Professional Documents

Culture Documents

Aerobic Thermophilic PDF

Uploaded by

Nachiappan CNOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aerobic Thermophilic PDF

Uploaded by

Nachiappan CNCopyright:

Available Formats

D V Wadkar et al.

/ International Journal of Engineering Science and Technology (IJEST)

Aerobic Thermophilic Composting of

Municipal Solid Waste

D V Wadkar1* ,P R Modak2,V S Chavan3

1,2,3

Assistant Professor, Department of Civil Engineering, AISSMS College of Engineering, Pune-01.

*dvwadkar_civil@yahoo.com

ABSTRACT

Composting is a natural process that turns organic material into a dark rich substance called compost. Aerobic

Composting is the creation of compost that depends on bacteria that thrive in an oxygen rich environment.

Aerobic bacteria manage the chemical process by converting the inputs (i.e. air, water and carbon and nitrogen

rich materials) into heat, carbon dioxide and ammonium. The ammonium is further converted by bacteria into

plant nourishing nitrites and nitrates through the process of nitrification. Thermophilic Composting is breaking

down biological waste with thermophilic (heat loving) bacteria. A cylindrical reactor was made. Organic waste

included dry vegetable waste collected from MSW ramp, Koregaon park, Pune. The characteristics of compost

like pH, moisture content, temperature, C/N ratio and volume reduction were studied for the period of

maturation (42days). It can be concluded that the values are within the desired limits and compost is suitable for

ornamental plants. The setup of reactor is affordable and thus the compost obtained is effective and economical.

Keywords: Aerobic Composting, Thermophilic composting, organic waste.

1. INTRODUCTION

Solid Waste Management is associated with the control of waste generation, storage, collection, transfer and

transport, processing and disposal in a manner that is in accordance with the environmental considerations. To

reduce the load on disposal system, solid waste must be processed. Composting can be one such process. It is a

process in which organic substances are reduced from larger volumes of rapidly decomposable material to small

volumes of material which continue to decompose slowly. Compost is particularly useful as organic manure

which contains plant nutrients (Nitrogen, Phosphorous and Potassium) as well as micro nutrients which can be

utilized for the growth of plants. Composting can be carried out in two ways i.e., aerobically and anaerobically.

During aerobic composting aerobic micro-organisms oxidise organic compounds to Carbon dioxide, Nitrite and

Nitrate. Carbon from organic compounds is used as a source of energy while nitrogen is recycled [1]. Due to

exothermic reaction, temperature of the mass rises. During anaerobic process, the anaerobic microorganisms,

while metabolising the nutrients, break down the organic compounds through a process of reduction [3]. A very

small amount of energy is released during the process and the temperature of composting mass does not rise

much. The gases evolved are mainly Methane and Carbon dioxide. An anaerobic process is a reduction process

and the final product is subjected to some minor oxidation when applied to land. Aerobic composting is a

dynamic system wherein bacteria, actinomycetes, fungi and other biological forms are actively involved.

Thermophilic bacteria are mainly responsible for the breakdown of proteins and other readily biodegradable

organic matter [4]. Windrow composting is the most common method of composting in India. It involves the

stabilization of organic solid waste through aerobic decomposition. Windrow composting facilities can

efficiently handle large quantities of waste in comparison to vermicomposting. While traditional composting

procedures take as long as 4-8 months to produce finished compost, rapid composting methods offer

possibilities for reducing the processing period up to three weeks[5]. A variety of approaches and their

combinations have been used to hasten the composting process like Shredding and frequent turnings, Use of

chemical nitrogen activators, Use of Effective Micro-organisms (EM), Use of worms, Use of cellulolytic

cultures. The aerated static pile method takes the piped aeration system a step further, using a blower to supply

air to the composting materials. The blower provides direct control of the process and allows larger piles. No

turning or agitation of the materials occurs once the pile is formed. When the pile has been properly formed and

if the air supply is sufficient and the distribution is uniform, the active composting period will be completed in

approximately three to five weeks [6]. In-vessel composting refers to a group of methods which confine the

composting materials within a building, container, or vessel. In-vessel methods rely on a variety of forced

aeration and mechanical turning techniques to speed up the composting process. Bin composting is perhaps the

simplest in-vessel method. The materials are contained by walls and usually a roof. The bin itself may simply be

wooden slatted walls (with or without a roof), a grain bin, or a bulk storage building. The buildings or bins

allow higher stacking of materials and better use of floor space than free-standing piles. Bins can also eliminate

weather problems, contain odours, and provide better temperature control [7]. The term vermicomposting had

recently been coined to mean the use of earthworms for composting organic residues. Earthworms can consume

practically all kinds of organic matter and they can eat their own body weight per day; thus, for example, one

kilogram of worms can consume one kilogram of residues every day [2].

ISSN : 0975-5462

Vol. 5 No.03 March 2013

716

D V Wadkar et al. / International Journal of Engineering Science and Technology (IJEST)

2. METHODOLOGY

A cylindrical wire mesh reactor was prepared. At the bottom, opening was provided for leachate to drain off.

The reactor was at a height from the ground level. It was kept in the open air with protection on the side from

birds and rain. At initial stage, following things were done: Waste is segregated to get organic waste. A layer of

dried leaves is laid at the base of reactor. Then organic waste is laid in layers each layer being approx. 10 cm

thick. First layer is laid and bacteria culture is sprinkled on it, more two layers are laid on top of the base layer.

Bacteria are mesophilic. When temperature rises to 35 degree to 40 degree Celsius, it gives rise to thermophilic

bacteria. This growth goes until the temperature reaches 55 to 60 degree Celsius. At second stage, mixing was

done every four days. Also water was sprinkled on waste to maintain its moisture content. Mixing was also

useful to spread bacteria throughout the waste. At last stage of composting, it was seen that the particle size of

waste has reduced considerably. Waste particles falling out were collected in a tub kept at the bottom of the

reactor. This stage was completed by sixth week.

3. RESULTS AND DISCUSSION

pH of a soil refers to how acid or alkaline the soil is. The availability of nutrients is directly affected by soil pH.

Plants have specific pH requirements for normal growth. The pH of compost at the end of sixth week is 6.8

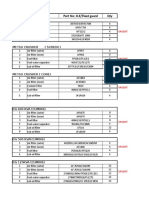

Table No .01: Details of pH of compost for respective weeks

Weeks

1

2

3

4

5

6

pH

8.2

7

6.0

5.6

6.0

6.8

The moisture content of air dried manure is around 9-15%. As manure dries, the nutrients not only concentrate

on a weight basis, but also on a volume basis due to structural changes of the manure. The moisture content of

compost is 10.36 %

Table No.02: Details of Moisture content of compost for respective weeks

Weeks

1

2

3

4

5

6

Moisture Content (%)

37.36

28.27

22.92

15.41

12.36

10.36

The volume reduction was observed from the 7th day onwards. After 42days the volume reduction was observed

to be more than 47% during the loading under laboratory conditions.

Table No.03: Details of volume reduction of compost for respective weeks

Weeks

1

2

3

4

5

6

Volume Reduction (%)

0

15.8

26.77

38.19

49.43

47

The temperature of 550C during 2 and 3rd week is due to mesophilic bacteria. The C/N ratio of compost is 15:1.

As carbon gets converted to CO2 (and assuming minimal nitrogen losses) the C/N ratio decreases during the

composting process, with the ratio of finished compost typically close to 10/1.

ISSN : 0975-5462

Vol. 5 No.03 March 2013

717

D V Wadkar et al. / International Journal of Engineering Science and Technology (IJEST)

Table No.04: Details of Temperature of compost for respective weeks

Temperature ( 0 C )

31

45

58

37

31

32

Weeks

1

2

3

4

5

6

The desired C/N ratios can be achieved by blending common used substrates of known C/N content, which are

readily available and easy to use.

4. CONCLUSION

Due to the addition of bacteria culture, the composting process was accelerated. The mesophilic bacteria added

trigger the thermophilic bacteria at temperature of 400C. The maturation period was 42days. Aeration provided

with the help of solar energy increased the efficiency of process. All these helped to keep various parameters

like pH, temperature, moisture content, C/N ratio within desired limits. The final compost obtained is suitable

for ornamental plants like azaleas, gardenias, camellias, etc.Thus it can be concluded that the compost can be

used effectively and economically.

REFERENCES

[1]

Cecilia Sundberg a, Ingrid H. Franke-Whittle b, Sari Kauppi c, Dan Yu c, ,Characterisation of source-separated household waste

intended for composting, Bio resource Technology ,102 (2011) 28592867

[2] Hang RT. (1998),The Practical Handbook of composting engineering. Boca Raton, Finland: Lewis publishers, 1998.

[3] Jordening H J and J. Winter.(2005)., Environmental Biotechnology.-Concepts and Applications,2005 WILEY & Co. KGaA,

Weinheim ISBN: 3-527-30585-8

[4] Liau PH, May AC, Chieng ST.,Monitoring process efficiency of a full Scale in vessel system for composting fisheries, J Bio resource

Technology ,1995;54: 15963.

[5] Pugalenthi Velan, Jen-Chie Tsai, Li-An Lu, Jin-Gaw Lin., fast composting of bear manufactures wastes using thermophilic bio

reactor. In: Int. conference on advances industrial waste treatment, Anna University, Chennai-25, India, February 911, 2005, 31924

[6] Pichler M, Knicker H, Kogel-knabner I. ,Changes in the chemical structures of municipal solid Waste, Journal Environmental Science

Technology, 2000;34:40348

[7] Saludesa RB, K. Iwabuchib, A. Kayanumab, T. Shiga(2007 ), Composting of dairycattle manure using a thermophilicmesophilic

sequence, Bio-systems engineering, 98 (2007 ) 198 205

[8] Tiquia SM, Wan JHC, Tam NFY., Microbial population dynamics and enzyme activities during composting, Compost Sci Util

,2002;10:15061

[9] Vallini G; di Gregorio S; Pera A; Cristina A; Cunha Queda F (2002). Exploitation of composting management for either reclamation

of organic wastes or solid-phase treatment., Environmental Review, 10, 195207

[10] Wong J WC, Fang M. Effects of lime addition on sewage sludge composting J Water resource ,2000; 34:36918

ISSN : 0975-5462

Vol. 5 No.03 March 2013

718

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Life & Missions of Sri Sathya Sai BabaDocument18 pagesLife & Missions of Sri Sathya Sai BabaNachiappan CN100% (2)

- Extrusion Technology (Compatibility Mode)Document64 pagesExtrusion Technology (Compatibility Mode)Nachiappan CNNo ratings yet

- Cocoa - A Guide To Trade Practices EnglishDocument196 pagesCocoa - A Guide To Trade Practices EnglishNachiappan CNNo ratings yet

- PesticidesDocument12 pagesPesticidesNachiappan CN100% (2)

- Haccp For Animal FeedDocument124 pagesHaccp For Animal FeedNachiappan CNNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- South SPTP Laboratory TrainingDocument22 pagesSouth SPTP Laboratory TrainingGerald ParamioNo ratings yet

- In Market Study Romanian Waste Sector PDFDocument74 pagesIn Market Study Romanian Waste Sector PDFElena Iulia CucoleaNo ratings yet

- McDonald's Case OutlineDocument2 pagesMcDonald's Case OutlineTim FosterNo ratings yet

- Literature Review of Wastewater Treatment PlantDocument7 pagesLiterature Review of Wastewater Treatment Plantc5eyjfnt100% (1)

- Zero Wast FashionDocument3 pagesZero Wast Fashionmirmoinul100% (1)

- Sanskrit I.....Document14 pagesSanskrit I.....ASEEM DUANo ratings yet

- Solid Waste SlideDocument47 pagesSolid Waste SlideikhwanstorageNo ratings yet

- Bacolod City Central Market Waste Management Segregation Practices Review of The Related LiteratureDocument12 pagesBacolod City Central Market Waste Management Segregation Practices Review of The Related LiteratureJoshua de JesusNo ratings yet

- 5 R For Waste ManagementDocument31 pages5 R For Waste ManagementAdrian Chua Daep100% (3)

- Reduce Usage of Plastic BagsDocument4 pagesReduce Usage of Plastic BagsSamantha Wong Sze YenNo ratings yet

- Beat Plastic PollutionDocument2 pagesBeat Plastic PollutionSΞIKH SΛMIMNo ratings yet

- Solid Waste Management PresentationDocument16 pagesSolid Waste Management PresentationEi XerNo ratings yet

- C&D Waste ManagementDocument10 pagesC&D Waste ManagementmaniNo ratings yet

- Filter EnquiryDocument2 pagesFilter EnquiryDivya AgarwalNo ratings yet

- Treasure The TrashDocument3 pagesTreasure The TrashGavin BarkerNo ratings yet

- Env-B.Tech-VII SemDocument12 pagesEnv-B.Tech-VII SemPasunkiliNo ratings yet

- Synthetic Yarn & Monofilament Production, Shipments & StocksDocument5 pagesSynthetic Yarn & Monofilament Production, Shipments & StocksDelwar HossainNo ratings yet

- WR PaperDocument2 pagesWR PaperJanice LiNo ratings yet

- Co2 Health 6 2023 2024Document26 pagesCo2 Health 6 2023 2024deliamariemjoy1578No ratings yet

- Food Waste Reuse ConceptDocument3 pagesFood Waste Reuse ConceptSyarifah Anis AqilaNo ratings yet

- Swot AnalysisDocument1 pageSwot AnalysisCycy Raga BacalsoNo ratings yet

- Utawala-Bantu Sewers DWGDocument28 pagesUtawala-Bantu Sewers DWGAsaph MungaiNo ratings yet

- The Advantages of Solid Waste ManagementDocument4 pagesThe Advantages of Solid Waste ManagementSumayyah SaipulnizamNo ratings yet

- Biogas ProductionDocument1 pageBiogas ProductionShah VrajNo ratings yet

- Ground Floor PlanDocument1 pageGround Floor PlanKamran SadiqNo ratings yet

- 43,47 Waste Management StepDocument4 pages43,47 Waste Management StepSajib BhuiyanNo ratings yet

- TOILET BLOCK PLAN AND ELEVATION (1) - ModelDocument1 pageTOILET BLOCK PLAN AND ELEVATION (1) - Modelgulfam ahmadNo ratings yet

- Class 7 CHP 18Document3 pagesClass 7 CHP 18GiteshNo ratings yet

- Green Office Poster PresentationDocument2 pagesGreen Office Poster PresentationPutri UtamiNo ratings yet

- Solar Heaters DM FormatDocument1 pageSolar Heaters DM Formatanas shehabiNo ratings yet