Professional Documents

Culture Documents

Foundation Systems

Uploaded by

Empress Vanessa TuticaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Foundation Systems

Uploaded by

Empress Vanessa TuticaCopyright:

Available Formats

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Reinforced Concrete

Concrete in which steel is embedded in such a manner that the two materials act

together in resisting forces. The reinforcing steelrods, bars, or meshabsorbs the

tensile, shear, and sometimes the compressive stresses in a concrete structure.

Plain concrete does not easily withstand tensile and shear stresses caused by wind,

earthquakes, vibrations, and other forces and is therefore unsuitable in most

structural applications. In reinforced concrete, the tensile strength of steel and the

compressive strength of concrete work together to allow the member to sustain

these stresses over considerable spans. The invention of reinforced concrete in the

19th century revolutionized the construction industry, and concrete became one of

the worlds most common building materials.

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Reinforced Concrete Building Elements:

1st Floor

It is the floor that has 1 storey height above ground.

Basement Floor

The floor of the basement of the building. It is also called cellar. The basement floor

is either completely or partially below the ground floor. A basement can be used in

almost exactly the same manner as an additional above-ground floor of a house or

other building. However, the use of basements depends largely on factors specific

to a particular geographical area such as climate, soil, seismic activity, building

technology, and real estate economics.

The concrete floor in most basements is structurally not part of the foundation; only

the basement walls are. Since warm air rises, basements are typically cooler than

the rest of the house. In summer, this makes basements damp, due to the higher

relative humidity.

Basement Wall

The wall surrounding the basement floor is called the basement wall. The basement

walls can be regarded structurally as part of the foundation. The basement walls are

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

shear walls which can resist lateral laods as well. Moreover, these walls are meant

to be higly non-porous and water resistant.

Column Bracket

Column Bracket is protrusion from the column also used for hanging or attaching

lamps, bulbs or other accessories to it like road signs.

Column Capital

Column capital is an architectural element used for aesthetic purposeswhich forms

the topmost member of a column.

Drop Panels

Drop panels are used to thicken the slab around the column in flat slabs to avoid

punching shear. Since flat slabs have no stirrups shear is resisted by thickening the

slab around the column to increase the concrete in shear. Beams can also be used,

but generally drop panels are preferred to avoid conflicts with the electromechanical

works of the structure.

The columns supporting the main structure of the building. Usually in frame

structures the exterior columns are of extreme importance and bear the load of the

building as well as resist environmental factors like wind, rain, and other physical

factors.

Flat Plate

Slabs connecting to columns directly. Flat plate system is widely adopted by

engineers as it provides many advantages . The system can reduce the height of

the building, provide more flexible spatial planning due to no beams present, and

further reduce the material cost. However, the main problem in practice is the

brittle failure of flat plate under punching shear. Due to the relatively small floor

loading and the close column spacing, flat plate construction is preferred. For

heavier loading and larger column spacing, column capitals are required, and for

even larger spans to reduce the self-weight, waffle slabs are used.

Flat Slab

The flat plate is a two-way reinforced concrete framing system utilizing a slab of

uniform thickness, the simplest of structural shapes. The flat slab is a two-way

reinforced structural system that includes either drop panels or column capitals at

columns to resist heavier loads and thus permit longer spans. Construction of flat

slabs is one of the quickest methods available. Lead times are very short as this is

one of the most common forms of construction.

Interior Columns

Interior columns in a frame structure suppor the slab and beams internally. They are

not as susceptible to buckling and environmental effects as the external ones but

still are extremely important considering the safety and stability of the building.

Interior columns can also serve aesthetic and architectural purposes.

Pedestal

An architectural support or base, as for a column or statue.

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Roof

A roof is the covering on the uppermost part of a building. A roof protects the

building and its contents from the effects of weather and the invasion of animals.

Structures that require roofs range from a letter box to a cathedral or stadium,

house buildings being the most numerous.

The elements in the design of a roof are:

the material

the construction

the durability &

Serviceability

Spread Footing

To distribute the load of the foundation on the soil, spread footings are installed

below the building's foundation. This type of footing is continous below the

perimeter of the house walls and may be thickened or widened at the points where

concentrated loads are applied e.g. columns. These components are constructed

from concrete and are often reinforced with rebar or steel to add additional support.

Depending on the size and configuration of the building, the footers can be buried

just below ground level or several feet below the surface. In cold climates, they are

always placed below the frost line to minimize problems with concrete heaving that

occurs during freeze/thaw cycles. This type of footer design is highly beneficial to

builders and homeowners. Since they transfer the weight of the building over a

large area, they have little risk of failure

Upturned Beam

Through the use of upturned concrete T-beams, designers created a naturally

ventilated workspace that employs the thermal mass of an exposed concrete

ceiling. This concrete absorbs heat during the day and is purged at night by cool

breezes. The term is usually used in concrete construction, in parking structures,

but here is how it works:

The beam is above the floor it supports, or a combination. Take a parking structure,

there is the required barrier wall, so if you turn the beam up it acts as support and

the barrier. Think of your simple beam diagram with a uniform load on it. The beam

supports this load, so it doesnt matter if the load is applied at the bottom (simply,

other than there are the compression/tension face)

This also works well in buildings, rather than have a large beam under the floor, the

beam is cast above and below the floors, acts as bearing and shear tension and

compression face reinforcement will be somewhat different, but beam cross section

area will stay the same.

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Foundation System

The type of structure which gives structural support to a building beneath its lowest

floor or ground base.

A structure's foundation is the structure which supports it in the ground. The forms

and materials of foundations vary according to ground conditions, frame material,

framing system, and other factors.

In large structures, the foundation (or basement) wall does not play a significant

role in carrying the structural loads above it - this wall mainly resists the lateral load

of the soil (and any water) that the basement is constructed in. Foundation systems

for large buildings are almost always built with concrete, except when steel or wood

piles are used.

In some building systems, the floor slab is designed to assist in carrying some of the

lateral loads of the structure, and the floor slab thereby become an integral part of

the framing system.

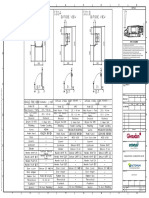

Examples of Foundation Systems

(a) Structure supported on a foundation bearing on

soil. (b) Structure supported on a foundation

bearing on rock. (c) Structure supported by a pile

foundation.

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

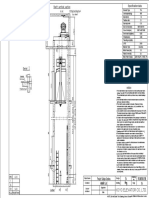

PIER FOUNDATION

It is similar to a deck built

ground. It is supported by

pilings.

several feet above the

pillars and posts or

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

PILE FOUNDATION

may be cast in place-concrete poured into

ground cased- steel pipe in ground then filled

uncased- cased concrete 'plug' placed & case

removed micropiles- small diameter drilled &

reinforced

WALL FOUNDATION

It includes footing, drainage system, and a cast in place wall.

SLAB

flat

FOUNDATION

concrete pad poured onto ground

which works well on level ground in

warmer climates.

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Classification of pile with respect to load transmission and functional

behavior

End bearing piles (point bearing piles)

Friction piles (cohesion piles )

Combination of friction and cohesion piles

End bearing piles

These piles transfer their load on to a firm stratum located at a considerable depth

below the base of the structure and they derive most of their carrying capacity from

the penetration resistance of the soil at the toe of the pile (see figure 1). The pile

behaves as an ordinary column and should be designed as such. Even in weak soil a

pile will not fail by buckling and this effect need only be considered if part of the pile

is unsupported, i.e. if it is in either air or water. Load is transmitted to the soil

through friction or cohesion. But sometimes, the soil surrounding the pile may

adhere to the surface of the pile and causes "Negative Skin Friction" on the pile.

This, sometimes have considerable effect on the capacity of the pile. Negative skin

friction is caused by the drainage of the ground water and consolidation of the soil.

The founding depth of the pile is influenced by the results of the site investigate on

and soil test.

Friction or cohesion piles

Carrying capacity is derived mainly from the adhesion or friction of the soil in

contact with the shaft of the pile (see fig 2).

piles

Figure 1:End bearing

Figure 2:Friction or cohesion pile

Cohesion piles

These piles transmit most of their load to the soil through skin friction. This process

of driving such piles close to each other in groups greatly reduces the porosity and

compressibility of the soil within and around the groups. Therefore piles of this

category are sometimes called compaction piles. During the process of driving the

pile into the ground, the soil becomes molded and, as a result loses some of its

strength. Therefore the pile is not able to transfer the exact amount of load which it

is intended to immediately after it has been driven. Usually, the soil regains some of

its strength three to five months after it has been driven.

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Friction piles

These piles also transfer their load to the ground through skin friction. The process

of driving such piles does not compact the soil appreciably. These types of pile

foundations are commonly known as floating pile foundations.

Combination of friction piles and cohesion piles

An extension of the end bearing pile when the bearing stratum is not hard, such as

firm clay. The pile is driven far enough into the lower material to develop adequate

frictional resistance. A farther variation of the end bearing pile is piles with enlarged

bearing areas. This is achieved by forcing a bulb of concrete into the soft stratum

immediately above the firm layer to give an enlarged base. A similar effect is

produced with bored piles by forming a large cone or bell at the bottom with a

special reaming tool. Bored piles which are provided with a bell have a high tensile

strength and can be used as tension piles (see fig.3)

Figure

3:under-reamed base enlargement to a bore-and-cast-in-situ pile

Classification of pile with respect to type of material

Piles are usually made of timber, concrete or steel. Timber can be used for the

manufacture of temporary piles and when the wood is available at an economical

price. Concrete is used for the manufacture of pre-cast concrete piles, cast in place

and pre-stressed concrete piles, while steel piles are used for permanent or

temporary works.

Timber

Concrete

Steel

Composite piles.

Timber piles

Used from earliest record time and still used for permanent works in regions where

timber is plentiful. Timber is most suitable for long cohesion piling and piling

beneath embankments. The timber should be in a good condition and should not

have been attacked by insects.

For timber piles of length less than 14 meters, the diameter of the tip should be

greater than 150 mm. If the length is greater than 18 meters a tip with a diameter

of 125 mm is acceptable. It is essential that the timber is driven in the right

direction and should not be driven into firm ground. As this can easily damage the

pile. Keeping the timber below the ground water level will protect the timber against

decay and putrefaction. To protect and strengthen the tip of the pile, timber piles

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

can be provided with toe cover. Pressure creosoting is the usual method of

protecting timber piles.

Advantages and disadvantages of Wood piles

+ The piles are easy to handle

+ Relatively inexpensive where timber is plentiful.

+ Sections can be joined together and excess length easily removed.

The piles will rot above the ground water level. Have a limited bearing capacity.

Can easily be damaged during driving by stones and boulders.

The piles are difficult to splice and are attacked by marine borers in salt water.

Concrete piles

Concrete piles can be divided to pre-cast and cast in place concrete piles:

Pre- cast concrete Piles or Pre fabricated concrete piles

it is formed and reinforced in a high-quality controlled concrete, Usually used of

square (see fig 1-4 b), triangle, circle or octagonal section, they are produced in

short length in one meter intervals between 3 and 13 meters. They are pre-caste so

that they can be easily connected together in order to reach to the required length

(fig 1-4 a). This will not decrease the design load capacity. Reinforcement is

necessary within the pile to help withstand both handling and driving stresses. Pre

stressed concrete piles are also used and are becoming more popular than the

ordinary pre cast as less reinforcement is required.

Figure 4:a) concrete pile connecting detail. b) squared pre-cast concert pile

The Hercules type of pile joint (Figure 5) is easily and accurately cast into the pile

and is quickly and safely joined on site. They are made to accurate dimensional

tolerances from high grade steels.

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Figure 5:Hercules type of pile joint

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Advantages and disadvantages of Pre- cast concrete Piles

+ Are easy to splice. Relatively inexpensive.

+ Stable in squeezing ground, for example, soft clays, silts and peats pile material

can be inspected before piling.

+ Can be driven in long lengths.

+ Can increase the relative density of a granular founding stratum.

Displacement, heave, and disturbance of the soil during driving.

Can be damaged during driving. Replacement piles may be required.

Cannot be driven with very large diameters or in condition of limited headroom.

Cast in place Concrete piles

Cast in place concrete piles are the most type commonly used for foundations due

to the great diversity available for pouring concrete and the introduction of the pile

into the soil. Driving and drilling piles are two types of cast in place concrete piles;

however, the implementation of these piles in place may be accompanied by some

problems such as arching, squeezing and segregation.

These piles are divided to:

Piles are poured in tubes with underneath heels and left when lifting the tubes.

some of those types:

Simplex pile: it is a tube of cast of diameter 40 cm, has an underneath heel,

it is banged underground by an automatic hammer until reaching the arable

land for the establishment, then concrete is poured inside it and banged by

another hammer. In the meantime, the pipe is raised with a certain amount

so as not to enter the soil inside. This pile can bear about 40 50 ton.

Frankie pile: It is a number of tubes entering each other in order to easily

access to great depths within the earth. A heel of reinforced concrete can be

used and left in the ground to prevent the entry of cold water pipes. This pile

can carry a load of 50 80 ton.

Vibro pile: It is a steel pipe of diameter 40 cm, has a conical heel with a

separate flange, it is banged underground by an automatic hammer until

reaching the arable land for the establishment, then the heel is removed and

put into a tube, after that concrete is poured. The tube is moved up and down

(about 80 times per minute) in order to compact concrete. This pile can bear

about 60 ton.

Strong pile: this pile is largely similar to Simplex pile except that the bottom

heel is made from reinforced concrete covered with cast heel. This pile can

carry a load of 25 30 ton.

Under rimed pile: this pile is used at black clayey soil and lands of non

residual soil, so this soil is very dangerous to be established on it.

Piles with open tubes without heel, then concrete are poured inside the tube.

The pipe has a diameter of 40 cm and an average concrete well of 12 to 15

meters depending on the level of land to be established. Some these piles:

Strauss pile: Which is very similar to the Simplex pile but without a heel.

Soil can be removed from the tubes by special devices and concrete is poured

instead of soil. The maximum load that can be carried by these piles is from

20 25 ton.

Kimbersol pile: A well is done of diameter about 80 cm, until reaching the

arable land for the establishment, then the bottom of the well is compacted

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

using a rounded hammer and filled with concrete with a ratio of 1 : 5 (cement

: sand). This pile can carry a load of 80 120 ton.

Welfchaulzer pile: a pipe of diameter 30 40 cm is banged until reaching

the arable land for the establishment, and the inside soil is removed, then

steel bars are placed and the opened upper hole is covered tightly Leaving

holes to connect the compressed air so that leachates can be expelled, then

concrete is poured by a ratio 1 : 4.

Raymond pile: Consists of cylindrical chips inside each other with a

diameter of 40 60 cm at the top of the pile and 20 28 cm at the bottom. It

is banged inside by a Mandrill and the cylindrical chips are leaved in the soil

and filled with concrete.

Advantages and disadvantages of cast-in-place concrete piles

+ Can be inspected before casting can easily be cut or extended to the desired

length.

+ Relatively inexpensive.

+ The piles can be cast before excavation.

+ Pile lengths are readily adjustable.

+ An enlarged base can be formed which can increase the relative density of a

granular founding stratum leading to much higher end bearing capacity.

+ Reinforcement is not determined by the effects of handling or driving stresses.

Heave of neighboring ground surface, which could lead to re consolidation and

the development of negative skin friction forces on piles..

Tensile damage to unreinforced piles or piles consisting of green concrete, where

forces at the toe have been sufficient to resist upward movements.

Damage piles consisting of uncased or thinly cased green concrete due to the

lateral forces set up in the soil. Concrete may be weakened if artesian flow pipes up

shaft of piles when tube is withdrawn.

Light steel section or Pre-cast concrete shells may be damaged or distorted by

hard driving.

Cannot be driven where headroom is limited.

Time consuming; cannot be used immediately after the installation.

Limited length.

Bored and cast in -place (non -displacement piles)

+ Length can be readily varied to suit varying ground conditions.

+ Can be installed in very large diameters.

+ End enlargement up to two or three diameters are possible in clays.

+ Material of piles is not dependent on handling or driving conditions.

+ Can be installed in very long lengths.

Concrete is not placed under ideal conditions and cannot be subsequently

inspected.

Water under artesian pressure may pipe up pile shaft washing out cement.

Cannot be readily extended above ground level especially in river and marine

structures.

Boring methods may loosen sandy or gravely soils requiring base grouting to

achieve economical base resistance.

Steel piles

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Made of sectors in the form of H, X or of thick pipes (see fig. 6). They are suitable

for handling and driving in long lengths. Their relatively small cross-sectional area

combined with their high strength makes penetration easier in firm soil. They can be

easily cut off or joined by welding. If the pile is driven into a soil with low pH value,

then there is a risk of corrosion, but risk of corrosion is not as great as one might

think. Although tar coating or cathodic protection can be employed in permanent

works.

It is common to allow for an amount of corrosion in design by simply over

dimensioning the cross-sectional area of the steel pile. In this way the corrosion

process can be prolonged up to 50 years. Normally the speed of corrosion is 0.2-0.5

mm/year and, in design, this value can be taken as 1mm/year

a) X- cross-section

b) H cross-section

c) steel pipe

Figure 6 Steel piles cross-sections

Advantages and disadvantages of Steel piles

+ The piles are easy to handle and can easily be cut to desire length.

+ Can be driven through dense layers. The lateral displacement of the soil during

driving is low (steel section H or I section piles) can be relatively easily spliced or

bolted.

+ Can be driven hard and in very long lengths.

+ Can carry heavy loads.

The piles will corrode,

Will deviate relatively easy during driving.

Are relatively expensive.

Composite piles

Combination of different materials in the same of pile. As indicated earlier, part of a

timber pile which is installed above ground water could be vulnerable to insect

attack and decay. To avoid this, concrete or steel pile is used above the ground

water level, whilst wood pile is installed under the ground water level (see figure 7).

Figure 7: Protecting timber piles from decay:

a) by pre-cast concrete upper section above water level.

b) by extending pile cap below water level

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Classification of pile with respect to effect on the soil

A simplified division into driven or bored piles is often employed.

Driven piles

Driven piles are considered to be displacement piles. In the process of driving the

pile into the ground, soil is moved radially as the pile shaft enters the ground. There

may also be a component of movement of the soil in the vertical direction.

Tutica, Empress Vanessa B.

1511719

Building Technology 3

Arch. Elmer Soliman Jr.

Figure 8: driven piles

Bored piles

Bored piles (Replacement piles) are generally considered to be non-displacement

piles a void is formed by boring or excavation before piles is produced. Piles can be

produced by casting concrete in the void. Some soils such as stiff clays are

particularly amenable to the formation of piles in this way, since the bore hole walls

do not requires temporary support except cloth to the ground surface. In unstable

ground, such as gravel the ground requires temporary support from casing or

bentonite slurry. Alternatively the casing may be permanent, but driven into a hole

which is bored as casing is advanced. A different technique, which is still essentially

non-displacement, is to intrude, a grout or a concrete from an auger which is

rotated into the granular soil, and hence produced a grouted column of soil.

There are three non-displacement methods: bored cast- in place piles, particularly

pre-formed piles and grout or concrete intruded piles.

The following are replacement piles:

Augered

Cable percussion drilling

Large-diameter under-reamed

Types incorporating pre caste concrete unite

Drilled-in tubes

Mini piles

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- PracDocument3 pagesPracEmpress Vanessa TuticaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- E 201 - Work, Energy and PowerDocument7 pagesE 201 - Work, Energy and PowerEmpress Vanessa TuticaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- GA Admission RequirementsDocument2 pagesGA Admission RequirementsEmpress Vanessa TuticaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Judicial DepartmentDocument47 pagesJudicial DepartmentEmpress Vanessa TuticaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Evaluation SheetDocument2 pagesEvaluation SheetEmpress Vanessa TuticaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Glass Both in Overall Strength and in Breakage PatternsDocument3 pagesGlass Both in Overall Strength and in Breakage PatternsEmpress Vanessa TuticaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Chapter5 Giacomini CatalogueDocument8 pagesChapter5 Giacomini CataloguecristyryeNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Name of Teacher Issues &concers Strategies Time Frame Person Involved SignatureDocument9 pagesName of Teacher Issues &concers Strategies Time Frame Person Involved SignatureMerlinda LibaoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Untitled DiagramDocument1 pageUntitled DiagramirfanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Sceco and Electrical RoomDocument15 pagesSceco and Electrical Roomxchannel28No ratings yet

- Residential HouseDocument10 pagesResidential HousePhakiso MolelekiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Bảng Tính Cột Áp QuạtDocument4 pagesBảng Tính Cột Áp QuạtNguyen PhamNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- RV Comfort Thermostat Replacement-9330-Manual PDFDocument2 pagesRV Comfort Thermostat Replacement-9330-Manual PDFBeverly BakerNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- RedGard Fabric Membrane Sell Sheet 2021 - 0525Document2 pagesRedGard Fabric Membrane Sell Sheet 2021 - 0525K PreitoNo ratings yet

- AC Pressure Test ChartsDocument8 pagesAC Pressure Test ChartsLogan Wohlford100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shop Drawing: Key PlanDocument1 pageShop Drawing: Key PlanEko WiyonoNo ratings yet

- Koyo Elevator Co,.Ltd.: Specification DataDocument4 pagesKoyo Elevator Co,.Ltd.: Specification DataFelipe Raul Chumpitaz GNo ratings yet

- HIL Limited: Selectivity of MaterialDocument20 pagesHIL Limited: Selectivity of MaterialRohit YadavNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- NotesDocument19 pagesNotesvenkatdasNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Fume Hood CatalogDocument42 pagesFume Hood CatalogJasmi Futihal UlaNo ratings yet

- (EIFS) WMS-A-041 R.3 and ITP-A-041 R.3 For Field Installation of STO VENTEC System in DA and AG - RequestedDocument58 pages(EIFS) WMS-A-041 R.3 and ITP-A-041 R.3 For Field Installation of STO VENTEC System in DA and AG - RequestedLito VasquezNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Rockwool Intumescent PillowsDocument3 pagesRockwool Intumescent PillowsBobana AdamovicNo ratings yet

- Profil Turap LengkapDocument11 pagesProfil Turap LengkapAlwanNo ratings yet

- Shibu John CVDocument1 pageShibu John CVLilly SunnyNo ratings yet

- Ampco 18.23: Technical Data SheetDocument1 pageAmpco 18.23: Technical Data SheetdedosimoesNo ratings yet

- Other 1088675 PDFDocument35 pagesOther 1088675 PDFazwanNo ratings yet

- #68 - Preliminary Assessment Report - JALESHWORI SSDocument17 pages#68 - Preliminary Assessment Report - JALESHWORI SSrajendra moktanNo ratings yet

- Metal Stairs ConstructionDocument28 pagesMetal Stairs ConstructionDivyam KakkadNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Public Toilet Elec-Pt-Type-1 (45 M2) GRNDDocument1 pagePublic Toilet Elec-Pt-Type-1 (45 M2) GRNDteddyNo ratings yet

- PdfstreamerDocument48 pagesPdfstreamerAshutosh GuptaNo ratings yet

- Air Conditioning in The Building Facility Management StudiesDocument13 pagesAir Conditioning in The Building Facility Management StudiesNurul Nabila SahriNo ratings yet

- Durakrit: Waterproof Breathable Cementitious Composite/Acrylic PolymerDocument1 pageDurakrit: Waterproof Breathable Cementitious Composite/Acrylic PolymerrudrabirNo ratings yet

- Water Proofing Damp ProofingDocument17 pagesWater Proofing Damp ProofingSalama ShurrabNo ratings yet

- Productivity Rate (Labor & Eqpt)Document35 pagesProductivity Rate (Labor & Eqpt)archie_72882% (192)

- Dubai Municipality Building Code RegulationsDocument93 pagesDubai Municipality Building Code RegulationsRajesh K Narayanan100% (2)

- Tool Shed PlansDocument26 pagesTool Shed PlansWinnie Mandela100% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)