Professional Documents

Culture Documents

Cutting Pile

Uploaded by

Yurizal FirmansyahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cutting Pile

Uploaded by

Yurizal FirmansyahCopyright:

Available Formats

Cilacap Resid Fluid Catalytic

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Cracking (RFCC) Project

Page No : 1 / 12

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

PROJECT

CILACAP RESID FLUID CATALYTIC CRACKING

(RFCC) PROJECT

LOCATION

PERTAMINA RU-IV, CILACAP, CENTRAL JAVA,

INDONESIA

OWNER

PT. PERTAMINA (PERSERO)

CONTRACT NO

15/C00000/2011-S2

CONSORTIUM ADHI GS E & C

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 2 / 12

Issued for Approval

Dec 7, 2012

NHK

YGK

IF/SDL

Rev.

Description

Date

Prepared

By

Checked

By

Approved

By

REVISION HISTORICAL SHEET

Rev.

Page/ Paragraf

Item

Description of Change

CONSORTIUM ADHI GS E&C

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 3 / 12

INDEX

1. INTRODUCTION(4/12)

2. METHOD OF WORK.(5/12)

3. QA / QC ..(10/12)

4. SAFETY ......(12/12)

5. ATTACHMENT

- JOB SAFETY ANALYSIS

1. INTRODUCTION

CONSORTIUM ADHI GS E&C

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 4 / 12

This method statement describes the method, sequence of work at construction site for

cutting pile work :

Project Name

: Cilacap RFCC Project

Contractor

: GS E & C (GS Engineering & Construction.)

Owner

: PT. Pertamina

This work procedure is a guidance to achieve a successful project completion with

acceptable quality, within specified schedule, and within a controllable budget for the

purpose of clients satisfaction. The following topics will be described / explained in this

work procedure.

To prevent uncontrollable discrepancy of work performance from this work procedure,

this procedure must be followed strictly. Any change or adapting action taken to nticipate

job site / work conditions, can only be performed under written notice / instruction from

Site Manager and approval of Client or Authorized Client Representative.

2. METHOD OF WORK

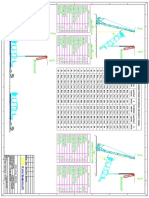

2.1 Cutting pile will be conducted by 2 (two) methods :

2.1.1 First method : pile is cut after the soil excavation is finished until elevation

below foundation or elevation match the planning design.

CONSORTIUM ADHI GS E&C

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 5 / 12

2.1.2 Second method : Pile is cut first as high as the existing ground level and

then excavation work is conducted until the design level. Afterward, the

pile is cutting.

2.2 The first method (2.1.1) is done because the height of the existing ground level is not

more than 3 meter.

2.3 The second (2.1.2) method is done because the height of the cutting pile is more

than 3 meter. This condition is not safe if the first method is applied.

2.4 There are 2 (two) stages for cutting pile:

- The first stage : pile is cut directly, concrete and iron, it means that the pile is all

cut. The equipments used are portable grinder machine for (iron and concrete)

- The second stage: pile will be sliced with 3-4 cm depth or not touch the iron part of

the pile. Then, the piles will be perforated carefully so that the iron pile for the

starter bar is not damaged or broken.

- The distance between the first stage and the second stage is 30 cm.

2.5 The equipments / tools used for cutting pile :

- String wire + clip + accessories

- Crane or excavator

If the height of the cutting pile is not more than 3.5 meter, string wire will be

installed in 4 (four) sides (north, south, east and west) to maintain the stability of

the cutting piles falling down and if the height of the cutting pile is more than 3.5

meter, crane will be used to maintain the balance of the cutting pile so that its

dropdown may be properly controlled.

CONSORTIUM ADHI GS E&C

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 6 / 12

2.6 The last stage is the finishing and cleaning pile cut waste in the work area:

- Cleaning cutting pile surface will use grinder so that surface of cutting pile will be

flat and rebar installation can be done properly.

CONSORTIUM ADHI GS E&C

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 7 / 12

- The concrete waste stuck in the pile /starter bar should be cleaned so that the

formwork foundation will completely bind the old re-bar and the new foundation

structure.

- The cutting pile waste will be removed to the temporary stock pile, that have been

provide by clients using dump truck or other vehicle .

2.7 Specification of cutting pile:

- Elevation is around 10 cm from the below foundation.

- The height of the existing pc wire is around 30 cm from the below foundation.

- When cutting the pile, collapsing the cutting pile is not allowed because it may

collide the other pile and cause damage.

CONSORTIUM ADHI GS E&C

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

CONSORTIUM ADHI GS E&C

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 8 / 12

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

CONSORTIUM ADHI GS E&C

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 9 / 12

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 10 / 12

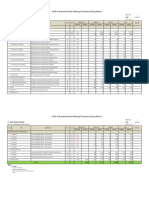

3. QA / QC

Site QA/QC Manager under the direction of Site Manager and Construction

Manager is responsible for supervision of Site Quality Assurance and Quality

Control activities and coordinates project quality control efforts to ensure the

desired results.

QC Engineer and Inspectors will be working under direction of QA/QC

Manager.

Site QA/QC Engineer & Inspector shall be responsible for the followings:

1)

Monitors and controls implementation of Site inspection policies and

procedures.

2)

Reviews individual inspection / testing procedure for each category of

work, prepared by engineer in charge or Subcontractor to ensure all

requisitions, project specification and codes are satisfied.

3)

Verifies inspection / testing results and documentation and issue

inspection reports to PERTAMINA.

4)

Holds

Inspection

Meeting

between

PERTAMINA,

other

parties

and

CONTRACTOR regarding inspection and quality control activities.

5)

Attends

kick-off

meeting

with

Subcontractors,

PERTAMINA

and

CONTRACTOR inspector / engineers of each discipline to review inspection

policy and procedures and to discuss detail procedure including inspection

/ test items to be witnessed by PERTAMINA.

6)

Attends or has his representative attend for all inspection / testing,

confirm the record and ensure the test results obtain the signature of

acceptance from PERTAMINA.

CONSORTIUM ADHI GS E&C

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

7)

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 11 / 12

Maintains close contact with PERTAMINA:

To solicit and study PERTAMINA comments and opinions on quality

control implementation.

To jointly study and resolve any problems related to inspection matters

and procedures applied.

8)

Sets up a documentation filing system including filing original documents

and controls all documents of inspection and quality control.

9)

Monitors and controls quality control activities to confirm that they comply

with the specified procedure.

10) Supports Site and Construction Managers activities for quality control

matters by:

Obtaining PERTAMINA ideas, by evaluating the specified procedures.

Demarcate inspection activities between QC group and Construction

group.

Advising or being consulted by QC Engineer or QC Inspector on quality

control procedures, methods and application.

Interpreting

codes,

standards,

specifications

and

government

regulations.

11) Holds Inspection Meeting between CONTRACTOR and Subcontractor to

emphasize procedures, progress or other inspection and test matters.

12) Reviews and submits Daily Inspection Schedule and Weekly Inspection

Schedule for specified items to PERTAMINA.

CONSORTIUM ADHI GS E&C

Cilacap Resid Fluid Catalytic Cracking (RFCC)

Project

PT. PERTAMINA (Persero)

METHOD STATEMENT FOR CUTTING PILE

Doc.No. : RFCC-G-CS-PR-006

Rev. No. : 0

Page No : 12 / 12

4. SAFETY

4.1 Before commencing the activity, the complete works force will receive a toolbox

meeting, which covers the importance of PPE precountionary measure to the

forecasted risk.

4.2 The field engineer in charge shall ensure that all necessary to work have been

obtained in advance and are available at site all the time for verification , and any

special condition imposed in the permit to work shall be implemented.

4.3 The use or restriction of the machine or hand tools will be monitored all the time by

the foreman concerned personally.

4.4 Prior to commence cutting pile work and if applicable and required, hard barricades,

signs and warning lights shall be arranged and assembled at the area of

excavation. Likewise suitable steps for safe access for workers and for inspection

purpose shall be provided.

4.5 Banksman or signal man must standy by for 1 (one) equipment in the site when

cutting pile work begin.

4.6 Toilet facility, shelter and drinkable water will be provided at site all time.

CONSORTIUM ADHI GS E&C

You might also like

- GRATI CCPP (PEAKER) EXTENSION PROJECT 450MW Field Inspection NotificationDocument4 pagesGRATI CCPP (PEAKER) EXTENSION PROJECT 450MW Field Inspection NotificationYurizal FirmansyahNo ratings yet

- Diverter Elevation #32Document8 pagesDiverter Elevation #32Yurizal FirmansyahNo ratings yet

- Methode Statement ESP 1Document9 pagesMethode Statement ESP 1Yurizal FirmansyahNo ratings yet

- M-12C-003 Padding Plate Fuel Gas Cold Vent StackDocument4 pagesM-12C-003 Padding Plate Fuel Gas Cold Vent StackYurizal FirmansyahNo ratings yet

- Lifting Calculation CSDocument1 pageLifting Calculation CSYurizal FirmansyahNo ratings yet

- Transmittal 003Document2 pagesTransmittal 003Yurizal FirmansyahNo ratings yet

- GRATI CCPP (PEAKER) EXTENSION PROJECT 450MW Field Inspection NotificationDocument4 pagesGRATI CCPP (PEAKER) EXTENSION PROJECT 450MW Field Inspection NotificationYurizal FirmansyahNo ratings yet

- Dual Crane Lift Calculation Sheet: Required SWL 0 Required SWL 0Document7 pagesDual Crane Lift Calculation Sheet: Required SWL 0 Required SWL 0Yurizal FirmansyahNo ratings yet

- Page 7 Lifting Module 2 (MOD C)Document1 pagePage 7 Lifting Module 2 (MOD C)Yurizal FirmansyahNo ratings yet

- As0112 68110100 003 0001 Support Structure AssemblyDocument1 pageAs0112 68110100 003 0001 Support Structure AssemblyYurizal FirmansyahNo ratings yet

- Transmittal (Welding Tracing)Document14 pagesTransmittal (Welding Tracing)Yurizal FirmansyahNo ratings yet

- Project Document TransmittalDocument2 pagesProject Document TransmittalYurizal FirmansyahNo ratings yet

- Project Document Transmittal for ApprovalDocument2 pagesProject Document Transmittal for ApprovalYurizal FirmansyahNo ratings yet

- Transmittal 003Document2 pagesTransmittal 003Yurizal FirmansyahNo ratings yet

- Fin-Me-402 Fin Form Internal STG Lube Oil Jacking OilDocument4 pagesFin-Me-402 Fin Form Internal STG Lube Oil Jacking OilYurizal FirmansyahNo ratings yet

- Transmittal (Welding Tracing)Document14 pagesTransmittal (Welding Tracing)Yurizal FirmansyahNo ratings yet

- As0112 68111000 003 0001 PDFDocument1 pageAs0112 68111000 003 0001 PDFYurizal FirmansyahNo ratings yet

- ANIMAL POEMS: Short Poems About AnimalsDocument12 pagesANIMAL POEMS: Short Poems About AnimalsYurizal FirmansyahNo ratings yet

- Grati CCPP (Peaker) Extension Project 450Mw: Pt. Perusahaan Listrik Negara (Persero)Document29 pagesGrati CCPP (Peaker) Extension Project 450Mw: Pt. Perusahaan Listrik Negara (Persero)Yurizal Firmansyah100% (1)

- CSWIP-WI-6-92 15th Edition April 2017Document17 pagesCSWIP-WI-6-92 15th Edition April 2017NarendrasinhNo ratings yet

- Fin-Me-606 Fin Form Internal Mrir InsulationDocument4 pagesFin-Me-606 Fin Form Internal Mrir InsulationYurizal FirmansyahNo ratings yet

- Fin-Me-434 Fin Form Internal 1st Alignment Boiler Feed Pump HRSG #31Document4 pagesFin-Me-434 Fin Form Internal 1st Alignment Boiler Feed Pump HRSG #31Yurizal FirmansyahNo ratings yet

- 1 Steam Blowing Bom 18 03 09 Rev. 1Document2 pages1 Steam Blowing Bom 18 03 09 Rev. 1Yurizal FirmansyahNo ratings yet

- Project Cost Tracking ReportDocument1 pageProject Cost Tracking Reportbl4ck_revo08No ratings yet

- Mechanical Engineering CAD - LKS 2018Document35 pagesMechanical Engineering CAD - LKS 2018rizalNo ratings yet

- 1 Steam Blowing Bom 18 03 09 Rev. 1Document2 pages1 Steam Blowing Bom 18 03 09 Rev. 1Yurizal FirmansyahNo ratings yet

- Eq InstallationDocument1 pageEq InstallationYurizal FirmansyahNo ratings yet

- Chapter 11 - Bolting: Certification RequirementsDocument21 pagesChapter 11 - Bolting: Certification RequirementsYurizal FirmansyahNo ratings yet

- Table of Content Pak DartoDocument2 pagesTable of Content Pak DartoYurizal FirmansyahNo ratings yet

- Project Document Transmittal for ApprovalDocument2 pagesProject Document Transmittal for ApprovalYurizal FirmansyahNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- C4 GuanzonvsRufon DigestDocument1 pageC4 GuanzonvsRufon DigestaiceljoyNo ratings yet

- Laws Regarding RapeDocument5 pagesLaws Regarding RapenurulNo ratings yet

- Ans 1Document2 pagesAns 1bhupendra barhatNo ratings yet

- ADF Motion To Intervene and Memorandum in SupportDocument27 pagesADF Motion To Intervene and Memorandum in SupportMary Margaret OlohanNo ratings yet

- 9 TortDocument6 pages9 TortrahulNo ratings yet

- A Short Essay On Legalization of Marijuana in PennsylvaniaDocument8 pagesA Short Essay On Legalization of Marijuana in Pennsylvaniaapi-253213430No ratings yet

- 07.06 End of Reconstruction Reading Questions WorksheetDocument2 pages07.06 End of Reconstruction Reading Questions WorksheetA'Him Kridsada ThirasophonNo ratings yet

- Suha Amin Abdullah Abushamma vs. Donald TrumpDocument22 pagesSuha Amin Abdullah Abushamma vs. Donald TrumpKimAndersonNo ratings yet

- Undue Influence in EquityDocument12 pagesUndue Influence in EquitymuhumuzaNo ratings yet

- Child Marriage and The LawDocument11 pagesChild Marriage and The LawA y u s hNo ratings yet

- Own assets abroad: NC backs law to curb tax evasion, money launderingDocument24 pagesOwn assets abroad: NC backs law to curb tax evasion, money launderingDeepen SharmaNo ratings yet

- CASE DIGEST: Ymca vs. Cir GR No. L-7988Document2 pagesCASE DIGEST: Ymca vs. Cir GR No. L-7988Lyka Angelique Cisneros100% (1)

- United States v. McCloud, 10th Cir. (2002)Document3 pagesUnited States v. McCloud, 10th Cir. (2002)Scribd Government DocsNo ratings yet

- Unaninous Special Verdict 2-17-16Document2 pagesUnaninous Special Verdict 2-17-16Nancy Duffy McCarronNo ratings yet

- (A.C. No. 10911. June 6, 2017.) Virgilio J. Mapalad, Sr. vs. Atty. Anselmo S. Echanez PrincipleDocument2 pages(A.C. No. 10911. June 6, 2017.) Virgilio J. Mapalad, Sr. vs. Atty. Anselmo S. Echanez Principlechrystel0% (1)

- Lewis and Kyrous Handy Hints On Legal Practice Second South Africa DRM UnlockedDocument489 pagesLewis and Kyrous Handy Hints On Legal Practice Second South Africa DRM UnlockedThaboNo ratings yet

- PTC Vs Sps RoxasDocument3 pagesPTC Vs Sps RoxasToni Rose Abrera100% (1)

- STEELE v. ARAMARK FOOD SERVICE CORP. Et Al - Document No. 2Document3 pagesSTEELE v. ARAMARK FOOD SERVICE CORP. Et Al - Document No. 2Justia.comNo ratings yet

- RA 4726 and PD 957Document3 pagesRA 4726 and PD 957remingiiiNo ratings yet

- Unit I: Introduction To Indian ConstitutionDocument28 pagesUnit I: Introduction To Indian ConstitutionANo ratings yet

- Administrative Complaint For Gross MisconductDocument13 pagesAdministrative Complaint For Gross Misconductcmv mendozaNo ratings yet

- Article 22 Preventive Detention India Constitutional SafeguardsDocument3 pagesArticle 22 Preventive Detention India Constitutional SafeguardsAvijit SilawatNo ratings yet

- Northgate ComplaintDocument14 pagesNorthgate ComplaintAnonymous 6f8RIS6No ratings yet

- As 5069-2006 Timber - Finger Joints in Non-Structural Products - Production RequirementsDocument7 pagesAs 5069-2006 Timber - Finger Joints in Non-Structural Products - Production RequirementsSAI Global - APACNo ratings yet

- Tcs Employment Application FormDocument5 pagesTcs Employment Application FormAjithNo ratings yet

- Manila Standard Today - Wednesday (November 14, 2012) IssueDocument18 pagesManila Standard Today - Wednesday (November 14, 2012) IssueManila Standard TodayNo ratings yet

- NPC liability for damages from typhoon-induced floodingDocument2 pagesNPC liability for damages from typhoon-induced floodingglaize587100% (1)

- TedBaker Annual Report 2013Document41 pagesTedBaker Annual Report 2013611953No ratings yet

- Recommendations For Welding of Metallic MaterialsDocument32 pagesRecommendations For Welding of Metallic MaterialsLuis Sanchez100% (3)

- March Arrests Southington PoliceDocument4 pagesMarch Arrests Southington PoliceRich ScintoNo ratings yet