Professional Documents

Culture Documents

Adaptive Tyre Traction System Using Ctis

Uploaded by

jaycee68Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adaptive Tyre Traction System Using Ctis

Uploaded by

jaycee68Copyright:

Available Formats

ADAPTIVE TYRE TRACTION SYSTEM

USING CENTRAL TYRE INFLATION

SYSTEM (CTIS)

S.Omar Farooq

Electronics and communication engineering, Velammal engineering college,

Ambattur redhills road, chennai-.66

Ph: 9894498833

omarfarooq0892@gmail.com

ABSTRACT: Tires are the only contact point

between the vehicle and the road, without danger

of overstatement, it is safe to say that tires are

among the most critical items on the car. Adaptive

Tire Traction System using Tire Inflator has been

designed and successfully developed, with the

objective of better tare traction. The project is a

reliable, resource efficient which can sense

automatically the type of the road by its ultrasonic

sensors and inflate and deflate the tare according

to it. Correct tare pressure with proper grip leads

safety & better fuel efficiency. In addition, this

system enables saving in energy required to

produce compressed air and the other resources

including manual effort. Adaptive tare traction

system varies the tare pressure of a vehicle's tires

while it is moving. Reduced tare pressure increases

its "footprint." The result can be improved

traction, improved vehicle ride, increased tire life,

reduced road maintenance, extended hauling

season. Reducing the air pressure in the tykes

increases the tare contact area (footprint) and

lowers the center of gravity. Depending on the

ground conditions and tire air pressure, twice as

much traction can be achieved. The tare inflation

system not only influences the vehicle mobility and

reliability when moving, it also helps to ensure that

a need for vehicle recoveries is avoided as far as

possible. It also prevents unnecessary damage &

especially for riders safety. Moreover, Adaptive

tare traction system is designed and developed with

embedded technology enables vehicle to adjust the

tare pressure while driving to match the relevant

road conditions.

I.

Introduction

Tires are the only contact point between the

vehicle and the road, without danger of

overstatement, it is safe to say that tires are

among the most critical items on the car.

Correct tare pressure with proper grip leads

safety & better fuel efficiency.

The project is to design a reliable, resource

efficient system which can sense automatically

the type of the road by its ultrasonic sensors and

inflate and deflate the tare according to it.

Adaptive tare traction system can vary the

pressure of a vehicle's tare while it is in motion.

Reduced tare pressure increases its "footprint."

The result can be improved traction, improved

vehicle ride, increased tare life, reduced road

maintenance, extended hauling season.

By reducing the air pressure in the tires we can

increase the tare contact area (footprint) and

lower the centre of gravity. Depending on the

ground conditions and tare air pressure, twice as

much traction may be achieved.

6. To monitor the dynamic pressure on the tare and

display through LCD.

7. To develop a system that also can manually vary

the pressure on the tires using switches present

onboard.

III.

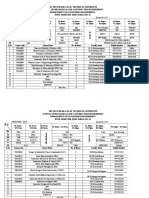

Fig. 1

Image of tires with different pressure

The tare inflation system can not only influence

the vehicle mobility and reliability while in

motion, it can also help to ensure that a need for

vehicle recoveries is avoided as far as possible.

The system can also prevent unnecessary

damage, especially for riders safety. Moreover,

Adaptive tare traction system will be designed

and developed with embedded technology which

can enable the vehicle to adjust the tare pressure

while driving to match the relevant road

conditions.

A Central Tire Inflation System (CTIS) is a

system to provide control over the air pressure in

the tare of a vehicle as a way to improve

performance on different surfaces. For example,

lowering the air pressure in a tire creates a larger

area of contact between the tire and the ground

and makes driving on softer ground much easier.

This also does less damage to the surface. This is

important on work sites and in agricultural fields.

By giving the driver direct control over the air

pressure in each tire, maneuverability can be

greatly improved

II.

Objectives

1. The objectives of the project are as follows:

2. To develop a system that is economical and easy

to implement.

3. To develop a system that can be used on small

passenger cars this increases passenger safety.

4. To prevent unnecessary damage, especially for

riders safety.

5. To develop a system that can autonomously vary

the pressure on the tires when it detects any

obstacle on its path.

Methodology

The idea behind the CTIS is to provide control

over the air pressure in each tire as a way to

improve performance on different surfaces.

Another function of the CTIS is to maintain

pressure in the tires if there is a slow leak or

puncture. In this case, the system controls

inflation automatically based on the selected

pressure the driver has set. The project comprises

of a microcontroller, which is the heart of the

system coordinating all the functions depending

on the signals received. The system involves in

tracking the tare pressure by the pressure sensors

attached to it dynamically and displaying it on

the LCD. To detect the type of road an ultrasonic

ranger is used and a signal is passed to the

microcontroller on detection of any type of

alteration in the road, if any. The microcontroller

on receiving such type of signal takes decision to

inflate or deflate the tare depending on the

current pressure value. This is done by supplying

the air compressor arrangement, accordingly.

There are two compressor arrangements

available for inflation and deflation. The tare and

wheel arrangement is to be modified so as to

integrate the air compressor arrangement, which

can be achieved through a solenoid valve. The

solenoid valve is used for the system to function

while the vehicle is in motion.

Fig. 2

IV.

Image of our model

CTIS

A Central Tire Inflation System (CTIS) is a

system to provide control over the air pressure in

each tire of a vehicle as a way to improve

performance on different surfaces. For example,

lowering the air pressure in a tire creates a larger

area of contact between the tire and the ground

and makes driving on softer ground much easier.

It also does less damage to the surface. This is

important on work sites and in agricultural fields.

By giving the driver direct control over the air

pressure in each tire, maneuverability is greatly

improved.

Another function of the CTIS is to maintain

pressure in the tires if there is a slow leak or

puncture. In this case, the system controls

inflation automatically based on the selected

pressure the driver has set.

V.

conditions. This dash-mounted panel displays

current tire pressures, selected modes and system

status. When the driver selects a tire-pressure

setting, signals from the control panel travel to

the electronic control unit to the pneumatic

control unit to the wheel valves.

When vehicles are moving faster (like on

a highway), tire pressure should be higher to

prevent tire damage. The CTIS includes a speed

sensor that sends vehicle speed information to

the electronic control unit. If the vehicle

continues moving at a higher speed for a set

period of time, the system automatically inflates

the tires to an appropriate pressure for that speed.

WORKING

CTIS: Inside

Here is a look at the overall system:

A wheel valve is located at each wheel end. For

dual wheels, the valves are typically connected

only to the outer wheel so the pressure between

the two tires can be balanced. Part of the wheel

valve's job is to isolate the tire from the system

when it's not in use in order to let the pressure off

of the seal and extend its life. The wheel valve

also enables on-demand inflation and deflation

of the tires.

An electronic control unit (ECU) mounted

behind the passenger seat is the brain of the

system. It processes driver commands, monitors

all signals throughout the system and tells the

system to check tire pressures every 10 minutes

to make sure the selected pressure is being

maintained. The ECU sends commands to

the pneumatic control unit, which directly

controls the wheel valves and air system. The

pneumatic control unit also contains a sensor that

transmits tire-pressure readings to the ECU.

An operator control panel allows the driver to

select tire-pressure modes to match current

Fig. 3

VI.

Image of the system

Brief model of CTIS

This type of system uses air from the same

compressor that supplies air to the brakes.

A pressure switch makes sure the brake system

gets priority, preventing the CTIS from taking air

from the supply tank until the brake system is

fully charged.

A Closer Look

Here is what happens on the road: The electronic

control unit tells the pneumatic control unit to

check current pressure and either inflate or

deflate the tire to the pressure selected by the

driver. If the system determines that inflation is

needed, it first checks to make sure that brake

pressure reserves are where they should be; if

they are, it applies a slight pressure to the wheel

valve to allow inflation.

If the tires are overinflated, the system applies a

slight vacuum to the wheel valve. When the

pneumatic control unit reads that the appropriate

pressure is reached, the valve closes.

In this illustration, you can see the pathway that

the air travels for inflation or deflation once it

gets to the wheel. The tubing runs from the

vehicle's air compressor through the wheel hub

and then to the tire valve. The "quick disconnect

fitting" allows the tire to be separated from the

CTIS system for removal or servicing. (This

diagram also shows the Hummer's run-flat

feature, which allows the tire to continue

supporting the vehicle even when it will not hold

any air.)

VII.

CONCLUSION

Thus the project will help the drivers to have a

better control over the vehicle and

maneuverability.

Thus can avoid lots of accidents which may safe

guard valuable human lives.

REFERENCE

Fig. 4

Image of the arrangement

Hummer self-inflating tire system: At the wheel

[1]. http://ieeexplore.ieee.org/stampPDF/getPDF.jsp?

tp=&arnumber=1341778&isnumber=29564

(INMOTION TYRE PRESSURE CONTROL SYSTEM

FOR VEHICLES)

[2]. http://ieeexplore.ieee.org/stampPDF/getPDF.jsp?

tp=&arnumber=551226&isnumber=11485

(MONITORING

AND

MEASURING

TYRE

PRESSURE)

[3]. http://www.ctibigfoot.co.nz/h00731.htm

[4]. http://www.aircti.com/

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Computer Simulation of Spark-Ignition Engine ProcessesDocument10 pagesComputer Simulation of Spark-Ignition Engine Processesjaycee68100% (2)

- Technology Livelihood Education-Computer System Servicing: Quarter 2 - Module 1.3: Microsoft Windows 10 InstallationDocument19 pagesTechnology Livelihood Education-Computer System Servicing: Quarter 2 - Module 1.3: Microsoft Windows 10 InstallationXhyel Mart75% (4)

- Workshop Manual Ibiza SC TrophyDocument29 pagesWorkshop Manual Ibiza SC Trophysalekojic53320% (1)

- Unit 4 Micro Controller 8051Document20 pagesUnit 4 Micro Controller 8051Anbalagan Guru100% (1)

- Vtu Question Paper Peic A38Document30 pagesVtu Question Paper Peic A38jaycee68No ratings yet

- 10th Board Exam English PDFDocument5 pages10th Board Exam English PDFjaycee68No ratings yet

- Belt Drives and Chain DrivesDocument39 pagesBelt Drives and Chain Drivesjaycee68No ratings yet

- Books For IITDocument3 pagesBooks For IITjaycee68No ratings yet

- P1icic03 Ic Engines SyllabusDocument8 pagesP1icic03 Ic Engines Syllabusjaycee68No ratings yet

- Academic Calendar 2016-2017Document1 pageAcademic Calendar 2016-2017jaycee68No ratings yet

- 07 PhysicsDocument19 pages07 PhysicsAbhiram ShajiNo ratings yet

- Diesel Engine Nomenclature GuideDocument3 pagesDiesel Engine Nomenclature Guidejaycee68No ratings yet

- Chap9 Part3Document5 pagesChap9 Part3jaycee68No ratings yet

- 38 Design of Flat Belt DrivesDocument9 pages38 Design of Flat Belt DrivesPRASAD326100% (1)

- TE-334: Elements of Machine Dynamics and Design Lecture: Belt Drive and DesignDocument30 pagesTE-334: Elements of Machine Dynamics and Design Lecture: Belt Drive and Designjaycee68No ratings yet

- Chapter 1thermodynamicsDocument9 pagesChapter 1thermodynamicsStanly ThomasNo ratings yet

- Chapter 2-Thermodynamics 1Document12 pagesChapter 2-Thermodynamics 1rkadiraj7011No ratings yet

- University College of Engineering KanchipuramDocument1 pageUniversity College of Engineering Kanchipuramjaycee68No ratings yet

- Automobile Advancements - KanchipuramDocument9 pagesAutomobile Advancements - Kanchipuramjaycee68No ratings yet

- Automobile Advancements - KanchipuramDocument9 pagesAutomobile Advancements - Kanchipuramjaycee68No ratings yet

- When You Are in The Highest Tax BracketDocument3 pagesWhen You Are in The Highest Tax Bracketjaycee68No ratings yet

- Name Lsit (2015-16Document2 pagesName Lsit (2015-16jaycee68No ratings yet

- Mid Term Test 1 Question PatternDocument2 pagesMid Term Test 1 Question Patternjaycee68No ratings yet

- I.C. Engines QP-1Document1 pageI.C. Engines QP-1jaycee68No ratings yet

- Pascal's Calculator. Babbage's Analytical EngineDocument2 pagesPascal's Calculator. Babbage's Analytical Enginejaycee68No ratings yet

- Settinsssg and Evaluation of A Question PaperDocument2 pagesSettinsssg and Evaluation of A Question Paperjaycee68No ratings yet

- Mid Term Test 1 Question PatternDocument2 pagesMid Term Test 1 Question Patternjaycee68No ratings yet

- Cycle Test 1 - P1auic05 - Fuels and Emissions Qp-1Document2 pagesCycle Test 1 - P1auic05 - Fuels and Emissions Qp-1jaycee68No ratings yet

- Full Advertisement DepartmentDocument3 pagesFull Advertisement Departmentjaycee68No ratings yet

- B.tech Auto - Time Table Even Sem 2015-16Document9 pagesB.tech Auto - Time Table Even Sem 2015-16jaycee68No ratings yet

- DDDDDDDDDDDDDDDDDDDDDocument2 pagesDDDDDDDDDDDDDDDDDDDDjaycee68No ratings yet

- Smarter PersonDocument3 pagesSmarter Personjaycee68No ratings yet

- Library Management System PresentationDocument22 pagesLibrary Management System PresentationLordly Emu417No ratings yet

- Sartech ARG5410 EPIRB TesterDocument3 pagesSartech ARG5410 EPIRB TesterEric PskdNo ratings yet

- Timer TM 848Document2 pagesTimer TM 848Luis Alfredo Mera VelascoNo ratings yet

- hEX SDocument2 pageshEX SjmiguelcdNo ratings yet

- Photoshop CC 2017 Tutorial: Getting Started with Image EditingDocument24 pagesPhotoshop CC 2017 Tutorial: Getting Started with Image EditingMohammadAssabiNo ratings yet

- DWIN 7-Inch 800x480 LCD SpecDocument3 pagesDWIN 7-Inch 800x480 LCD SpecMatheus Maia Barbosa D. OliveiraNo ratings yet

- Injector Installation 107 EngineDocument5 pagesInjector Installation 107 EnginevalterripNo ratings yet

- Prestige XT-W Installation InstructionsDocument2 pagesPrestige XT-W Installation Instructionstatiana_370273750No ratings yet

- Melco Control Panel Software Release 2001-10Document5 pagesMelco Control Panel Software Release 2001-10Cesar EspinozaNo ratings yet

- Transpose Rows To ColumnDocument34 pagesTranspose Rows To ColumnAmit Sharma100% (1)

- JskalDocument102 pagesJskalFahmie PagayawanNo ratings yet

- Vijay Kumar Singh (Oracle DBA)Document7 pagesVijay Kumar Singh (Oracle DBA)api-3776870No ratings yet

- Contact WasherDocument4 pagesContact Washerwuw74824No ratings yet

- Mercap 2-Wire Smart Level Measurement: Setting A New World StandardDocument6 pagesMercap 2-Wire Smart Level Measurement: Setting A New World StandardchochoroyNo ratings yet

- Daniela Rus - Rise of The Robots PDFDocument9 pagesDaniela Rus - Rise of The Robots PDFashisdashNo ratings yet

- Getting Started With Exchange Server 2013Document11 pagesGetting Started With Exchange Server 2013henriquecongoNo ratings yet

- Extreme NXT PDFDocument2 pagesExtreme NXT PDFShawnNo ratings yet

- Gigabyte Ga h61m Ds2h r2.0 SchematicDocument30 pagesGigabyte Ga h61m Ds2h r2.0 Schematicgledyson gue0% (1)

- Mainboard 17MB120DSDocument64 pagesMainboard 17MB120DSatomo333No ratings yet

- Introduction To DSA Chapter 1Document20 pagesIntroduction To DSA Chapter 1Abdiaziz Qabile100% (3)

- Computer Awareness Capsule For FCI AGM Exam 2021Document34 pagesComputer Awareness Capsule For FCI AGM Exam 2021moidus93No ratings yet

- Data SheetDocument60 pagesData SheetCarlos MendezNo ratings yet

- TK808 GPS ManualDocument7 pagesTK808 GPS ManualepalpaNo ratings yet

- Junos Node Slicing PDFDocument154 pagesJunos Node Slicing PDFAshish NamdeoNo ratings yet

- Sokkia Cx-50 Brochure Sok 1034 Reva SMDocument2 pagesSokkia Cx-50 Brochure Sok 1034 Reva SMHerdi Ade PrasetyoNo ratings yet

- Redis Cheat SheetDocument2 pagesRedis Cheat SheetRizqyFaishalTanjung100% (1)

- Operating Systems: Internals and Design Principles: ThreadsDocument59 pagesOperating Systems: Internals and Design Principles: ThreadsSafwan Md IsaNo ratings yet