Professional Documents

Culture Documents

Factory Acceptance Test (FAT) Guide

Uploaded by

Omar AnguloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Factory Acceptance Test (FAT) Guide

Uploaded by

Omar AnguloCopyright:

Available Formats

Guidelines for Safe Automation of Chemical Processes

by Center for Chemical Process Safety

Copyright 1993 American Institute of Chemical Engineers

APPENDIX H

FACTORY ACCEPTANCE TEST

GUIDELINES

Before a BPCS/SIS is shipped from its staging site to the final plant site, a

factory acceptance test (FAT) may be perfonned. Use of guidelines such as the

following will ensure a successful FAT. The user may select alternate method@)

to accomplish similar objectives.

H.1 PURPOSE OF THE FAT

ThepurposeoftheFATisto test both thesoftwareand hardware functionality

of the BPCS/SIS system as an integrated unit. The goal is to identify and

resolve any problems in the system before it arrives at the plant site. There

may be some areas where certain problems cannot be corrected until the

equipment is received at the plant, b u t these should be kept to a minimum.

The FAT should include testing of all hardware components and software

in the system. This may be accomplished by having the testing perfonned by

the vendor or the user, ora combination of the two. The latter approach is the

most desirable.

H.2 PARTICIPANTS IN THE FAT

Participants of the FAT represent both the vendor and the user. The combined

team should consist of the following personnel:

The user engineer responsible for the system specification.

The user and/or vendor personnel responsible for software programming/configuration.

The user and/or vendor personnel responsible for hardware integration.

The user and/or vendor support personnel.

One of the team members, generally the user engineer, should be selected

as leader of the FAT. The number of participants depends on the technologies

involved and the size, and complexity of the system to be tested.

402

APPENDIX H. FACTORY ACCEPTENCE TEST GUIDELINES

403

H.3 PREPARATION FOR T H E FAT

As a part of the purchase order, the user team members should specify the test

requirements by including a list of items that the test will encompass. This

should include, at a minimum:

A general description of the test procedure based on the system specification.

A definition of responsibilities for each task during the FAT.

A schedule showing the daily activities during the FAT.

A list of the documents that are required at the FAT site during the test.

A list of the test equipment and instruments required to conduct the FAT.

A detailed procedure to be followed during the FAT.

The FAT team leader should present the list of requirements to the vendor

thmugh written correspondence prior to the scheduled FAT. The vendor may

wish to modify some items, but this should only be done with the agreement

of all team members. The final document may be referred to as the FAT

Preparation Document.

H.4 GENERAL PROCEDURE

The general testing procedure should outline the details to be addressed in

the test. These should include the following considerations, as a minimum:

A statement of the location and dates of the FAT.

A description of the general approach.

A description of the format of the FAT punch-list.

Specification of the revision levels of the hardware and software to be

tested.

Specification of the exact configuration of equipment being tested.

Personnel safety issues that may apply during the test.

Documentation of procedures and results is key to accomplishing the tests

intended purpose. One method of ensuring that all findings are documented

is to maintain a punch-list for logging any e m r s found during the test. Each

item on the punch-list should be numbered serially dated when found,

described in an understandable format, dated when corrected, and dated

when rechecked.

404

APPENDIX H. FACTORY ACCEPTENCE TEST GUIDELINES

H.5 RESPONSIBILITIES

The general assignment of responsibilities should depend on the application.

Table H.1 indicates several scenarios of distribution. The FAT Preparation

Document should identify the general responsibility assignments. In all instances, the user should approve the test(s).

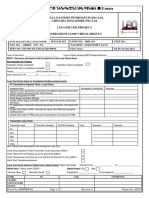

I Table H.l

Case No.

Possible Testina Scenarios

Hardware

Integration*

Software

Programming/

Configuration*

Responsible

for Conducting

Test

Hardware

Corrections

Software

Correction

s/u

s/ u

S = responsibility assigned vendor

U = responsibility assigned user

= determined system specification

Case 1:The vendor is responsible for integrating the hardware and programming (or configuring) the software. The test is run by the vendor, and problems are corrected by the vendor. The user team members witness the test.

Case 2: Responsibilities are the same as Case 1 except the user team members

conduct the test, and the vendor corrects any problems found.

C u e 3: Responsibilities are the same as Case 2 except that the vendor team

members assist the customer in conducting the test.

Case 4: The user is responsible for the software program/configuration. The

test is conducted by both user and vendor. The user is responsible for comcting problems found in software programs/configurations.

Case 5: The user is responsible for software programming/configuration and

conducting the test. The vendor is responsible for correcting any hardware

problems.

Case 6: This is an example of a BPCS/SIS for which the user purchased

off-the-shelf hardware, integrated the system in-house, and perfonned the

pmgramming/configuration. The user is responsible for conducting the test

and resolving all pmblems encountered during the test.

APPENDIX H. FACTORY ACCEPTENCE TEST GUIDELINES

405

If possible, the FAT team should be separated into two groups: one p u p

conducting the test; the second group correcting the problems identified by

the first. The benefit of this method is that the FAT may continue nearly

uninterrupted for one shift while problems are com:cted on the following

shift. This will require some overlapping of the hours of work of the two teams

to ensure information is transferred in a timely and accurate manner.

Each individual team inember should be assigned specific tasks during the

FAT. The FAT Preparation Document should define these task assignments as

clearly as possible.

H.6 FAT SCHEDULE

The FAT schedule should show a daily list of activities, identifying each item

in the system to be checked on a particular day. The schedule should include

enough time to review the punch-list.

The schedule should allow enough slack time to permit one day each week,

usually on the weekend, when testing is discontinued. This day should be

used to reduce the punch-list to a manageable size. It is the responsibility of

the FAT team leader to utilize the slack time for such purpose.

H.7 DOCUMENTS

The purchase order for the system should list the documents required for the

test. An example of such a list follows:

System Functional Requirements Specification

System 1 / 0 List

Process Control Description

Control Logic Specification Sheets

Configuration Worksheets

Logic Flow Diagrams

Instrument Specifications

Process Flow Sheets

Graphic Design Drawings

Program Listings (Documented)

System Self-documentation Printouts

System Arrangement Drawings

Termination Lists

Vendor Manuals

Punch-list Form

406

APPENDIX H. FACTORY ACCEPTENCE TEST GUIDELINES

Responsibility of supply should be assigned to either the useror the vendor

for each document on the list. The FAT should not onlycheck the functionality

of the system, but should also check the accuracy of the documentation. A t

the end of the FAT, all documentation should accurately describe the system.

Any exceptions should be included on the punch-list.

H.8 TEST EQUIPMENT

The purchase order should list the test equipment required to perfonn the

FAT. The list should be submitted separately to the vendor for confirmation.

Both parties should agree upon responsibility of supply for each item on

the test equipment list.

The test equipment list should include all items required to perform 100%

of the test. The list should also include equipment required for tmubleshooting. The user teain leader should verify the availability of required tools such

as screwdrivers, pliers, wrenches, special tools, jumpers, soldering iron, etc.

An example of a typical test equipment list follows:

Usage

Device

~~~~

Digital Multi-meter

Monitor system outputs and

troubleshoot wiring

DC m A Source

Input current signals

(instrument siniula tion)

Two-w i re Transni it ter

Simulator (instrument

simulation)

Input current signals

DC mV Source

IPulse G n e r a tor

Thermocouple or other

low-voltaac input simulation

1 Input

. p. u l s e T"m a l s

RTD sinlulation

(instrument simulation)

Bred kou t Box

Troubleshoot ddld

communication links

Discrete Device Simulation

Panel (with discrete switch

devices, lights, and power

S U D U ~ Vif needed)

Test sequence logic involving

(valve, switches, and

contactI/O simulation)

I

I

I

APPENDIX H. FACTORY ACCEMENCE TEST GUIDELINES

407

H.9 DETAILED TEST PROCEDURE

The detailed test procedure should ensure that all aspects of the system are

checked against system documentation. It should include, at a minimum, the

following:

Adescriptionofa typicalloop testforeachtypeofI/Oin thesystemusing

the proper test equipment. Inputs should be simulated at O%, 50%, and

100% signal input. Outputs should be monitored at 0%, 50%, and 100%

of output level.

A description of a typical method for testing each classification of software programs in the system (i.e., interlocks, special calculation blocks,

batch control programs, etc.).

A description of what checks are to be made on graphic displays. These

should include graphic layout, color specifications, text, touch areas,

paging functions, point addressing, and any system-specific items.

A description of the method to ensure proper point (DCS tag) configuration. Included in this check should be point range, signal conditioning,

alarm settings, and point type,

Provision for a method for checking all other aspects of the system (i.e.,

visual checks, trends, logs, system failures, etc.).

H.10 EQUIPMENT ACCEPTANCE

The equipment maybe released for shipping at the conclusion of the FAT. An

official document should be signed by both the user team leader and by the

vendor.

The acceptance document should state whether open items on the punchlist are to be resolved in the field or prior to shipping.

The user should have the right to return to the factory to back-check any

items agreed to be resolved at the factory. For convenience, the user may

choose to waive this right.

H . l l FAT PREPARATION DOCUMENT

The FAT Preparation Document should include the items described in Sections H.4 through H.9 and should be submitted for review and acceptance to

all team members prior to the issuance of the purchase order for the system.

This document should then become a part of the purchase order.

You might also like

- AMS2473 Chemical Film Treatment For Aluminum Alloys General Purpose Coating Rev. HDocument6 pagesAMS2473 Chemical Film Treatment For Aluminum Alloys General Purpose Coating Rev. HRubén Eduardo Galindo CarmonaNo ratings yet

- Loop Check Procedure PDFDocument8 pagesLoop Check Procedure PDFImran Nawaz Mehthal75% (4)

- Dont Let Me Down - The Chainsmokers For PianoDocument5 pagesDont Let Me Down - The Chainsmokers For PianoOmar AnguloNo ratings yet

- Commissioning 2Document227 pagesCommissioning 2afm100% (1)

- Repuestos Camflex IIDocument43 pagesRepuestos Camflex IIOmar AnguloNo ratings yet

- 5-ITP Control SystemDocument14 pages5-ITP Control Systemeraswasta67% (3)

- Construction Instrument Tubing Pressure & Leak Test ProcedureDocument9 pagesConstruction Instrument Tubing Pressure & Leak Test Procedurezack zeeartNo ratings yet

- ASTM F104 Gasket MaterialsDocument12 pagesASTM F104 Gasket MaterialsDieguitoOmarMoralesNo ratings yet

- FACTORY TEST EQUIPMENTDocument1 pageFACTORY TEST EQUIPMENTBalakrishnan S NadarNo ratings yet

- Factory Acceptance Testing Ensures Equipment Meets SpecsDocument8 pagesFactory Acceptance Testing Ensures Equipment Meets Specspsn_kylm100% (2)

- FAT ProcedureDocument6 pagesFAT Procedurebmanojkumar16100% (2)

- Factory Acceptance Test ProtocolDocument28 pagesFactory Acceptance Test ProtocolShabbir Hussain Palitanawala100% (6)

- Acceptance Testing & Documentation To Support Validation-PresentationDocument34 pagesAcceptance Testing & Documentation To Support Validation-PresentationpoketupiNo ratings yet

- Quality Assurance in Instrumentation: DocumentationDocument2 pagesQuality Assurance in Instrumentation: DocumentationdimbillNo ratings yet

- Pipeline Inspection ManualDocument74 pagesPipeline Inspection ManualPrabhakar Kattula100% (3)

- FAT Procedure-FGI Kakinada Rev-1Document13 pagesFAT Procedure-FGI Kakinada Rev-1vsrikala68No ratings yet

- STFFD-P1-004003-P05-0001 Rev C FAT Procedure For Complete SkidDocument50 pagesSTFFD-P1-004003-P05-0001 Rev C FAT Procedure For Complete SkidTuyen Pham100% (2)

- Site Acceptance Test ProcedureDocument55 pagesSite Acceptance Test ProcedureveeakumarNo ratings yet

- Site Acceptance Test (SAT)Document23 pagesSite Acceptance Test (SAT)Arfan Athafariz100% (2)

- FAT & SAT in Automation SystemDocument97 pagesFAT & SAT in Automation SystemSonal Power Unlimitd100% (1)

- Procurement PolicyDocument5 pagesProcurement PolicyarjunkaushikNo ratings yet

- Loop Check PresentationDocument39 pagesLoop Check Presentationsaqib javaid100% (5)

- Instrument Commissioning ChecklistDocument13 pagesInstrument Commissioning Checklistrajeshkumarab100% (10)

- Fat ProcedureDocument16 pagesFat ProcedureAngeloluigi MerelliNo ratings yet

- Mil STD 1678 4Document34 pagesMil STD 1678 4theportalportalNo ratings yet

- Site Acceptance Test PlanDocument12 pagesSite Acceptance Test PlanUmar Adamu83% (6)

- Bituminous Prime Coat MaterialsDocument4 pagesBituminous Prime Coat MaterialsDevrim Gürsel100% (2)

- Factory Acceptance Test ProceduresDocument14 pagesFactory Acceptance Test ProceduresPrashant Mohokar100% (1)

- FAT ChecklistDocument17 pagesFAT ChecklistNoe Jimenez100% (2)

- FAT Test Procedure NKT Flexible Hose PDFDocument10 pagesFAT Test Procedure NKT Flexible Hose PDFTomasPavlovicNo ratings yet

- The Difference Between A FAT and A SATDocument2 pagesThe Difference Between A FAT and A SATValerian PopescuNo ratings yet

- MMFX Steel Quality Assurance Manual 5th EditionDocument12 pagesMMFX Steel Quality Assurance Manual 5th Editionns koNo ratings yet

- What Is Commissioning?Document9 pagesWhat Is Commissioning?chinedu0% (1)

- The FAT Test ProcedureDocument1 pageThe FAT Test Procedurenisha_khanNo ratings yet

- FAT Procedure Rev.1Document9 pagesFAT Procedure Rev.1Rahul Deva100% (1)

- Learning Guid For Elecrical CommisioningDocument9 pagesLearning Guid For Elecrical CommisioningAbela DrrsNo ratings yet

- MQDP4 instrument loop checkDocument2 pagesMQDP4 instrument loop checkshanks263100% (1)

- 11 Steps of Automation ProjectDocument12 pages11 Steps of Automation ProjectKok MunNo ratings yet

- Visual and Technical Checking of I&C SystemsDocument13 pagesVisual and Technical Checking of I&C SystemszhangyiliNo ratings yet

- Abrasion-Resistant Cast Irons: Standard Specification ForDocument4 pagesAbrasion-Resistant Cast Irons: Standard Specification ForDeepakRajurkarNo ratings yet

- Electrical ITPDocument4 pagesElectrical ITPVictor Biacolo100% (1)

- ITP (Instrumentation)Document9 pagesITP (Instrumentation)Yaser A. Al-Bustanji100% (1)

- Advanced Oilfield Technology Company Work Procedure for Control ValvesDocument6 pagesAdvanced Oilfield Technology Company Work Procedure for Control ValvesJustin Joy0% (1)

- Factory Acceptance Test For RDDocument3 pagesFactory Acceptance Test For RDUmair Awan100% (1)

- Oakwell Engineering's 17-Page Chemical Injection Skid FAT ProcedureDocument18 pagesOakwell Engineering's 17-Page Chemical Injection Skid FAT ProcedurePham Thai Tuyen100% (1)

- Method Statement Loop CheckDocument4 pagesMethod Statement Loop CheckMohamed Rafih100% (1)

- Factory Acceptance Test PDFDocument2 pagesFactory Acceptance Test PDFStephanie0% (3)

- Loop Checking and Field Instrument Testing ProcedureDocument7 pagesLoop Checking and Field Instrument Testing Procedurecharzree0% (1)

- BeldenGenerale UKDocument98 pagesBeldenGenerale UKquito412No ratings yet

- Factory and site testing of electrical switchgearDocument2 pagesFactory and site testing of electrical switchgearAlla Naveen KumarNo ratings yet

- FATDocument36 pagesFATSanjay Kumar ChaubeyNo ratings yet

- Mechanical Completion Check Sheet Electrical: Lighting & Power CircuitDocument2 pagesMechanical Completion Check Sheet Electrical: Lighting & Power CircuitYadira Centanaro GutierrezNo ratings yet

- Factory Acceptance Test New Sample ReportDocument13 pagesFactory Acceptance Test New Sample ReportJafarov VuqarNo ratings yet

- SAT & FAT DifferencesDocument2 pagesSAT & FAT DifferencesAvinashtomer20No ratings yet

- Site Acceptance Test ProceduresDocument19 pagesSite Acceptance Test ProceduresMayank Porwal100% (2)

- VariStroke-I (VS-I) 26727 - GDocument135 pagesVariStroke-I (VS-I) 26727 - GOmar AnguloNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- FACTORY ACCEPTANCE TEST REPORT FOR 261 EX D 400 WATTDocument3 pagesFACTORY ACCEPTANCE TEST REPORT FOR 261 EX D 400 WATTLuqman BostNo ratings yet

- Loop Checking Procedure IdeasDocument2 pagesLoop Checking Procedure IdeasJonatas13No ratings yet

- QS HNDDocument127 pagesQS HNDpandula198950% (4)

- HV Switchgear Factory Test ReportDocument49 pagesHV Switchgear Factory Test Reportcaigithe852456100% (3)

- Factory Acceptance Test (FAT)Document9 pagesFactory Acceptance Test (FAT)Horas Canman SianiparNo ratings yet

- M.thiruselvam BE Electrical CP ExperienceDocument7 pagesM.thiruselvam BE Electrical CP ExperiencethiruNo ratings yet

- Factory and Site Acceptance Testing Dave Lawrence TCT ConsultancyDocument17 pagesFactory and Site Acceptance Testing Dave Lawrence TCT ConsultancySuguna DeviNo ratings yet

- Factory Acceptance Tests – A Winning CombinationDocument9 pagesFactory Acceptance Tests – A Winning Combinationmahesh5277No ratings yet

- Factory Acceptance Testing Guideline Process - NoRestrictionDocument16 pagesFactory Acceptance Testing Guideline Process - NoRestrictionhamed51060No ratings yet

- Completion Manager Job DesDocument2 pagesCompletion Manager Job DesjrladduNo ratings yet

- Site Acceptance Test ProcedureDocument40 pagesSite Acceptance Test Procedurematreng0% (1)

- Factory Acceptance Testing (FAT): Key StepsDocument4 pagesFactory Acceptance Testing (FAT): Key StepsKhaled KamalNo ratings yet

- Factory Acceptance Test Plan - LTE ENodeBDocument6 pagesFactory Acceptance Test Plan - LTE ENodeBLaura VillarrealNo ratings yet

- MSDS for Sodium Hypochlorite, 5% SolutionDocument19 pagesMSDS for Sodium Hypochlorite, 5% SolutionMuhammadPurnamaSugiriNo ratings yet

- Factory Test Procedure For AccessoriesDocument7 pagesFactory Test Procedure For Accessoriesrenjithas2005No ratings yet

- SCOPE OF WORK AND TECHNICAL SPECIFICATIONSDocument40 pagesSCOPE OF WORK AND TECHNICAL SPECIFICATIONSPerfectionistSushantNo ratings yet

- Operations ManualDocument19 pagesOperations ManuallogesniceNo ratings yet

- Saudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestDocument4 pagesSaudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestRashid Arshad100% (1)

- Factory Acceptance Test: Appendix HDocument6 pagesFactory Acceptance Test: Appendix HArif ShakeelNo ratings yet

- Essential Requirements of PPAPDocument4 pagesEssential Requirements of PPAPeditor_ijtelNo ratings yet

- Dont Let Me Down C MajorDocument6 pagesDont Let Me Down C MajorOmar AnguloNo ratings yet

- Dont Let Me Down - The Chainsmokers For Piano PDFDocument5 pagesDont Let Me Down - The Chainsmokers For Piano PDFOmar AnguloNo ratings yet

- SC/ST Multimode & Singlemode Connector IIDocument4 pagesSC/ST Multimode & Singlemode Connector IIOmar AnguloNo ratings yet

- ORI-148.8 Orion JupiterDocument16 pagesORI-148.8 Orion JupiterOmar AnguloNo ratings yet

- Nuflo Orifice PlatesDocument8 pagesNuflo Orifice Platesdp75No ratings yet

- Advantys PLC Mkted206061en-UsDocument108 pagesAdvantys PLC Mkted206061en-UsOmar AnguloNo ratings yet

- RCS Safety Manual V9535R2 Solenoid ValveDocument22 pagesRCS Safety Manual V9535R2 Solenoid ValveOmar AnguloNo ratings yet

- PV SamsonDocument8 pagesPV SamsonOmar AnguloNo ratings yet

- VariStroke-II Electro-Hydraulic Actuator 26740 - NEWDocument171 pagesVariStroke-II Electro-Hydraulic Actuator 26740 - NEWOmar AnguloNo ratings yet

- Inspection and Quality Assurance For Special Purpose FastenersDocument21 pagesInspection and Quality Assurance For Special Purpose FastenersJoel CieltoNo ratings yet

- MIEEIDocument408 pagesMIEEIsaw1511985No ratings yet

- Hempathane 55213Document3 pagesHempathane 55213Hung NGUYEN SYNo ratings yet

- ISA RP 12.6 1996 Wiring Pratices Hazarousous Location InstrumentationDocument94 pagesISA RP 12.6 1996 Wiring Pratices Hazarousous Location InstrumentationDiego GonzalezNo ratings yet

- D 2694 - 91 R96 Rdi2otqtotfsotyDocument1 pageD 2694 - 91 R96 Rdi2otqtotfsotymohammad1361No ratings yet

- Specification - Safety Instrumented SystemsDocument36 pagesSpecification - Safety Instrumented SystemsJaseelKanhirathinkalNo ratings yet

- Satellite M65-S9092 Series Detailed Product Specification: Operating System Input DevicesDocument4 pagesSatellite M65-S9092 Series Detailed Product Specification: Operating System Input Devicestitaneros6019No ratings yet

- GRINNELL US Mech 05-13 v1 FittingDocument128 pagesGRINNELL US Mech 05-13 v1 FittingWahyu AdiNo ratings yet

- Coating Specification No. 39Document6 pagesCoating Specification No. 39Gerson Suarez CastellonNo ratings yet

- 0.2S Class SpecificationDocument15 pages0.2S Class SpecificationAnil MarturiNo ratings yet

- Radilon S Hs 105 M NT: Product InformationDocument3 pagesRadilon S Hs 105 M NT: Product InformationOptimuz TsNo ratings yet

- Dash Course Calender Cswip GhanaDocument6 pagesDash Course Calender Cswip GhanadashNo ratings yet

- ASCE2000 VisualizationDocument8 pagesASCE2000 Visualizationapi-27145250No ratings yet

- Bamboo Processing Self-Assessment GuideDocument13 pagesBamboo Processing Self-Assessment GuideRoland Z. CawatilNo ratings yet

- Bidding for Jhakan Jhora Madhes Pakali Road ConstructionDocument108 pagesBidding for Jhakan Jhora Madhes Pakali Road Constructionnitish JhaNo ratings yet

- Performance and Potential Management Final - SCDLDocument858 pagesPerformance and Potential Management Final - SCDLsinduchari50% (2)

- Computer System Validation SOP 730 V2Document17 pagesComputer System Validation SOP 730 V2Use EreNo ratings yet

- Steel Forgings, Carbon and Alloy, For General Industrial UseDocument10 pagesSteel Forgings, Carbon and Alloy, For General Industrial UseRed RedNo ratings yet