Professional Documents

Culture Documents

McLANAHAN - Agg - Dewatering Screen

Uploaded by

B V SrikantCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

McLANAHAN - Agg - Dewatering Screen

Uploaded by

B V SrikantCopyright:

Available Formats

Dewatering

Screens

AGGREGATE PROCESSING

Over 30 years ago, McLanahan Corporation was the first

to introduce Dewatering Screens to the mining industry,

where the screens quickly became the standard.

Dewatering screens offer multiple advantages for

construction

and

specialty

aggregate

producers,

including a dry drip-free product that other types of

equipment cannot provide. With hundreds of units in

service,

the

Dewatering

Screen

exemplifies

the

unbeatable toughness you expect from McLanahan

Corporation.

Dewatering Screens have several functions:

Dewatering

Desliming

Degritting

Rinsing

Scrubbing

Washing

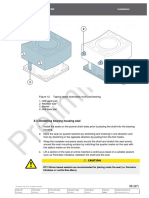

HOW DEWATERING SCREENS WORK

1. Slurry feeds onto a steeply inclined screen surface

to achieve rapid drainage

2. A pool of water forms in the valley as sand builds

up on the inclined surface

3. Counter rotating motors create a linear motion that

forces solids uphill while water drains through the

screen media

4. The uphill slope of the screen along with a discharge

weir creates a deep bed that acts as a filter medium,

allowing retention of material much finer than the

screen openings

Dewatering Screens feature custom engineered, heavy

duty screen media for the high capacity applications

SLURRY

FEED

encountered in todays production conscious market.

Side frames and beams are Huck bolted together, not

welded, so individual components can be replaced. They

also have a combination of standard, high quality wear

resistant side wear linings, optional deck dividers, and

dams. Performance flexibility is enhanced by variations

in screen media and the use of deck dividers.

McLanahan Dewatering Screens have the highest

capacities available in the industry and can process up

to 400 tph of coarse sand on a single machine. Available

sizes are 3' x 8', 4' x 10', 5' x 12', 6' x 12', 7' x 12', and

7' x 16'.

DEWATERED

SOLIDS

WATER DRAINS THROUGH SCREEN MEDIA

IMPROVES YOUR BOTTOM LINE

By applying our worldwide industry experience and just

the right combination of frequency and amplitude,

McLanahan Dewatering Screens provide drip-free

discharge for applications that range from primary

sand products to ultra fines recovery. The resulting

improvements in housekeeping and immediate availability

of products mean bottom line benefits!

APPLICATIONS

Aggregates & Industrial Minerals

Cyclone / Separator Underflow

Hydrosizer Underflow

Feed To VSI, Dryers Or Other Moisture Sensitive

Operations

Fines Recovery

Aglime

Screw Discharge

Coal

Coal Spiral Products

Shaking Table Products

Heavy Media Feed Preparation

Underground Mine Clean-up

Hard Rock Mining

CIP / CIL Circuits

Trash

Loaded Carbon

Safety Screens

Carbon Quench

Flotation Tailings

BENEFITS

High Capacities Per Foot Width

Consistent, Drip Free Product

High G Force

Upward Inclination Of Deck Helps To Handle

Fluctuations In Feed Solids

Reduces Water Losses To Product

Better Stockpile Management

Quiet & Low Power Consumption

Driven By Vibratory Motors

Low Maintenance

FEATURES

High Quality Wear Liners

Optional Deck Dividers

Huck Bolt Construction

Heavy Duty Urethane Screen Media

Silica sand processed through McLanahans Sand Manager

Classifying Tank is dewatered by a 7' x 16' dewatering screen.

OUR ENGINEERING CAPABILITIES

McLanahan Corporation provides cost effective solutions

to issues facing todays sand and aggregate producers

as well as complete plant and equipment designs.

Process Engineering McLanahan is unique in its

experienced team of qualified Process Engineers who

can analyze current plant configurations and provide

solutions utilizing the latest technologies available.

We will help you make money because we will design

commercially viable processes to achieve highest product

yields including reducing the amount of saleable material

sent to waste. We will reduce inefficiencies (horsepower

and manual operations), reduce water usage, eliminate

excess equipment, and provide practical answers to deal

with environmentally troublesome waste.

Design Engineering Using the latest CAD software

McLanahans highly qualified and experienced engineers

have a tradition of creating innovative equipment and

system designs. Technologies such as vibration and finite

element analysis are used to provide our customers with

the highest quality products. Having been field tested

and trained in process engineering, our engineers can

provide better solutions for the industrys problems.

McLanahan Corporation Offers

The Widest Range Of Processing

Equipment Available From

A Single Manufacturer

Crushing Rock

ROLL CRUSHERS

DDC-SIZERS

IMPACT FEEDER-BREAKERS

Scrubbing Rock

ROTARY SCRUBBERS

LOG WASHERS

COARSE MATERIAL SCREW WASHERS

AGGREGATE CONDITIONERS

Sand Processing

RECIPE SAND PLANTS

IN-LINE BLENDING SAND PLANTS

SAND-MANAGER CLASSIFYING TANKS

ULTRA SAND PLANTS

SCREW WASHERS

DEWATERING SCREENS

PUMPS

CYCLONES

SEPARATORS

Contaminant Removal

COARSE MATERIAL SCREWS

LITES-OUT CLASSIFIER

ULTRA CLEAN ATTRITION SCRUBBER

HYDROSIZERS

Fines Recovery

SEPARATOR SYSTEMS

UFR PLANTS

Water Management

THICKENERS

FILTER PRESSES

Sampling Systems

Please Contact The McLanahan Sales Department

For The Drawing Of The Dewatering Screen

Needed For Your Installation.

AGGREGATE PROCESSING

We Invite Your Inquiries.

NORTH AMERICA Corporate Office, Pennsylvania, USA +1 (814) 695 9807 sales@mclanahan.com

Florida, USA +1 (863) 667 2090 polymers@mclanahan.com

Iowa, USA +1 (319) 365 0441 sales@mclanahan.com

Tennessee, USA +1 (615) 451 4440 sales@mclanahan.com

AUSTRALIA New South Wales +61 2 4924 8248 sales@mclanahan.com.au

Queensland +61 7 3375 4700 sales@mclanahan.com.au

EUROPE Southeast England, UK +44 (0)1420 542489 infoUK@mclanahan.com

mclanahan.com

Guards are recommended for safe operation of equipment. In some photos, safety guards may not be shown.

DWS-2102

You might also like

- Kreiselbrecher enDocument7 pagesKreiselbrecher enDiegoAlvarezHuguezNo ratings yet

- Jaw Crushers and Disk Mills: FritschDocument20 pagesJaw Crushers and Disk Mills: FritschAnil Kumar KnNo ratings yet

- Pebble Crusher Specific EnergyDocument10 pagesPebble Crusher Specific Energy12milehillNo ratings yet

- 1238 Jaw Crusher PDFDocument12 pages1238 Jaw Crusher PDFRasoolKhadibiNo ratings yet

- Thyssenkrupp - Jaw Crusher PDFDocument7 pagesThyssenkrupp - Jaw Crusher PDFFernando MilmanNo ratings yet

- SAG Mill ManufacturerDocument2 pagesSAG Mill ManufacturerRodrigo GarcíaNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFมนต์ชัย บุญธนลาภNo ratings yet

- Jaw CrusherDocument4 pagesJaw CrusherRebekah HaleNo ratings yet

- Dynamic Modeling and Simulation of Cone Crushing Circuits PDFDocument7 pagesDynamic Modeling and Simulation of Cone Crushing Circuits PDFmarceladeveraNo ratings yet

- Gyratory Mill: EccentricDocument10 pagesGyratory Mill: EccentricAbhishek Kumar100% (1)

- Cerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18Document5 pagesCerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18jhonNo ratings yet

- Vibrating Screens - Circular Motion Rev 1Document2 pagesVibrating Screens - Circular Motion Rev 1Ziggy Gregory100% (1)

- Exciter Vibrating FeederDocument5 pagesExciter Vibrating Feedergopi_ggg20016099No ratings yet

- E - Manual - 18x72 TRC - 20122010 PDFDocument159 pagesE - Manual - 18x72 TRC - 20122010 PDFEdward LarensNo ratings yet

- PaperC Optimization of Crushing Stage Using On-Line Speed Regulation On Cone Crushers PDFDocument9 pagesPaperC Optimization of Crushing Stage Using On-Line Speed Regulation On Cone Crushers PDFRagab AbulmagdNo ratings yet

- Project Case - CT4254 JAW PLATESDocument4 pagesProject Case - CT4254 JAW PLATESNicole WuNo ratings yet

- HE Crushing Solutions Engineeing and MN OverviewDocument48 pagesHE Crushing Solutions Engineeing and MN OverviewJorge VillalobosNo ratings yet

- PresentationDocument46 pagesPresentationDanielSantosNo ratings yet

- Vibrating ScreenDocument2 pagesVibrating ScreenChetan Patel100% (1)

- WO 2014/075722 Al: International BureauDocument17 pagesWO 2014/075722 Al: International BureauneusonNo ratings yet

- Mobile Jaw Crusher PDFDocument7 pagesMobile Jaw Crusher PDFNguyễn LinhNo ratings yet

- CrawlerMobileCrusher SDocument7 pagesCrawlerMobileCrusher Sjoyalcrusher100% (1)

- TST JawCrusherDocument8 pagesTST JawCrusherHãy Tin Anh100% (1)

- O17607v101 Flyer Blow Bars enDocument4 pagesO17607v101 Flyer Blow Bars enhesham elokailyNo ratings yet

- Flowsheet 130TPH II Stage Wheel Mounted Plant-0-22mm&GSBDocument1 pageFlowsheet 130TPH II Stage Wheel Mounted Plant-0-22mm&GSBMukesh BharatNo ratings yet

- Washing and Classifying Brochure EnglishDocument24 pagesWashing and Classifying Brochure EnglishMohammed Alshami GeologistNo ratings yet

- Crushers: Wills' Mineral Processing Technology. © 2016 Elsevier Ltd. All Rights ReservedDocument24 pagesCrushers: Wills' Mineral Processing Technology. © 2016 Elsevier Ltd. All Rights ReservedDanny Joaquin Flores CruzNo ratings yet

- Cone Ranger: Mobile Cone Crushing UnitsDocument2 pagesCone Ranger: Mobile Cone Crushing UnitsYousef AlipourNo ratings yet

- 8r77r-Cybas I ConeDocument6 pages8r77r-Cybas I Coneturkishdjem100% (1)

- Yade DEM DocumentationDocument466 pagesYade DEM DocumentationossomansNo ratings yet

- Gray Iron ASTM Class 40B Material StandardDocument4 pagesGray Iron ASTM Class 40B Material StandardRIYASNo ratings yet

- Size Control: - Screening Using A Geometrical Pattern For Size ControlDocument5 pagesSize Control: - Screening Using A Geometrical Pattern For Size ControlSergei DumrovaNo ratings yet

- KG Gyratory CrusherDocument5 pagesKG Gyratory CrusherJhunior Contreras NeyraNo ratings yet

- Rollsizers enDocument5 pagesRollsizers enIrvanda ZiaurrahmanNo ratings yet

- Bearings For Cone Crushers: Serving Industries WorldwideDocument4 pagesBearings For Cone Crushers: Serving Industries WorldwideJgonzalez GonzalezNo ratings yet

- Pans PDFDocument8 pagesPans PDFJorge Prado DiazNo ratings yet

- Washing Equipment Product Handbook - WEB - 06 2016Document52 pagesWashing Equipment Product Handbook - WEB - 06 2016Lmf DanielNo ratings yet

- The Basic Principle of A Cone Crusher Is Depicted in Figure 9 and Described HereDocument1 pageThe Basic Principle of A Cone Crusher Is Depicted in Figure 9 and Described HereKudzie Maphy MasaireNo ratings yet

- Ore Separation - Screening and Classification (Sizing-Ore Sorting)Document37 pagesOre Separation - Screening and Classification (Sizing-Ore Sorting)Maruti NandanNo ratings yet

- CEDARAPIDS (2015) - Quality Paving Guide BookDocument96 pagesCEDARAPIDS (2015) - Quality Paving Guide BookRodrigo DíazNo ratings yet

- Informativo: PR O CE SSF LO WDocument3 pagesInformativo: PR O CE SSF LO WricardoferNo ratings yet

- QMS - General BrochureDocument6 pagesQMS - General BrochureArpit VermaNo ratings yet

- CR600 Sizer Brochure PDFDocument8 pagesCR600 Sizer Brochure PDFAdil DouziNo ratings yet

- The MP2500: The Largest Cone Crusher Ever Built: Materials Handling and LogisticsDocument1 pageThe MP2500: The Largest Cone Crusher Ever Built: Materials Handling and LogisticsDiegoAlvarezHuguezNo ratings yet

- 11 - Transport Cross-Beam For Roll UnitsDocument43 pages11 - Transport Cross-Beam For Roll UnitsCHRISTIAN ROJAS VALENZUELANo ratings yet

- MANUAL1 - Copia - 4Document50 pagesMANUAL1 - Copia - 4Jose NoriegaNo ratings yet

- Energy Efficient Mineral Liberation Using HPGR Technology: Valid Solutions SpaceDocument236 pagesEnergy Efficient Mineral Liberation Using HPGR Technology: Valid Solutions SpaceMarcos BuenoNo ratings yet

- MML45Semi Mobile Primary Gyratory Crushing Plant GADwgs Technical InformationDocument19 pagesMML45Semi Mobile Primary Gyratory Crushing Plant GADwgs Technical Informationgytoman0% (1)

- 655828-Rev 1 PDFDocument2 pages655828-Rev 1 PDFricardoferNo ratings yet

- MANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFDocument27 pagesMANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFGuillermo BalarinniNo ratings yet

- Fine Grinding in The Australian Mining IndustryDocument11 pagesFine Grinding in The Australian Mining IndustryATon GarsaNo ratings yet

- Ubc 2003-0537Document163 pagesUbc 2003-0537Lmf DanielNo ratings yet

- HPGR en WebDocument11 pagesHPGR en WebFranciscoNo ratings yet

- Cone Crusher Metso Nordberg gp220 en 2816Document3 pagesCone Crusher Metso Nordberg gp220 en 2816Binu VarkeyNo ratings yet

- UH320 ClassicDocument2 pagesUH320 ClassicRicardo E Andrea RachelNo ratings yet

- Screw Washer A 01Document15 pagesScrew Washer A 01joule357No ratings yet

- Telsmith Product OverviewDocument12 pagesTelsmith Product OverviewRicardoNo ratings yet

- Sandvik HSI EN PDFDocument8 pagesSandvik HSI EN PDFkranthiNo ratings yet

- Dewatering ScreenDocument4 pagesDewatering ScreenMiguel Pereyra OyarceNo ratings yet

- CDE ProductsDocument5 pagesCDE ProductsFiras MaitigNo ratings yet

- Gold Production and Its Environmental ImpactDocument37 pagesGold Production and Its Environmental ImpactN. SasidharNo ratings yet

- Frank Richardson v. Homestake Mining Company, A California Corporation, 322 F.2d 329, 10th Cir. (1963)Document5 pagesFrank Richardson v. Homestake Mining Company, A California Corporation, 322 F.2d 329, 10th Cir. (1963)Scribd Government DocsNo ratings yet

- Barrick 2017 Operations and Technical Update 2Document219 pagesBarrick 2017 Operations and Technical Update 2Rudy Dwi PrasetyoNo ratings yet

- V-Wall Coring Rod: Featuring Our New Light Weight, Variable-Wall TechnologyDocument2 pagesV-Wall Coring Rod: Featuring Our New Light Weight, Variable-Wall Technologyprocurement 02No ratings yet

- Bernhard DoldDocument44 pagesBernhard DoldJulio CamelNo ratings yet

- Curriculum Vitae - Jerry Anwar Halim, S.T.: Personal DetailsDocument3 pagesCurriculum Vitae - Jerry Anwar Halim, S.T.: Personal DetailsDodhy SetiawanNo ratings yet

- Diamond Drilling Corp V Newmont Philippines IncDocument8 pagesDiamond Drilling Corp V Newmont Philippines IncRei TongNo ratings yet

- DMDW-Solution For Unit 1-5Document20 pagesDMDW-Solution For Unit 1-5Manish Arya50% (2)

- Footprint Finder Tool For Sublevel CavingDocument14 pagesFootprint Finder Tool For Sublevel Cavingalvaroaac4No ratings yet

- IRAN Sleeping Giant at A Turning PointDocument58 pagesIRAN Sleeping Giant at A Turning PointmahdiseifNo ratings yet

- Telestack Radial Telescopics Brochure 2017Document16 pagesTelestack Radial Telescopics Brochure 2017Alok MehtaNo ratings yet

- Job Advert - ServicemanDocument2 pagesJob Advert - ServicemanJoseph buluguNo ratings yet

- Balt - Cost Management of The Availability (2007) PDFDocument233 pagesBalt - Cost Management of The Availability (2007) PDFJhoncastilloNo ratings yet

- Emergency Braking Systems For Mine ElevatorsDocument19 pagesEmergency Braking Systems For Mine ElevatorsDhanraj PatilNo ratings yet

- MR Holdings, LTD v. Sheriff Carlos Bajar, Et Al.Document1 pageMR Holdings, LTD v. Sheriff Carlos Bajar, Et Al.CheCheNo ratings yet

- Argus FMB Potash Market NewsDocument8 pagesArgus FMB Potash Market NewsAlphatrackerNo ratings yet

- Copper Market Analysis RFC Ambrian May 2022Document30 pagesCopper Market Analysis RFC Ambrian May 2022qleapNo ratings yet

- Brochure JacoviDocument5 pagesBrochure JacovimenriquepcNo ratings yet

- Dividend Policy VeddantaDocument14 pagesDividend Policy VeddantaVivek rathodNo ratings yet

- FRS Florida Retirement System InvestmentsDocument2,620 pagesFRS Florida Retirement System InvestmentsTA WebsterNo ratings yet

- Schenckprocessminingna BrochureDocument8 pagesSchenckprocessminingna Brochurehalder_kalyan9216No ratings yet

- PT Ascon PDF Company Profile 2019Document10 pagesPT Ascon PDF Company Profile 2019Ika SetiawatyNo ratings yet

- World Directory of LBMA-Accredited RefineriesDocument3 pagesWorld Directory of LBMA-Accredited RefineriesSamscribdingNo ratings yet

- Lec 09Document6 pagesLec 09Karim ElbeheryNo ratings yet

- 144 Modele CV en AnglaisDocument2 pages144 Modele CV en AnglaiskhaireddineNo ratings yet

- Reaction Towards GlobalizationDocument2 pagesReaction Towards GlobalizationAPALE Ralph Glenn PatronNo ratings yet

- 4th BOCE Minutes .DT 19.11.2019 PDFDocument51 pages4th BOCE Minutes .DT 19.11.2019 PDFSEPR NlgNo ratings yet

- Main ProjectDocument84 pagesMain ProjectMani PrasanthNo ratings yet

- EspDocument36 pagesEspprasenjitsayantanNo ratings yet

- Moa PNP PDFDocument3 pagesMoa PNP PDFkitakattt0% (1)