Professional Documents

Culture Documents

Productivity Cut and Fill

Uploaded by

oscar villanueva quiñonesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Productivity Cut and Fill

Uploaded by

oscar villanueva quiñonesCopyright:

Available Formats

CUT AND FILL

LIFT BY UPPERS

Version: January 18, 2002

1.0 - DIRECT FIXED ACTIVITIES PER SHIFT (outside the stope)

Frequency or

Units

Cage (at beginning and end of shift)

Travelling (shaft - refuge station - shaft)

Other travelling delays

Back and forth to stope

Supervision

Work planning

Complete daily reports

Lunch

Time

Total Time

(min)/Unit

(min)

2

2

10

5

4

1

1

1

1

10

15

10

12

30

NOTES

20

10

0

40

15

10

12

30

0

137 minutes

2.28 hours/shift

2.0 - DIRECT FIXED ACTIVITIES PER STEP (inside the stope)

RELATED TO GROUND

SUPPORT

Frequency or

Units

Bring equipment and material

Install setup platform

Store material

15

15

0

5

0

20

0.33

minutes/setup

hours/setup

RELATED TO DRILLING

Prepare material

Store equipment and material

Frequency or

Units

Time

Total Time

(min)/Unit

(min)

1

1

5

5

minutes/setup

hours/setup

File: 324843914.xls

Sheet: UPPERS

Page 1 of 18

RELATED TO

BLASTING

Time

Total Time

(min)/Unit

(min)

5

5

0

10

0.17

Experimental Mine

Val-d'Or

Bring explosives

Bring and prepare material

Store equipment and explosives

Remove setup platform

Equipment checks

Connect the blast

Access verification

Extra scaling

Repair and install ventilation

Frequency or Time

Total Time

Units

(min)/Unit

(min)

1

1

1

5

6

5

1

1

1

1

1

10

8

5

5

15

minutes/blast

hours/blast

5

6

5

0

10

8

5

5

15

0

0

59

0.98

07/26/2016

05:11:28

CUT AND FILL

LIFT BY UPPERS

Version: January 18, 2002

3.0 - DIRECT FIXED ACTIVITIES PER LIFT (inside the stope)

RELATED TO BACKFILL,

MILL HOLES AND MANWAYS

Frequency or

Units

Drainage system*

Mill holes *

Manways *

Barricades inside the stope *

Move equipment prior to backfill

Install backfill line inside the stope

Connect to the main line

Wash the line before backfilling

Wash the line after backfilling

Spill fences (outside the stope)

2

3

3

30

360

360

60

1080

1080

3

2

360

300

1080

600

2

2

180

20

360

40

6

6

7

12

42

72

15

30

0

part A

RAISE

Geologists

Surveyors

Mechanics and electricians

Repairs in main access

Frequency or Time

Total Time

Units

(min)/Unit

(min)

2

2

1

2

20

30

30

20

minutes

hours

40

60

30

20

0

0

150

2.5

4444 minutes

74.07 hours (backfill)

* must include material handling and construction

OTHER ACTIVITIES

PER LIFT

Time

Total Time

(min)/Unit

(min)

BACKFILL

FENCE

Here are the most common steps

in Cut and Fill:

part B

The two slot raises at either end of the stope are optional. If you would

rather use the main raise as a slot, just enter "0" in the "Number of

rounds per lift" cell in the "Slot raise parameters" section.

4.0 - DIRECT VARIABLE ACTIVITIES PER STEP (inside the stope)

4.1 - Lift Dimensions

Slot raise

parameters

Number of rounds/lift

Drilled length/round

Broken length/round

Total tonnes in rounds

File: 324843914.xls

Sheet: UPPERS

Page 2 of 18

3

2.4

2.2

80

Lift

parameters

Length

Average width

Height

Tonnes

99.6

1.7

2.2

1099

Experimental Mine

Val-d'Or

Length to be mined without the

slot raises and the main raise

ore density (t/m)

2.95

07/26/2016

05:11:28

CUT AND FILL

LIFT BY UPPERS

Version: January 18, 2002

4.2 - Scaling

minutes/

minutes/

longitudinal m

hours

longitudinal m

15

0.6

15

Wash, scale and clean bootlegs

total hours

(lift )

Time

Time necessary

required toto

scale

advance

one meter

one meter

(the

inculding

roof and the

thetwo

back

walls)

and the

andtwo

to clean

walls

and

the bootlegs

cleaning the bootlegs.

24.9

GROUND SUPPORT PARAMETERS

4.3 - Ground Support

Drilling for support

installation time

/bolt (min)

Installation of ground support

8.5

(screen included)

hours

hours

2.2

32.0

hours

hours

6.6

98.8

total hours

total hours

8.8

130.8

Drilled

length/bolt

Number of

bolts/1.2 m

advanced

Drilled

meters/m

avanced

Roof pattern

1.2

3.00

3.10

Hanging wall pattern

1.2

2.00

2.10

Footwall pattern

1.2

2.00

2.10

7.00

7.30

FINAL FLOOR CLEAN-UP PARAMETERS

4.4 - Mucking or Scraping

Mucking

Surface to clean (m2)

see see

sheet

"MUCKING"

" MUCKING

sheet

"

tonnes/hour

hours

tonnes/hour

hours

Rounds

Lift

TOTAL

50

1.6

53

20.8

12.24

169.32

181.56

Aver. thickness (m)

0.15

Recovered tonnage

Final clean-up before backfill

m2/hour

hours

m2/hour

hours

Rounds

Lift

TOTAL

15

0.9

20

8.5

55

60

If

If the

the grade

grade does

does not

not justify

justify the

the time

time

required

required for

for the

the final

final clean-up,

clean-up, enter

enter

"0"

"0" in

in the

the "m

"m22/hour"

/hour" cell

cell

File: 324843914.xls

Sheet: UPPERS

Page 3 of 18

Experimental Mine

Val-d'Or

07/26/2016

05:11:28

CUT AND FILL

LIFT BY UPPERS

Version: January 18, 2002

If

If the

the grade

grade does

does not

not justify

justify the

the time

time

required

required for

for the

the final

final clean-up,

clean-up, enter

enter

22

"0"

"0" in

in the

the "m

"m /hour"

/hour" cell

cell

4.5 - Drilling

DRILLING PARAMETERS

2.16

Time required to drill a 1.2-m hole (min)

Meters to drill

drilled holes/round

31

meters

223.2

# holes

664

hours

9.8

Time required for drilling (hours)

80

meters

1593.6

Time required for repositioning, changing drilling steel and

bits, etc per hole of 2.4 m (min)

Total average time to drill a 2.4-m hole (min)

Average drilling rate

hours

69.9

tonnes

1099

DRILLING PATTERN (uppers)

tonnes

Number of rows

166

t/drilled m

4.6 - Loading and Blasting

0.7

average time/

hole (min)

hours

1.0

0.7

Hole diameter (mm)

total hours (lift)

Spacing

0.84

Number of holes/row

3.0

Explosive density (g/cc)

2.2

number of blasts

holes/blast

length (m)/blast

28

42

8.3

55

32

1.01

18.6

holes/blast

Required explosives (kg)

Ventilation

(evacuation of fumes)

Burden

0.6

tonnes per hole

0.91

Kg of explosives/meter

4.7 - Ventilation

Average

width (m)

1.7

BLASTING PARAMETERS

average time/

hole (min)

Blasting

6.32

22.8

(drilled meters per hour/man/drill)

Drilled length

(m)

Broken length (m)

2.4

2.2

Clean and load holes

You must

adjust the

spacing to

obtain a round

number in the

"Number of

holes/row" cell

0.81

Number of blasts (lift)

Powder factor (kg/tonne)

0.82

12

897

The number of holes per blast must be a multiple of the

"Number of holes per row" cell of the "Drilling pattern" section

(To use when blasting causes a delay during the shift or when the work schedule is 24 hours a day)

Total number of blasts (rounds + lift)

minutes required

15.0

/blast

total hours

0.0

0.0

4.8 - Backfill

m

400

File: 324843914.xls

Sheet: UPPERS

Page 4 of 18

=t/m

1.9765

t/hour

110

hours

7.2

for the entire lift

Experimental Mine

Val-d'Or

07/26/2016

05:11:28

CUT AND FILL

LIFT BY UPPERS

Version: January 18, 2002

MILLHOLES,

MANWAYS,

BACKFILL

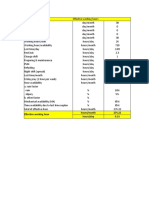

5.0 - LIFT COMPILATION

TABLE OF REQUIRED HOURS PER LIFT

DIRECT ACTIVITIES PER LIFT

SCALING

(inside the stope)

SUPPORT

see support

25.5

DIRECT FIXED

(hours)

DIRECT VARIABLE (hours)

DRILLING

5.00

139.6

MUCKING

2.50

79.7

3.75

31.8

8.5

14.75

19.6

VENTILATION

0.0

OTHERS

74.07

7.2

Scheduled hrs

2.5

102.57

303.41

NOT PROPORTIONAL TO THE NUMBER OF

IN THE STOPE

MEN INSIDE

THE STOPE

ONLY DIRECT VARIABLE ACTIVITIES ARE INFLUENCED BY THE NUMBER OF MEN.

THEREFORE, ACCORDING TO THE NUMBER OF MEN ENTERED, WE OBTAIN:

DIRECT VARIABLE (hours) *

BLASTING

46.5

26.6

31.8

6.5

106.7

13.3

63.8

8.0

7.2

127.14

* The number of required hours is corrected according to the number of men entered in section 5.0.

REQUIRED MANHOURS

REQUIRED MANSHIFTS

25.5

3.2

154.6

19.3

87.2

10.9

0.0

0.0

243.8

30.5

7.5

0.9

509.01 manhours

63.63 manshifts

+

REQUIRED NUMBER OF MEN

NUMBER OF HOURS PER SHIFT

3

8 hours

with a contingency of

15.0%

9.54

manshift contingency

=

required manshifts inside the stope

73.17

+

required manshifts from direct fixed activities (outside the stope)

29.23

=

total manshifts required

102.40

MANSHIFTS

INSIDE THE STOPE

File: 324843914.xls

Sheet: UPPERS

Page 5 of 18

OUTSIDE STOPE

TOTAL

PRODUCTIVE

CONTINGENCY

TOTAL (STOPE)

FIXED

63.6

9.5

73.2

29.2

102.4

62%

9%

71%

29%

100%

Experimental Mine

Val-d'Or

PRODUCTIVITY

1179

tonnes

11.5

tonnes/manshift

07/26/2016

05:11:28

B89:

Time necessary to advance one meter inculding the back and the two walls and cleaning the bootlegs.

B104:

see "MUCKING" sheet

B107:

If the grade does not justify the time required for the final clean-up, enter "0" in the "m 2/hour" cell

E89:

Time required to scale one meter (the roof and the two walls) and to clean the bootlegs

E104:

see sheet " MUCKING "

E107:

If the grade does not justify the time required for the final clean-up, enter "0" in the "m 2/hour" cell

E134:

The number of holes per blast must be a multiple of the "Number of holes per row" cell of the "Drilling pattern" section

F81:

Length to be mined without the slot raises and the main raise

F164:

NOT PROPORTIONAL TO THE NUMBER OF MEN INSIDE THE STOPE

I164:

NOT PROPORTIONAL TO THE NUMBER OF MEN IN THE STOPE

K121:

You must adjust the spacing to obtain a round number in the "Number of holes/row" cell

File: 324843914.xls

Sheet: Comments

Page 6 of 18

Experimental Mine

Val-d'Or

07/26/2016

05:11:28

CUT AND FILL

LIFT BY BREASTS

Version: January 18, 2002

1.0 - DIRECT FIXED ACTIVITIES PER SHIFT (outside the stope)

Frequency or

Units

Cage (at beginning and end of shift)

Travelling (shaft - refuge station - shaft)

Other travelling delays

Back and forth to stope

Supervision

Work planning

Complete daily reports

Lunch

Time

Total Time

(min)/Unit

(min)

2

2

10

5

4

1

1

1

1

10

15

10

12

30

NOTES

20

10

0

40

15

10

12

30

0

137 minutes

2.28 hours/shift

2.0 - DIRECT FIXED ACTIVITIES PER STEP (inside the stope)

RELATED TO GROUND

SUPPORT

Frequency or

Units

Bring equipment and material

Install setup platform

Store material

10

5

minutes/setup

hours/setup

RELATED TO DRILLING

Prepare material

Store equipment and material

Frequency or

Units

10

0

5

0

15

0.25

Time

Total Time

(min)/Unit

(min)

1

1

5

5

minutes/setup

hours/setup

File: 324843914.xls

Sheet: BREASTS

Page 7 of 18

RELATED TO

BLASTING

Time

Total Time

(min)/Unit

(min)

5

5

0

10

0.17

Frequency or

Units

Time

Total Time

(min)

(min)/Unit

Bring explosives

Bring and prepare material

Store equipment and explosives

Remove setup platform

Equipment checks

Connect the blast

Access verification

Extra scaling

1

1

1

1

5

6

8

5

1

1

1

10

5

5

Repair and install ventilation

15

minutes/blast

hours/blast

Experimental Mine

Val-d'Or

5

6

8

5

0

10

5

5

15

0

0

59

0.98

07/26/2016

05:11:28

CUT AND FILL

LIFT BY BREASTS

Version: January 18, 2002

3.0 - DIRECT FIXED ACTIVITIES PER LIFT (inside the stope)

RELATED TO BACKFILL,

MILL HOLES AND MANWAYS

Frequency or

Units

Drainage system*

Mill holes *

Manways *

Barricades inside the stope *

Move equipment prior to backfill

Install backfill line inside the stope

Connect to the main line

Wash the line before backfilling

Wash the line after backfilling

Spill fences (outside the stope)

OTHER ACTIVITIES

PER LIFT

Time

Total Time

(min)/Unit

(min)

2

3

3

3

2

30

360

360

360

300

60

1080

1080

1080

600

2

2

6

6

2

180

20

7

12

15

360

40

42

72

Frequency or

Units

Geologists

Surveyors

Mechanics and electricians

Repairs in main access

2

1

1

1

Time

(min)/Unit

20

30

30

10

minutes

hours

Total Time

(min)

40

30

30

10

0

0

110

1.83

15

0

4429 minutes

73.82 hours (backfill)

* must include material handling and construction

part A

Here are the most common steps

in Cut and Fill:

part B

RAISE

4

3

1

2

5&6

BACKFILL

FENCE

File: 324843914.xls

Sheet: BREASTS

Page 8 of 18

Experimental Mine

Val-d'Or

07/26/2016

05:11:28

CUT AND FILL

LIFT BY BREASTS

Version: January 18, 2002

4.0 - DIRECT VARIABLE ACTIVITIES PER STEP (inside the stope)

4.1 - Lift Dimensions

Breast

parameters

Lift

parameters

Drilled length

Broken length

Height

Width

3.67

3.60

2.4

1.7

Tonnes/breast

44

Length

Height

Average width

# advances

99.6

2.4

1.7

28

Tonnes

1199

4.2 - Scaling

Wash, scale and clean bootlegs

minutes/

longitudinal m

15

total hours

hours

0.9

installation time

/bolt (min)

8.5

hours

1.0

hours

28.0

hours

3.1

total hours

4.1

hours

86.8

total hours

114.8

"MUCKING"

sheet

see see

sheet

" MUCKING

"

File: 324843914.xls

Sheet: BREASTS

Page 9 of 18

Roof pattern

Hanging wall pattern

Footwall pattern

Drilled

length/bolt

1.2

1.2

1.2

Number of

bolts/1.2 m

advanced

2.00

2.00

2.00

6.0

Drilled

meters/m

avanced

2.10

2.10

2.10

6.30

FINAL FLOOR CLEAN-UP PARAMETERS

4.4 - Mucking or Scraping

Final clean-up before backfill

Time required to scale one meter (the

roof and the two walls) and to clean

the bootlegs

GROUND SUPPORT PARAMETERS

Drilling for support

Mucking

Length to be mined without the

main raise

(lift)

24.9

4.3 - Ground Support

Installation of ground support

(screen included)

ore density (t/m)

2.95

Surface to clean (m2)

tonnes/hour

hours

tonnes/hour

hours

50

0.1

53

22.7

m2/hour

hours

m2/hour

hours

15

0.5

20

8.5

If

If the

the grade

grade does

does not

not justify

justify the

the time

time

required

required for

for the

the final

final clean-up,

clean-up, enter

enter

"0"

"0" in

in the

the "m

"m22/hour"

/hour" cell

cell

Experimental Mine

Val-d'Or

LIFT TOTAL

169.32

Aver. thickness (m)

0.15

Recovered tonnage

for the lift

49

07/26/2016

05:11:28

CUT AND FILL

LIFT BY BREASTS

Version: January 18, 2002

4.5 - Drilling

If

If the

the grade

grade does

does not

not justify

justify the

the time

time

required

required for

for the

the final

final clean-up,

clean-up, enter

enter

22

"0"

"0" in

in the

the "m

"m /hour"

/hour" cell

cell

DRILLING PARAMETERS

2.16

Time required to drill a 1.2-m hole (min)

Time required for repositioning, changing drilling steel and

bits, etc. per hole of 2.4 m (min)

2

6.32

Total average time to drill a 2.4-m hole (min)

Meters to drill

Time required for drilling (hours)

meters

meters

Average drilling rate

33.03

924.8

(drilled meters per hour/man/drill)

hours

hours

1.5

40.6

22.8

DRILLING PATTERN (breasts)

Number of holes/breast

tonnes/drilled m

tonnes per hole

1.33

4.9

BLASTING PARAMETERS

4.6 - Loading and Blasting

Clean and load holes

average time/

hole

(min)

1.3

Required explosives (kg)

Hole diameter (mm)

Explosive density (g/cc)

hours

0.2

total hours (lift)

5.6

26.0

717.0

Kg of explosives/meter

32

1.01

Powder factor

per breast

0.81

0.60

Number of blasts (lift)

(kg/tonne)

28

4.7 - Ventilation

Ventilation

(evacuation of fumes)

(To use when blasting causes a delay during the shift or when the work schedule is 24 hours a day)

minutes required

/blast

total hours

0

0.0

4.8 - Backfill

m

406

File: 324843914.xls

Sheet: BREASTS

Page 10 of 18

=t/m

1.947

t/hour

110

hours

7.2

for the entire lift

Experimental Mine

Val-d'Or

07/26/2016

05:11:28

CUT AND FILL

LIFT BY BREASTS

Version: January 18, 2002

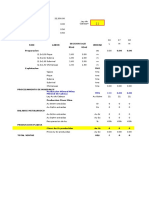

5.0 - BREAST COMPILATION

TABLE OF REQUIRED HOURS PER BREAST

DIRECT ACTIVITIES

PER ADVANCE

DIRECT FIXED

(hours)

DIRECT VARIABLE (hours)

SCALING

SUPPORT

see support

0.9

DRILLING

0.25

4.10

MUCKING

0.17

1.50

BLASTING

0.25

0.10

0.45

0.0

OTHERS

Scheduled hrs

0.1

1.46

6.80

NOT PROPORTIONAL TO THE NUMBER OF MEN INSIDE THE STOPE

ONLY DIRECT VARIABLE ACTIVITIES ARE INFLUENCED BY THE NUMBER OF MEN.

THEREFORE, ACCORDING TO THE NUMBER OF MEN ENTERED, WE OBTAIN:

DIRECT VARIABLE (hours) *

VENTILATION

0.73

0.20

2.05

0.75

0.1

0.10

3.45

4.91

total :

* The number of required hours is corrected according to the number of men entered in section 5.0.

contingency (ventilation included)

+

15.0%

allocated time for contingency

44 minutes

total time required inside the stope (contingency included)

5.7 hours

+

total time of direct fixed activities outside the stope

REQUIRED NUMBER OF MEN

NUMBER OF HOURS PER SHIFT

2.3 hours

=

<=>

total time required per advance

8.0 hours

occupation rate of the stope per advance

71.3%

occupation rate of the shift per advance

99.8%

5.1 - CALCULATION OF THE POSSIBLE NUMBER OF ADVANCES PER SHIFT ACCORDING TO ENTERED DATA:

In this section, you can optimize your operating parameters to simulate your operation or to find

the required parameters to reach the desired performance.

Number of hours per shift

8

-

Direct fixed time outside the stope/shift

2.3

total time required inside the stope

(contingency included)

=

Available time inside the stope/shift

5.7

Is it possible to blast during the shift?

File: 324843914.xls

Sheet: BREASTS

Page 11 of 18

5.7

Possible number of advances per

shift

1.00

If yes, optimize the parameters to obtain the desired results.

Experimental Mine

Val-d'Or

07/26/2016

05:11:28

CUT AND FILL

LIFT BY BREASTS

Version: January 18, 2002

DIRECT ACTIVITIES PER LIFT

DIRECT FIXED

SCALING

SUPPORT

see support

24.9

(hours)

DIRECT VARIABLE (hours)

DRILLING

7.00

114.80

ONLY DIRECT VARIABLE ACTIVITIES ARE INFLUENCED BY THE NUMBER OF MEN.

THEREFORE, ACCORDING TO THE NUMBER OF MEN ENTERED, WE OBTAIN:

12.5

57.40

DIRECT VARIABLE (hours) *

MUCKING

4.67

40.60

BLASTING

7.00

31.2

20.53

5.60

MILLHOLES,

MANWAYS,

BACKFILL

6.0 - LIFT COMPILATION

VENTILATION

0.0

73.8

7.2

OTHERS

Scheduled hrs

1.67

114.68

224.30

NOT PROPORTIONAL TO THE NUMBER OF MEN INSIDE THE STOPE

20.30

31.2

2.80

7.2

* The number of required hours is corrected according to the number of men entered in section 5.0.

131.35

total :

246.03

total

492.07

REQUIRED MANHOURS

24.9

128.8

49.9

76.4

46.7

0.0

162.0

3.3

REQUIRED MANSHIFTS

3.1

16.1

6.2

9.6

5.8

0.0

20.3

0.4

61.51

+

REQUIRED NUMBER OF MEN

NUMBER OF HOURS PER SHIFT

with a contingency of

15.0%

9.23

manshift contingency

8 hours

required manshifts inside the stope

70.73

+

required manshifts from direct fixed activities (outside the stope)

28.25

=

total manshifts required

98.99

1.00 advance/shift

with a performance of

From your best estimate, you can maintain

which represents an occupation rate of the shift (contingency included) of

1.00

100%

advance/shift

MANSHIFTS

INSIDE THE STOPE

File: 324843914.xls

Sheet: BREASTS

Page 12 of 18

OUTSIDE STOPE

PRODUCTIVE

CONTINGENCY

TOTAL (STOPE)

FIXED

61.7

62%

9.3

9%

70.9

72%

28.3

28%

Experimental Mine

Val-d'Or

TOTAL

99.2

100%

PRODUCTIVITY

1199

tonnes

12.1

tonnes/manshift

07/26/2016

05:11:28

B97:

Time required to scale one meter (the roof and the two walls) and to clean the bootlegs

B114:

see "MUCKING" sheet

B117:

If the grade does not justify the time required for the final clean-up, enter "0" in the "m 2/hour" cell

E114:

see sheet " MUCKING "

E117:

If the grade does not justify the time required for the final clean-up, enter "0" in the "m 2/hour" cell

F89:

Length to be mined without the main raise

F167:

NOT PROPORTIONAL TO THE NUMBER OF MEN INSIDE THE STOPE

F206:

NOT PROPORTIONAL TO THE NUMBER OF MEN INSIDE THE STOPE

I206:

NOT PROPORTIONAL TO THE NUMBER OF MEN INSIDE THE STOPE

File: 324843914.xls

Sheet: Comments

Page 13 of 18

Experimental Mine

Val-d'Or

07/26/2016

05:11:28

Version: January 18, 2002

MUCKING

tonnes/ hour

ENTER YOUR CHOICE IN CYCLE

CALCULATIONS

equipment

46

18.5 HP

distance (m)

availability

tonnes/hr

18

55

25.6

95%

52.25

50

36

16.7

90%

32.4

80

39

18.1

85%

33.15

90

39

18.4

85%

33.15

CAVO 310

ELECTRIC SCOOP

EJC 60E

distance (ft)

32

25

20

17

14

13

12

11

9

8

8

6

40

60

80

100

120

140

160

180

200

220

240

300

sh.tons/hour

76

59

47

40

34

30

28

26

21

20

18

14

PERFORMANCE OF HOIST

35

f(x) = 272.5540355851 x^-0.8232905266

30

25

20

15

10

5

0

0.0

20.0

40.0

60.0

80.0

100.0

Distance (m)

Ingersoll-Rand 18.5hp

compresserd air (90psi)

25.61

CAVO 310

PERFORMANCE OF CAVO 310

30

distance (m)

t/hour

m/hour

10

52

24.2

25

43

20

50

35

16.3

75

28

13.3

100

24

11.2

Enter your average operating distance

50

36

16.65

25

f(x) = 25.34472742 exp( -0.0084074068 x )

m/hour

20

15

10

5

0

0

Atlas Copco

EJC 60E

t/hour

m/hour

10

53

25

25

47

22

50

43

20

75

38

18

100

34

16

125

32

15

150

30

14

175

28

13

Enter your average operating distance

80

39

18.10

30

40

60

80

100

120

Distance (m)

m/hour

25

f(x) = 24.5297713072 exp( -0.003828778 x )

20

15

10

5

0

estimate

YOUR EQUIPMENT

20

40

60

80 100 120 140 160 180 200

Distance (m)

YOUR EQUIPMENT

30

distance (m)

25

f(x) = 25.4926574258 exp( -0.0036220591 x )

20

m/hour

t/hour

m/hour

10

56

26

25

49

23

50

45

21

75

41

19

100

36

17

125

34

16

150

32

15

175

30

14

Enter your average operating distance

90

39

18.44

20

PERFORMANCE OF ELECTRIC SCOOP

EJC 60E

distance (m)

File: 324843914.xls

Sheet: MUCKING

Page 14 of 18

m/hour

(Ingersoll-Rand)

m/hour

12.2

69

18.3

54

24.4

43

30.5

36

36.6

31

42.7

27

48.8

25

54.9

24

61.0

19

67.1

18

73.2

16

91.5

13

Enter your average operating distance

18

55

ELECTRIC SCOOP

t/hour

YOUR EQUIPMENT

@ 90psi

t/hour

distance (m)

HOIST

18.5 HP

@ 90psi

(Ingersoll-Rand)

m/hour

HOIST

2.14

Availability observed at

your site or from your

references

Table (entries, results)

hoist

Methodology:

1- Enter the distance and availability per equipment.

(It is possible to optimize the distance per

equipment)

2- Enter the broken ore density.

3- Enter the chosen performance to use in the model.

Broken ore

density (t/m)

Enter the average mucking

distance according to your

stope configuration

15

10

5

Modify the formula

according to the one

in the graph

0

estimate

50

100

150

200

Distance (m)

Experimental MIne

Val-d'Or

07/26/2016

05:11:28

A6:

Methodology:

1- Enter the distance and availability per equipment.

(It is possible to optimize the distance per equipment)

2- Enter the broken ore density.

3- Enter the chosen performance to use in the model.

C73:

Modify the formula according to the one in the graph

H5:

Enter the average mucking distance according to your stope configuration

K5:

Availability observed at your site or from your references

File: 324843914.xls

Sheet: Comments

Page 15 of 18

Experimental MIne

Val-d'Or

07/26/2016

05:11:28

BACKFILL

Version: January 18, 2002

BACKFILL PREPARATION

Surface of floor

to clean (m)

450

Actvities

Clean the floor

Cleaning productivity

(m/hour)

20

Hours/shift

Time (hours)

22.50

# men

2

Manshifts

5.6

length (m)

110.0

productivity (m/hour)

20

5.50

1.4

number of trips

56

productivity (#/hour)

4

14.00

3.5

number of parts

38

productivity (#/hour)

5

7.60

1.9

number of parts

54

productivity (#/hour)

4

13.50

3.4

Install drainage

length (m)

20

productivity (m/hour)

30

0.67

0.2

Move equipment

(with a fence)

number of parts

6

productivity (#/hour)

0.4

15.00

3.8

Move equipment

(without a fence)

number of parts

6

productivity (#/hour)

0.9

6.67

1.7

Remove services

Remove pipes, hoses, electric

cables, ventilation ducts

Bring material

Build mill holes and manways

Build fences

Direct fixed time outside the stope per shift

(see section 1.0 of the "UPPERS" or "BREASTS" worksheets)

2.45

hours

Manshifts

with a fence

without a fence

CONTINUOUS BACKFILLING

Activities

Fixed time outside the stope

Connect to main line

Call the backfill

Backfilling

Wash the line

Time (hours)

2.45

0.75

0.08

7.16

# men

2

2

2

2

M-Sh

0.61

0.19

0.02

1.79

0.30

0.08

Total time between

the call and the

arrival of the

backfill flow

required

volume (m)

400.0

total

29.0

total

21.0

hours/shift

solid rate (m/hour)

55.8

total : 2.69 manshifts

BACKFILLING PER SHIFT

hours/shift

Total time between the call and the

arrival of the backfill flow

Activities

Fixed time outside the stope

Connect to main line

Call the backfill

Backfilling/shift

Wash the line

required

volume (m)

400.0

Time (hours)

2.45

0.75

0.08

4.42

0.30

solid rate (m/hour)

55.8

m/sh

247

# men

Number of required shifts

1.62

Manshifts

total

3.24

SUMMARY - TOTAL MANSHIFTS REQUIRED

BACKFILLING

CONTINUOUS

PER SHIFT

WITH A FENCE

BACKFILL PREPARATION

31.7

32.2

WITHOUT A FENCE

23.7

24.2

File: 324843914.xls

Sheet: BACKFILL

Page 16 of 18

Experimental Mine

Val-d'Or

07/26/2016

05:11:29

A9:

Remove pipes, hoses, electric cables, ventilation ducts

A42:

Total time between the call and the arrival of the backfill flow

A56:

Total time between the call and the arrival of the backfill flow

File: 324843914.xls

Sheet: Comments

Page 17 of 18

Experimental Mine

Val-d'Or

07/26/2016

05:11:29

Steps for breast mining with a fence

RAISE

part A

part B

4

3

1

2

5&6

FENCE

BACKFILL

Steps for breast mining without a fence

RAISE

part A

4

part B

BACKFILL

Steps for upper mining with a fence

part A

1

RAISE

2

4

BACKFILL

FENCE

File: 324843914.xls

Experimental Mine

Sheet: DRAWINGS

Val-d'Or

part B

07/26/2016

05:11:29

You might also like

- Construction Equipment ManagementDocument14 pagesConstruction Equipment ManagementSiddhartha Kamat100% (1)

- Truck Data Comp.Document1 pageTruck Data Comp.Marco PintoNo ratings yet

- Equipment Productivity DetailsDocument3 pagesEquipment Productivity DetailsRana Muhammad TalhaNo ratings yet

- SAB 3122 10 ExcavationDocument26 pagesSAB 3122 10 ExcavationNSBMRNo ratings yet

- Factors Affecting Fuel Consumption of Heavy EquipmentDocument3 pagesFactors Affecting Fuel Consumption of Heavy EquipmentSIVACHANDRANNo ratings yet

- Master List For Labor Eqpt MatlsDocument2 pagesMaster List For Labor Eqpt MatlsroldskiNo ratings yet

- Tutorial-Driven Precast Pile Estimation CostDocument3 pagesTutorial-Driven Precast Pile Estimation CostMuhd FiziNo ratings yet

- Estimate Line Detail for Process Plant ProjectDocument35 pagesEstimate Line Detail for Process Plant Projectstefax2010No ratings yet

- Cost of Handling and TR Ansporting Material: 1 - Loading 2 - Hauling, Loaded 3 - Unloading 4 - Returning, EmptyDocument29 pagesCost of Handling and TR Ansporting Material: 1 - Loading 2 - Hauling, Loaded 3 - Unloading 4 - Returning, Emptyascom asNo ratings yet

- Calculate mine slope parametersDocument6 pagesCalculate mine slope parametersarmadi harisNo ratings yet

- Equipment ProductivityDocument8 pagesEquipment ProductivityHary AntoNo ratings yet

- Estimating Tendering Question and Answers FinalDocument2 pagesEstimating Tendering Question and Answers FinalJon50% (2)

- Mining Methods: PlotmakerDocument78 pagesMining Methods: PlotmakertamanimoNo ratings yet

- Site Work Estimating TipsDocument30 pagesSite Work Estimating TipsAguirre De Joya RonaldoNo ratings yet

- Rate AnalysisDocument15 pagesRate AnalysisBhagirath Bishnoi100% (1)

- Material Schedule TypicalDocument3 pagesMaterial Schedule TypicalMwesigwa DaniNo ratings yet

- Rate Analysis Report - Concrete Block MachineAMEX (Version 1)Document21 pagesRate Analysis Report - Concrete Block MachineAMEX (Version 1)Jayaraman KamarajNo ratings yet

- 4 - Equipment Cycle TimeDocument23 pages4 - Equipment Cycle TimeFeteneNo ratings yet

- Formwork CostingDocument19 pagesFormwork CostingAmaresh BeheraNo ratings yet

- Rate of Hdpe Pipe Jointing Works (With Butt-Welded Joints) : Fiscal YearDocument21 pagesRate of Hdpe Pipe Jointing Works (With Butt-Welded Joints) : Fiscal YearSanoj gautam100% (1)

- Rate Analysis160511Document17 pagesRate Analysis160511kaustubhp9875% (8)

- Formwork cost calculation for RCC footings and beamsDocument33 pagesFormwork cost calculation for RCC footings and beamsanon_789699787No ratings yet

- Production and Construction RatesDocument21 pagesProduction and Construction RatesAMMAR MAWNo ratings yet

- Hauling Time Cycle DTDocument34 pagesHauling Time Cycle DTAda DamsNo ratings yet

- Standard-Productivity-Details For Heavy MachineryDocument1 pageStandard-Productivity-Details For Heavy MachineryvinayNo ratings yet

- Equipment Plan & BGT Calculation: Base Calculation Planned Calculation PC 200 PC 300 PC 300Document13 pagesEquipment Plan & BGT Calculation: Base Calculation Planned Calculation PC 200 PC 300 PC 300Iwan DermawanNo ratings yet

- CIVL 392 - Chapter 3 - Excavating MachinesDocument50 pagesCIVL 392 - Chapter 3 - Excavating MachinesheroNo ratings yet

- BuldozerDocument12 pagesBuldozercapelfernandoNo ratings yet

- Rate Analysis-RevDocument8 pagesRate Analysis-Revsrinivasa raoNo ratings yet

- Build Up Rate I 1819Document5 pagesBuild Up Rate I 1819Norhafizah Khairol AnuarNo ratings yet

- ProductivityDocument349 pagesProductivitydimar agusriawanNo ratings yet

- INDOT Highway Construction RatesDocument95 pagesINDOT Highway Construction RatesKshamata DesaiNo ratings yet

- Tender DrainageDocument19 pagesTender DrainageSeng Koon ConstructionNo ratings yet

- Work Done ReportDocument443 pagesWork Done ReportNagarajNo ratings yet

- Shuttering CalculationDocument49 pagesShuttering CalculationCurious S.R.No ratings yet

- Arunachal Pradesh Analysis of Rates For Road and Bridge Works 2010Document232 pagesArunachal Pradesh Analysis of Rates For Road and Bridge Works 2010Harish Kumar MahavarNo ratings yet

- Calculation Hire Charge MachineDocument2 pagesCalculation Hire Charge MachineMoni Sankar HazraNo ratings yet

- Schedule of RatesDocument42 pagesSchedule of RatesShaukat Ali KhanNo ratings yet

- Earth Moving Equipment Function and Standard ProductivityDocument5 pagesEarth Moving Equipment Function and Standard ProductivityMaxwell ChikasimaNo ratings yet

- Piney Estimation of QuantitiesDocument75 pagesPiney Estimation of QuantitiesPrince50% (2)

- Chapter 3 Build Up RateDocument5 pagesChapter 3 Build Up RateFrancis TiehNo ratings yet

- COST of EquipmentDocument12 pagesCOST of EquipmentAdithyaArifin100% (1)

- Rate Analysis r4Document60 pagesRate Analysis r4Akshay dareNo ratings yet

- Brick work ratesDocument1,986 pagesBrick work ratesHamid NaveedNo ratings yet

- Ch.3 - Earth Work & Equipment529015Document41 pagesCh.3 - Earth Work & Equipment529015Ahmed AmediNo ratings yet

- Data Rates-Canal Works Part 1Document20 pagesData Rates-Canal Works Part 1vpmohammedNo ratings yet

- Slab on grade design checksDocument3 pagesSlab on grade design checksTAMER RAGAANo ratings yet

- Cost Analysis of Civil WorkDocument12 pagesCost Analysis of Civil WorkHossen Ali MollahNo ratings yet

- Cost Calculation of Jamtara-Dumka ProjectDocument24 pagesCost Calculation of Jamtara-Dumka ProjectnsureshbabuNo ratings yet

- Preliminary EstimateDocument34 pagesPreliminary EstimatesambhaviNo ratings yet

- Material & Equipment MGMT - NICMAR NCP-24 25Document22 pagesMaterial & Equipment MGMT - NICMAR NCP-24 25madhuwadi67% (6)

- EandC Rate AnlysisDocument19 pagesEandC Rate AnlysisVenkata Tharun GangulaNo ratings yet

- Concrete Work Productivity RateDocument10 pagesConcrete Work Productivity RateTUALLA KAL-EL JOHNRAY 3ANo ratings yet

- RQS3S3 Price AnalysisDocument14 pagesRQS3S3 Price AnalysisWENG LUCK CHEANGNo ratings yet

- Equipment ProductionDocument16 pagesEquipment ProductionjgiraolewisNo ratings yet

- 6.drainlayer BurDocument23 pages6.drainlayer BurzulfaisalNo ratings yet

- Standard construction equipment performanceDocument34 pagesStandard construction equipment performanceTewodros TadesseNo ratings yet

- Cut & Fill Build Up Rates 2012Document18 pagesCut & Fill Build Up Rates 2012Tuan HafizuddinNo ratings yet

- Productivity Long-HoleDocument16 pagesProductivity Long-HoleSujib BarmanNo ratings yet

- Productivity Shrinkage StopeDocument21 pagesProductivity Shrinkage Stopeoscar villanueva quiñones100% (1)

- Metas Fisicas (Mensual-Real) - v5Document48 pagesMetas Fisicas (Mensual-Real) - v5oscar villanueva quiñonesNo ratings yet

- Metas Fisicas (Mensual-Real) - v4Document48 pagesMetas Fisicas (Mensual-Real) - v4oscar villanueva quiñonesNo ratings yet

- Productivity Shrinkage StopeDocument21 pagesProductivity Shrinkage Stopeoscar villanueva quiñones100% (1)

- Productivity Long HoleDocument16 pagesProductivity Long Holeoscar villanueva quiñones100% (1)

- Metas Fisicas (Mensual-Real) - v5Document69 pagesMetas Fisicas (Mensual-Real) - v5oscar villanueva quiñonesNo ratings yet

- Metas Fisicas (Mensual-Real) - v5Document69 pagesMetas Fisicas (Mensual-Real) - v5oscar villanueva quiñonesNo ratings yet

- Metas Fisicas (Mensual-Real) - v5Document69 pagesMetas Fisicas (Mensual-Real) - v5oscar villanueva quiñonesNo ratings yet

- Metas Fisicas (Mensual-Real) - v5Document69 pagesMetas Fisicas (Mensual-Real) - v5oscar villanueva quiñonesNo ratings yet

- Control de Insumos BrasilDocument14 pagesControl de Insumos Brasiloscar villanueva quiñonesNo ratings yet

- My Internship Report Y2Document24 pagesMy Internship Report Y2Nji Munang OfMbamluNo ratings yet

- Amc Bore Hole Stabiliser™: Multifunctional Solution For Poor Collaring, Hole Decay and Sidewall InstabilityDocument2 pagesAmc Bore Hole Stabiliser™: Multifunctional Solution For Poor Collaring, Hole Decay and Sidewall InstabilityFiorela FarmNo ratings yet

- Tricone Bit BrochureDocument8 pagesTricone Bit BrochureDony ArifNo ratings yet

- Mesda Drill Rig CatalogDocument4 pagesMesda Drill Rig CatalogJake HuangNo ratings yet

- Vibration Effects During COnventional Drilling by Talha Bin RiazDocument1 pageVibration Effects During COnventional Drilling by Talha Bin RiazUsamaNo ratings yet

- Tunnel EngineeringDocument63 pagesTunnel EngineeringSreejith Reddy Sree67% (3)

- A-Complete Building-Estimation-Sample by WWWDocument66 pagesA-Complete Building-Estimation-Sample by WWWapi-234133280100% (1)

- Core Drilling MachinesDocument2 pagesCore Drilling MachinesAsad AijazNo ratings yet

- Liebherr LB 28 Rotary Drilling Rig Technical Data Sheet Specifications English 10351286Document12 pagesLiebherr LB 28 Rotary Drilling Rig Technical Data Sheet Specifications English 10351286Dhiraj Kumar SarafNo ratings yet

- Indications of KickDocument36 pagesIndications of KickAbhishek allwinNo ratings yet

- MasterCAM - X4 - Beginner Training Tutorial - SampleDocument53 pagesMasterCAM - X4 - Beginner Training Tutorial - SampleRafael Donadio100% (1)

- AnnalsDocument540 pagesAnnalselderufsjNo ratings yet

- 4 ToolsDocument24 pages4 ToolsChristian OliveiraNo ratings yet

- T-101 Drilling Machine: Sizes: 1/2-To 4-InchesDocument7 pagesT-101 Drilling Machine: Sizes: 1/2-To 4-InchesERICK RALPH MONTENEGRO CASTRONo ratings yet

- Cement Plant ProcessDocument653 pagesCement Plant ProcessRRHH100% (4)

- Underground Gas Dial Before You DigDocument8 pagesUnderground Gas Dial Before You DigBrett AndreassenNo ratings yet

- 12-BT-0092 Impreg Dull Grade BookDocument52 pages12-BT-0092 Impreg Dull Grade BookFredy Farell OrtegaNo ratings yet

- Став Atlas Copco DM30, DM45Document16 pagesСтав Atlas Copco DM30, DM45Дамир Назипов100% (1)

- CNC Machine Tools and Control Systems GuideDocument39 pagesCNC Machine Tools and Control Systems Guidep_a_jeevaNo ratings yet

- Examen SPTFOrdDocument4 pagesExamen SPTFOrdIRENE PASCUAL HERANZ BRONCHALONo ratings yet

- Dd422ie Specification Sheet English 5Document4 pagesDd422ie Specification Sheet English 5P. Morales EdgarNo ratings yet

- Training Handbook en HQDocument3 pagesTraining Handbook en HQparadoxid78No ratings yet

- 3331Document4 pages3331Elwathig BakhietNo ratings yet

- Catalog Uk DrillingDocument226 pagesCatalog Uk DrillingJuanNo ratings yet

- Horizontal & Extended Reach WellsDocument18 pagesHorizontal & Extended Reach WellsRachid Touati100% (6)

- Lecture 1 - Fundamentals of Drilling FluidsDocument25 pagesLecture 1 - Fundamentals of Drilling FluidshuutaiphamNo ratings yet

- Travel Charts From CL-12 Operating Manual (Form 8895)Document20 pagesTravel Charts From CL-12 Operating Manual (Form 8895)Roberto Lagos ValdesNo ratings yet

- Mes Drill, Mill, Shaper, Grinding ClassDocument46 pagesMes Drill, Mill, Shaper, Grinding ClassomkardashetwarNo ratings yet

- Brother - SPEEDIO - S700X2 - Canned Cycle FormatDocument2 pagesBrother - SPEEDIO - S700X2 - Canned Cycle FormatstephenawoodruffNo ratings yet

- Analytical Application On Wellplan Software Studing Torque and DragDocument70 pagesAnalytical Application On Wellplan Software Studing Torque and DragJose Manuel Lezama SantaellaNo ratings yet