Professional Documents

Culture Documents

EQUIPMENT DATA SHEET Self Propelled Skidding Systems

Uploaded by

mathew1965Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EQUIPMENT DATA SHEET Self Propelled Skidding Systems

Uploaded by

mathew1965Copyright:

Available Formats

Equipment Data

Sheet

Self-Propelled

Skidding Systems

For reference only

Issue:1

www.ale-heavylift.com

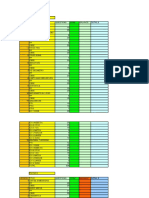

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDSHOE SYSTEM

Self Propelled Skidshoe SPSS-1200 (1200t Capacity)

Self Propelled Skidshoe SPSS-1000 (1000t Capacity)

Self Propelled Skidshoe SPSS-0650 ( 650t Capacity)

Self Propelled Skidshoe SPSS-0500 ( 500t Capacity)

Self Propelled Skidshoe SPSS-0300 ( 300t Capacity)

Self Propelled Skidshoe SPSS-0150 ( 150t Capacity)

Self Propelled Skidshoe SPSS-0090 (

Specification

SPSS

Capacity (t)

1200

1200

Length (mm)

90t Capacity)

Self Propelled Skidshoe System

SPSS

SPSS

SPSS

SPSS

SPSS

0300

0150

0650

1000

0500

SPSS

0090

650

500

300

150

90

6000

5500

4720

4674

3700

2500

2000

Weight (kg)

13000

9000

5372

4500

1730

610

345

Cylinder

1200

2x500

650

500

300

150

90

Cylinder stroke

460

300

600

600

400

250

150

Distance

1000

1000

1000

1000

750

500

500

Pushing

83/64.3

83/64.3

83/64.3

83/64.3

42.4

16.3

16.3

Pulling

52/33.9

52/33.9

52/33.9

52/33.9

24.3

8.5

8.5

1250/

1250/

1250/

1000/

600

600

1400

1250

Skidshoe

1000

Push-Pull Unit

Stroke (mm)

1400

1400

1400

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDBEAM SYSTEM

Self Propelled Skidbeam SPSB-0500 (500t Capacity)

Self Propelled Skidbeam SPSB-0300 (300t Capacity)

Self Propelled Skidbeam SPSB-0150 (150t Capacity)

Self Propelled Skidbeam SPSB-0025 ( 25t Capacity)

Self Propelled Skidbeam System

Specification

SPSB

SPSB

0500

SPSB

0300

Length (mm)

4500

3500

Weight (kg)

2100

955

1000

750

500

400

64.3

42.4

16.3

6.8

33.9

24.3

8.5

3.4

1250/1400

1000/125

600

500

Skidbeam

0150

2000/ 2500/ 3000/

4500

267 / 325 / 397 /

1513

SPSB

0025

1450

60

Distance

Push-Pull Unit

between

clamps (mm)

Pushing

Capacity (t)

Pulling

Capacity (t)

Stroke (mm)

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDSHOE SYSTEM

SPSS-1200 (1200t Capacity)

SKID-SHOE

CAPACITY

MINIMUM HEIGHT

MAXIMUM HEIGHT

1200 t

1885 mm

2345 mm

PUSH AND PULL UNIT

83.0 t

PUSHING CAPACITY

52.0 t

PULLING CAPACITY

1250/1400 mm

STROKE

The movement / load-out equipment is a skidding system designed and developed by ALE, in

which hydraulic skidshoes with stainless steel bottom move over P.T.F.E. blocks which are laid into

steel skidtracks.

The skid system is designed as indicated in the drawing here above as a 1200t skidshoe

incorporating a 1200t capacity cylinder with a working stroke of 460 mm.

On top of the cylinder a pivot arrangement affords movement in the longitudinal axis.

The movement is intermittent, following

extend/retract sequence of the cylinders.

an

The motive force required for displacing the structure

is generated by hydraulic push-pull cylinders, which

are an integral part of the skidway. The units are

directly coupled to the skidshoes by means of

pin-construction.

Centralised diesel-driven powerpacks will generate the hydraulic power required for operation of

the hydraulic cylinders of the skidshoes and the push-pull units.

The skidshoe stability is designed on a

side-force from 20t up to a maximum of 10%

of the vertical load on the skidshoe involved.

The max. capacity of each ALE skidshoe of

1000t creates an unique system for the

movement of high point loads / concentrated loads.

A combination of a number of skidshoes creates a flexible system to move complicated and heavy

loads.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDSHOE SYSTEM

SPSS-1000 (1000t Capacity)

SKID-SHOE

CAPACITY

MINIMUM HEIGHT

MAXIMUM HEIGHT

1000 t

1015 mm

1315 mm

PUSH AND PULL UNIT

64.3 t

PUSHING CAPACITY

33.9 t

PULLING CAPACITY

1250/1400 mm

STROKE

The movement / load-out equipment is a skidding system designed and developed by ALE, in

which hydraulic skidshoes with stainless steel bottom move over P.T.F.E. blocks which are laid into

steel skidtracks.

The skid system is designed as indicated in the drawing here above as a 1000t skidshoe

incorporating a 2 x 500t capacity cylinder with a working stroke of 300 mm.

On top of the cylinder a pivot arrangement affords movement in the longitudinal axis.

Besides the 1000t jacks other configurations can be made up whereby the same hydraulic

pressure in the system gives individual jacking forces.

The motive force required for displacing the structure is generated

by hydraulic push-pull cylinders, which are an integral part of the

skidway. The units are directly coupled to the skidshoes by means

of pin-construction.

Centralised diesel-driven powerpacks will generate the hydraulic

power required for operation of the hydraulic cylinders of the

skidshoes and the push-pull units.

The skidshoe stability is designed on a side-force

from 20t up to a maximum of 10% of the vertical load

on the skidshoe involved. The max. capacity of each

AlLE skidshoe of 1000t creates an unique system for

the movement of high point loads / concentrated

loads.

A combination of a number of skidshoes creates a flexible system to move complicated and heavy

loads.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDSHOE SYSTEM

SPSS-0650 (650t Capacity)

1800

Min: 1450

Max: 2050

800

700

SKID-SHOE

CAPACITY

MINIMUM HEIGHT

MAXIMUM HEIGHT

650 t

1450 mm

2050 mm

PUSH AND PULL UNIT

4100

2005

83.0 t

PUSHING CAPACITY

52.0 t

PULLING CAPACITY

1250/1400 mm

STROKE

4500

The movement / load-out equipment is a skidding system designed and developed by ALE, in

which hydraulic skidshoes with stainless steel bottom move over P.T.F.E. blocks which are laid into

steel skidtracks.

The skid system is designed as indicated in the

drawing here above as a 650t skidshoe incorporating

a 650t capacity cylinder with a working stroke of 600

mm. On top of this cylinder a pivot arrangement

affords movement in the longitudinal axis.

The movement is intermittent, following an

extend/retract sequence of the cylinders.

The motive force required for displacing the structure is generated by hydraulic push-pull cylinders,

which are an integral part of the skidway. The units are directly coupled to the skidshoes by means

of pin-construction.

Centralised diesel-driven powerpacks will generate the

hydraulic power required for operation of the hydraulic

cylinders of the skidshoes and the push-pull units.

The skidshoe stability is designed on a

side-force up to a maximum of 10% of the vertical load

on the skidshoe involved. The max. capacity of each

ALE skidshoe of 650t creates an unique system for the

movement of high point loads / concentrated loads.

A combination of a number of skidshoes creates a

flexible system to move complicated and heavy loads.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDSHOE SYSTEM

SPSS-0500 (500t Capacity)

SKID-SHOE

CAPACITY

MINIMUM HEIGHT

MAXIMUM HEIGHT

500 t

1450 mm

2050 mm

PUSH AND PULL UNIT

PUSHING CAPACITY

PULLING CAPACITY

STROKE

64.3 t

33.9 t

1250/1400 mm

The movement / load-out equipment is a skidding system

designed and developed by ALE, in which hydraulic skidshoes

with stainless steel bottom move over P.T.F.E. blocks which

are laid into steel skidtracks.

The skid system is designed as indicated in the drawing here

above as a 500t skidshoe incorporating a 500t capacity

cylinder with a working stroke of 620 mm. On top of this

cylinder a pivot arrangement affords movement in the

longitudinal axis.

The movement is intermittent, following an extend/retract sequence

of the cylinders.

The motive force required for displacing the structure is generated

by hydraulic push-pull cylinders, which are an integral part of the

skidway. The units are directly coupled to the skidshoes by means

of pin-construction.

Centralised diesel-driven powerpacks will generate the hydraulic

power required for operation of the hydraulic cylinders of the

skidshoes and the push-pull units.

The skidshoe stability is designed on a side-force from 20t up to a maximum of 10% of the vertical

load on the skidshoe involved. The max. capacity of each ALE skidshoe of 500t creates an unique

system for the movement of high point loads / concentrated loads.

A combination of a number of skidshoes creates a flexible system to move complicated and heavy

loads.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDSHOE SYSTEM

SPSS-0300 (300t Capacity)

SKID-SHOE

CAPACITY

MINIMUM HEIGHT

MAXIMUM HEIGHT

300 t

1283 mm

1683 mm

PUSH AND PULL UNIT

PUSHING CAPACITY

PULLING CAPACITY

STROKE

42.4 t

24.3 t

1000 mm

The movement / load-out equipment is a skidding system designed and developed by ALE, in

which hydraulic skidshoes with stainless steel bottom move over P.T.F.E. blocks which are laid into

steel skidtracks.

The skid system is designed as indicated in the drawing here above as a 300t skidshoe

incorporating a 300t capacity cylinder with a working stroke of 400 mm. On top of this cylinder a

pivot arrangement affords movement in the longitudinal axis.

The movement is intermittent, following an extend/retract sequence of the cylinders.

The motive force required for displacing the structure is generated by hydraulic push-pull cylinders,

which are an integral part of the skidway.

The units are directly coupled to the

skidshoes by means of pin-construction.

Centralised diesel-driven powerpacks will

generate the hydraulic power required for

operation of the hydraulic cylinders of the

skidshoes and the push-pull units.

The skidshoe stability is designed on a

side-force from 20t up to a maximum of

10% of the vertical load on the skidshoe

involved. The max. capacity of each ALE

skidshoe of 300t creates an unique system for the movement of high point loads / concentrated

loads.

A combination of a number of skidshoes creates a flexible system to move complicated and heavy

loads.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDSHOE SYSTEM

SPSS-0150 (150t Capacity)

SKID-SHOE

CAPACITY

150 t

MINIMUM HEIGHT

863 mm

MAXIMUM HEIGHT

1113 mm

PUSH AND PULL UNIT

PUSHING CAPACITY

16.3 t

PULLING CAPACITY

8.5 t

STROKE

600 mm

The movement / load-out equipment is a skidding system designed and developed by ALE, in

which hydraulic skidshoes with stainless steel bottom move over P.T.F.E. blocks which are laid into

steel skidtracks.

The skid system is designed as indicated in the drawing here above as a 150t skidshoe

incorporating a 150t capacity cylinder with a working stroke of 250 mm. On top of this cylinder a

pivot arrangement affords movement in the longitudinal axis.

The movement is intermittent, following an extend/retract sequence of the cylinders.

The motive force required for displacing the structure is generated by hydraulic push-pull cylinders,

which are an integral part of the skidway. The units are directly coupled to the skidshoes by means

of pin-construction.

Centralised diesel-driven powerpacks will

generate the hydraulic power required for

operation of the hydraulic cylinders of the

skidshoes and the push-pull units.

The skidshoe stability is designed on a

side-force from 20t up to a maximum of 10%

of the vertical load on the skidshoe involved.

The max. capacity of each ALE skidshoe of

150t creates an unique system for the

movement of high point loads / concentrated

loads.

A combination of a number of skidshoes creates a flexible system to move complicated and heavy

loads.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDSHOE SYSTEM

SPSS-0090 (90t Capacity)

SWIVEL

SKID-SHOE 90T

CYLINDER

PUSH-PULL UNIT

SKID TRACK

TEFLON PADS

SKID-SHOE

CAPACITY

MINIMUM HEIGHT

MAXIMUM HEIGHT

90 t

538 mm

688 mm

PUSH AND PULL UNIT

PUSHING CAPACITY

PULLING CAPACITY

STROKE

16.3 t

8.5 t

600 mm

The movement / load-out equipment is a skidding system designed and developed by ALE, in

which hydraulic skidshoes with stainless steel bottom move over P.T.F.E. blocks which are laid into

steel skidtracks.

The skid system is designed as indicated in the drawing here above as a 90t skidshoe

incorporating a 90t capacity cylinder with a working stroke of 150 mm. On top of this cylinder a

pivot arrangement affords movement in the longitudinal axis.

The movement is intermittent, following an extend/retract sequence of the cylinders.

The motive force required for displacing the structure is generated by hydraulic push-pull cylinders,

which are an integral part of the skidway. The units are directly coupled to the skidshoes by means

of pin-construction.

Centralised diesel-driven powerpacks will generate the

hydraulic power required for operation of the hydraulic

cylinders of the skidshoes and the push-pull units.

The skidshoe stability is designed on a side-force from

20t up to a maximum of 10% of the vertical load on the

skidshoe involved. The max. capacity of each ALE

skidshoe of 90t creates an unique system for the

movement of high point loads / concentrated loads.

A combination of a number of skidshoes creates a

flexible system to move complicated and heavy loads.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDBEAM SYSTEM

SPSB-0500 (500t Capacity)

SKID-BEAM

CAPACITY

HEIGHT

500 t

485 mm

PUSH AND PULL UNIT

64.3 t

PUSHING CAPACITY

33.9 t

PULLING CAPACITY

1250/1400 mm

STROKE

Skidding system with flat skid beam.

In this system, each skid beam is made of HEM400 profile of 4500 mm length and a capacity up to

500t. The base of the skid beam has a plate of stainless

steel of 3 mm thickness which provides low friction

coefficient when it slides over the Teflon pads.

The skid beams run along specially designed skid

tracks with three functions:

-to serve as a guide for the skid beam.

-to lodge the Teflon pads.

-to incorporate the support elements of the push-pull units.

Each skid beam is equipped with one push and pull unit of 64t

pushing capacity and a stroke of 1400 mm. The push-pull units

hook to the clamps built in the skid tracks each 1000 mm and then it

pushes the skid beam.

As the push-pull units are double acting, once the

stroke is finished they automatically retrieve and

then hook the next clamp in order to start the next

stroke.

The drawing above shows the details of the

different components.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDBEAM SYSTEM

SPSB-0300 (300t Capacity)

SKID-BEAM

CAPACITY

HEIGHT

300 t

395 mm

PUSH AND PULL UNIT

PUSHING CAPACITY

PULLING CAPACITY

STROKE

42.4 t

24.3 t

1250/1400 mm

Skidding system with flat skid beam.

In this system, each skid beam is made of HEM350 profile of 3500 mm length and a capacity of

300t. The base of the skid beam has a plate of stainless steel of 3 mm thickness which provides

low friction coefficient when it slides over the Teflon pads.

The skid beams run along specially designed skid tracks with three functions:

-to serve as a guide for the skid beam.

-to lodge the Teflon pads.

-to incorporate the support elements of

the push-pull units.

Each skid beam is equipped with one

push and pull unit of 53t pushing

capacity and a stroke of 1200 mm. The

push-pull units hook to the clamps built in

the skid tracks each 1000 mm and then it

pushes the skid beam.

As the push-pull units are double acting, once the stroke is finished they automatically retrieve and

then hook the next clamp in order to start the next stroke.

The drawing above shows the details of the different components.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDBEAM SYSTEM

SPSB-0150 (150t Capacity)

SKID-BEAM

CAPACITY

HEIGHT

150 t

310 mm

PUSH AND PULL UNIT

PUSHING CAPACITY

PULLING CAPACITY

STROKE

16.3 t

8.5 t

600 mm

Skidding system with flat skid beam.

In this system, each skid beam is made of HEM220 profile with different lenghs of 2000, 2500,

3000 and 4500 mm and a capacity 150t. The base of the skid beam has a plate of stainless steel

of 3 mm thickness which provides low friction coefficient when it slides over the Teflon pads.

The skid beams run along specially designed skid

tracks with three functions:

-to serve as a guide for the skid beam.

-to lodge the Teflon pads.

-to incorporate the support elements of the push

pull units.

Each skid beam is equipped with one push and

pull unit of 16t pushing capacity and a stroke of

600 mm. The push-pull units hook to the clamps

built in the skid tracks each 500 mm and then it

pushes the skid beam.

As the push-pull units are double acting, once the

stroke is finished they automatically retrieve and

then hook the next clamp in order to start the next stroke.

The drawing above shows the details of the different components.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - SELF PROPELLED SKIDBEAM SYSTEM

SPSB-0025 (25t Capacity)

SKID-BEAM

CAPACITY

HEIGHT

25 t

166 mm

PUSH AND PULL UNIT

PUSHING CAPACITY

PULLING CAPACITY

STROKE

6.8 t

3.4 t

500 mm

Skidding system with flat skid beam.

In this system, each skid beam is made of 2 x IPN 140 profile

of 1450 mm length and a capacity of 25t. The base of the skid

beam has a plate of stainless steel of 3 mm thickness which

provides low friction coefficient when it slides over the Teflon

pads.

The skid beams run along specially designed skid tracks with

three functions:

-to serve as a guide for the skid beam.

-to lodge the Teflon pads.

-to incorporate the support elements of the push-pull units.

Each skid beam is equipped with one push and pull unit of 6,8t

pushing capacity and a stroke of 500 mm. The push-pull

units hook to the clamps built in the skid tracks each 400

mm and then it pushes the skid beam.

As the push-pull units are double acting, once the stroke is

finished they automatically retrieve and then hook the next

clamp in order to start the next stroke.

The drawing above shows the details of the different

components.

For reference only

Issue:1

www.ale-heavylift.com

EQUIPMENT DATA SHEET - CURVED SKIDSHOE SYSTEM

SPSS-1200 (1200t Capacity)

SKID-SHOE

CAPACITY

MINIMUM HEIGHT

MAXIMUM HEIGHT

1200 t

1885 mm

2345 mm

PUSH AND PULL UNIT

100.0 t

PUSHING CAPACITY

100.0 t

PULLING CAPACITY

1250/1400 mm

STROKE

The AL.SK190 & AL.SK350 lifting

machines are devices that have been

designed for the lifting and installation of

ultra-heavy loads. They can be equipped

with a standard winching system for

weights of up to 600t and a strand jack

lifting system for loads of up to 5000t.

In order to maximise the utilization of the

crane ALE has designed the machine so

that most of the components are

multi-functional and can be adapted to

other uses. This feature enables the

optimisation of equipment resulting in a

efficient lifting operation and cost

savings to the customer.

For reference only

Issue:1

www.ale-heavylift.com

You might also like

- Volvo 200 Series DataSheet Section 2c B200 and B230 EnginesDocument22 pagesVolvo 200 Series DataSheet Section 2c B200 and B230 Engines2bjorn100% (4)

- Transprotion Multi Axle Qxidation TowerDocument1 pageTransprotion Multi Axle Qxidation TowerMuhammad Reza PutraNo ratings yet

- The SPMT Trailer1Document38 pagesThe SPMT Trailer1Anwar ShanNo ratings yet

- 02 Technical DataDocument17 pages02 Technical DataDaniel VarvaraNo ratings yet

- Heavy LiftDocument31 pagesHeavy LiftFachrurrazi100% (2)

- THT-FAGIOLI-BAPCO - NAPHTHA SPLITTER-019C0010-TP For PermitDocument1 pageTHT-FAGIOLI-BAPCO - NAPHTHA SPLITTER-019C0010-TP For PermitEdward CelebreNo ratings yet

- 4.1 SPMT Loading DiagramsDocument167 pages4.1 SPMT Loading DiagramsDaniel Varvara0% (1)

- SPMT Loading Diagrams X24 Doku 20130305Document56 pagesSPMT Loading Diagrams X24 Doku 20130305BoyNo ratings yet

- SPMT Project Transport DetailsDocument1 pageSPMT Project Transport DetailsBHAUMIK SOLANKINo ratings yet

- SPMT Description Incl DrawingsDocument10 pagesSPMT Description Incl DrawingssefazNo ratings yet

- 0013-Nd Rev 8.1 28-Jun-16 Guidelines For Load-OutsDocument16 pages0013-Nd Rev 8.1 28-Jun-16 Guidelines For Load-OutsJanuNo ratings yet

- Types of Heavy Haul TrailersDocument30 pagesTypes of Heavy Haul TrailersAnonymous qT66pyKNo ratings yet

- Aht PDF PreviewDocument12 pagesAht PDF PreviewHermon Pakpahan100% (1)

- Top Drive ModelDocument10 pagesTop Drive ModelJimy Barron100% (1)

- Goldhofer Spec For ProcedureDocument6 pagesGoldhofer Spec For ProcedureBoyNo ratings yet

- TLash22 ManualDocument35 pagesTLash22 ManualEkwak Zcelebre100% (2)

- Modular TrailerHydraulic Multi Axle ChinaheavyliftDocument6 pagesModular TrailerHydraulic Multi Axle ChinaheavyliftSulaim Al KautsarNo ratings yet

- RL04000-D-EQD-0001-00 SPMT 6-Line Module PEKZ 210.12.4.X24-RL4000 METRICDocument1 pageRL04000-D-EQD-0001-00 SPMT 6-Line Module PEKZ 210.12.4.X24-RL4000 METRICMuhammad Reza PutraNo ratings yet

- Tractive Force Prime MoverDocument1 pageTractive Force Prime MoverBHAUMIK SOLANKI0% (1)

- Piping Engineering Man-Hour EstimateDocument16 pagesPiping Engineering Man-Hour EstimatekamlNo ratings yet

- Stowage Plan On Barge Mitra AbadiDocument1 pageStowage Plan On Barge Mitra AbadifajrikarNo ratings yet

- 1.different LIFTING and TRANSPORT Types: 1. Rolling MaterialDocument8 pages1.different LIFTING and TRANSPORT Types: 1. Rolling MaterialSalah SalahNo ratings yet

- TP Mammoet Trailers Stability&Lashing - Rev03-2Document88 pagesTP Mammoet Trailers Stability&Lashing - Rev03-2paramarthasom197490% (10)

- Tractive Force SPMTDocument1 pageTractive Force SPMTBHAUMIK SOLANKI0% (2)

- SPMT SpecificationsDocument15 pagesSPMT SpecificationsAnonymous qT66pyKNo ratings yet

- 03 HeavyTransport 2day UK 50 Pages - KeyDocument25 pages03 HeavyTransport 2day UK 50 Pages - KeyJavier Páez100% (5)

- ## - Expense Report MM Colombia - ##Document6 pages## - Expense Report MM Colombia - ##Yonny Alexander Salazar AngelNo ratings yet

- Self Propelled Modular TransportersDocument5 pagesSelf Propelled Modular TransportersHimanshu Purohit100% (1)

- 6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHDocument22 pages6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHsrikanthc8550% (2)

- 5642-MS-009 REV. A Part 1 PDFDocument24 pages5642-MS-009 REV. A Part 1 PDFMilandro Lou AcuzarNo ratings yet

- SCS - Batch of 1983 - 19122008Document2 pagesSCS - Batch of 1983 - 19122008mathew1965No ratings yet

- Product Brochure for Heavy-Duty Towed ModulesDocument8 pagesProduct Brochure for Heavy-Duty Towed ModulesCHRISTIAN LOPEZ FLOREZNo ratings yet

- HydrospecDocument16 pagesHydrospecg665013No ratings yet

- Cometto MGSL Operating ManualDocument3 pagesCometto MGSL Operating ManualRuben OscarNo ratings yet

- Operations Report of Balnaves Project - MobilizationDocument15 pagesOperations Report of Balnaves Project - MobilizationBoyNo ratings yet

- Mammoet 2002 PDFDocument20 pagesMammoet 2002 PDFCuong Dinh100% (1)

- Mammoet SPMT Incident in Thailand On Nov.16,2008Document7 pagesMammoet SPMT Incident in Thailand On Nov.16,2008egy pureNo ratings yet

- List of Malaysian StandardDocument49 pagesList of Malaysian StandardPaklong Itm Perlis33% (3)

- SPMT - Module Weight EstimationDocument4 pagesSPMT - Module Weight EstimationShreyas RautNo ratings yet

- SPMTDocument5 pagesSPMTLinhNguyenViet100% (2)

- Superkrane Company Profile Presentation v8Document37 pagesSuperkrane Company Profile Presentation v8Boy Trio ManikNo ratings yet

- ICT50 2019: Up all areas as Transport 50 listing shows 7% increase in specialized transport capacityDocument5 pagesICT50 2019: Up all areas as Transport 50 listing shows 7% increase in specialized transport capacity无时差No ratings yet

- Scheuerle SPMT SpecDocument17 pagesScheuerle SPMT SpecBoy100% (2)

- 500 600 Eci 1350Document2 pages500 600 Eci 1350Jack Yang100% (1)

- Simulation and Structural Analysis of Modules During Land TransportationDocument6 pagesSimulation and Structural Analysis of Modules During Land TransportationRay Lee100% (1)

- reportSTEIFY'S Training Report (MO-2013)Document45 pagesreportSTEIFY'S Training Report (MO-2013)Sahil Sharma Attri100% (1)

- Cosco Heavy Transport BrochureDocument15 pagesCosco Heavy Transport BrochurecaptanupamNo ratings yet

- Project 7Document56 pagesProject 7Ravi Sharma100% (2)

- Completion TechniqueDocument143 pagesCompletion TechniquenaefmubarakNo ratings yet

- Welding Dissimilar MetalsDocument6 pagesWelding Dissimilar MetalsNitintak100% (1)

- Demag CC2600 equipment data sheetDocument7 pagesDemag CC2600 equipment data sheetAdvent ManurungNo ratings yet

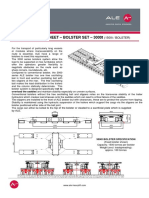

- 3000t Bolster Set Data Sheet for Long LoadsDocument1 page3000t Bolster Set Data Sheet for Long LoadsLuis LuperdiNo ratings yet

- Kien Hang Lon PDFDocument8 pagesKien Hang Lon PDFCuong DinhNo ratings yet

- 1.1 General Information SPMT'sDocument4 pages1.1 General Information SPMT'sSky MoonNo ratings yet

- Engineering Synoptic ViewDocument1 pageEngineering Synoptic Viewmathew1965No ratings yet

- O'Brien Met-Track Workstation Bridge CranesDocument16 pagesO'Brien Met-Track Workstation Bridge Cranesdf_campos3353No ratings yet

- 2.1 GeneralDocument248 pages2.1 GeneralHugo Alfredo Calderon TapiaNo ratings yet

- Tesco 750 ESIDocument2 pagesTesco 750 ESIjlmunozvNo ratings yet

- Project Cargo ReportDocument10 pagesProject Cargo ReportDeepak PatilNo ratings yet

- Lashing Project CargoDocument1 pageLashing Project CargoBHAUMIK SOLANKINo ratings yet

- Daily Report 25 Feb - ActivityDocument2 pagesDaily Report 25 Feb - ActivityBiyanNo ratings yet

- Rodson Universal 1975 COMETTO Modular Transporter 181-254 Ton PayloadDocument4 pagesRodson Universal 1975 COMETTO Modular Transporter 181-254 Ton PayloadCuong DinhNo ratings yet

- 9b2b01 - 40 Axles 2 PPu Info AertssenDocument16 pages9b2b01 - 40 Axles 2 PPu Info AertssenTommy JunNo ratings yet

- Thesis Nick VerhoefDocument127 pagesThesis Nick VerhoefBHAUMIK SOLANKI100% (1)

- Mod TransDocument1 pageMod TransmrmerajNo ratings yet

- Ic50 2018Document7 pagesIc50 2018DahanTowerCraneNo ratings yet

- Kamag k25 SeriesDocument12 pagesKamag k25 SeriesCHRISTIAN LOPEZ FLOREZ100% (1)

- EW - Ammann AVH Vibratory Plate Compactors (2004)Document8 pagesEW - Ammann AVH Vibratory Plate Compactors (2004)sandycastleNo ratings yet

- Physical Education (Code No.048)Document10 pagesPhysical Education (Code No.048)RachitNo ratings yet

- Oil and Natural Gas Corporation Ltd. Vasai East Development ProjectDocument7 pagesOil and Natural Gas Corporation Ltd. Vasai East Development Projectmathew1965No ratings yet

- Oil and Natural Gas Corporation Ltd. Vasai East Development ProjectDocument12 pagesOil and Natural Gas Corporation Ltd. Vasai East Development Projectmathew1965No ratings yet

- Medical Reimbursement FormDocument2 pagesMedical Reimbursement Formmathew1965No ratings yet

- EC3EXT200102 Steel Reference in EC3Document6 pagesEC3EXT200102 Steel Reference in EC3mileNo ratings yet

- Oil and Natural Gas Corporation Ltd. Vasai East Development ProjectDocument12 pagesOil and Natural Gas Corporation Ltd. Vasai East Development Projectmathew1965No ratings yet

- PDMS volume clash detection and resolutionDocument2 pagesPDMS volume clash detection and resolutionmathew1965No ratings yet

- Mathematics Lesson Title Questions Done Balance Details 1 SetsDocument34 pagesMathematics Lesson Title Questions Done Balance Details 1 Setsmathew1965No ratings yet

- Chemistry QuestDocument184 pagesChemistry QuestAshish Kumar100% (2)

- Shell StandardDocument12 pagesShell Standardmathew1965No ratings yet

- Promotionlist July10 L17Document1 pagePromotionlist July10 L17mathew1965No ratings yet

- Conicsections PDFDocument7 pagesConicsections PDFmathew1965No ratings yet

- Goiit DCE-2009 Brilliant Tutorials Solutions (CPM) PDFDocument38 pagesGoiit DCE-2009 Brilliant Tutorials Solutions (CPM) PDFmathew1965No ratings yet

- Unit3 MagDocument10 pagesUnit3 MagMahesh MahajanNo ratings yet

- Full Name: 2. Full Address: Make Sure You Send These Details To For The Release of Fund 3. State: 4. Occupation: 5. Age: 6. Sex: 7. Mobile Number: 8. Country 9. Winning EmailDocument12 pagesFull Name: 2. Full Address: Make Sure You Send These Details To For The Release of Fund 3. State: 4. Occupation: 5. Age: 6. Sex: 7. Mobile Number: 8. Country 9. Winning Emailmathew1965No ratings yet

- Dual Nature of MatterDocument8 pagesDual Nature of MatterK_S_Krishna0001No ratings yet

- Hots Xii 2007Document12 pagesHots Xii 2007mathew1965No ratings yet

- List of Officers Promoted From Level 16 To Level 17 (PC July 2010) W.E.F. 01 JULY 2010 (Sort On Emp. No.)Document2 pagesList of Officers Promoted From Level 16 To Level 17 (PC July 2010) W.E.F. 01 JULY 2010 (Sort On Emp. No.)mathew1965No ratings yet

- FlowChart For General Civil ActivitiesDocument3 pagesFlowChart For General Civil Activitiesmathew1965No ratings yet

- Demons From The Dark2 PDFDocument31 pagesDemons From The Dark2 PDFmathew1965No ratings yet

- 7 1 37 - Head Structural EngineeringDocument3 pages7 1 37 - Head Structural Engineeringmathew1965No ratings yet

- 07 TurkDocument10 pages07 TurkDeanna BarrettNo ratings yet

- MohrDocument10 pagesMohrmathew1965No ratings yet

- Aluminium Rate AnalysisDocument2 pagesAluminium Rate Analysismathew1965No ratings yet

- Goldbeard's Strike ForceDocument25 pagesGoldbeard's Strike ForcePradip BaksiNo ratings yet

- Exchange Rate Report 1Document23 pagesExchange Rate Report 1mathew1965No ratings yet

- Eternia Brochure PDFDocument16 pagesEternia Brochure PDFmathew1965No ratings yet

- Long Term Skill Shortage ListDocument15 pagesLong Term Skill Shortage ListramNo ratings yet

- Vishay Dale Wirewound Resistors GuideDocument5 pagesVishay Dale Wirewound Resistors GuideDAS1300No ratings yet

- FCAWDocument4 pagesFCAWRamanujadaasanNo ratings yet

- Quantity Estimate of 600 SS RCC GumbaDocument10 pagesQuantity Estimate of 600 SS RCC GumbaKale DaiNo ratings yet

- HVAC Guide Specifications Commercial Air-Cooled Condensing Units 63 To 87 KW (18 To 25 Tons), Nominal 38AH Part 1 GeneralDocument4 pagesHVAC Guide Specifications Commercial Air-Cooled Condensing Units 63 To 87 KW (18 To 25 Tons), Nominal 38AH Part 1 GeneralcarlosorizabaNo ratings yet

- Honeywell - 63-2515 - ML7421 - Data Sheet PDFDocument8 pagesHoneywell - 63-2515 - ML7421 - Data Sheet PDFMarcello PorrinoNo ratings yet

- Installation, 2 F E: FreezerDocument24 pagesInstallation, 2 F E: FreezerDamian FulgoniNo ratings yet

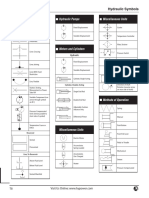

- Fluid Power Symbols PDFDocument4 pagesFluid Power Symbols PDFsanisah1245100% (1)

- Shell Morlina s2 B 320Document4 pagesShell Morlina s2 B 320Aep HidayatNo ratings yet

- Chapter 6: Momentum Analysis of Flow Systems: Eric G. PatersonDocument16 pagesChapter 6: Momentum Analysis of Flow Systems: Eric G. PatersonIan RidzuanNo ratings yet

- Texcan Teck 5KV UnshieldedDocument2 pagesTexcan Teck 5KV UnshieldedJames Ernes Llacza CarmeloNo ratings yet

- Filtro de Gas - MUELLERDocument2 pagesFiltro de Gas - MUELLERCarlos BaezaNo ratings yet

- Bostrig Type P VFD 2kVDocument3 pagesBostrig Type P VFD 2kVEnrique MartínezNo ratings yet

- Supply and Fabrication Steel Structures SpecificationDocument18 pagesSupply and Fabrication Steel Structures Specificationgowtham_venkat_4No ratings yet

- 100kW Induction Heater PrototypeDocument13 pages100kW Induction Heater PrototypeaungkyawmyoNo ratings yet

- MMCDocument39 pagesMMCgopal rao sirNo ratings yet

- Recent Innovations in Concrete and Foundations Lead to More Sustainable GrowthDocument49 pagesRecent Innovations in Concrete and Foundations Lead to More Sustainable Growthprakash.sharmaNo ratings yet

- Keystone Better Mann CatalogDocument12 pagesKeystone Better Mann CatalogSpencer100% (1)

- Van de Graaff GeneratorDocument5 pagesVan de Graaff Generatorahmed s. NourNo ratings yet

- Installing a Cabinet on a Battery Rack GuideDocument25 pagesInstalling a Cabinet on a Battery Rack Guideryl_fans_neh67% (3)

- Electrometallurgy: Electrochemical, Economic and Environmental (3e) AspectsDocument11 pagesElectrometallurgy: Electrochemical, Economic and Environmental (3e) AspectsEdon BediNo ratings yet

- Cambridge International Examinations Cambridge International General Certificate of Secondary EducationDocument20 pagesCambridge International Examinations Cambridge International General Certificate of Secondary EducationNissa AECNo ratings yet

- Midea Klima Katalogus Midea Main 2008 EngDocument43 pagesMidea Klima Katalogus Midea Main 2008 EngJoao NogueiraNo ratings yet

- Causes and Cures of Regulator InstabilityDocument5 pagesCauses and Cures of Regulator Instabilityratninp9368100% (1)

- CAE DS – Designing Cast FeaturesDocument15 pagesCAE DS – Designing Cast Featurespatiltushar79No ratings yet