Professional Documents

Culture Documents

ASTM E407-2007 Standard Practice for Microetching Metals and Alloys - 百度文库 PDF

Uploaded by

karthikkandaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E407-2007 Standard Practice for Microetching Metals and Alloys - 百度文库 PDF

Uploaded by

karthikkandaCopyright:

Available Formats

ASTME4072007StandardPracticeforMicroetchingMetalsandAlloys_

10/23/2015

3

ASTME407-2007StandardPracticeforMicroetchingMetalsandAlloys

DOC

PPT

TXT

APP

XLS

20

VIP

50

...

ASTME407-2007StandardPracticeforMicroetchingMet

alsandAlloys

yhphbdz 2010-12-06

(31)

5154

86

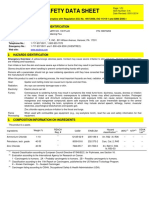

Designation: E 407 07

Standard Practice for

Microetching Metals and Alloys1

This standard is issued under the xed designation E 407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

deposition of a dielectric compound (such as ZnTe, ZnSe,

TiO2, ZnS or ZnO) with a known index of refraction, generally

due to light interference effects (also known as the Pepperhoff

method).

1. Scope

1.1 This practice covers chemical solutions and procedures

to be used in etching metals and alloys for microscopic

examination. Safety precautions and miscellaneous information are also included.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specic

cautionary statements, see 6.1 and Table 2.

4. Summary of Practice

4.1 Table 1 is an alphabetical listing of the metals (including rare earths) and their alloys for which etching information

is available. For each metal and alloy, one or more etchant

numbers and their corresponding use is indicated. Alloys are

listed as a group or series when one or more etchants are

common to the group or series. Specic alloys are listed only

when necessary. When more than one etchant number is given

for a particular use, they are usually given in order of

preference. The numbers of electrolytic etchants are italicized

to differentiate them from nonelectrolytic etchants.

4.2 Table 2 is a numerical listing of all the etchants referenced in Table 1and includes the composition and general

VIP,

1 /23

3

procedure

to be followed

for each etchant.

4.3 To use the tables, look up the metal or alloy of interest

in Table 1 and note the etchant numbers corresponding to the

results desired. The etchant composition and procedure is then

located in Table 2corresponding to the etchant number.

2. Referenced Documents

2.1 ASTM Standards: 2

D 71193

Specication

for Reagent

Water

E

Terminology

Relating

to Metallography

E 2014 Guide on Metallographic Laboratory Safety

3. Terminology

3.1 Denitions:

3.1.1 For denition of terms used in this standard, see

Terminology E 7.

3.2 Denitions of Terms Specic to This Standard:

3.2.1 tint

immersion

etchant that

producesincolor

etchan

contrast,

often

selective

to a particular

constituent

the

microstructure, due to a thin oxide, sulde, molybdate, chromate or elemental selenium lm on the polished surface that

reveals the structure due to variations in light interference

effects as a function of the lm thickness (also called a 88stain

etch).

3.2.2 vapor-deposition interference layer method a technique for producing enhanced contrast between microstructural

4.4 If the

common

of an etchant

is known

(Marbles,

Vilellas,

etc.),

and itname

is desired

to know

the composition,

Table 3contains an alphabetical listing of etchant names, each

coded with a number corresponding to the etchant composition

given in Table 2.

constituents, usually in color, by thin lms formed by vacuum

Solutions

are listed to highlight phases present in most major

alloy systems.

ASTMD1535-08

ASTME164-03S

ASTME308-96

ASTMG1-03-ES

ASTME4072007

ASTME3_2001

ASTM+E407-99+

ASTME340-2002

ASTME3-11201

5. Signicance and Use

5.1 This practice lists recommended methods and solutions

for the etching of specimens for metallographic examination.

6. Safety Precautions

6.1 Before using or mixing any chemicals, all product labels

and pertinent Material Safety Data Sheets (MSDS) should be

read and understood concerning all of the hazards and safety

precautions to be observed. Users should be aware of the type

of hazards involved in the use of all chemicals used, including

1

This practice is under the jurisdiction of ASTM Committee E04 on Metallography and is the direct responsibility of Subcommittee E04.01 on Specimen

Preparation.

Current edition approved May 1, 2007. Published May 2007. Originally

approved in 1999. Last previous edition approved in 1999 as E 40799

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on

the ASTM website.

those hazards that are immediate, long-term, visible, invisible,

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 194282959, United States.

``,,,,,,```,`,,``,``,,`,,,```,,`,,`,`,,`

http://wenku.baidu.com/view/0c7eadea19e8b8f67c1cb9fc.html

1/4

10/23/2015

ASTME4072007StandardPracticeforMicroetchingMetalsandAlloys_

E 407 07

and with or without odors. See Guide E 2014 on Metallographic Laboratory Safety for additional information on;

cream or other appropriate HF neutralizing agent be available

for use if direct skin contact of the etchant occurs.

Chemical Safety, Electrolytic Polishing/Etching and Laboratory Ventilation/Fume Hoods.

6.1.1 Consult the product labels and MSDSs for recommendations concerning proper protective clothing.

6.1.2 All chemicals are potentially dangerous. All persons

using any etchants should be thoroughly familiar with all of the

chemicals involved and the proper procedure for handling,

mixing, and disposing of each chemical, as well as any

combinations of those chemicals. This includes being familiar

with the federal, state, and local regulations governing the

handling, storage, and disposal of these chemical etchants.

6.2 Some basic suggestions for the handling and disposing

of etchants and their ingredients are as follows:

6.2.1 When pouring, mixing, or etching, always use the

proper protective equipment, (glasses, gloves, apron, etc.) and

it is strongly recommended to always work under a certied

and tested fume hood. This is imperative with etchants that

6.2.8 The EPA states that human studies have clearly

established that inhaled chromium (VI) is a human carcinogen,

resulting in an increased risk of lung cancer. Animal studies

have shown chromium (VI) to cause lung tumors via inhalation

exposure. Therefore, when working with Cr(VI) compounds

such as K2Cr2O7 and CrO3 always use a certied and tested

fume hood. Additional information can be obtained at the EPA

website3.

6.2.9 For safety in transportation, picric acid is distributed

by the manufacturer wet with greater than 30% water. Care

must be taken to keep it moist because dry picric acid is shock

sensitive and highly explosive especially when it is combined

with metals such as copper, lead, zinc, and iron. It will also

react with alkaline materials including plaster and concrete to

form explosive compounds. It should be purchased in small

quantities suitable for use in six to twelve months and checked

periodically for lack of hydration. Distilled water may be

added to maintain hydration, It must only be stored in plastic or

glass bottles with nonmetallic lids. If dried particles are noted

on or near the lid, submerge the bottle in water to re-hydrate

them before opening. It is recommended that any bottle of

picric acid that appears dry or is of unknown vintage not be

opened and that proper emergency personnel be notied.

6.2.10 Wipe up or ush any and all spills, no matter how

minute in nature.

6.2.11 Properly dispose of all solutions that are not identi-

give off noxious

odors

or toxic vapors

thatsolutions

may accumulate

or

become

explosive.

In particular,

note that

containing

perchloric acid must be used in an exclusive hood equipped

with a wash down feature to avoid accumulation of explosive

perchlorates. See Guide E 2014 on Metallographic Laboratory

Safety for additional information on safety precautions for

electrolytes containing perchloric acid..

6.2.2 No single type of glove will protect against all

possible hazards. Therefore, a glove must be carefully selected

and used to ensure that it will provide the needed protection for

the specic etchant being used. In some instances it may be

necessary to wear more than one pair of gloves to provide

proper protection. Information describing the appropriate glove

may be obtained by consulting the MSDS for the chemical

being used. If that does not provide enough detailed information, contact the chemical manufacturer directly. Additionally,

one can contact the glove manufacturer or, if available, consult

the manufacturers glove chart. If the chemical is not listed or if

chemical mixtures are being used, contact the glove manufacturer for a recommendation.

6.2.3 Use proper devices (glass or plastic) for weighing,

mixing, containing, and storage of solutions. A number of

etchants generate fumes or vapors and should only be stored in

properly vented containers. Storage of fuming etchants in

sealed or non-vented containers may create an explosion

hazard.

ed

by composition

andand

concentration.

6.2.12

Store, handle

dispose of chemicals according to

the manufacturers recommendations. Observe printed cautions on reagent bottles.

6.2.13 Information pertaining to the toxicity, hazards, and

working precautions of the chemicals, solvents, acids, bases,

etc. being used (such as material safety data sheets, MSDS)

should be available for rapid consultation. A selection of useful

books on this subject is given in Refs. (1-11)4.

6.2.14 Facilities which routinely use chemical etchants

should have an employee safety training program to insure the

employees have the knowledge to properly handle chemical

etchants.

6.2.15 When working with etchants always know where the

nearest safety shower, eye-wash station, and emergency telephone are located.

7. Miscellaneous Information

7.1 If you know the trade name of an alloy and need to

know the composition to facilitate the use of Table 1, refer to

a compilation such as Ref (12).

7.2 Reagent grade chemicals shall be used for all etchants.

Unless otherwise indicated, it is intended that all reagents

conform to specications of the Committee on Analytical

Reagents of the American Chemical Society where such

specications are available. Other grades, such as United States

6.2.4 unless

When specic

mixing instructions

etchants, always

addotherwise.

reagents to the

solvent

indicate

6.2.5 When etching, always avoid direct physical contact

with the etchant and specimen; use devices such as tongs to

hold the specimen (and tufts of cotton, if used).

6.2.6 Methanol is a cumulative poison hazard. Where ethanol or methanol, or both are listed as alternates, ethanol is the

preferred solvent. Methanol should be used in a properly

designed chemical fume hood.

6.2.7 When working with HF always be sure to wear the

appropriate gloves, eye protection and apron. Buying HF at the

lowest useable concentration will signicantly reduce risk.

Additionally, it is recommended that a calcium gluconate

http://www.epa.gov/ttn/atw/hlthef/chromium.html

The boldface numbers in parentheses refer to the list of references at the end

of this standard.

4

E 407 07

Pharmacopeia (USP), may be used, provided it is rst ascer-

http://wenku.baidu.com/view/0c7eadea19e8b8f67c1cb9fc.html

An extremely high quality polish is required as tint etchants

2/4

10/23/2015

ASTME4072007StandardPracticeforMicroetchingMetalsandAlloys_

tained that the reagent is of sufficiently high purity to permit its

use without detrimental effect.

will reveal remaining polishing damage even if it is not visible

with bright eld illumination. After polishing, the surface must

Unlesstootherwise

indicated,

to water

shall

be7.2.1

understood

mean reagent

water references

as dened by

Type IV

of

specication D 1193. Experience has shown that the quality of

tap water varies signicantly and can adversely affect some

etchants.

7.3 Methanol is usually available only as absolute methanol.

When using this alcohol it is imperative that approximately 5

volume % of water is added whenever an etchant composition

calls for 95 % methanol. Some of these etchants will not work

be carefully

a polyethylene

to contain

the

etchant

if itcleaned.

containsUse

uorine

ions (forbeaker

example,

etchants

containing ammonium biuoride, NH4 FHF). The specimen is

placed in the solution using tongs, polished face up. Gently

agitate the solution while observing the polished surface. After

coloration begins, allow the solution to settle and remain

motionless. Remove the specimen from the etchant when the

surface is colored violet, rinse and dry. A light pre-etch with a

general-purpose chemical etchant may lead to sharper delinea-

at all if water is not present.

7.4 For conversion of small liquid measurements, there are

approximately 20 drops/mL.

7.5 Etching should be carried out on a freshly polished

specimen.

7.6 Gentle agitation of the specimen or solution during

immersion etching will result in a more uniform etch.

7.7 The etching times given are only suggested starting

ranges and not absolute limits.

7.8 In electrolytic etching, d-c current is implied unless

indicated otherwise.

7.9 A good economical source of d-c current for small scale

electrolytic etching is the standard 6-V lantern battery.

7.10 In electrolytic etching, the specimen is the anode

unless indicated otherwise.

7.11 Do not overlook the possibility of multiple etching

with more than one solution in order to fully develop the

tion of the structure after tint etching.

7.14 Specimens should be carefully cleaned before use of a

vapor-deposition interference lm (Pepperhoff) method (13,

14-17). A light pre-etch, or a slight amount of polishing relief,

may lead to sharper delination of the constituents after vapor

deposition. The deposition is conducted inside a vacuum

evaporator of the type used to prepare replicas for electron

microscopy. One or several small lumps of a suitable dielectric

compound with the desired index of refraction is heated under

a vacuum

until it evaporates. A vacuum level of 1.3 to 0.013 Pa

(103 to 105 mm Hg) is adequate and the polished surface

should be about 1015 cm beneath the device that holds the

dielectric compound. Slowly evaporate the lumps and observe

the surface of the specimen. It may be helpful to place the

specimen on a small piece of white paper. As the lm thickness

increases, the surface (and the paper) will become colored with

the color sequence changing in the order yellow, green, red,

purple, violet, blue, silvery blue. Stop the evaporation when the

color is purple to violet, although in some cases, thinner lms

with green or red colors have produced good results.

7.15 Metals Handbook (18) provides additional advice on

etching solutions and techniques for various alloys.

structure of the specimen.

7.12 Microscope objectives can be ruined by exposure to

hydrouoric acid fumes from etchant residue inadvertently left

on the specimen. This problem is very common when the

specimen or mounting media contain porosity and when the

mounting material (such as Bakelite) does not bond tightly to

the specimen resulting in seepage along the edges of the

specimen. In all cases, extreme care should be taken to remove

all traces of the etchant by thorough washing and complete

drying of the specimen before placing it on the microscope

stage.

7.13 Tint etchants (13, 14-16) are always used by immersion, never by swabbing, as this would inhibit lm formation.

8. Precision and Bias

8.1 It is not possible to specify the precision or bias of this

practice since quantitative measurements are not made.

9. Keywords

9.1 etch; etchant; interference method; metallography; metals; microetch; microscope; microstructure; Pepperhoff

method; tint etch

386

20

http://wenku.baidu.com/view/0c7eadea19e8b8f67c1cb9fc.html

3/4

ASTME4072007StandardPracticeforMicroetchingMetalsandAlloys_

10/23/2015

2015

2015

2015

~

240

2015Baidu||

http://wenku.baidu.com/view/0c7eadea19e8b8f67c1cb9fc.html

4/4

You might also like

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 5 out of 5 stars5/5 (2)

- ASTM E407-07 Standard Practice For Microetching Metals and AlloysDocument22 pagesASTM E407-07 Standard Practice For Microetching Metals and AlloysRifqiMahendraPutra100% (3)

- Guidelines for Combustible Dust Hazard AnalysisFrom EverandGuidelines for Combustible Dust Hazard AnalysisNo ratings yet

- Norma Astm E407.1093127-1Document22 pagesNorma Astm E407.1093127-1Gabriela AlmeidaNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Astm e 407Document22 pagesAstm e 407Rafael ScatolinNo ratings yet

- Corrosion HandbookDocument5 pagesCorrosion HandbookTroy ThomasNo ratings yet

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Astm F 402 - 93Document2 pagesAstm F 402 - 93jovindhaNo ratings yet

- An Overview of Corrosion, Inhibitors and JournalsFrom EverandAn Overview of Corrosion, Inhibitors and JournalsNo ratings yet

- s3m Scotch Weld Ec3524 FSTDocument4 pagess3m Scotch Weld Ec3524 FSTHugo CoelhoNo ratings yet

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesFrom EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesRating: 4.5 out of 5 stars4.5/5 (5)

- Microetching Metals and Alloys: Standard Practice ForDocument3 pagesMicroetching Metals and Alloys: Standard Practice ForGabriela InfanteNo ratings yet

- E407-07 (2015) E1 Standard Practice For Microetching Metals and AlloysDocument22 pagesE407-07 (2015) E1 Standard Practice For Microetching Metals and AlloysOlss BbzoNo ratings yet

- ASTM E291 - TM - Chemical Analysis of Caustic Soda and Caustic PotashDocument14 pagesASTM E291 - TM - Chemical Analysis of Caustic Soda and Caustic Potashphamthuyha50% (2)

- Chemistry: Confidential InstructionsDocument8 pagesChemistry: Confidential InstructionsHubbak KhanNo ratings yet

- Astm e 407-2007 Ataque Metalográfico PDFDocument23 pagesAstm e 407-2007 Ataque Metalográfico PDFCamilo PolaniaNo ratings yet

- Astm E407Document22 pagesAstm E407Carlos Pinto PradillaNo ratings yet

- Schlumberger Dowell Lab ManualDocument76 pagesSchlumberger Dowell Lab ManualmenocaNo ratings yet

- Environment Health Safety GuidelinesDocument67 pagesEnvironment Health Safety GuidelinesEngr Qaisar NazeerNo ratings yet

- MSDS Used Oil Lubricant 2010Document10 pagesMSDS Used Oil Lubricant 2010FabiolaNUrreaNo ratings yet

- ASTM E-407 Composición de Los Reactivos Químicos Utilizados PDFDocument22 pagesASTM E-407 Composición de Los Reactivos Químicos Utilizados PDFTiti HendrickNo ratings yet

- E2193 02Document3 pagesE2193 02Luz Ma R CNo ratings yet

- ASTM E407 Standard Practice For Microetching Metals and AlloysDocument22 pagesASTM E407 Standard Practice For Microetching Metals and AlloysTyson BoyceNo ratings yet

- ASTMDocument8 pagesASTMabdulghaniyu obaroNo ratings yet

- Mil PRF 29608CDocument13 pagesMil PRF 29608CSutopoNo ratings yet

- Astm e 407Document22 pagesAstm e 407Vinicio Parra100% (1)

- MSDS Polyken 955Document5 pagesMSDS Polyken 955raditia2205No ratings yet

- 3m Scotchbrite Quick Clean Griddle Cleaning SystemDocument12 pages3m Scotchbrite Quick Clean Griddle Cleaning Systemarturo gmoNo ratings yet

- F1855 1479757-1Document2 pagesF1855 1479757-1Thaweekarn ChangthongNo ratings yet

- MIL-PRF-907f Performance Specification Anti-Sieze CompoundDocument9 pagesMIL-PRF-907f Performance Specification Anti-Sieze CompoundGarthSandersNo ratings yet

- CLT-K806S MsdsDocument9 pagesCLT-K806S MsdsChong Gyu SongNo ratings yet

- CT0311CH1KDocument4 pagesCT0311CH1Ktewiyoj511No ratings yet

- WercsDocument10 pagesWercsNoviyanto Dwi NNo ratings yet

- ts601B ENDocument7 pagests601B ENDiegoNo ratings yet

- Waters Synapt g2 Mass Spectrometry System OomgraDocument236 pagesWaters Synapt g2 Mass Spectrometry System OomgraFafa AlunksNo ratings yet

- Safety Data Sheet for All-State AquaSafe No. 100 FluxDocument5 pagesSafety Data Sheet for All-State AquaSafe No. 100 Fluxmohamed AdelNo ratings yet

- Astm D4416 - 1 (En)Document2 pagesAstm D4416 - 1 (En)svvasin2013No ratings yet

- OSHA Safety - ElectroplatingDocument35 pagesOSHA Safety - Electroplatingvinithgandhi90No ratings yet

- TM 3-4240-348-10 M45 Mask Jan. 2000Document120 pagesTM 3-4240-348-10 M45 Mask Jan. 2000GLOCK35No ratings yet

- DP100Document20 pagesDP100NikolayNo ratings yet

- 103 Solution EC Msds 5-08Document3 pages103 Solution EC Msds 5-08Brian HernandezNo ratings yet

- Corrosion Guide Instructions: WarningDocument13 pagesCorrosion Guide Instructions: WarningiyyaniNo ratings yet

- Hoja de Seguridad Interline 925 Componente ADocument10 pagesHoja de Seguridad Interline 925 Componente AdonaldoguerreroNo ratings yet

- Core Abilities Tahap 3 Modul 1Document19 pagesCore Abilities Tahap 3 Modul 1Intan Farhana100% (2)

- MSDS AlloysDocument15 pagesMSDS AlloysMaryam EradewiNo ratings yet

- Hydraulic Anti-Lock Braking Systems (HABS) for Medium-Duty Trucks, Buses and Motor Home Chassisای بی اس وابکوDocument49 pagesHydraulic Anti-Lock Braking Systems (HABS) for Medium-Duty Trucks, Buses and Motor Home Chassisای بی اس وابکوناصر چهاردولی100% (2)

- Bezpečnostní List S-717 - EngDocument8 pagesBezpečnostní List S-717 - Engz9zsbwnnfvNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- DAP Aquarium Silicone Sealant Safety Data SheetDocument7 pagesDAP Aquarium Silicone Sealant Safety Data Sheetmerc2No ratings yet

- Astm D3547 - 1 (En)Document2 pagesAstm D3547 - 1 (En)svvasin2013No ratings yet

- SSPC Guide 3 - Paint Safety PDFDocument19 pagesSSPC Guide 3 - Paint Safety PDFAlexander SaulNo ratings yet

- George Fischer Engineering Handbook - Chemical Resistance Plastics & ElastomersDocument72 pagesGeorge Fischer Engineering Handbook - Chemical Resistance Plastics & ElastomersRanja SarkarNo ratings yet

- Protective Calcium Grease for Marine EquipmentDocument2 pagesProtective Calcium Grease for Marine EquipmentSilvio RodriguezNo ratings yet

- Safety Data Sheet: According To Regulation (EC) No. 1907/2006Document0 pagesSafety Data Sheet: According To Regulation (EC) No. 1907/2006William ChandraNo ratings yet

- Astm E2014Document7 pagesAstm E2014o_l_0No ratings yet

- Safety Data Sheet: Glass WoolDocument11 pagesSafety Data Sheet: Glass WoolIqbal Muhamad FarizNo ratings yet

- 6C9FDB6B0AD9436FB05722DB4EED4B61Document9 pages6C9FDB6B0AD9436FB05722DB4EED4B61Gabrielle JohnsonNo ratings yet

- Black 2.0 Magnetic Particle Testing YokeDocument2 pagesBlack 2.0 Magnetic Particle Testing YokeirwanNo ratings yet

- BlowholeDocument4 pagesBlowholekarthikkandaNo ratings yet

- Hot Topics: Casting Defect: Inclusions - SandDocument5 pagesHot Topics: Casting Defect: Inclusions - SandSachin KumbharNo ratings yet

- 001 How To Use The 5-Whys For Root Cause AnalysisDocument9 pages001 How To Use The 5-Whys For Root Cause AnalysisAbd ZouhierNo ratings yet

- Simulation of Casting Defects in A356Document6 pagesSimulation of Casting Defects in A356karthikkandaNo ratings yet

- Velocity Measurement DIS Fall 2017 MeetingDocument33 pagesVelocity Measurement DIS Fall 2017 MeetingkarthikkandaNo ratings yet

- Aluminum and Aluminum Alloys Casting ProblemsDocument5 pagesAluminum and Aluminum Alloys Casting ProblemskarthikkandaNo ratings yet

- Effect of Alloying Elements On Eutectic Temperatures in Cast Irons - MNS Ratio Grey IronDocument9 pagesEffect of Alloying Elements On Eutectic Temperatures in Cast Irons - MNS Ratio Grey IronkarthikkandaNo ratings yet

- CASTING DEFECT Cavities-MicroshrinkageDocument6 pagesCASTING DEFECT Cavities-MicroshrinkagekarthikkandaNo ratings yet

- Casitng Defecs Inverse ChillDocument2 pagesCasitng Defecs Inverse Chillkarthikkanda100% (1)

- 5 Whys Root Cause AnalysisDocument2 pages5 Whys Root Cause AnalysiskarthikkandaNo ratings yet

- 07 p1950Document7 pages07 p1950karthikkandaNo ratings yet

- P320Document14 pagesP320karthikkandaNo ratings yet

- 2011 WednesdayDocument123 pages2011 WednesdaykarthikkandaNo ratings yet

- Aluminum Quality PDFDocument17 pagesAluminum Quality PDFkarthikkandaNo ratings yet

- 2009 NADCA Alloy DataDocument38 pages2009 NADCA Alloy Dataramaswamykama786No ratings yet

- A356.0 Alloy DetailDocument2 pagesA356.0 Alloy DetailAdrian LimantoNo ratings yet

- Decomposition and Reaction of Thermal-Formed Alumina in Aluminum Alloy CastingsDocument9 pagesDecomposition and Reaction of Thermal-Formed Alumina in Aluminum Alloy CastingskarthikkandaNo ratings yet

- A356-T6 Properties - Gravity CastDocument1 pageA356-T6 Properties - Gravity CastkarthikkandaNo ratings yet

- 20 Completed Fact SheetDocument5 pages20 Completed Fact SheetkarthikkandaNo ratings yet

- 10 1 1 746 8619Document26 pages10 1 1 746 8619karthikkandaNo ratings yet

- 02 p007 s01Document7 pages02 p007 s01karthikkandaNo ratings yet

- 2D 05Document6 pages2D 05karthikkandaNo ratings yet

- Technology for Aluminium FoundriesDocument3 pagesTechnology for Aluminium FoundrieskarthikkandaNo ratings yet

- (Archive of Mechanical Engineering) Casting Pore Characterization by X-Ray Computed Tomography and MetallographyDocument11 pages(Archive of Mechanical Engineering) Casting Pore Characterization by X-Ray Computed Tomography and MetallographykarthikkandaNo ratings yet

- wj1106 264 PDFDocument6 pageswj1106 264 PDFkarthikkandaNo ratings yet

- World's Largest Science, Technology & Medicine Open Access Book PublisherDocument18 pagesWorld's Largest Science, Technology & Medicine Open Access Book PublisherkarthikkandaNo ratings yet

- 1 s2.0 S1877705810000834 MainDocument7 pages1 s2.0 S1877705810000834 MainkarthikkandaNo ratings yet

- Technology for Aluminium FoundriesDocument3 pagesTechnology for Aluminium FoundrieskarthikkandaNo ratings yet

- AluminumDocument5 pagesAluminumBlueOneGaussNo ratings yet

- World's Largest Science, Technology & Medicine Open Access Book PublisherDocument18 pagesWorld's Largest Science, Technology & Medicine Open Access Book PublisherkarthikkandaNo ratings yet

- Art AnalysisDocument3 pagesArt AnalysisCheeny VelascoNo ratings yet

- Chapter - 3.2 - Finale Internal Forced ConvectionDocument18 pagesChapter - 3.2 - Finale Internal Forced ConvectioneirinaNo ratings yet

- CH20005-Chemical Reaction Engineering:) C C CRDocument2 pagesCH20005-Chemical Reaction Engineering:) C C CRSunny KashyapNo ratings yet

- 53 TOP Structural Analysis - Civil Engineering Multiple Choice Questions AnDocument7 pages53 TOP Structural Analysis - Civil Engineering Multiple Choice Questions AnJohn Aries Almelor Sarza100% (1)

- STAAD Service Stage and Seismic Analysis ResultsDocument14 pagesSTAAD Service Stage and Seismic Analysis ResultsVikasNo ratings yet

- Stp417-Eb 5820 PDFDocument219 pagesStp417-Eb 5820 PDFS R Kumar KonathalaNo ratings yet

- Heat Exchangers Types & Applications, LMTD Derivation & ProblemsDocument11 pagesHeat Exchangers Types & Applications, LMTD Derivation & Problemsananth2012No ratings yet

- Anti Derivative Chain RuleDocument4 pagesAnti Derivative Chain Ruletutorciecle123No ratings yet

- Concrete Technology Internal Assessment QuestionsDocument2 pagesConcrete Technology Internal Assessment QuestionsSubodh AdhikariNo ratings yet

- Diagnostic Fracture Injection Tests in Ultra Low Perm FormationsDocument6 pagesDiagnostic Fracture Injection Tests in Ultra Low Perm FormationsBolsec14No ratings yet

- PEGN 419 / GPGN 419 Spring 2017: Manika Prasad Mansur Ermila Expert Resource: Robert LieberDocument30 pagesPEGN 419 / GPGN 419 Spring 2017: Manika Prasad Mansur Ermila Expert Resource: Robert LiebertahermohNo ratings yet

- Thesis MainDocument144 pagesThesis MainIvan GrkajacNo ratings yet

- Chemical Process Instrumentation: Pressure Measurement: Moderate and High Pressure Measuring InstrumentsDocument10 pagesChemical Process Instrumentation: Pressure Measurement: Moderate and High Pressure Measuring InstrumentslvrevathiNo ratings yet

- Solving rectangular double-well potential problemDocument10 pagesSolving rectangular double-well potential problemMendoza JohnyNo ratings yet

- Norma Japonesa Aij-Rlb-1996Document36 pagesNorma Japonesa Aij-Rlb-1996AnaApcarianNo ratings yet

- Galloway 1989 Genetic Stratigraphic Sequence Basin Analysis IDocument18 pagesGalloway 1989 Genetic Stratigraphic Sequence Basin Analysis IMitreNo ratings yet

- Cati Pakistan Training Course - MechanicalDocument13 pagesCati Pakistan Training Course - MechanicalImam Haryadi WibowoNo ratings yet

- Worksheet On Quantum NumbersDocument2 pagesWorksheet On Quantum NumbersJannah Mae IsioNo ratings yet

- Literature SurveyDocument6 pagesLiterature SurveyAnonymous j0aO95fgNo ratings yet

- NextFEM Designer Users Manual v1.10 p3Document96 pagesNextFEM Designer Users Manual v1.10 p3Anonymous kBodCGQ79No ratings yet

- Performance-Based Plastic Design and Energy-Based Evaluation of Seismic Resistant RC Moment FrameDocument7 pagesPerformance-Based Plastic Design and Energy-Based Evaluation of Seismic Resistant RC Moment FrameARJafariNo ratings yet

- System Modelling and SimulationDocument260 pagesSystem Modelling and SimulationArvind Kumar100% (13)

- Meteorology and Wind Resource Geostrophic BalanceDocument10 pagesMeteorology and Wind Resource Geostrophic BalanceSilvio NunesNo ratings yet

- Slide Micro Teaching 5.3Document18 pagesSlide Micro Teaching 5.3Mastura MohamadNo ratings yet

- ZDocument265 pagesZAdal ContrerasNo ratings yet

- MasteringPhysics Pearson-Intro To Mastering and Math ReviewDocument57 pagesMasteringPhysics Pearson-Intro To Mastering and Math ReviewShristi Singh80% (10)

- Master1 AM CoursesDocument3 pagesMaster1 AM CoursesParokotil MidhunNo ratings yet

- Skema Chemistry Paper 3Document8 pagesSkema Chemistry Paper 3nurul atiqahNo ratings yet

- FLUIDME Quiz 02 AnswersDocument5 pagesFLUIDME Quiz 02 AnswersSam Denielle TugaoenNo ratings yet

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldFrom EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldRating: 4 out of 5 stars4/5 (289)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Napoleon's Buttons: 17 Molecules That Changed HistoryFrom EverandNapoleon's Buttons: 17 Molecules That Changed HistoryRating: 4 out of 5 stars4/5 (25)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeRating: 4 out of 5 stars4/5 (9)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingFrom EverandIt's Elemental: The Hidden Chemistry in EverythingRating: 4 out of 5 stars4/5 (10)

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)

- Chemical Elements Pocket Guide: Detailed Summary of the Periodic TableFrom EverandChemical Elements Pocket Guide: Detailed Summary of the Periodic TableNo ratings yet

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)