Professional Documents

Culture Documents

Chemical Safety Checklist

Uploaded by

Pillai Sreejith100%(10)100% found this document useful (10 votes)

3K views3 pagesThis checklist could be used by safety engineers for process plants and is prepared based on practical safety auditing experience of process plants.

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis checklist could be used by safety engineers for process plants and is prepared based on practical safety auditing experience of process plants.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(10)100% found this document useful (10 votes)

3K views3 pagesChemical Safety Checklist

Uploaded by

Pillai SreejithThis checklist could be used by safety engineers for process plants and is prepared based on practical safety auditing experience of process plants.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

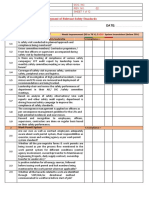

CHEMICAL PROCESS INSTRUMENTATION

CARSL Safety Audit Checklist /Hazard Guidline

Pillai Sreejith

Serial CPI Checkpoint Hazard Ranking

No.

1 Are critical ESD / trip loops identified?

2 Was HAZOP carried out after plant / unit

modification / addition?

3 Last HAZOP recommendations

implementation status? Percentage of

implementation.

4 Is the above a MoC procedure requirement

and is this defined?

5 Isolation valves affecting process

measurement kept locked?

6 Are the maintenance schedules for critical

loops made separately?

7 Are all instruments tagged / instrument tag

number engraved with service details, etc?

8 Is physical inspections carried out for critical

field instruments, including wiring

terminations?

9 Is review of redundancy level determined

based on process safety?

10 Is the collective fail-safeness of the system

ensured?

11 Surge protection for field instruments in

place?

12 Specific gravity of stored liquid considered

while Level switch / indicator calibration?

13 EX ‘i’ type on-line field calibrators used in

flammable areas?

14 Risk-Based preventive maintenance

schedules arrived at based on MTBF / MTBR

failure rates and event probabilities?

15 How periodic is the optometric tests done for

instrument technicians?

16 Are all critical trip loop separately identified

(at wiring terminations, PLC cabinets, etc)?

17 Are the critical ESD loop cables provided

with passive fire protection measures?

18 Are the ESD cables exposed to excessive

Chemical Instrumentation Safety / Checklist / Sreejith

heat conditions (near furnace, boiler, etc.) or

passing under gas lines, steam lines/traps,

high-pressure vessels, etc?

19 Any plans to adopt IEC 61508 or SIL levels?

20 Field instruments for corrosive chemicals –

internally coated?

21 Is periodic checking of control valve

internals for erosion, proper functioning, etc.

(depending on flow rate, type of chemical,

etc.) carried out?

22 Effects of extreme atmospheric conditions on

instrumentation (accuracy, etc.)?

23 Routing of ESD cables in two different routes

carried out considering potential failures in

mind?

24 Change of critical parameter settings / over-

ride facility at the DCS console? Password

protection, etc.

25 Calibration periodicity of master instruments

used in the calibration room defined and

carried out?

26 Positioning of critical instruments (near

vents, drains, PSVs, flanges, etc.)

27 Is all field instrumentation approachable

without obstructions?

28 Maintenance schedules of UPS, Battery

banks, PLC systems, DCS consoles, etc.

29 Is ROL (Re-Order Level) defined &

maintained for critical instruments, I/O

modules, etc.?

30 Review of logic for loop diagrams as part of

MoC carried out?

31 Are all changes reflected in the as-built

drawings?

32 Are all field instruments appropriate to the

type of atmospheric conditions exposed

(flameproof, intrinsically safe, IP /NEMA)?

33 Is review of response time between

instruments and PLC /DCS system reviewed

periodically?

34 DCS / SCADA software along with the set

parameter detail stored in a separate room in

a fire safe cabinet?

Chemical Instrumentation Safety / Checklist / Sreejith

Hazard Rank Indicated as Checkpoint Interpretation /

Guideline

High RH Critical issue. Immediate Corrective

Action may be suggested

Medium RM Comparatively less critical or medium

hazard category. Corrective Action is

required at the next available

opportunity

Low RL Not critical or low hazard level.

Adherence to these recommendations

would be helpful in improving the risk

levels in future.

Contact:

Pillai Sreejith

pillai_sreejith@hotmail.com

Chemical Instrumentation Safety / Checklist / Sreejith

You might also like

- 4.4.3.3 Data and Trend AnalysisDocument6 pages4.4.3.3 Data and Trend AnalysisIndermohan MehtaNo ratings yet

- Monorails Installation Five Why ReportDocument1 pageMonorails Installation Five Why ReporttanoycometNo ratings yet

- Near Miss Reporting and ManagementDocument28 pagesNear Miss Reporting and ManagementWahyu ArdaniNo ratings yet

- South Pars Permit System ExplainedDocument25 pagesSouth Pars Permit System ExplainedAntonne E. PhillipNo ratings yet

- Health & Safety Audits: E-BookDocument12 pagesHealth & Safety Audits: E-BookSarmad Hussain100% (2)

- Compressed Gas Cylinder StorageDocument4 pagesCompressed Gas Cylinder StorageNoel WengNo ratings yet

- PPE MatrixDocument1 pagePPE MatrixcaptainphihungNo ratings yet

- Safety ObservationDocument48 pagesSafety Observationpooloo70100% (1)

- Behavior-Based Safety For SupervisorsDocument72 pagesBehavior-Based Safety For SupervisorsS Anantha Prasanna Venkatesh94% (16)

- Safety Department Checklist FormatDocument32 pagesSafety Department Checklist Formatrockyvinoo100% (18)

- Behavior Based SafetyDocument27 pagesBehavior Based SafetySuresh KumarNo ratings yet

- Emirates ERM Abu Dhabi Process Safety Management Training MethodologyDocument5 pagesEmirates ERM Abu Dhabi Process Safety Management Training MethodologyShailendraNo ratings yet

- Monthly HSE Report April .2013Document8 pagesMonthly HSE Report April .2013sakthivelNo ratings yet

- Chemical and MSDS RegisterDocument5 pagesChemical and MSDS RegisterRhen HalfferzrheinsNo ratings yet

- Scaffold Safety ProcedureDocument4 pagesScaffold Safety ProcedurePraful E. PawarNo ratings yet

- HSE 201 Safety Managment & Engineering - EbookDocument88 pagesHSE 201 Safety Managment & Engineering - EbookNitish RajNo ratings yet

- Safety Anglo Hindi 20tlsDocument22 pagesSafety Anglo Hindi 20tlsliewananda91% (11)

- Process Safety Management Standard Audit Protocol PDFDocument19 pagesProcess Safety Management Standard Audit Protocol PDFJosé Manuel García MartínNo ratings yet

- NEBOSH HSE Certificate in Process Safety ManagementDocument50 pagesNEBOSH HSE Certificate in Process Safety ManagementVicky SinghNo ratings yet

- Site ObservationDocument8 pagesSite ObservationAzhari KlewanNo ratings yet

- COSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsDocument2 pagesCOSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsPaulSwinbankNo ratings yet

- Hsems 8 ElementsDocument86 pagesHsems 8 ElementsIndermohan Mehta100% (2)

- Hse Policy StatementDocument1 pageHse Policy StatementVICTORNo ratings yet

- Understanding Workplace Accidents & Safety TerminologiesDocument34 pagesUnderstanding Workplace Accidents & Safety Terminologiesadel santosNo ratings yet

- Chemical SafetyDocument26 pagesChemical Safetysuryavenkat_79No ratings yet

- Fire Warden Duties and ResponsibilitiesDocument1 pageFire Warden Duties and ResponsibilitiesrthomsanNo ratings yet

- Mock DrillDocument18 pagesMock DrillfaisalnadimNo ratings yet

- NEBOSH Certificate in Process Safety ManagementDocument17 pagesNEBOSH Certificate in Process Safety ManagementAnas KelothNo ratings yet

- 7 Important Step of Process Hazard Analysis - Process SafetyDocument8 pages7 Important Step of Process Hazard Analysis - Process SafetypritiNo ratings yet

- HSE Committee Meeting Rev1Document25 pagesHSE Committee Meeting Rev1Khaled Ismail100% (1)

- Weekly HSE Report Feb .2013Document12 pagesWeekly HSE Report Feb .2013sakthivelNo ratings yet

- What Is Process Safety EngineeringDocument3 pagesWhat Is Process Safety EngineeringCLPWC100% (11)

- Weekly excavator checklist template for construction projectsDocument4 pagesWeekly excavator checklist template for construction projectssamiran RouthNo ratings yet

- Fire Safety Mock Drill ContentsDocument11 pagesFire Safety Mock Drill ContentsBinoy Gopinathan50% (2)

- Safety Resume Without Certificate PDFDocument4 pagesSafety Resume Without Certificate PDFSAFETY RNo ratings yet

- Behavior Based Safety ProgramsDocument27 pagesBehavior Based Safety ProgramsEdy Permana Tadjudin100% (2)

- CONTROL SHEETS & FORMS permit guideDocument3 pagesCONTROL SHEETS & FORMS permit guideHenry WoartNo ratings yet

- Lockout Tagout Permit FormDocument9 pagesLockout Tagout Permit FormJoey GNo ratings yet

- HSE RegulationsDocument60 pagesHSE RegulationsChandrasekhar SonarNo ratings yet

- Near MissDocument10 pagesNear Misspradeepagarwal62No ratings yet

- ASSE 04 Process Safety ManagementDocument37 pagesASSE 04 Process Safety ManagementCarlos Cueva GallegosNo ratings yet

- Developing HSE ExcellenceDocument26 pagesDeveloping HSE Excellenceantonmp66100% (1)

- A New Framework For HSE Performance Measurement and Monitoring PDFDocument11 pagesA New Framework For HSE Performance Measurement and Monitoring PDFwhite heart green mindNo ratings yet

- Check Hard Hat Expiry Dates Before UseDocument1 pageCheck Hard Hat Expiry Dates Before UsetimbulNo ratings yet

- JSA IndexDocument2 pagesJSA IndexDie HArdNo ratings yet

- HSE Hot Work Permit ProcedureDocument2 pagesHSE Hot Work Permit ProcedureHSE S4No ratings yet

- Behavior Based Safety 1Document67 pagesBehavior Based Safety 1xcalade82100% (1)

- Office Risk Assessment Rev 1Document5 pagesOffice Risk Assessment Rev 1Abraham BarbeytoNo ratings yet

- OSHMS Audit Interview QuestionsDocument76 pagesOSHMS Audit Interview Questionseliasox123100% (1)

- Presentation & Training - HSE Behavior Based SafetyDocument26 pagesPresentation & Training - HSE Behavior Based SafetyHimawan Sutardjo100% (6)

- Workplace Health and Safety Assessment FormDocument9 pagesWorkplace Health and Safety Assessment Forms9n9No ratings yet

- Process and Plant Safety HazardsDocument71 pagesProcess and Plant Safety Hazardsapi-2614241788% (17)

- Hse Orientation Training & TopicsDocument2 pagesHse Orientation Training & TopicsGanga Daran100% (1)

- Safety STD Audit Check ListDocument12 pagesSafety STD Audit Check Listfaraz ahmed0% (1)

- 0 - Markov Paper ExampleDocument4 pages0 - Markov Paper ExampleNishantAbrahamNo ratings yet

- 5 - DHHS Adjusting Instructions PDFDocument39 pages5 - DHHS Adjusting Instructions PDFToddNo ratings yet

- Major EMOC RA and Controls ChecklistDocument3 pagesMajor EMOC RA and Controls Checklisttejcd1234No ratings yet

- Technical Integrity Guidance NoteDocument4 pagesTechnical Integrity Guidance NotePillai Sreejith100% (1)

- Managing OE Operationalization ChallengesDocument2 pagesManaging OE Operationalization ChallengesPillai Sreejith100% (1)

- Asset Integrity FAQ 2Document4 pagesAsset Integrity FAQ 2Pillai SreejithNo ratings yet

- Process Safety Master Class I Sreejith Pillai 2018Document22 pagesProcess Safety Master Class I Sreejith Pillai 2018Pillai Sreejith100% (1)

- HAZOP Pre ConcessionsDocument1 pageHAZOP Pre ConcessionsPillai Sreejith100% (1)

- Bow Ties and Offshore Safety StudiesDocument3 pagesBow Ties and Offshore Safety StudiesPillai Sreejith100% (7)

- Offshore Technical Safety FAQDocument12 pagesOffshore Technical Safety FAQPillai Sreejith100% (15)

- Offshore Safety Performance ManagementDocument7 pagesOffshore Safety Performance ManagementPillai Sreejith100% (9)

- Explosion Riks-Battery RoomsDocument6 pagesExplosion Riks-Battery RoomsPillai Sreejith100% (12)

- Asset Integrity Performance Management FAQDocument5 pagesAsset Integrity Performance Management FAQPillai Sreejith100% (1)

- Offshore QRA ChecklistDocument2 pagesOffshore QRA ChecklistPillai Sreejith100% (5)

- Insights Into ESSADocument7 pagesInsights Into ESSAPillai Sreejith100% (2)

- Sample Electrical Safety Training ProgrammeDocument2 pagesSample Electrical Safety Training ProgrammePillai Sreejith100% (2)

- Electrical Thermal ImagingDocument6 pagesElectrical Thermal ImagingPillai Sreejith90% (10)

- 25 Major Power Plant LossesDocument28 pages25 Major Power Plant LossesPillai Sreejith100% (31)

- SafetyPerceptionSurvey-A Case StudyDocument5 pagesSafetyPerceptionSurvey-A Case StudyPillai SreejithNo ratings yet

- Risk Management-A Balancing ActDocument19 pagesRisk Management-A Balancing ActPillai Sreejith100% (13)

- Work at Height SurveyDocument5 pagesWork at Height SurveyPillai Sreejith100% (3)

- Mumbai Offshore Platform FireDocument18 pagesMumbai Offshore Platform FirePillai Sreejith100% (18)

- Offshore Safety Case TrainingDocument114 pagesOffshore Safety Case TrainingPillai Sreejith100% (131)

- Piper Alpha DiscussionDocument8 pagesPiper Alpha DiscussionPillai Sreejith100% (7)

- Syndicate Excercise Hazardous Area ClassificationDocument6 pagesSyndicate Excercise Hazardous Area ClassificationPillai Sreejith100% (3)

- QUIZ-Hazardous Area ClassificationDocument2 pagesQUIZ-Hazardous Area ClassificationPillai Sreejith100% (4)

- Piper Alpha Case StudyDocument21 pagesPiper Alpha Case StudyPillai Sreejith100% (38)

- BP Texas ExplosionDocument24 pagesBP Texas ExplosionPillai Sreejith92% (12)

- Safety Audit Observations & RecommmendationsDocument41 pagesSafety Audit Observations & RecommmendationsPillai Sreejith100% (36)

- Electrical Engineer EmployabilityDocument30 pagesElectrical Engineer EmployabilityPillai Sreejith96% (27)

- Personal Lightning SafetyDocument25 pagesPersonal Lightning SafetyPillai Sreejith100% (7)

- Lightning Risk NoteDocument7 pagesLightning Risk NotePillai Sreejith100% (5)

- Major 50 Fires & ExplosionsDocument53 pagesMajor 50 Fires & ExplosionsPillai Sreejith100% (11)

- Jurnal 1-S2.0-S1364032121001350-MainDocument10 pagesJurnal 1-S2.0-S1364032121001350-MainRizka Yulia ShafiraNo ratings yet

- AutomationX GeneralDocument16 pagesAutomationX GeneralAbdul-Moniem Al-HumoudNo ratings yet

- Design and Validation of Distributed Control With Decentralized Intelligence in Process Industries: A SurveyDocument6 pagesDesign and Validation of Distributed Control With Decentralized Intelligence in Process Industries: A SurveyjosethompsonNo ratings yet

- Contents 01 A Leader in Process Automation 09 Inplant Total Solution 13 Typical Projects 19 Corporate Social Responsibility 20 Where To Find UsDocument12 pagesContents 01 A Leader in Process Automation 09 Inplant Total Solution 13 Typical Projects 19 Corporate Social Responsibility 20 Where To Find UsNauman ZafarNo ratings yet

- Curriculum Vitae: Kalpesh R. Chauhan (B.E in Instrumentation and Control)Document8 pagesCurriculum Vitae: Kalpesh R. Chauhan (B.E in Instrumentation and Control)Danish HNo ratings yet

- Control Engineering R S SHEHUDocument50 pagesControl Engineering R S SHEHUMOSHOOD IBRAHIMNo ratings yet

- Yokogawa Universal IODocument6 pagesYokogawa Universal IOsinambeladavidNo ratings yet

- Concrete Batching PlantsDocument6 pagesConcrete Batching PlantsHunaid Elkamushi100% (1)

- Instrument Identification Abbreviations & Letter Symbols Line LegendDocument1 pageInstrument Identification Abbreviations & Letter Symbols Line LegendVocem LuxNo ratings yet

- 1.0 Introduction To Distributed Control SystemDocument18 pages1.0 Introduction To Distributed Control SystemLalola Hahoha100% (2)

- S10332300-3001 - 1 (1) General Instrument and Control SystemDocument30 pagesS10332300-3001 - 1 (1) General Instrument and Control Systemappril26No ratings yet

- SETPOINT Machinery Protection System Overview Data SheetDocument32 pagesSETPOINT Machinery Protection System Overview Data SheetBrickvilleNo ratings yet

- Flyer BlueLine Rev-05 enDocument8 pagesFlyer BlueLine Rev-05 enajaysapruNo ratings yet

- Field Control SystemDocument12 pagesField Control SystemLinh Vo TanNo ratings yet

- HOLLiAS MACS V6.5 User Manual 1 Software InstallationDocument121 pagesHOLLiAS MACS V6.5 User Manual 1 Software InstallationSidra BibiNo ratings yet

- ETP - STP DigitalizationDocument8 pagesETP - STP DigitalizationHarisomNo ratings yet

- 998-22735626 - Software Tools - GMA - BrochureDocument20 pages998-22735626 - Software Tools - GMA - Brochureabderraoufdob2No ratings yet

- SAP Manufacturing Integration & Intelligence Certification OverviewDocument10 pagesSAP Manufacturing Integration & Intelligence Certification OverviewNhâm NhiNo ratings yet

- Electrical Instrument Interface PhilosophyDocument11 pagesElectrical Instrument Interface Philosophyiviji81No ratings yet

- Discrete Controller Synthesis Applied To Smart GreenhouseDocument9 pagesDiscrete Controller Synthesis Applied To Smart GreenhouseflaviorochaavilaNo ratings yet

- Distributed Control SystemDocument31 pagesDistributed Control SystemAbdullah BarkaNo ratings yet

- Materials System SpecificationDocument20 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- DEP Metering For Liquid Hydrocarbon (00000002)Document44 pagesDEP Metering For Liquid Hydrocarbon (00000002)Chijioke Obi100% (1)

- Manual 2CDC135013D0202Document158 pagesManual 2CDC135013D0202Juan TorresNo ratings yet

- TPL OGH PresentationDocument35 pagesTPL OGH PresentationGurnam Singh100% (1)

- Field Control Processor 270 (FCP270) User's Guide: I/A Series SystemDocument120 pagesField Control Processor 270 (FCP270) User's Guide: I/A Series SystemAnonymous u0wETydFNo ratings yet

- Steam Turbine - Various ApplicationsDocument3 pagesSteam Turbine - Various ApplicationsSyed Mohammad NaveedNo ratings yet

- Instrument Design CriteriaDocument41 pagesInstrument Design CriteriasanthaNo ratings yet

- Citectscada Technical Overview PDFDocument64 pagesCitectscada Technical Overview PDFandrewfthNo ratings yet

- Dcs Control SystemsDocument33 pagesDcs Control SystemsSultan SikandarNo ratings yet