Professional Documents

Culture Documents

Ibr Calc GSR

Uploaded by

Aniket GaikwadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ibr Calc GSR

Uploaded by

Aniket GaikwadCopyright:

Available Formats

MAX.

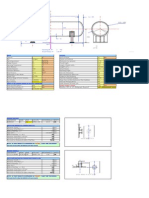

WORKING PRESSURE CALCULATIONS OF PARTS AS PER IBR

by G. Subhash Reddy, Rtd. Director of Boilers

shell - Reg. 270

efficiency of ligament - Reg. 215

p=

350 mm - pitch of tube holes

d=

50 mm - diameter of tube holes

E=

0.85714 (p-d)/p - efficiency of ligament

T=

12 mm - thickness, min. 6

D=

1500 mm - max. internal diameter

f=

1406 kg/sq.cm - permissible working stress at temp upto 250 C for SA515-70

WP = 17.9236 kg/sq.cm - 2 X f X E X(T-0.762)/(D+T-0.762) - working pressure

tube/end plate

1 pitch of the tubes -Reg.580

p=

90 mm - min. pitch of tube hole

D=

63.5 mm - diameter of the tube hole

L=

20.6375 mm - D/8+12.7 - ligament required

L1 =

26.5 mm - (p-D) - ligament provided

2 stayed flat surface - Reg. 574

e=

16 mm - thickness, min. 8

d=

450 mm - diameter of the largest circle taken between staying points of the plate

f=

1406 kg/sq.cm - permissible working stress at temp upto 250 C for SA515-70

f1 =

1195.1 kg/sq.cm - 0.85 X f

e1 =

0.75 mm

C=

0.4

P=

8.57825 kg/sq.cm - f1 X ((e-e1)/(C X d))2 - design pressure

headerl - Reg. 342(a) & eq. 72

efficiency of ligament - Reg. 215

p=

mm - pitch of tube holes

d=

mm - diameter of tube holes

E = (p-d)/p - efficiency of ligament

Tn = mm -nominal thickness

T=

mm - 0.875 X Tn - min. thickness

Do = mm - outside diameter

D = mm - (Do-2XT) - max. internal diameter

f=

1202 kg/sq.cm - permissible working stress at temperature upto 250 C for SA106-Gr.B

WP = kg/sq.cm - 2 X f X E X(T-0.762)/(D+T-0.762) - working pressure

p

d

100

100

E

50.8

50.8

fire tube eq. XII/14

t=

3.25

D=

63.5

C=

0.75

f=

870

WP = 54.8031

Tn

0.492

0.492

T

5.49

3.91

Do

4.6665

3.3235

D

88.9

60.3

mm - min. thickness of tube

mm - outside tube diameter

mm - corrosion allowance

kg/sq.cm - permissible working stress

kg/sq.cm - 1.6 X f X (T-C)/D - working pressure

water tube Reg. 338

T=

3.25 mm - min. thickness of tube

f

79.567

53.653

W.P.

1202 55.325682

1202 53.89464

MAX. WORKING PRESSURE CALCULATIONS OF PARTS AS PER IBR

by G. Subhash Reddy, Rtd. Director of Boilers

D=

50.8

C=

0.75

f=

870

WP = 90.0621

mm - external diameter of the tube

mm - corrosion allowance

kg/sq.cm - permissible working stress

kg/sq.cm - 2 X f X (T-C)/(D-T+C) - working pressure

header end plates Reg. 342(b)

t=

10 mm - min. thickness of plate

d=

200 mm - diameter of plate

C=

1 mm - corrosion allowance

f=

1312 kg/sq.cm - permissible working stress

K=

0.28 for ends directly strength welded to header/shell

WP = 9.48857 kg/sq.cm - f X (T-C)2/(d2XK) - working pressure

stay tubes Reg.577

Tp

5.08

D

48.3

A

20000

C

1

T

4.08

f

713

a

566.8

WP 20.2064

mm

mm

mm

mm

mm

kg/cm2

mm2

kg/cm2

provided thickness of tube

outside tube diameter

max. area supported by tube

additional thickness

net thickness

permissible working stress at temperature Reg. 577(a)(IV)

cross sectional area of tube = 0.7854 X {D2- (D2-2 X T)2}

max. allowed working pressure = f X a/A

thickness of cylindrical parts under external pressure Reg. 592

kg/cm2 design pressure

P

10

Et

2051.6

kg/cm2 yield stress at design temperature

d

2200

mm

mean diameter

L

1187

mm

distance between centres of two effective points of support

E

2E+006 kg/cm2 youngs modulus at design temperature Reg. 592

S1

2.5

2.5 for clas I boiler

S2

3

3 for clas I boiler

u

1.5

mm

out of roundness = 1.5 for plain furnaces

B

11.9301

P*d*S1/(2*Et*(1+d/15/L))

e1

20.8615

mm

thk=u/2*(1+SQRT(1+0.12*d*u/B/(1+d/0.3/L)))+0.75

e2

17.6838

mm

thk = d^0.6*(L*S2*P/1.73/E)^0.4+0.75

Tp

11

mm

provided thickness

check for moment of inertia of stiffener Reg. 592(i)

mm4

second moment of area of stiffener = P X d3 X L/1.35X10 7

Is

9E+006

As

1024

mm2

cross sectional area of stiffener ring 16 X 64

4

I

349525

mm

available moment of inertia of stiffener ring

Lr

37.5

mm

distance of NA of stiffener ring from center lineof shell thickness

w

182.12

mm

width of shell contributing to MI = 1.1*sqrt(d*tp) Reg. 592

x

12.6845

mm

distance of NA of combined ring-shell from CL of shell thick=

As*Lr/(As+w*ts)

mm4

Ia

1E+006

available moment of inertia of combined ring-shell about its NA =

I+w X tp3/12+As X (Lr-x)2+ w X tp X x2

elliptical manhole cover, reg166

a

305 mm

minor axis of the opening to which door is fitted

MAX. WORKING PRESSURE CALCULATIONS OF PARTS AS PER IBR

by G. Subhash Reddy, Rtd. Director of Boilers

b

d

tp

P

f

fb

W

t

410

20

16

10

1300

509.684

178471

12.9902

mm

mm

mm

kg/cm2

kg/cm2

kg/cm2

kg

mm

circular manhole cover, reg166

d

305 mm

ds

20 mm

P

10 kg/cm2

f

1300 kg/cm2

fb

509.684 kg/cm2

W

178471 kg

t

20.348 mm

major axis of the opening to which door is fitted

root diameter of stud

provided thickness

design pressure

allowed pressure

design stress value of stud up to 300 0C = 50 N/mm2

full load capacity of one stud = pi/4*d2*fb

calculated thickness =squre root of {(0.35*(2a-b)a^2+W)/f}

diameter of the opening to which door is fitted

root diameter of stud

design pressure

allowed pressure

design stress value of stud up to 300 0C = 50 N/mm2

full load capacity of one stud = pi/4*d2*fb

calculated thickness =squre root of {(0.35*d^2+W)/f}

stay bars

longitudinal stay bars, Reg.587

D

A

C

W.P.

50

74000

655.4

22.1419

mm

mm2

kg/cm2

kg/cm2

W.P.

diameter at its smallest part

area supported by one stay

depends on ten.strength,44.1-50.4=607.5, 47.25-53.55=655.4

max. allowed working pressure = C X D2/A

gusset , Reg 591

w

100

tp

40

A

110000

result 4922

f

703.143

L/L'

0.866

W.P. 22.1426

mm

mm

mm2

kg/cm2

kg/cm2

kg/cm2

material specification

width at its tangential section

provided thickness, not < 7/8 of shell thick & 11.113 mm

area supported by one stay

tensile stress

allowable stress =R / 7

cos( angle with shell) for 300 it is 0.866

max. allowed working pressure = f X w x tp X L / L' /A

flat plate margin for flat stayed plates

flat plate margin for flat stayed plates, Reg. 589

kg/cm2 design pressure

WP

10

t

29

mm

thickness of flat plate

C

3.7

3.47 for plates exposed to flame, 3.7 not exposed

FPM 280.094

mm

flat plate margin in inch=C X (t-1)/sqrtWP,t in inch/32, WP in psi

link stay Reg.591

fp

1040.79

A

212150

P

10

d

45

n

3

w

120

kg/cm2

mm2

kg/cm2

mm

kg/cm2

mm

allowable shear stress for pin, double shear, Reg 591(ss-562.5)

area supported by one gusset/anchor plate

design pressure

diameter of pin

number of pins per gusset

width of link stay

MAX. WORKING PRESSURE CALCULATIONS OF PARTS AS PER IBR

by G. Subhash Reddy, Rtd. Director of Boilers

t

tg

Rl

Et

fb

fl

Sp

result

Sl

result

Sb

Sba

result

fw

La

Sw

result

20

40

4216

1652

1239

602.286

444.637

OK

272.197

OK

453.661

453.661

OK

10

700

kg/cm2

not safe

mm

mm

kg/cm2

mm

kg/cm2

kg/cm2

kg/cm2

kg/cm2

kg/cm2

kg/cm3

mm

mm

kg/cm2

thickness of link stay

thichness of anchor plate

tensile strength of link sec IID

yield stress of link/gusset at metal temperature

bearing stress for link and gusset=0.75Xyield stress at t, IS800

allowable stress for link = Rl/7 , Reg 591

shear stress induced in pin, double shear =P X A /(nX0.7854Xd 2)

fp > Sp

stress induced in link =P X A /{2XnX(w-d)XtX0.866}

fl > Sl

bearing stress induced in link = PXA/(0.866X2XnXdXt)

bearing stress induced in gusset = PXA/(0.866XnXdXtg)

fb. > max(Sb,Sba)

fillet leg for anchor plate to shell/ tube sheet

length of shortest anchor plate

stress in weld = P*A/(2*La*fw*0.7*0.55)

Sw < 1100

You might also like

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- Extreme Fiber Elongation Calcs - J.SDocument1 pageExtreme Fiber Elongation Calcs - J.SJ.SIVIRA100% (1)

- Shipping Container DrawingDocument8 pagesShipping Container DrawingAniket GaikwadNo ratings yet

- Tube Sheet CalculationDocument3 pagesTube Sheet CalculationAbhay UpadhyayNo ratings yet

- Figure 9.4-9 Cylindrical Shell With Isolated Opening, Increased Wall Thickness and Set-In Nozzle en 13445-3 - Figure 9.4-9Document4 pagesFigure 9.4-9 Cylindrical Shell With Isolated Opening, Increased Wall Thickness and Set-In Nozzle en 13445-3 - Figure 9.4-9met-calcNo ratings yet

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationAliNo ratings yet

- Ad2000 b5 Fixed Tubesheet-3Document3 pagesAd2000 b5 Fixed Tubesheet-3akisdassasNo ratings yet

- Pressure Vessel THCK CalcDocument8 pagesPressure Vessel THCK Calcmkchy12100% (1)

- Pipe Support CalculationDocument2 pagesPipe Support Calculationjsmnjasmines86% (7)

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 pagesSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Wartsila Engine 18V50DFDocument3 pagesWartsila Engine 18V50DFAniket Gaikwad100% (1)

- Heat Loss From PipeDocument8 pagesHeat Loss From PipeTon PhichitNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Ibr CalcDocument4 pagesIbr CalcUmesh Kondkar100% (7)

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhobleNo ratings yet

- IBR - 1950 - Reg. 366Document2 pagesIBR - 1950 - Reg. 366Vijay ParmarNo ratings yet

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindeNo ratings yet

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocument12 pagesMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00No ratings yet

- Ferrofab Fze: Collar Bolt Sizing CalculationDocument2 pagesFerrofab Fze: Collar Bolt Sizing CalculationMohammad Zahid50% (2)

- IBR CalculationsDocument20 pagesIBR CalculationsSivi NallamothuNo ratings yet

- Weld Shear Stress Check For FAVID Clips Welded On CladDocument3 pagesWeld Shear Stress Check For FAVID Clips Welded On CladrsubramaniNo ratings yet

- Body Flange Thkickness CalculationDocument2 pagesBody Flange Thkickness CalculationsachmayaNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleNithin ZsNo ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- Stresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFDocument8 pagesStresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFanishNo ratings yet

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Document4 pagesFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNo ratings yet

- UHX - Osweiller - WhitePaper PDFDocument20 pagesUHX - Osweiller - WhitePaper PDFMichael BasaNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Mo ZeroNo ratings yet

- Asme Sec 8 Div 1 - App 1-10Document11 pagesAsme Sec 8 Div 1 - App 1-10BibinBabuNo ratings yet

- Cone Design Tool: Pressure Vessel Engineering LTDDocument1 pageCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiNo ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- IB-PRO Welding FiguresDocument12 pagesIB-PRO Welding FiguresSUNNY GUPTANo ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Flange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gDocument10 pagesFlange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gAsep MulyadiNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Nozzle Check Top Head: Input ParametersDocument2 pagesNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongNo ratings yet

- Calculation Sheet: Design CodeDocument1 pageCalculation Sheet: Design CodeCak AndiNo ratings yet

- Lug Support DesignDocument3 pagesLug Support DesignSajal KulshresthaNo ratings yet

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- SA 516M GR 485: If Actual Thickness of Head After Forming 9 MMDocument2 pagesSA 516M GR 485: If Actual Thickness of Head After Forming 9 MMMehta MehulNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- Boiler CalcDocument92 pagesBoiler CalcPrasanta Kumar BeheraNo ratings yet

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Boiler CalculationDocument67 pagesBoiler Calculationkeerthi dayarathnaNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument17 pagesThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 pagesDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of Nozzlehardik5818No ratings yet

- L 8 IhjnmklgfDocument27 pagesL 8 IhjnmklgfbrintopvNo ratings yet

- Project 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataDocument13 pagesProject 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataP s Jagatheesan100% (1)

- Bracket - 4 DesignDocument1 pageBracket - 4 Designbjreddy100% (2)

- Unit 5Document31 pagesUnit 5Nirina ArimananaNo ratings yet

- ASME Air Tank DesignDocument2 pagesASME Air Tank Designchethan100% (1)

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Manual On Payment Mode in Food Licensing & Registration System For North Eastern Region (State License and Registration Only)Document72 pagesManual On Payment Mode in Food Licensing & Registration System For North Eastern Region (State License and Registration Only)Aniket GaikwadNo ratings yet

- AEL - A1 - M - 101-01 Rev.-4 (General Arrangement) PDFDocument1 pageAEL - A1 - M - 101-01 Rev.-4 (General Arrangement) PDFAniket GaikwadNo ratings yet

- Nuclear Fuel Complex: Tata Projects LimitedDocument4 pagesNuclear Fuel Complex: Tata Projects LimitedAniket GaikwadNo ratings yet

- Resignation Letter - Sandeep BhosaleDocument1 pageResignation Letter - Sandeep BhosaleAniket GaikwadNo ratings yet

- Number of Patient Prabhag Samiti WiseDocument2 pagesNumber of Patient Prabhag Samiti WiseAniket GaikwadNo ratings yet

- Bolt Up CalculationDocument12 pagesBolt Up CalculationAniket GaikwadNo ratings yet

- Certified Fuel Steel Tanks For: Flammable & Combustible LiquidsDocument4 pagesCertified Fuel Steel Tanks For: Flammable & Combustible LiquidsAniket GaikwadNo ratings yet

- Grand Polycoat PolyurethaneDocument1 pageGrand Polycoat PolyurethaneAniket GaikwadNo ratings yet

- ISO-281-2-2008 Corrigendum-2009Document3 pagesISO-281-2-2008 Corrigendum-2009antonioNo ratings yet

- HC7260LS L enUS ASTMDocument1 pageHC7260LS L enUS ASTMCristian Tomas Del Solar EspoueysNo ratings yet

- Introdution To Mbrace Strengthening SystemsDocument69 pagesIntrodution To Mbrace Strengthening SystemsrendroedywibowoNo ratings yet

- SMP SDocument23 pagesSMP Salireza198No ratings yet

- CH 06 Binary PhaseDocument62 pagesCH 06 Binary PhaseUltrichNo ratings yet

- 2 - Morphology and Commercial FormsDocument15 pages2 - Morphology and Commercial FormsGloria GonzálezNo ratings yet

- 13 Ext Pressure PDFDocument37 pages13 Ext Pressure PDFSagarNo ratings yet

- CAMSDM100/EMSD413: Cambridge Engineering Selector: Materials Data ModuleDocument18 pagesCAMSDM100/EMSD413: Cambridge Engineering Selector: Materials Data ModuleYubelgxNo ratings yet

- Chapter03-Handbook of Polyethylene PipeDocument61 pagesChapter03-Handbook of Polyethylene Pipepca97No ratings yet

- Square Blind Flange With Stiffener ULDocument5 pagesSquare Blind Flange With Stiffener ULjoeriji100% (1)

- Neoprene TypesDocument2 pagesNeoprene TypesAnonymous yy8In96j0rNo ratings yet

- Steel Expert ECDocument34 pagesSteel Expert ECcamagaNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10132-4Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10132-4farshid KarpasandNo ratings yet

- MEM103 - Problems Sheet - Mechanical Properties of Materials - Problems Sheet - Mechanical Properties of MaterialsDocument2 pagesMEM103 - Problems Sheet - Mechanical Properties of Materials - Problems Sheet - Mechanical Properties of MaterialsEashurock KnigamNo ratings yet

- Fenwick ThesisDocument358 pagesFenwick ThesisMaurício Prado MartinsNo ratings yet

- Warpage of Fibre Reinforced PlasticsDocument8 pagesWarpage of Fibre Reinforced PlasticsSantolashNo ratings yet

- Report PDFDocument58 pagesReport PDFTiểu Bảo ViNo ratings yet

- Additive ManufacturingDocument7 pagesAdditive ManufacturingIslam HelazaNo ratings yet

- Electron Energy-Loss Spectroscopy (EELS) Studies of An Yttria Stabilized TZP CeramicDocument7 pagesElectron Energy-Loss Spectroscopy (EELS) Studies of An Yttria Stabilized TZP Ceramicyehia ElarefNo ratings yet

- ModelingSCBF PDFDocument28 pagesModelingSCBF PDFadnanraisahmedNo ratings yet

- An Analytical Study of The Moments in Continuous Slabs Subjected To Concentrated LoadsDocument164 pagesAn Analytical Study of The Moments in Continuous Slabs Subjected To Concentrated LoadsfefahimNo ratings yet

- PHYS1001 Test 1 2017 SEM-1Document14 pagesPHYS1001 Test 1 2017 SEM-1Angad MangatNo ratings yet

- Weir Plate or Baffle Plate CalculationDocument6 pagesWeir Plate or Baffle Plate CalculationPugel Yeremias50% (2)

- Guidelines To Hardness TestingDocument15 pagesGuidelines To Hardness TestingJosi ArayaNo ratings yet

- 4014 03Document7 pages4014 03Carlos Romero Muñoz100% (2)

- APM2018Document26 pagesAPM2018Prashant GuptaNo ratings yet

- Soil Model Okt 2010Document22 pagesSoil Model Okt 2010HawaiiChongNo ratings yet

- BeamDocument55 pagesBeamstarq1No ratings yet