Professional Documents

Culture Documents

Mechatronics Notes Unit1

Uploaded by

Varun BanurCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechatronics Notes Unit1

Uploaded by

Varun BanurCopyright:

Available Formats

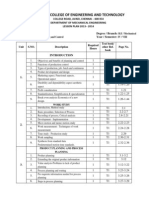

Mechatronics and Microprocessors(10ME65) Class Notes

from Yogeesha H.C.AP/Mech, NCET

1.

Define Mechatronics. Briefly explain various evolution stages of Mechatronics

- 10 marks

Mechatronics is the synergistic combination of Mechanical engineering, Electronic engineering, Computer engineering,

Control engineering, and Systems Design engineering in order to design, and manufacture useful products. The term

mechatronics is defined as a multidisciplinary engineering system design, that is to say it rejects splitting engineering into

separate disciplines.

A mechatronics engineer unites the principles of mechanics, electronics, and computing to generate a simpler, more

economical and reliable system. Mechatronics is centered on mechanics, electronics, computing, control engineering,

molecular engineering (from nanochemistry and biology), and optical engineering, which, combined, make possible the

generation of simpler, more economical, reliable and versatile systems. The word "mechatronics" was coined by Tetsuro

Mori, the senior engineer of the Japanese company Yaskawa in 1969. An industrial robot is a prime example of a

mechatronics system; it includes aspects of electronics, mechanics, and computing to do its day-to-day jobs.

Evolution of Mechatronics:

Mechatronics has evolved through the following stages:

Primary Level Mechatronics: Integrates electrical signaling with mechanical action at the basic control level for

e.g.fluid valves and relay switches

Secondary Level Mechatronics: Integrates microelectronics into electrically controlled devices for e.g. cassette tape

player.

Tertiary Level Mechantronics: Incorporates advanced control strategy using microelectronics, microprocessors and

other application specific integrated circuits for e.g. microprocessor based electrical motor used for actuation purpose

in robots.

Quaternary Level Mechatronics: This level attempts to improve smartness a step ahead by introducing intelligence

(artificial neutral network and fuzzy logic ) and fault detection and isolation ( F.D.I.) capability into the system

2.

What are the objectives of mechatronics? Explain with a block diagram, the key components in a

Typical mechatronic system

- 10 marks

Objectives of Mechatronics:

The primary objective of mechatronics is to integrate the mechanical systems with electrical, electronics and computer

systems and to provide multidisciplinary approach to product development and manufacturing system design.

As a discipline mechatronics encompasses electronics enhancing mechanics and electronics replacing mechanics. The

Secondary objectives of mechatronics are:

To improve efficiency of the system

To reduce cost of production

To achieve higher precision and accuracy

For easy control of systems

Customer satisfaction and comfort

Elements of a Mechatronics System

The different elements of a mechatronic system are as shown in the figure

The actuators produce motion or cause some action.

The sensors detect the state of system parameters, inputs, and outputs devices

Digital devices control the system.

Conditioning and interfacing circuits provide connections between the control circuits and the

input/output devices.

Graphical displays provide visual feedback to users.

3.

What are the advantages, disadvantages and applications of mechatronics

- 05 marks

Advantages:

a. Mechatronic products are better than the just the sum of its parts

b. They exhibit high performance characteristics

c. Mechatronic approach result in greater productivity, higher quality and production reliability.

d. Mechatronics provides high degree of flexibilities.

e. Mechatronics enhances plant/system utilization

Page No 1

Mechatronics and Microprocessors(10ME65) Class Notes

from Yogeesha H.C.AP/Mech, NCET

f. Mechatronic products are cost effective and good durability.

Disadvantages:

a. Implementation cost is high

b. Knowledge of different engineering field is essential

c. Very expensive to incorporate to an existing or old system.

d. Expensive to repair and maintain.

e. Requires highly skilled man power

Applications:

Machine vision

Automation and robotics

Servo-mechanics

Sensing and control systems

Automotive engineering, automotive equipment in the design of subsystems such as anti-lock braking

systems

Computer-machine controls, such as computer driven machines like IE CNC milling machines

Expert systems

Industrial goods

Consumer products

Mechatronics systems

Medical mechatronics, medical imaging systems

Structural dynamic systems

Transportation and vehicular systems

Mechatronics as the new language of the automobile

Diagnostic, reliability, and control system techniques

Computer aided and integrated manufacturing systems

Computer-aided design

Engineering and manufacturing systems

Packaging

Microcontrollers / PLCs

Mobile apps

4.

Give the origin of Mechatronics

- 05 marks

The genesis of mechatronics began in 1969 in Japan when Tetsura Mori, a senior engineer for Yaskawa Electric Corp.,

coined the term. Back then, mechatronics was viewed strictly as electromechanical systems or control and automation

engineering. As is evident, the term mechatronics is a combination of words, which is nothing new for Yaskawa; a

company that has been combining words and concepts since the 1950s. One of the first terms they created was minertia,

which was named for a servomotor line that used minimum inertia to develop super-fast starting and stopping ability. Next

came, mochintrol short for motor, machine and control which boasts electrical actuators capable of freely controlling

mechanical arms and fingers.

Yaskawa applied for a registered trademark for mechatronics in 1970 and won the rights to the term in 1973. Although the

foundation was set for the study of mechatronics, it failed to take off to its full potential; Yaskawa and its engineers were

ahead of their time, and so they did not pursue widespread publicity.

It wasnt until the mid-1980s that the term began to gain popularity. Yaskawa decided not to renew its trademark and

relinquish the rights to the term so as not to limit the industrys research and advancement of the technology.

During the 1970s, mechatronics focused on servo technology, in which simple implementation aided technologies related

to sophisticated control methods such as automatic door openers and auto-focus cameras. In the 1980s, mechatronics was

used to focus on information technology whereby microprocessors were imbedded into mechanical systems to improve

performance, such as antilock braking and electric seats. Finally, in the 1990s, mechatronics centered on communication

technology to connect products into large networks, including the production of air bags and other related technologies

The field of mechatronics has received the international recognition only within the last few years. The word originated in

Japan in late 1970s to describe the philosophy adopted in designing subsystem of electro mechanical products. At the

Research and Development level, ten technical areas are classified under mechatronics discipline.

a. Motion control

b. Robotics

c. Automatic systems

d. Intelligent control

e. Actuators and Sensors

f. Modelling and Design

g. System integration

h. Manufacturing

i. Micro devices and opto electronics

j. Vibration and noise control

5.

State the functions of basic elements of a closed loop control system with a block diagram

- 08 marks

A system in which input is dependent on the output i.e variation of the output influences the input by some means of

controlling on the input is called a closed loop control system. A closed loop control system is characterized by the

presence of feedback system. The feedback system permits the output to be compared with the reference input so that

appropriate controlling action can be achieved. The main feature of the closed loop control system is the comparison of the

actual value of the variable with the desired value of that variable and any difference between these two values causes

action to be taken in such a manner that it eliminates this difference or make the error zero. The basic elements of a closed

loop control system are shown in the figure.

Page No 2

Mechatronics and Microprocessors(10ME65) Class Notes

from Yogeesha H.C.AP/Mech, NCET

1. Comparision Element : This element compares the required or reference value of the variable condition being

controlled with the measured value of what is being achieved and produces an error signal. The error signal is the

difference between the reference and mesured values.

2. Control Element : This element analyses the error signal and decides what action to be taken, may be to operate a

switch or valve. The manipulation of the control unit is such that the error will approach zero.

3. Correction Element : It produces a change in the process to correct tor change the controlled condition. Change in the

process may be, allowing more power to the room heater to increase the temperature or vice versa.

4. Process Unit : It is the one which is being controlled. It could be a room in a house with its temperature being

controlled or a tank of water with its level being controlled.

5. Measurement unit : This produces a signal related to the variable condition of the process that is being controlled. It

might be , for example, a switch which switched on when a particular position is reached or a thermo couple which

gives the emf related to the temperaute.

Example 1: Room Heater

Controlled variable: Room temperature

Reference Value : Required room temp

Comparision Element : The person comparing the measured and actual temp

Error Signal : Difference between measured and actual temp

Control Unit : The Person

Correction unit: The switch

Process : The heating of the room

Measuring device: Thermo meter.

Example 2: Water Level control of a Tank

6.

Mention the differences between open loop and closed loop control system

- 05 marks

7.

Explain with block diagram, the basic elements of a measurement system

- 08 marks

8.

Explain with a block diagram the working of a microprocessor controlled washing machine

- 10 marks

9.

Compare the traditional design approach with that of the mechatronic design approach

- 04 marks

10. Explain with a block diagram, how a microprocessor control system is used to control the focusing

and exposure in an automatic camera

- 12 marks

11. Define microprocessor based controllers. Explain with a block diagram the working of an engine

management system

- 07 marks

Page No 3

Mechatronics and Microprocessors(10ME65) Class Notes

from Yogeesha H.C.AP/Mech, NCET

Page No 4

You might also like

- ESIGDocument670 pagesESIGalejandro calixtoNo ratings yet

- Ch01intro To MechatronicsDocument6 pagesCh01intro To MechatronicsElizabeth PaulNo ratings yet

- Design of Machine Elements - IIDocument93 pagesDesign of Machine Elements - IIASHAMS KCNo ratings yet

- DMS QB 2015 RDocument8 pagesDMS QB 2015 RKeerthe VaasanNo ratings yet

- M&e 18me51 NotesDocument156 pagesM&e 18me51 NotesRoman EmpireNo ratings yet

- USM Machining Guide: Principles, Parameters, Applications & Case StudiesDocument29 pagesUSM Machining Guide: Principles, Parameters, Applications & Case StudiesAnonymous ML4hh4MOyBNo ratings yet

- DMS UNIT I QB Answ KeyDocument31 pagesDMS UNIT I QB Answ KeyRahul Valath100% (1)

- Intelligent VehicleDocument16 pagesIntelligent VehicleSaurav SumanNo ratings yet

- ME 1402 - Mechatronics PDFDocument6 pagesME 1402 - Mechatronics PDFnagarajanceNo ratings yet

- What is a Transfer FunctionDocument27 pagesWhat is a Transfer FunctionNandakumarNo ratings yet

- Design of Mechatronics SystemsDocument2 pagesDesign of Mechatronics Systemsmundu mustafa100% (1)

- Inter Intra Vehicle Wireless CommunicationDocument20 pagesInter Intra Vehicle Wireless CommunicationSuhi TeoNo ratings yet

- SPM Chapter5Document63 pagesSPM Chapter5KidusNo ratings yet

- Mechatronics - AbstractDocument1 pageMechatronics - AbstractPragathi Sundar100% (2)

- FFS Design ReportDocument23 pagesFFS Design ReportPranjal ShuklaNo ratings yet

- Lecture 3 Example of Mechatronic SystemDocument36 pagesLecture 3 Example of Mechatronic SystemIljuha9No ratings yet

- Chapter 26: Remote Log-In, Electronic Mail and File TransferDocument34 pagesChapter 26: Remote Log-In, Electronic Mail and File Transferedsheeran23170% (1)

- Fundamentals of Mechatronics Short CourseDocument3 pagesFundamentals of Mechatronics Short CourseAamir Hasan KhanNo ratings yet

- LTCC and HTCC PDFDocument3 pagesLTCC and HTCC PDFPhan Xuân TuấnNo ratings yet

- Matlab MCQDocument4 pagesMatlab MCQalihamed7320% (1)

- Computer Aided Metrology PrinciplesDocument3 pagesComputer Aided Metrology PrinciplesramptechNo ratings yet

- Updated DSP Manual 15ECL57 PDFDocument97 pagesUpdated DSP Manual 15ECL57 PDFanujna100% (1)

- Introduction To Control Engineering: Andy Pomfret and Tim ClarkeDocument54 pagesIntroduction To Control Engineering: Andy Pomfret and Tim ClarkemmmNo ratings yet

- CIM Lecture Notes 12Document13 pagesCIM Lecture Notes 12Babatunde Victor JuniorNo ratings yet

- Smart Ration Card and Automatic Ration Material Distribution System Based On IOTDocument3 pagesSmart Ration Card and Automatic Ration Material Distribution System Based On IOTIJRASETPublicationsNo ratings yet

- Design Analysis and AlgorithmDocument78 pagesDesign Analysis and AlgorithmShivam Singhal100% (1)

- Motor Speed - Simulink ControlDocument9 pagesMotor Speed - Simulink ControlJesamarsNo ratings yet

- Dsp320 Experimental ManualDocument236 pagesDsp320 Experimental ManualKsrinivas RaoNo ratings yet

- PhaseDocument14 pagesPhaseDesaigouda S TNo ratings yet

- Mechatronics Digital Material RMK Unit I PDFDocument57 pagesMechatronics Digital Material RMK Unit I PDFRajmchzNo ratings yet

- Lab File: University of KarachiDocument6 pagesLab File: University of KarachiSaira AwanNo ratings yet

- PPC Lesson PlanDocument2 pagesPPC Lesson PlanSathiya MoorthyNo ratings yet

- Cost & EstimationDocument70 pagesCost & EstimationPalash DongreNo ratings yet

- 01 Modelling and SimulationDocument18 pages01 Modelling and SimulationMuslihNo ratings yet

- Week 3 B 2 Electric MotorsDocument59 pagesWeek 3 B 2 Electric MotorsCharlton S.InaoNo ratings yet

- Bachelor Electronics Telecom Engineering Revised Syllabus 2013-14Document46 pagesBachelor Electronics Telecom Engineering Revised Syllabus 2013-14SG CanNo ratings yet

- Lab Report 1 PDFDocument6 pagesLab Report 1 PDFmr xyzNo ratings yet

- Mechatronic Sensor and Actuator SystemsDocument1 pageMechatronic Sensor and Actuator SystemscakarenesNo ratings yet

- MEC 203 Mechanics of Machines Course OverviewDocument48 pagesMEC 203 Mechanics of Machines Course OverviewYuvraj Singh100% (1)

- Direct Memory Access (DMA) Is A Feature of Modern Computers That Allows Certain HardwareDocument15 pagesDirect Memory Access (DMA) Is A Feature of Modern Computers That Allows Certain HardwareAshutosh KumarNo ratings yet

- Robotics Notes1Document19 pagesRobotics Notes1Prince PavanNo ratings yet

- Engineering Materials ScienceDocument463 pagesEngineering Materials ScienceNilanjan KunduNo ratings yet

- Robot Motion Planning: Approaches and Research IssuesDocument26 pagesRobot Motion Planning: Approaches and Research IssuesRahul KalaNo ratings yet

- C AssignDocument4 pagesC Assigndharangutti_anupNo ratings yet

- Spice Mosfet Model IntroDocument50 pagesSpice Mosfet Model Intro高慶樺No ratings yet

- Mechatronics Notes22Document23 pagesMechatronics Notes22Arun KumarNo ratings yet

- Computer OrgnisationDocument138 pagesComputer OrgnisationmadhuNo ratings yet

- Fetch / Execute CycleDocument19 pagesFetch / Execute CycleazhiNo ratings yet

- Unit-7-Wireless-Modulation-Techniques-And-Hardware Malini MamDocument40 pagesUnit-7-Wireless-Modulation-Techniques-And-Hardware Malini MamRoopa NayakNo ratings yet

- CIM LAB ManualDocument58 pagesCIM LAB ManualBruce ColonNo ratings yet

- Lecture1428910741 PDFDocument66 pagesLecture1428910741 PDFSanwar Tagra0% (1)

- Final Module 2Document32 pagesFinal Module 2RachnaNo ratings yet

- Acs PDFDocument2 pagesAcs PDFAkshay PowarNo ratings yet

- IE368 Facilties Layout and Material Handling PDFDocument2 pagesIE368 Facilties Layout and Material Handling PDFloshidhNo ratings yet

- MotionControlTerminologyPrimerv2 PDFDocument2 pagesMotionControlTerminologyPrimerv2 PDFFouad ElhajjiNo ratings yet

- C++ FundamentalsDocument207 pagesC++ Fundamentalsbrm1shubhaNo ratings yet

- RoboticsDocument18 pagesRoboticslakshmigsr6610100% (1)

- Design and Fabrication of 4 Straight Line MechanismsDocument34 pagesDesign and Fabrication of 4 Straight Line MechanismsArunkuma81No ratings yet

- CS2 Lab PDFDocument82 pagesCS2 Lab PDFShreekara ShastryNo ratings yet

- Unit-5 MechatronicsDocument34 pagesUnit-5 Mechatronicsrudrav3210No ratings yet

- Core 3 Install Wiring Devices For Floor and Wall Mounted Outlets Lighting Fixtures Switches and Auxilliary OutletsDocument81 pagesCore 3 Install Wiring Devices For Floor and Wall Mounted Outlets Lighting Fixtures Switches and Auxilliary OutletsSuigen JM MontejoNo ratings yet

- Hrocat 8Document7 pagesHrocat 8Sparky73No ratings yet

- 3SU11000AB401FA0 Datasheet enDocument4 pages3SU11000AB401FA0 Datasheet enpatrykk11195No ratings yet

- MC14528B Dual Monostable Multivibrator: PDIP-16 P Suffix CASE 648Document12 pagesMC14528B Dual Monostable Multivibrator: PDIP-16 P Suffix CASE 648catsoithahuong84No ratings yet

- SA100 V 14 BulletinDocument8 pagesSA100 V 14 BulletinTeepoonsab somsaiNo ratings yet

- TD Docomo IntegrationDocument3 pagesTD Docomo IntegrationVishal SuryawaniNo ratings yet

- CSC 111 - Introduction To Computing Lecture One: C. I Eke Eke - Ifeanyi @fulafia - Edu.ngDocument49 pagesCSC 111 - Introduction To Computing Lecture One: C. I Eke Eke - Ifeanyi @fulafia - Edu.ngLawalNo ratings yet

- VLSI Quiz QuestionsDocument17 pagesVLSI Quiz Questionsjitu_40% (1)

- Gate 2014 Syllabus For Instrumentation Engineering inDocument6 pagesGate 2014 Syllabus For Instrumentation Engineering inrahulchangderNo ratings yet

- DatasheetDocument56 pagesDatasheetrajkumarmalathiNo ratings yet

- G550 - MTM - App ADocument31 pagesG550 - MTM - App Astive100% (1)

- Danfoss Scroll Compressors in Parallel Installation SMSYSZDocument48 pagesDanfoss Scroll Compressors in Parallel Installation SMSYSZNikolas Chionas100% (1)

- Computer 8 Fourth QuarterDocument8 pagesComputer 8 Fourth QuarterReygina Mae Sibayan PalaganasNo ratings yet

- ADAM-6000 User Manaul Ed 9Document252 pagesADAM-6000 User Manaul Ed 9fernandoviolante8551No ratings yet

- CV of Farha Islam MimeDocument3 pagesCV of Farha Islam MimeRajesh RoyNo ratings yet

- Chapter 1 Homework SolutionDocument7 pagesChapter 1 Homework SolutionPao JJNo ratings yet

- PR 436Document2 pagesPR 436hieu0% (1)

- Vec 1180 KDocument35 pagesVec 1180 Kyu3zaNo ratings yet

- Low-Power CODEC With Audio/Voice DSP: 1. General DescriptionDocument4 pagesLow-Power CODEC With Audio/Voice DSP: 1. General Descriptionwicka3No ratings yet

- Texas - Instruments LP3965ES ADJ - NOPB DatasheetDocument23 pagesTexas - Instruments LP3965ES ADJ - NOPB DatasheetBadawe NageebNo ratings yet

- SJ-20200929135033-015-ZXA10 C680&C600&C650&C620 (V1.2.1) Optical Access Aggregation Equipment Routine Maintenance - 996110Document44 pagesSJ-20200929135033-015-ZXA10 C680&C600&C650&C620 (V1.2.1) Optical Access Aggregation Equipment Routine Maintenance - 996110paulo gadelhaNo ratings yet

- LG PHILIPS 15.0 XGA Color TFT-LCD LM150X08-TLB1 PDFDocument29 pagesLG PHILIPS 15.0 XGA Color TFT-LCD LM150X08-TLB1 PDFDmitri PetrenkoNo ratings yet

- Transformer FundamentalsDocument6 pagesTransformer FundamentalsAditya TiwariNo ratings yet

- 5G Network Technical Department Agenda: Key Features and TrendsDocument17 pages5G Network Technical Department Agenda: Key Features and TrendsMr LazyNo ratings yet

- RRCS PricelistDocument63 pagesRRCS PricelistGarett MaloneNo ratings yet

- Digital Transmission Encoding SchemesDocument16 pagesDigital Transmission Encoding SchemesFATIN YUNIARTINo ratings yet

- 3ADW000163R0201 - Technical Guide - e - B PDFDocument28 pages3ADW000163R0201 - Technical Guide - e - B PDFAhmed MoustafaNo ratings yet

- Alto Ms8ma Ms10ma Ms12maDocument48 pagesAlto Ms8ma Ms10ma Ms12mavictor mogajaneNo ratings yet

- Connector: 2.0mm Pitch/crimp Style Wire-To-Wire ConnectorsDocument2 pagesConnector: 2.0mm Pitch/crimp Style Wire-To-Wire ConnectorsMr. TNo ratings yet