Professional Documents

Culture Documents

Modified Design of Speed Breaker For Power Generation

Uploaded by

suraj dhulannavarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modified Design of Speed Breaker For Power Generation

Uploaded by

suraj dhulannavarCopyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

MODIFIED DESIGN OF SPEED BREAKER FOR POWER

GENERATION

B. Aravind Reddy1, T.Venkata Sahaj2, Yarram Arun Kumar3, D.Ramana Reddy4

1

Department of mechanical engineering, Methodist college of engineering and technology, Telangana, India

Department of mechanical engineering, Methodist college of engineering and technology, Telangana, India

3

Department of mechanical engineering, Methodist college of engineering and technology, Telangana, India

4

Department of mechanical engineering, Methodist college of engineering and technology, Telangana, India

2

Abstract

Energy plays a prominent role in the day to day life, starting from the cells in the TV remote to the Air conditioner. But the

scarcity in the power led to the increase in demand for the low cost power generation systems. There are many techniques evolved

to overcome the problems in the power generation. One such attempt is made by our paper. To increase the efficiency of

conventional speed breaker power generator. The energy is getting wasted due to many moving parts in the present system.

Loss compensation is possible by eliminating excess moving parts and incorporating the recoil spring, to increase the shaft

rotation. This will ultimately lead to the effective usage of mechanical input. Other thing is that nowadays the demand for any

technology depends on cost of deployment. By considering all those parameters it can be said that this system is economic to

deploy.

Keywords: power generation, sustainability, speed breaker

--------------------------------------------------------------------***---------------------------------------------------------------------1. INTRODUCTION

2.2 Ribbon Recoil Spring

Many studies were made on this technique especially in the

recent times where the natural resources are terminating.

There is plenty of matter in the internet which deals with the

design and propagation of speed breaker. But the main

problem is to trap maximum energy out of it. So, the

research has been started to make the effective usage of the

available energy. My paper is going to bolster the research

which has the plenty of scope.

It is incorporated inside the pinion so that for every one

backward rotation of gear lead to the three forward rotations

of the same gear. This helps to increase the number of

rotations of the shaft which ultimately lead to the good

power generation. Number of springs can be increased for

more strength. i.e. fixing at two symmetric sides of the gear.

Generally high strength materials can be used. The recoil

spring is as shown in figure1.

It is said that the wonderful innovations comes from the

place where the problem is severe. One such example is

taken from worst power hit country. The First one to make

use were South African people, their electrical crisis has

made them to implement this method to light up small

villages of the highway. The idea of basic physics to convert

the kinetic energy into electrical energy that goes waste

when the vehicle runs over the speed- break was used. Since

then a lot has been done in this field. The idea caught our

working team and we have decided to develop such a

project that will produce more power and store it for use at

night time as it proves to be a boon to the economy of the

country

2. DESCRIPTION OF COMPONENTS

Fig -1: Recoil Spring

2.1 Rack and Pinion Gears

General function of this mesh is to convert linear motion

into rotary motion and there by shaft starts rotating. In this

system the rack is shortened so that the pinion rotates freely.

2.3 Sprocket and Chain

This is arranged in order to transfer the rotational motion

from one shaft to the other shaft. If we are able to make the

sprocket size more in the primary shaft than in the

secondary shaft then power developed will be more.

_______________________________________________________________________________________

Volume: 04 Special Issue: 02 | NCIRET-2015 | Apr-2015, Available @ http://www.ijret.org

78

IJRET: International Journal of Research in Engineering and Technology

2.4 Spur Gear

It is a positive power transmission device with definite

velocity ratio. It is preferred for adjusting some linear

misalignment. It should have high wear and tear, shockabsorbing capacity.

2.5 Free Wheel

This is placed at one end of the shaft so that it wont rotate

in the reverse direction which is undesirable. This is the

crucial module which helps to reduce the lot of energy

wastage. Without this there would be a chance of forming

reverse current which is going to make use of available

energy in the generator and finally there wont be any power

left in the system output. The free-wheel is as shown in

figure 2.

eISSN: 2319-1163 | pISSN: 2321-7308

uncoiled. The recoil ribbon spring designed in such a way

that it can bear heavy loads and gives the more outward

force in order to retain its original shape and structure. One

more main aspect of the shaft is that the backward motion is

restricted. Because the recoil spring need some stationary

reference to get uncoiled. For this condition to be achieved

free wheel is arranged at one end of the shaft which restricts

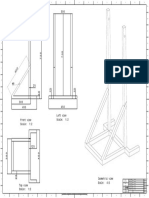

the backward motion. The designed system for development

is shown in figure4.

Fig -3: Recoil spring incorporated in the gear

Free wheel Rack

sprocket

generator

Fig -2: Free wheel

2.6 Flywheel

The purpose of this component is to reduce the thrust force

and Thereby reducing the fluctuations in the system. It is

basically made of cast iron which is a heaver metal to

restrict the shaft in the perpendicular direction.

2.7 Generator

Fig -4: Design of the system

4. CALCULATION OF POWER GENERATED

It is the prime system which converts mechanical input to

the electrical output in which the flux lines are cut by the

armature coil in the presence of electrical current.

Weight of the vehicle (pair of wheels) range from 250kg300kg, Assume it to be

=

275kg

Distance travelled by the rack

=

0.12m.

Work done by the force = F*S.

= 275*9.81*0.12.

3. WORKING

Power estimated as P = (F*S)/t

The working model is quite same as the conventional

design. That is, when the vehicle passes over the speed

breaker the rack and pinion arrangement gets actuated by

converting the linear motion into rotational motion. This in

turn rotates the primary shaft. The chain drive consecutively

attached to the primary shaft starts rotating. This will in fact

rotate the secondary shaft. Passed into the generator there by

the power get generated. The flywheel is arranged in

between the chain drive and the generator for absorbing the

shocks. The working of recoil spring and gear is shown in

figure 3.

5.3955 watts

As the recoil spring tends to rotate the gear 2.5 times more

than conventional gear, the power should be multiplied by

2.5, then

= 13.4887watts.

Our study mainly emphasise on the increasing the shaft

rotation with the help of the ribbon spring and the gear

arrangement which will tend to recoil as soon as it gets

Power generated in 1 hour = 13.4 *60 = 804 watts

_______________________________________________________________________________________

Volume: 04 Special Issue: 02 | NCIRET-2015 | Apr-2015, Available @ http://www.ijret.org

79

IJRET: International Journal of Research in Engineering and Technology

This power generation is twice that of the conventional

system and the power generation is sufficient to run help

stations and toll gates on highways.

As the shaft approaches final rotations i.e. 2 and 2.5 the

power generation decreases because of the less torque and

less speed production. So the graph above is perfectly

depicting the situation of the motion.

The sum of powers for each rotation = 6+4+1.02= 11.02

watts/hour (from the graph) compared to the

13.44watts/hour.

Error in the power calculation is given by =13.4411.02=2.42 watts/hour.

Hence the value 11.02 watts/hour obtained by considering

different speeds for different rotations of gear

eISSN: 2319-1163 | pISSN: 2321-7308

Power developed is higher when compared to the

conventional working model. In the previous journals the

power calculated is 441 watts in one hour but we were able

to develop 840 watts because of the recoil spring

arrangement. Further as the number of parts decreased the

cost of investment will also be decreased. This is mentioned

in the thesis of the journal and also necessary proof is given.

The general point is that the Electricity can be generated

throughout the year without any delay. Not only can be used

to lit street lamps but also for the other small scale

companies. In fact it is Easy for maintenance and no fuel

transportation problem. The reason is that there is no costly

component involved in this system.

It is said to be a pollution free power generation. Because

there is no usage of non-renewable resources like coal,

petrol, Diesel. In deed less floor area required and no

obstruction to traffic. No need of manpower during power

generation. Except that there should be some maintenance.

6. CONCLUSION

As the demand increases for electricity the new techniques

will be evolved to make effective use of all the available

energy. So this technique would help street lights and other

electric equipment which are located nearby the road to

work. As the emissions from the system are zero it will be

the most eco-friendly reliable one in the scope perception.

Another thing is that huge power is getting wasted because

of transportation to great distances but in our concept there

will be no wastage because it is located behind the highway

lamps. So, this concept is the most reliable and

modifications can be done to generate more power.

REFERENCES

Fig -5: power generated based on shaft rotation

5.

COMPARISON

WITH

[1]

CONVENTIONAL

DESIGN

The shaft used here is free to move forward because of the

shortened rack which remains in contact with the gear when

the car wheels pass over the speed breaker. Further the other

spur gears are removed because the flywheel can handle the

fluctuations. This would help our system to reduce the

number of moving parts and thereby increasing the power

generation.

The ribbon coil spring is incorporated inside the gear so, that

the gear makes more rotations which will lead to the

considerable increase in the power generation compared to

the conventional system. Another thing is that Free wheel is

placed at one end of the shaft so that backward motion of

the shaft can be restricted. And the reverse current can be

restricted which is formed when the shaft rotates in the

backward direction.

[2]

[3]

[4]

[5]

[6]

Ankita, Meenu Bala, Power Generation From Speed

Breaker International Journal Of Advance Research

In Science and Engineering 2(2), 2013.

Totaram Ingle Devanand, System of Genreating

Electricity; Patent publication No. WO 2013011519

A1, 2013.

Shakun Srivastava , Ankit Asthana, Produce

electricity by the use of speed Breakers; Journal of

Engineering Research and Studies , 2(1), 2011, 163

165.

Noor Fatima ,Jiyaul Mustafa, Production of

electricity by the method of road power generation,

International Journal of Advances in Electrical and

Electronics Engineering, 1(1), 9-14.

[2]. Aswathaman. V, Priyadharshini.M, Every Speed

Breaker Is Now A Source of Power; International

Conference on Biology, Environment and Chemistry

(IPCBEE), 1, 2011, 234 - 236.

Sharma.P.C, Non - Conventional power plants

(Public printing service, New Delhi, 2003)

_______________________________________________________________________________________

Volume: 04 Special Issue: 02 | NCIRET-2015 | Apr-2015, Available @ http://www.ijret.org

80

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

BIOGRAPHIES

Mr D.Ramana Reddy, Associate

professor working in department of

mechanical engineering, Methodist

College

of

Engineering

and

Technology, Hyderabad. He holds a

Masters degree from Indian Institute of

Technology (IIT) Madras and has over

10 years of experience in teaching and research in the field

of advanced materials processing and manufacturing.

During his career, he has involved in research activities and

published many research papers in composite materials, bio

materials and simulation of manufacturing processes in

reputed journals and conference proceedings. He has

organized two international conferences and one FDP. He

received GOLD MEDAL in GATE-04 for securing 6th

rank at all India level. He also received project/seminar

grants from various organizations. He is pursuing Ph.D. in

composite materials. He Received Letter of Appreciation

for securing 100% results consecutively for three years both

in U.G and P.G. He attended conferences in Singapore,

Malaysia and Australia and presented his research work.

_______________________________________________________________________________________

Volume: 04 Special Issue: 02 | NCIRET-2015 | Apr-2015, Available @ http://www.ijret.org

81

You might also like

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- IJCRT22A6397Document5 pagesIJCRT22A6397Mobeen AyyazNo ratings yet

- Power Generation Fromwasted Energy of Moving Vehicle Using Speed BreakerDocument4 pagesPower Generation Fromwasted Energy of Moving Vehicle Using Speed Breakerhasan bishNo ratings yet

- AbstractDocument10 pagesAbstractMUSKAN PRNNo ratings yet

- Bike-Powered Electricity GeneratorDocument10 pagesBike-Powered Electricity GeneratorAsia Pacific Journal of Multidisciplinary ResearchNo ratings yet

- The International Journal of Engineering and Science (The IJES)Document3 pagesThe International Journal of Engineering and Science (The IJES)theijes100% (1)

- Power Generation Using Speed Breaker With Auto Street Light: ISO 9001:2008 CertifiedDocument4 pagesPower Generation Using Speed Breaker With Auto Street Light: ISO 9001:2008 CertifiedChetan Sanikoppa AkkisNo ratings yet

- Electricity Generation From Speed Breakers 2016Document5 pagesElectricity Generation From Speed Breakers 2016Allen PrasadNo ratings yet

- Bike Powered Electricity GeneratorDocument27 pagesBike Powered Electricity GeneratorRamakrishna KatkamNo ratings yet

- Main Project PrsDocument40 pagesMain Project PrsSabari NathanNo ratings yet

- Every Speed Breaker Is A Source of Power: N. N. Ghuge, Arati Sathe, Varsha Patil, Anagha WarankarDocument5 pagesEvery Speed Breaker Is A Source of Power: N. N. Ghuge, Arati Sathe, Varsha Patil, Anagha WarankarMayurMahajanNo ratings yet

- Tom ProjectDocument18 pagesTom ProjectAditya SinghNo ratings yet

- Modification and Implementation of Foot Step Power Generation System in Weighting Scale of The GymDocument4 pagesModification and Implementation of Foot Step Power Generation System in Weighting Scale of The GymCrispNo ratings yet

- Regenerative Shock Absorber: Me451-Project PreliminaryDocument7 pagesRegenerative Shock Absorber: Me451-Project PreliminaryJyothish DevadasNo ratings yet

- Thesis 1Document2 pagesThesis 1Sarwer Hussain FaisalNo ratings yet

- Mini Project Report Phase 2Document21 pagesMini Project Report Phase 2bharathahsNo ratings yet

- Generation of Electricity Through Speed Breaker MechanismDocument7 pagesGeneration of Electricity Through Speed Breaker MechanismDK3002No ratings yet

- Treadmill Power Generation Cycle Project ReportDocument21 pagesTreadmill Power Generation Cycle Project ReportPrashant Karande100% (1)

- Design of Power Generation Unit Using Roller Mechanism: B. Santosh Sarma, V. Jyothi D. SudhirDocument6 pagesDesign of Power Generation Unit Using Roller Mechanism: B. Santosh Sarma, V. Jyothi D. Sudhirmd junuNo ratings yet

- Design and Analysis of Power Generating Speed BreakerDocument23 pagesDesign and Analysis of Power Generating Speed BreakerIJRASETPublicationsNo ratings yet

- MaglevDocument52 pagesMaglevDeepak GovardhaneNo ratings yet

- HAILIN Design Project 3Document10 pagesHAILIN Design Project 3BennetHailinkNo ratings yet

- Generation of Electricity Through Rack and Pinion: Laxmi Gupta Ankita BhartiDocument3 pagesGeneration of Electricity Through Rack and Pinion: Laxmi Gupta Ankita BhartisandyyansikuNo ratings yet

- Research Papers On Power Generation From Speed BreakerDocument6 pagesResearch Papers On Power Generation From Speed Breakerc9rvcwhfNo ratings yet

- Extra Project ReserchDocument5 pagesExtra Project Reserchsoham thumbreNo ratings yet

- 25IJAERS 06202026 Designand PDFDocument8 pages25IJAERS 06202026 Designand PDFIJAERS JOURNALNo ratings yet

- Gym Power Station Turning Workout Into EDocument3 pagesGym Power Station Turning Workout Into EEternal TuneNo ratings yet

- Power Generation by Foot Steps Using Rack and Pinion ArrangementDocument5 pagesPower Generation by Foot Steps Using Rack and Pinion ArrangementVignesh RvpNo ratings yet

- Power Generation by Using Railway Track: ISSN: 2455-2631 © March 2020 IJSDR - Volume 5, Issue 3Document4 pagesPower Generation by Using Railway Track: ISSN: 2455-2631 © March 2020 IJSDR - Volume 5, Issue 3ChanduNo ratings yet

- Power Generation Through Speed BreakersDocument22 pagesPower Generation Through Speed BreakersSaikumar MysaNo ratings yet

- Generation of Electricity Using GravityDocument6 pagesGeneration of Electricity Using GravityIAEME Publication100% (1)

- Drilling Machine ReportDocument38 pagesDrilling Machine ReportPraveen Mathias79% (14)

- ScienceFare SpeedBreakerDocument11 pagesScienceFare SpeedBreakerYaser Ali TariqNo ratings yet

- Green Vehicle: Venkatesh Janakiraman, J.Sam Jeba Kumar, Tejasvi Singh AnejaDocument5 pagesGreen Vehicle: Venkatesh Janakiraman, J.Sam Jeba Kumar, Tejasvi Singh AnejaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Design and Construction of A Speed Bump Power GeneratorDocument5 pagesDesign and Construction of A Speed Bump Power GeneratorramaNo ratings yet

- Production of Electricity by The Method of Road Power GenerationDocument5 pagesProduction of Electricity by The Method of Road Power GenerationUsama RiazNo ratings yet

- Forearms Power GenerationDocument25 pagesForearms Power GenerationM.t.s.k.tejeshNo ratings yet

- Fluid 1Document8 pagesFluid 1Kaneki SSSNo ratings yet

- 1013 2519 1 SMDocument12 pages1013 2519 1 SMmuhammad ivanNo ratings yet

- Ijeee Simulink ModelDocument9 pagesIjeee Simulink ModelSurya KiranNo ratings yet

- Irjet V4i4595 PDFDocument3 pagesIrjet V4i4595 PDFUjash VasaniNo ratings yet

- Free Energy Generation by Using FlywheelDocument8 pagesFree Energy Generation by Using FlywheelWael Abdelgadir AbdelazizNo ratings yet

- 1.1 Research OverviewDocument4 pages1.1 Research OverviewmattdaehliNo ratings yet

- APJMR 2015-3-172 Bike Powered Electricity GeneratorDocument10 pagesAPJMR 2015-3-172 Bike Powered Electricity Generatorsuper meal coleenNo ratings yet

- Design and Testing of Regenerative Suspension SystemDocument6 pagesDesign and Testing of Regenerative Suspension SystemSayed azharNo ratings yet

- PR20211003 - Prathmesh KakdeDocument5 pagesPR20211003 - Prathmesh KakdePrathmesh KakadeNo ratings yet

- Using Bicycle For Power GenerationDocument6 pagesUsing Bicycle For Power GenerationMuhammad FurqanNo ratings yet

- Fabrication Study On The Effect of Double Sprocket Mechanism in BicycleDocument4 pagesFabrication Study On The Effect of Double Sprocket Mechanism in BicycleTJPRC PublicationsNo ratings yet

- Review of Free Energy GeneratorDocument7 pagesReview of Free Energy GeneratorAmode OlamideNo ratings yet

- Power Generation by Shock AbsorberDocument8 pagesPower Generation by Shock AbsorberIJRASETPublicationsNo ratings yet

- Kinetic RoadsDocument16 pagesKinetic RoadssethyankitaraniNo ratings yet

- Regen Rat IveDocument35 pagesRegen Rat IveEr Dinesh TambeNo ratings yet

- Circular Rotor Windmill (Wind Turbine)Document105 pagesCircular Rotor Windmill (Wind Turbine)SanjaySherikarNo ratings yet

- Modelling and Analysis of Power Generating Jump BoxDocument8 pagesModelling and Analysis of Power Generating Jump Boxshivam rathorNo ratings yet

- Design and Feasibility Analysis of A Self-Induction Motor-Generator SystemDocument7 pagesDesign and Feasibility Analysis of A Self-Induction Motor-Generator SystemLuc BerNo ratings yet

- Flywheel Based Mechanical BatteryDocument2 pagesFlywheel Based Mechanical BatterySaksham TanejaNo ratings yet

- Guia Ilagan Sauz Balinado Pedal Power GenerationDocument5 pagesGuia Ilagan Sauz Balinado Pedal Power Generationyifiyyfyi bhvxhddfiNo ratings yet

- Energy Production Using Speed BumpsDocument12 pagesEnergy Production Using Speed BumpsBilal El-Sayed Ali100% (1)

- Solar Irrigation System Using Brush Less DC Motor: Renu Singh, Ahmed Sharique Anees, Devang TyagiDocument5 pagesSolar Irrigation System Using Brush Less DC Motor: Renu Singh, Ahmed Sharique Anees, Devang TyagiEdamEdamNo ratings yet

- Wind Driven Mobile Charging of Automobile BatteryDocument7 pagesWind Driven Mobile Charging of Automobile Batterysuraj dhulannavarNo ratings yet

- Visvesvaraya Technological University BelgaumDocument2 pagesVisvesvaraya Technological University Belgaumsuraj dhulannavarNo ratings yet

- 1:1 XXX A1: Toshavi PCDocument1 page1:1 XXX A1: Toshavi PCsuraj dhulannavarNo ratings yet

- FrameDocument1 pageFramesuraj dhulannavarNo ratings yet

- Left View Scale: 1:2: 1:1 XXX A0Document1 pageLeft View Scale: 1:2: 1:1 XXX A0suraj dhulannavarNo ratings yet

- D e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N eDocument13 pagesD e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N esuraj dhulannavarNo ratings yet

- M.H.Saboo Siddik PolytechnicDocument5 pagesM.H.Saboo Siddik Polytechnicsuraj dhulannavarNo ratings yet

- 1:1 XXX A1: Toshavi 5/3/2016Document1 page1:1 XXX A1: Toshavi 5/3/2016suraj dhulannavarNo ratings yet

- 1:1 XXX A4: Designed By: DateDocument1 page1:1 XXX A4: Designed By: Datesuraj dhulannavarNo ratings yet

- FrameDocument1 pageFramesuraj dhulannavarNo ratings yet

- WWW Mechengg Net 2015 09 Design and Fabrication of InjectionDocument17 pagesWWW Mechengg Net 2015 09 Design and Fabrication of Injectionsuraj dhulannavarNo ratings yet

- 1:1 XXX A1: Designed By: DateDocument1 page1:1 XXX A1: Designed By: Datesuraj dhulannavarNo ratings yet

- 1:1 XXX A4: Toshavi 4/8/2016Document1 page1:1 XXX A4: Toshavi 4/8/2016suraj dhulannavarNo ratings yet

- Grundfosliterature 3666021Document7 pagesGrundfosliterature 3666021Agustín Borbor LimónNo ratings yet

- Flowmeters MonitorsDocument12 pagesFlowmeters MonitorsDaniel MarNo ratings yet

- Tac4598 - 3350KW - Instruction ManualDocument48 pagesTac4598 - 3350KW - Instruction ManualMiguel Angel RodriguezNo ratings yet

- Operator and Maintenance Manual Spare Parts Lists Included: Serial Number: 1016387 & Up Printed in CanadaDocument47 pagesOperator and Maintenance Manual Spare Parts Lists Included: Serial Number: 1016387 & Up Printed in CanadaDavid OrtizNo ratings yet

- Toaz - Info Astm d4543 Preparing Rock Core Specimens PRDocument4 pagesToaz - Info Astm d4543 Preparing Rock Core Specimens PRAdriel senciaNo ratings yet

- Solution ChemistryDocument27 pagesSolution ChemistryZarahbeth Claire G. ArcederaNo ratings yet

- Class 11 Economic Competency Based Question Chapter-Collection of DataDocument18 pagesClass 11 Economic Competency Based Question Chapter-Collection of DataKabri VagelaNo ratings yet

- Kayser Shambaugh (1991)Document15 pagesKayser Shambaugh (1991)Process LibraryNo ratings yet

- 4.11.-Eaton CCM Freedom - Nema Contactor and StartersDocument37 pages4.11.-Eaton CCM Freedom - Nema Contactor and Startersmartinel noob y baty mozNo ratings yet

- On An Elliptic Equation of P Kirchhoff Type Via Variational MethodsDocument15 pagesOn An Elliptic Equation of P Kirchhoff Type Via Variational MethodsAdal ZaidNo ratings yet

- Gudny Jonsdottir How To Use The Posture and PoDocument11 pagesGudny Jonsdottir How To Use The Posture and PoyocondaariasNo ratings yet

- Mm204E Thermodynamics-Ii Second Midterm Exam: Q1 Q2 Q3 Q4 Q5 Total /20 /20 /20 /20 /20 /100Document2 pagesMm204E Thermodynamics-Ii Second Midterm Exam: Q1 Q2 Q3 Q4 Q5 Total /20 /20 /20 /20 /20 /100Ali DoğruNo ratings yet

- Heat and Mass Transfer: Haramay University Haramaya Institute of TechnologyDocument50 pagesHeat and Mass Transfer: Haramay University Haramaya Institute of TechnologyworkisaNo ratings yet

- ch25 PDFDocument21 pagesch25 PDFRodrigo S QuirinoNo ratings yet

- January 2004 MS - M1 EdexcelDocument4 pagesJanuary 2004 MS - M1 EdexcelKollol KolllolNo ratings yet

- Geometric Stiffness and P-Delta EffectsDocument14 pagesGeometric Stiffness and P-Delta EffectsabdallahNo ratings yet

- Atoms, Elements and Compounds g7Document40 pagesAtoms, Elements and Compounds g7Menaga A/P IlangkovanNo ratings yet

- Transition and Inner Transition Metal Chemistry: CML 524Document57 pagesTransition and Inner Transition Metal Chemistry: CML 524Rahul MalikNo ratings yet

- VC.02 Perpendicularity Literacy: S S T XDocument7 pagesVC.02 Perpendicularity Literacy: S S T XSri RaghavanNo ratings yet

- Mathew Et Al. - 2015 - PHYSIOLOGICAL IMPACT OF PHYTO-SYNTHESIZED ANANAS CDocument17 pagesMathew Et Al. - 2015 - PHYSIOLOGICAL IMPACT OF PHYTO-SYNTHESIZED ANANAS CNithin VijayakumarNo ratings yet

- Hamaker H. C., Physica IV. 10, 1058 (1937)Document15 pagesHamaker H. C., Physica IV. 10, 1058 (1937)sk8sudNo ratings yet

- TN12 PDFDocument10 pagesTN12 PDFRamon LopezNo ratings yet

- Applications of The Definite Integral in Geometry, Science, and EngineeringDocument9 pagesApplications of The Definite Integral in Geometry, Science, and EngineeringZain MohammedNo ratings yet

- Simple Explicit Equations For Transient Heat Conduction in Finite SolidsDocument11 pagesSimple Explicit Equations For Transient Heat Conduction in Finite SolidsQuimica Grupo 3No ratings yet

- November 2021 Ce Board Exam Santos 1: Eview NnovationsDocument3 pagesNovember 2021 Ce Board Exam Santos 1: Eview NnovationsamberNo ratings yet

- Principle of UV SpectrosDocument10 pagesPrinciple of UV SpectrosHesham AlsoghierNo ratings yet

- Lecture 4B Year 3-Sounding - Depth DeterminationDocument19 pagesLecture 4B Year 3-Sounding - Depth Determinationlegendibra8No ratings yet

- 7) EquilibriumDocument3 pages7) EquilibriumB9 Adi JainNo ratings yet

- tp2 Vom-1Document4 pagestp2 Vom-1HoussamdineNo ratings yet

- Reflection of Light Total Internal Reflection Refraction of LightDocument1 pageReflection of Light Total Internal Reflection Refraction of LightGaming X YT100% (1)