defined only in terms of this test

method.

11. Keywords

10. Precision and Bias

10.1 PrecisionAn interlaboratory study of this test

method has not been performed. Available research data,3

11.1 cylindrical concrete specimens; splitting tension; tensile strength

3

Wright, P. J. F., Comments on an Indirect Tensile Test on Concrete Cylinders,

Magazine of Concrete Research, Vol 7, No. 20, July 1955, pp. 8795.

SUMMARY OF CHANGES

Committee C09 has identified the location of selected changes to this test method since the last issue,

C 496 96, that may impact the use of this test method. (Approved February 1, 2004)

(5)

(6)

(7)

(8)

(1) Revised 1.2.

(2) Added 1.4.

(3) Revised 5.1, 6.1, Section 2, and Note 1 to correct references.

(4) Revised 5.2, 6.2, 7.2, 7.5, 10.1, and Note 4 by metrication

rules.

Revised Section 4.

Revised 3.2 and 5.3.

Revised Note 2.

Figs. 1, 2, and 4 were revised and redrawn.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

You might also like

- CO2-Reducing Cement Based On Calcium SilicatesDocument9 pagesCO2-Reducing Cement Based On Calcium Silicatesyinglv100% (1)

- Astm D4355 PDFDocument5 pagesAstm D4355 PDFgadNo ratings yet

- Ultrasonic Pulse VelocityDocument3 pagesUltrasonic Pulse VelocitySougata DasNo ratings yet

- ''C496.142250 Splitting Tensile Strength of ConcreteDocument5 pages''C496.142250 Splitting Tensile Strength of ConcreteAbu Bakar Muzamil ButtNo ratings yet

- Astm C-496Document5 pagesAstm C-496Carlos R Martinez100% (2)

- FINENESS OF HYDRAULIC CEMENT - Group - 7Document5 pagesFINENESS OF HYDRAULIC CEMENT - Group - 7K PrinceNo ratings yet

- ASTM C 535 03 Abrasion TestDocument3 pagesASTM C 535 03 Abrasion TestIsmaelMartinezNo ratings yet

- Concrete Cylinder Curing MethodsDocument8 pagesConcrete Cylinder Curing Methodsjem guiNo ratings yet

- ASTMC39Document5 pagesASTMC39Isaac NuñezNo ratings yet

- Eng R Midterm ExamDocument15 pagesEng R Midterm ExamMotim So0% (1)

- Time of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForDocument6 pagesTime of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForAhmed AbidNo ratings yet

- Flexural TestDocument13 pagesFlexural TestAliaNo ratings yet

- CA Test 221: Unconfined Compressive Strength of SoilDocument4 pagesCA Test 221: Unconfined Compressive Strength of Soilnickie_harvey4046998No ratings yet

- Investigate The Combination of Coconut Shell and Grained Palm Kernel To Replace Aggregate in Concrete: A Technical ReviewDocument10 pagesInvestigate The Combination of Coconut Shell and Grained Palm Kernel To Replace Aggregate in Concrete: A Technical ReviewKhan BrothersNo ratings yet

- Astm C 796-04 SecureDocument6 pagesAstm C 796-04 Securesaras100% (1)

- Method B7 - The Determination of The Treton Impact Value of Aggregate.Document3 pagesMethod B7 - The Determination of The Treton Impact Value of Aggregate.GUO LEI100% (1)

- Compressive Strength TestDocument6 pagesCompressive Strength TestjejojuNo ratings yet

- Bending Test For SteelDocument2 pagesBending Test For SteelDeku50% (2)

- Vicat ApparatusDocument5 pagesVicat ApparatusFeras TemimiNo ratings yet

- Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and ConcretesDocument3 pagesMixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and ConcretesSatya kaliprasad vangaraNo ratings yet

- ASTM C1552 - 16 Standard Practice For Capping Concrete Masonry Units, Related Units and Masonry Prisms For Compression TestingDocument3 pagesASTM C1552 - 16 Standard Practice For Capping Concrete Masonry Units, Related Units and Masonry Prisms For Compression TestingShaneNo ratings yet

- Concrete masonry testing standardsDocument4 pagesConcrete masonry testing standardsHaniAminNo ratings yet

- Split Tensile Strength of ConcreteDocument9 pagesSplit Tensile Strength of Concreteabhineet srivastavaNo ratings yet

- BEAMDocument114 pagesBEAMPaul Macharia Ndungu100% (1)

- Density (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteDocument4 pagesDensity (Unit Weight), Yield, and Air Content (Gravimetric) of ConcretemickyfelixNo ratings yet

- Astm C 215Document7 pagesAstm C 215mickyfelixNo ratings yet

- Astm C-39 Standard Test Method For Compressive Strength of Cylindrical Concrete SpecimensDocument14 pagesAstm C-39 Standard Test Method For Compressive Strength of Cylindrical Concrete SpecimensVíctor M Fernández Jiménez100% (1)

- Cement Mortar Ultrasonic EvaluationDocument11 pagesCement Mortar Ultrasonic EvaluationAdam PapworthNo ratings yet

- m2l10 Lesson 10 The Force Method of Analysis: TrussesDocument17 pagesm2l10 Lesson 10 The Force Method of Analysis: TrussesVitor ValeNo ratings yet

- C1582C1582M-Aditivos Inhibidores de CorrosionDocument10 pagesC1582C1582M-Aditivos Inhibidores de CorrosionAnthony López HuamanNo ratings yet

- C 803 PDFDocument5 pagesC 803 PDFMacky Novera0% (1)

- C943Document4 pagesC943Jorge Luis Arevalo Lopez100% (1)

- Pervious Concrete As A Sustainable Pavement Material-Research Findings and Future Prospects A State-Of-The-Art-reviewDocument13 pagesPervious Concrete As A Sustainable Pavement Material-Research Findings and Future Prospects A State-Of-The-Art-reviewNoéMestas100% (1)

- AGGREGATE ABRASION TEST VALUESDocument6 pagesAGGREGATE ABRASION TEST VALUESAbdur RazzakNo ratings yet

- T119Document2 pagesT119Katerin HernandezNo ratings yet

- Hardened ConcreteDocument50 pagesHardened ConcreteMayank KapriNo ratings yet

- Astm C 127 PDFDocument7 pagesAstm C 127 PDFNikolay DrumevNo ratings yet

- Sand Cement Brick Containing Recycled PDFDocument7 pagesSand Cement Brick Containing Recycled PDFsyakirohNo ratings yet

- Compressive C 129 17Document3 pagesCompressive C 129 17Pamela PoloNo ratings yet

- Soil SamplingDocument3 pagesSoil SamplingHamza NadeemNo ratings yet

- Specific Gravity of Cement TestDocument9 pagesSpecific Gravity of Cement TestSyed Mohd MehdiNo ratings yet

- Time of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForDocument3 pagesTime of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForNazmus SakibNo ratings yet

- Is 14858 2000 Compression Testing Machine Used For Testing of Concrete and Mortar RequirementsDocument9 pagesIs 14858 2000 Compression Testing Machine Used For Testing of Concrete and Mortar RequirementsVanu VamalaiNo ratings yet

- Astm C 1064-2017Document3 pagesAstm C 1064-2017Mohammed AliNo ratings yet

- Testing Concrete: BS 1881: Part 116: 1983Document8 pagesTesting Concrete: BS 1881: Part 116: 1983Muhammad AmmarNo ratings yet

- Experimental Investigation On Compressive Strength of PaverblockDocument35 pagesExperimental Investigation On Compressive Strength of PaverblockPachai ManiNo ratings yet

- Is 5512 1983 PDFDocument17 pagesIs 5512 1983 PDFBijaya RaulaNo ratings yet

- TEST PROCEDURES FOR CONCRETE PAVING UNITSDocument5 pagesTEST PROCEDURES FOR CONCRETE PAVING UNITSLan CorpuzNo ratings yet

- Modulus of Elasticity and Poisson Ratio of Concrete TestDocument18 pagesModulus of Elasticity and Poisson Ratio of Concrete TestSushil SawantNo ratings yet

- Hyper CreteDocument2 pagesHyper CretedjgiumixNo ratings yet

- Triaxial TestDocument4 pagesTriaxial TestshahrolhazrienNo ratings yet

- Determination of Angularity Number For The Given Aggregate SampleDocument4 pagesDetermination of Angularity Number For The Given Aggregate SampleEngr Muhammad TariqNo ratings yet

- Controlled Low Strength MaterialDocument4 pagesControlled Low Strength MaterialDevrim GürselNo ratings yet

- NDT On Concrete Pull Off Test: by Subhodeep Neogi Sai Prakash VaddiDocument12 pagesNDT On Concrete Pull Off Test: by Subhodeep Neogi Sai Prakash VaddiManish Mittal100% (1)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- Norma TestDocument3 pagesNorma TestIvan Huilcapaz MoraNo ratings yet

- Splitting Tensile Strength of Cylindrical Concrete SpecimensDocument5 pagesSplitting Tensile Strength of Cylindrical Concrete Specimenssayra chavezNo ratings yet

- Splitting Tensile Strength of Cylindrical Concrete SpecimensDocument5 pagesSplitting Tensile Strength of Cylindrical Concrete SpecimensmickyfelixNo ratings yet

- ASTM C293-1-Flexural Strebgth Test-Centre PointDocument3 pagesASTM C293-1-Flexural Strebgth Test-Centre PointAnnur Kamarudin100% (3)

- Standard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Document3 pagesStandard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Lupita RamirezNo ratings yet

- ASTM D 1633-00 Standard Methods For Compressive Strength of Molded Soil-Cement CylindersDocument4 pagesASTM D 1633-00 Standard Methods For Compressive Strength of Molded Soil-Cement CylindersPablo Antonio Valcárcel VargasNo ratings yet

- Astm c131 06 LaavDocument4 pagesAstm c131 06 LaavRasya FiezaNo ratings yet

- Menu Room Service 2.0Document26 pagesMenu Room Service 2.0Lupita RamirezNo ratings yet

- Sampling of Geosynthetics For TestingDocument3 pagesSampling of Geosynthetics For TestingLupita RamirezNo ratings yet

- Dma PDFDocument9 pagesDma PDFkrishna saiNo ratings yet

- Non Reinforced PVC (Polyvinyl Chloride) Geomembrane Seams: Standard Specification ForDocument5 pagesNon Reinforced PVC (Polyvinyl Chloride) Geomembrane Seams: Standard Specification ForLupita RamirezNo ratings yet

- Geosynthetics: Standard Terminology ForDocument5 pagesGeosynthetics: Standard Terminology ForEdmundo Jaita CuellarNo ratings yet

- Astm C1707Document3 pagesAstm C1707Jino LegastoNo ratings yet

- Water Permeability of Geotextiles by Permittivity: Standard Test Methods ForDocument6 pagesWater Permeability of Geotextiles by Permittivity: Standard Test Methods ForLupita RamirezNo ratings yet

- Astm D-4437Document2 pagesAstm D-4437VIDAL AMAU RUIZNo ratings yet

- Biological Clogging of Geotextile or Soil/Geotextile FiltersDocument6 pagesBiological Clogging of Geotextile or Soil/Geotextile FiltersLupita RamirezNo ratings yet

- Astm D7466Document3 pagesAstm D7466Nhuận PhạmNo ratings yet

- D 7002 Â " 03 RDCWMDIDocument6 pagesD 7002 Â " 03 RDCWMDILeón SuárezNo ratings yet

- Masonry Cement: Standard Specification ForDocument4 pagesMasonry Cement: Standard Specification ForLupita RamirezNo ratings yet

- Alkaline Stabilization of Wastewater Treatment Plant ResidualsDocument6 pagesAlkaline Stabilization of Wastewater Treatment Plant ResidualsLupita RamirezNo ratings yet

- ASTM Designation: E1166 00 (Reapproved 2009)Document2 pagesASTM Designation: E1166 00 (Reapproved 2009)Lupita RamirezNo ratings yet

- GoodReader - Getting StartedDocument10 pagesGoodReader - Getting StartedAditya WaliyantoNo ratings yet

- Index of Aggregate Particle Shape and Texture: Standard Test Method ForDocument4 pagesIndex of Aggregate Particle Shape and Texture: Standard Test Method ForLupita RamirezNo ratings yet

- Lime and Limestone (As Used by The Industry) : Standard Terminology Relating ToDocument3 pagesLime and Limestone (As Used by The Industry) : Standard Terminology Relating Toasemamaw damtieNo ratings yet

- ASTM Designation: D4469 11Document4 pagesASTM Designation: D4469 11Lupita RamirezNo ratings yet

- Astm E1448/e1448m 09Document9 pagesAstm E1448/e1448m 09Lupita RamirezNo ratings yet

- Designation: D7175 08Document16 pagesDesignation: D7175 08Lupita RamirezNo ratings yet

- ASTM Designation: C 1305 - 08Document3 pagesASTM Designation: C 1305 - 08Lupita RamirezNo ratings yet

- Designation: E1530 11Document9 pagesDesignation: E1530 11Lupita RamirezNo ratings yet

- ASTM Designation: D517 98 (Reapproved 2008)Document3 pagesASTM Designation: D517 98 (Reapproved 2008)Lupita RamirezNo ratings yet

- ASTM Designation: D3142/D3142M 11Document4 pagesASTM Designation: D3142/D3142M 11Lupita RamirezNo ratings yet

- Innovations in Concrete Pavement ConstructionDocument34 pagesInnovations in Concrete Pavement ConstructionLupita RamirezNo ratings yet

- ASTM Designation: D6723 12Document13 pagesASTM Designation: D6723 12Lupita RamirezNo ratings yet

- Designation: D7404 07 (Reapproved 2012)Document3 pagesDesignation: D7404 07 (Reapproved 2012)Lupita RamirezNo ratings yet

- Designation: D7175 08Document16 pagesDesignation: D7175 08Lupita RamirezNo ratings yet

- Designation: D7404 07 (Reapproved 2012)Document3 pagesDesignation: D7404 07 (Reapproved 2012)Lupita RamirezNo ratings yet

- Biological Effect and Medical Applications of Electromagnetic EnergyDocument580 pagesBiological Effect and Medical Applications of Electromagnetic EnergyTienRienNo ratings yet

- SKEM 3742 Electro Hydraulic LabsheetDocument6 pagesSKEM 3742 Electro Hydraulic Labsheetcikgu_relaNo ratings yet

- Synperonic EthoxylatesDocument2 pagesSynperonic Ethoxylatesjacky ye100% (1)

- Alloy ZN Ni PDFDocument8 pagesAlloy ZN Ni PDFElenaNo ratings yet

- CASD 2017. Robust H-Infinity Backstepping Control Design of A Wheeled Inverted Pendulum SystemDocument5 pagesCASD 2017. Robust H-Infinity Backstepping Control Design of A Wheeled Inverted Pendulum SystemNam Hoang ThanhNo ratings yet

- Working of Steam Turbines and Its AuxillariesDocument48 pagesWorking of Steam Turbines and Its AuxillariesbalajigandhirajanNo ratings yet

- Microplan - Katalog 2016 ENDocument55 pagesMicroplan - Katalog 2016 END.T.No ratings yet

- CPM cc1 - CH 2 VocabularyDocument3 pagesCPM cc1 - CH 2 Vocabularyapi-252110147No ratings yet

- Mathematics - Ijmcar - An Approach For Continuous Method For The GeneralDocument12 pagesMathematics - Ijmcar - An Approach For Continuous Method For The GeneralTJPRC PublicationsNo ratings yet

- Free Electron Theory 2015-16 (VTU) PDFDocument14 pagesFree Electron Theory 2015-16 (VTU) PDFU and me SNo ratings yet

- How retinal adaptation maintains visual perception despite illumination changesDocument1 pageHow retinal adaptation maintains visual perception despite illumination changesAkicaNo ratings yet

- Role of Infill WallDocument16 pagesRole of Infill WallGaurav MallaNo ratings yet

- P Ractical Approaches To Fast Gas Chromatography-Mass Spectrometry Muy BuenoDocument28 pagesP Ractical Approaches To Fast Gas Chromatography-Mass Spectrometry Muy BuenoJavier Joao Lloyd IglesiasNo ratings yet

- Berco Product FA 6E: General Information Fa 6E 12040002 Idler Group, With Tensioning Device Not Integrated inDocument1 pageBerco Product FA 6E: General Information Fa 6E 12040002 Idler Group, With Tensioning Device Not Integrated inrameshNo ratings yet

- Astm D 1746 97 TH 2002 PDFDocument5 pagesAstm D 1746 97 TH 2002 PDFJed BrionesNo ratings yet

- 50 Years of The Turbidite Paradigm (Shanmugam, 2000)Document58 pages50 Years of The Turbidite Paradigm (Shanmugam, 2000)hilman_satriaNo ratings yet

- Tuned Liquid Dampers for Efficient Tall Building DesignDocument9 pagesTuned Liquid Dampers for Efficient Tall Building Designsukanya12345No ratings yet

- Filter Programs MatlabDocument8 pagesFilter Programs MatlabPreethi Sj100% (1)

- Chocolate RheologyDocument7 pagesChocolate RheologyAdil AnwarNo ratings yet

- MAVEN: Motion Analysis and Visualization of Elastic Networks and Structure Ensembles Version 1.1 User's Manual ContentsDocument30 pagesMAVEN: Motion Analysis and Visualization of Elastic Networks and Structure Ensembles Version 1.1 User's Manual ContentsOscar DedNo ratings yet

- PMM WordDocument3 pagesPMM WordShrey R DhanawadkarNo ratings yet

- Steam Drum Design CalsDocument78 pagesSteam Drum Design Calsabdulrehmandescon100% (1)

- Cem - Part 1 PDFDocument19 pagesCem - Part 1 PDFDavin OtogleNo ratings yet

- Group Theory PDFDocument280 pagesGroup Theory PDFLuis Cancino Arancibia100% (1)

- Physics Module Form 4 Chapter 3 Forces & PressureDocument25 pagesPhysics Module Form 4 Chapter 3 Forces & PressureMisratul A'la Mahyuddin100% (2)

- Cement Chapter 4Document11 pagesCement Chapter 4shani5573100% (2)

- Normal Distribution Giuded SolutionsDocument5 pagesNormal Distribution Giuded SolutionsleeshanghaoNo ratings yet

- Chapter 1 Lecture1Document39 pagesChapter 1 Lecture1Anonymous AFFiZnNo ratings yet

- Computer Graphics and AnimationDocument2 pagesComputer Graphics and AnimationManoj PrasadNo ratings yet