Professional Documents

Culture Documents

SAW WPS Procedure for 2010 Section IX

Uploaded by

halil ozgunOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAW WPS Procedure for 2010 Section IX

Uploaded by

halil ozgunCopyright:

Available Formats

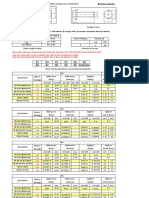

2010 SECTION IX

QW-254

WELDING VARIABLES PROCEDURE SPECIFICATIONS (WPS)

Submerged-Arc Welding (SAW)

Paragraph

QW-402

Joints

QW-403

Base

Metals

Brief of Variables

Groove design

Backing

.10

Root spacing

.11

Retainers

.5

Group Number

.6

T Limits

.8

T Qualified

X

X

X

t Pass 12 in. (13 mm)

.11

P-No. qualified

.4

F-Number

.5

A-Number

.6

Diameter

.9

Flux/wire class.

X

X

.10

Alloy flux

.24

Supplemental

.27

Alloy elements

.29

Flux designation

.30

.33

Classification

.34

Flux type

.35

Flux/wire class.

QW-405

Positions

.1

QW-406

Preheat

.1

.2

.3

X

X

X

X

X

Recrushed slag

Decrease > 100F (55C)

Preheat maint.

Increase > 100F (55C) (IP)

PWHT

.2

PWHT (T & T range)

+ Position

.1

.4

QW-409

Electrical

Characteristics

Nonessential

.1

.36

QW-407

PWHT

Supplementary

Essential

.4

.9

QW-404

Filler

Metals

Essential

X

X

X

T Limits

.1

> Heat input

.4

Current or polarity

.8

I & E range

X

X

24

2010 SECTION IX

QW-254

WELDING VARIABLES PROCEDURE SPECIFICATIONS (WPS) (CONTD)

Submerged-Arc Welding (SAW)

Paragraph

QW-410

Technique

Brief of Variables

Supplementary

Essential

Nonessential

.1

String/weave

.5

Method cleaning

.6

Method back gouge

.7

Oscillation

.8

Tube-work distance

.9

Multi to single pass/side

.10

Single to multi electrodes

.15

Electrode spacing

.25

Manual or automatic

.26

Peening

.64

Legend:

+ Addition

Deletion

Essential

Use of thermal processes

Uphill

Downhill

Forehand

Backhand

> Increase/greater than

< Decrease/less than

25

Change

2010 SECTION IX

QW-254.1

WELDING VARIABLES PROCEDURE SPECIFICATIONS (WPS)

Submerged-Arc Welding (SAW)

Special Process Variables

Essential Variables

Hard-Facing

Overlay (HFO)

(QW-216)

Paragraph

QW-402

Joints

QW-403

Base

Metals

Corrosion-Resistant

Overlay (CRO)

(QW-214)

.16

<

Finished t

<

Finished t

.20

P-Number

P-Number

.23

T Qualified

T Qualified

Nominal size of electrode

.6

QW-404

Filler

Metals

.12

Classification

.24

or > 10% in supplemental

filler metal

.27

Alloy elements

.37

or > 10% in supplemental

filler metal

A-Number

.39

Nominal flux comp.

Nominal flux comp.

QW-405

Positions

.4

Position

Position

QW-406

Preheat

.4

QW-407

PWHT

QW-409

Electrical

Characteristics

QW-410

Technique

.6

Dec. > 100F (55C) preheat

> Interpass

.26

Current or polarity

PWHT

Current or polarity

1st layer Heat input

> 10%

1st layer Heat input

> 10%

.1

String/weave

.5

Method of cleaning

.7

Oscillation

.8

Tube to work distance

.15

Electrode spacing

.25

Manual or automatic

.26

Peening

.38

Multiple to single layer

.40

.50

Legend:

+ Addition

Deletion

Dec. > 100F (55C) preheat

> Interpass

PWHT

.9

.4

Nonessential Variables

for HFO and CRO

No. of electrodes

> Increase/greater than

< Decrease/less than

Uphill

Downhill

Multiple to single layer

Supplemental device

No. of electrodes

Forehand

Backhand

26

Change

You might also like

- Sa 420Document10 pagesSa 420Widya widyaNo ratings yet

- Api Tank 400M3 HCDocument10 pagesApi Tank 400M3 HCCharles DogneNo ratings yet

- API 5L Line Pipe Chemical Composition & Mechanical PropertiesDocument4 pagesAPI 5L Line Pipe Chemical Composition & Mechanical Propertiesamir_hayfaNo ratings yet

- PB101266 0Document10 pagesPB101266 0emilio mendez olveraNo ratings yet

- The in Uence of The Bourdon Effect On Pipe Elbow: September 2016Document11 pagesThe in Uence of The Bourdon Effect On Pipe Elbow: September 2016araz_1985No ratings yet

- AP-NozzleTutorial R01 PDFDocument31 pagesAP-NozzleTutorial R01 PDFbalumagesh1979No ratings yet

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02No ratings yet

- Co-Efficient of Friction For Pipe Supporting During Stress Analysis Using Caesar IIDocument2 pagesCo-Efficient of Friction For Pipe Supporting During Stress Analysis Using Caesar IIHmd MokhtariNo ratings yet

- Thread Data ChartsDocument4 pagesThread Data Chartsrasinv100% (1)

- Miter Bend Calculation: E W S D T' BDocument4 pagesMiter Bend Calculation: E W S D T' BSong TaoNo ratings yet

- LS 164-04 - 6 Identification Traceability of Piping Material On Construction Site (EN)Document6 pagesLS 164-04 - 6 Identification Traceability of Piping Material On Construction Site (EN)Kreshna Wisnu BrataNo ratings yet

- 2 PN40 (WCB)Document2 pages2 PN40 (WCB)siddhesh_guessNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Gasket Paking ListDocument1 pageGasket Paking ListIrwansyah MuchtarNo ratings yet

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyNo ratings yet

- Alloy D-205Document2 pagesAlloy D-205Walter J Naspirán CastañedaNo ratings yet

- WELD DESIGN CHECK FOR ANCHOR SUPPORTDocument8 pagesWELD DESIGN CHECK FOR ANCHOR SUPPORTUmer AziqNo ratings yet

- Astm F436.04 PDFDocument6 pagesAstm F436.04 PDFWelington Volpatto MoraisNo ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

- 127.study The Effect of Welding Parameters of Tig Welding of PlateDocument43 pages127.study The Effect of Welding Parameters of Tig Welding of PlatemoorthikumarNo ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- LiquidDocument2 pagesLiquidsiddhesh_guessNo ratings yet

- 4 2500 (F347H)Document2 pages4 2500 (F347H)siddhesh_guessNo ratings yet

- EGE11B21Document25 pagesEGE11B21Jhonny Rafael Blanco CauraNo ratings yet

- Pipe and Tube DifferencesDocument5 pagesPipe and Tube DifferencesRaakze MoviNo ratings yet

- API 5L Grade X65 Pipe Chemical Composition and Mechanical PropertiesDocument1 pageAPI 5L Grade X65 Pipe Chemical Composition and Mechanical PropertiesGEORGE VARGASNo ratings yet

- LE B-255 H4R: ClassificationDocument2 pagesLE B-255 H4R: ClassificationVivien EmeraldoNo ratings yet

- Dimensions of Bolts and Nuts BS3692Document6 pagesDimensions of Bolts and Nuts BS3692azam RazzaqNo ratings yet

- Technical Catalogue: Pipes Tubes Fittings FlangesDocument121 pagesTechnical Catalogue: Pipes Tubes Fittings FlangesDANIELVENZUELAANo ratings yet

- Gasket BrochureDocument8 pagesGasket BrochureKumar JbsNo ratings yet

- OCS Prel WPS 007Document2 pagesOCS Prel WPS 007vinothNo ratings yet

- ASTM F1545 Plastic Lined Pipe 0803Document6 pagesASTM F1545 Plastic Lined Pipe 0803JabranYounasNo ratings yet

- Afnor 28 CDV 5-08 SteelDocument1 pageAfnor 28 CDV 5-08 SteelMagoroku D. YudhoNo ratings yet

- ITP For PipingDocument5 pagesITP For PipingAldeline SungahidNo ratings yet

- WQT For CSDocument5 pagesWQT For CSkumar08686No ratings yet

- PipesDocument37 pagesPipesGautam BhardwajNo ratings yet

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Document31 pagesStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaNo ratings yet

- Boq For AS BoilerDocument1 pageBoq For AS BoilerGayan ChathurangaNo ratings yet

- Catalogo SchulzDocument61 pagesCatalogo SchulzIsabel PulidoNo ratings yet

- Astm A 106 - A 106M-06Document8 pagesAstm A 106 - A 106M-06Ramsi AnkziNo ratings yet

- Bull's Eye PWHT Stress Relief ProcedureDocument11 pagesBull's Eye PWHT Stress Relief ProcedureJ.CarrascoNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- SBC (Safety Break-Away Couplings) v140630Document16 pagesSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Pig Trap End Closure105671465 PDFDocument24 pagesPig Trap End Closure105671465 PDFashishNo ratings yet

- Side Mounted HandwheelDocument20 pagesSide Mounted HandwheelaaaNo ratings yet

- En 13121-3:2008+a1:2010 (E)Document1 pageEn 13121-3:2008+a1:2010 (E)TIME STAR COMPOSITENo ratings yet

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- ASME Sec I Cylinder Thickness and Pressure Calculation FormulasDocument1 pageASME Sec I Cylinder Thickness and Pressure Calculation Formulasramananrv123No ratings yet

- Designing A CGMP BioprocessDocument5 pagesDesigning A CGMP Bioprocesshareesh13hNo ratings yet

- Introduction To Heat Exchangers (HXS) : DR Rashid AliDocument36 pagesIntroduction To Heat Exchangers (HXS) : DR Rashid AliUsama IbrahimNo ratings yet

- TEM-En-001-00 - Spring Support Data SheetDocument2 pagesTEM-En-001-00 - Spring Support Data SheetPhilippe AlexandreNo ratings yet

- Performance of Austenitic Stainless Steel in Wet Sour Gas Part 2Document5 pagesPerformance of Austenitic Stainless Steel in Wet Sour Gas Part 2wholenumberNo ratings yet

- Design of I-Shape Column Base PlateDocument4 pagesDesign of I-Shape Column Base PlatePereira da SilvaNo ratings yet

- QW-253 Welding Variables Procedure Specifications (WPS) Shielded Metal-Arc Welding (SMAW)Document1 pageQW-253 Welding Variables Procedure Specifications (WPS) Shielded Metal-Arc Welding (SMAW)dhasdjNo ratings yet

- Automated vertical GMAW vertical welding procedureDocument1 pageAutomated vertical GMAW vertical welding procedurehalil ozgunNo ratings yet

- Welding Variable Procedure SpecificationsDocument1 pageWelding Variable Procedure Specificationsgigiphi1No ratings yet

- WPS Variables for SMAW, SAW, GTAWDocument12 pagesWPS Variables for SMAW, SAW, GTAWSaran KumarNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111Document15 pagesWELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111surya1960No ratings yet

- Saline Water Conversion CorporationDocument60 pagesSaline Water Conversion Corporationhalil ozgunNo ratings yet

- Saline Water Conversion CorporationDocument60 pagesSaline Water Conversion Corporationhalil ozgunNo ratings yet

- Saline Water Conversion CorporationDocument60 pagesSaline Water Conversion Corporationhalil ozgunNo ratings yet

- Automated vertical GMAW vertical welding procedureDocument1 pageAutomated vertical GMAW vertical welding procedurehalil ozgunNo ratings yet

- Automated vertical GMAW vertical welding procedureDocument1 pageAutomated vertical GMAW vertical welding procedurehalil ozgunNo ratings yet

- DesDocument7 pagesDesVaishu DhanapalanNo ratings yet

- An Aperture-Coupled Microstrip Antenna With Reconfigurable Radiation Pattern PDFDocument24 pagesAn Aperture-Coupled Microstrip Antenna With Reconfigurable Radiation Pattern PDFrajendrasoloniNo ratings yet

- Proceedings Expres 2017-21-26Document6 pagesProceedings Expres 2017-21-26Amogha G C 1SI19CH002No ratings yet

- Umbrella Tool Changer - Troubleshooting Guide: Haas Technical DocumentationDocument7 pagesUmbrella Tool Changer - Troubleshooting Guide: Haas Technical Documentation2aicnNo ratings yet

- Fast Food Restaurant Database DesignDocument43 pagesFast Food Restaurant Database DesignAbeerHassanNo ratings yet

- Surds Indices Logarithms 2 SolDocument4 pagesSurds Indices Logarithms 2 SolJohn Goh100% (1)

- 2CDC112211D0201 PDFDocument13 pages2CDC112211D0201 PDFdabalejoNo ratings yet

- 7 Heat SolutionsDocument7 pages7 Heat Solutionssmi_santhoshNo ratings yet

- Characteristics of Copper Tailings in Direct Simple Shearing - A Critical State ApproachDocument17 pagesCharacteristics of Copper Tailings in Direct Simple Shearing - A Critical State Approachgabriela.p.alfaro.aNo ratings yet

- Wing Rib Stress Analysis and Design OptimizationDocument90 pagesWing Rib Stress Analysis and Design Optimizationsrikanthlaxminrayan586967% (3)

- EasyRET 8-Port Antenna Specs and Integrated RET DetailsDocument2 pagesEasyRET 8-Port Antenna Specs and Integrated RET DetailsNOKIAXL CJNo ratings yet

- R2G Conversation QuestionsDocument4 pagesR2G Conversation QuestionsMileta SandićNo ratings yet

- DS600-46A Baffle Check Valve 21K0004Document2 pagesDS600-46A Baffle Check Valve 21K0004Tanveer AhmedNo ratings yet

- Poncon Savarit MethodDocument5 pagesPoncon Savarit MethodSyed Fayaz AhmedNo ratings yet

- Qlik Joins CheatsheetDocument1 pageQlik Joins CheatsheetJonas SandströmNo ratings yet

- Pulse Light Sterilizer SuperiorityDocument7 pagesPulse Light Sterilizer SuperiorityOtoy Mar-otoyNo ratings yet

- Analyzing 3D structures using equivalent frame methodDocument34 pagesAnalyzing 3D structures using equivalent frame methodMarlo Aristorenas100% (3)

- Química OrgánicaDocument3 pagesQuímica OrgánicaDaniel Alejandro Quispe CaballeroNo ratings yet

- Gaps Set Up UsblDocument15 pagesGaps Set Up Usblneeraj_165No ratings yet

- Concrete Practice B&FDocument259 pagesConcrete Practice B&Fvijay100% (1)

- Dokumen - Tips - Astm e 145 94 Reapproved 2006 Standard Specification For Gravity ConvectionDocument3 pagesDokumen - Tips - Astm e 145 94 Reapproved 2006 Standard Specification For Gravity ConvectionChulaka PitigalaNo ratings yet

- Lilypond Essay On Automated Music Engraving: The Lilypond Development TeamDocument39 pagesLilypond Essay On Automated Music Engraving: The Lilypond Development TeamSookwan LeeNo ratings yet

- Data Sheet: SFH250 and SFH250VDocument4 pagesData Sheet: SFH250 and SFH250VCharoon SuriyawichitwongNo ratings yet

- Intelligent Stepper Motor Driver With DRV8824Document22 pagesIntelligent Stepper Motor Driver With DRV8824RintheGreatNo ratings yet

- RT522 92 - 96Document5 pagesRT522 92 - 96muhamad iqbalNo ratings yet

- Connect and Work with SAP Business One DataDocument24 pagesConnect and Work with SAP Business One DataPaulo André MoraesNo ratings yet

- Chapter TwoDocument12 pagesChapter TwoBediria MohamadNo ratings yet

- Analysis of Vibration Detection Using Active Controller in The Smart Cantilever Composite Beam With LQR and Fuzzy TechniquesDocument10 pagesAnalysis of Vibration Detection Using Active Controller in The Smart Cantilever Composite Beam With LQR and Fuzzy TechniquesTJPRC PublicationsNo ratings yet

- Helical Springs and Shear and Moment DiagramDocument25 pagesHelical Springs and Shear and Moment DiagramPoncelito KachupoyNo ratings yet

- Revision 26 Table2Document208 pagesRevision 26 Table2arqcpnNo ratings yet