Professional Documents

Culture Documents

SAIC-W-2015 Rev 7 (NDE Selection)

Uploaded by

vijayachiduOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAIC-W-2015 Rev 7 (NDE Selection)

Uploaded by

vijayachiduCopyright:

Available Formats

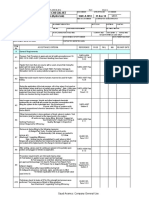

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2013)

Rev 7

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

Selection of Welds for NDE (On-Plot Piping )

31-Mar-13

DATE APPROVED

QR NUMBER

SAIC-W-2015

PROJECT TITLE

30-Apr-13

WBS / BI / JO NUMBER

032174

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

02-July-16

02-July-16

3.11

PLANT NO.

EC / PMCC / MCC NO.

MH's SPENT

TRAVEL TIME

WORK PERMIT REQUIRED?

ACCEPTANCE CRITERIA

REFERENCE

General Requirements

A1

Weld Selection for NDT / NDT Percentage to be Applied

shall be identified in design along with the Welding specification per line

class & per line (SAES-L-310, Sect 7) This is set forth in a proposed

project NDE specification for owner

Project NDE

Spec

Reqmt,

SAES-L-310,

Section 7

A2

Weld Selection for NDT shall be identified (collected, linked, &

maintained for each weld applicable) on an SAEP-1160 Database.

When UT is used in lieu of RT the tracking & reporting requirements

shall remain the same.(Also recorded on SAIC-W-2008 Checklist).

SAEP-1160,

Section

6.1

A3

Weld Selection for NDT ... See Attachment 1

A) NDT for welds of P-Nos 3, 4 & 5 materials shall be

conducted after PWHT. Any NDT appled prior to PWHT should be

considered for information only & not final acceptance. The intent is to

evaluate the weld quality prior to PWHT so any unacceptable

discontinuities canbe repaired prior to PWHT.

B) NDE Process Control

Procedure shall state sequence of NDE (Refer to Notes)

SAEP-1160,

Section

6.1

A6

N/A

CONTRACTOR INSPECTION LEVEL

A5

SYSTEM ID.

N/A

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO ACTIVITY NUMBER

A4

EQPT CODE

QUANTITY INSP.

SATIP-W-011-01

ITEM

No.

SAS Ltd

PURCHASE ORDER NUMBER

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO INSPECTION LEVEL

WELD-

CONTRACTOR / SUBCONTRACTOR

NDT Control and Identification ... See Attachment 1

NDT Report number, once assigned to a weld, shall remain

SAEP-1160,

with weld until final acceptance. Repeated NDT on a weld shall be

Section

indicated by adding or modifying the NDT Report Number suffix similar

6.1

to that used for weld repair as stated below as specified in SAEP-1160.

Selection of Tracer Welds ... See Attachment 1

A) Two tracer welds must be selected for each

rejected weld in a 10% RT system. The two welds must have been

welded by the same welder using the same welding process and use the SAEP-1160,

NDT method as the initial weld for evaluation.

Section

B) Progressive sampling of welds

6.1

(tracer welds) shall follow the progressive sampling method as stated in

governing SAES. Tracer welds are not to be counted in the 10%

sampling process.

Results of RT Film Evaluation by Saudi Aramco

A) Welds rejected for weld quality requiring repair have

their original weld id numbers modified by suffix & progression

(R1, R2, T1, T2, T1R1, T1R2, T2R1,

T2R2, etc) As specified in SAEP-1160

SAEP-1160,

Section

B) Welds rejected for film quality require reshoot as follows:

6.1

W-01 (RS) ... Not

specified in SAEP-1160 contractor shall include it in NDE Process

control procedure. (Refer to Notes)

Page 1 of 17

PASS

FAIL

N/A

RE-INSP DATE

A7

Initial production work of contractor welders shall be monitored by

the project inspector to determine their ability to make sound welds.

Page 2 of 17

SAEP-324,

Para. 6.2.6

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2013)

Rev 7

SAUDI ARAMCO INSPECTION CHECKLIST

Selection of Welds for NDE (On-Plot Piping )

SAIC NUMBER

SAIC-W-2015

PROJECT TITLE

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

A8

For progressive examination requirements, a lot shall be defined as all of

the same kind of welds made since the last acceptable weld, excluding

"penalty" examinations, for a given welder from any previous production

on a specific line classification.

SAES-W-011,

Para. 17.1.9

A9

The progressive examination shall be limited to the specific welder with

the defective welds.

SAES-W-011,

Para. 17.1.9

A10

The last acceptable weld is defined as a weld that has been examined

and accepted by both RT (or UT) and all other specified NDT methods

(visual, PT, MT).

SAES-W-011,

Para. 17.1.9

A11

The "same kind" of weld is defined as: the same process or

combination of processes, same type of joint (groove vs. fillet), and

same P-Number. Different diameters and wall thicknesses may be

classified within the "same kind" of weld.

SAES-W-011,

Para. 17.1.9

A12

Contractor shall establish "lot & kind" by agreement with project

Ispection at the start of the project for less than 100% Radiography.

Note: Where less than 100% radiographic coverage is reqd, random

selection of welds is based on the weekly weld production.

Initial Testing of Newly Certified Welders

B1

Initial 3* butt welds of each welder are selected for RT.

For decision path on the first three (3) production welds see SAEP324 Appendix III.

B3

C

C1

C2

C3

Radiograph acceptance shall be as specified by the applicable Code

ASMECoverage

B31.3 for plant piping.

NDT

All welds are inspected per ASME B31.3 & SAES-W-011.

SERVICE CATEGORY IS DESIGNATED & KNOWN:

NDT Coverage A) CATEGORY D = D

B) CATEGORY M = M

C) NORMAL SERV = N

D) SEVERE

CYCLE = S

NEVER

SELECT OR EVALUATE NDE WITHOUT USING THE CORRECT

Visual

Examination:

SERVICE CATEGORY AND CODE CRITERIA!

A) All weldsSEE

shallATTACHMENT

be visually examined.

exam

shall be performed

2 (ASMEVisual

TABLE

341.3.2)

(and accepted) prior to other NDT.

B) Where accessible, welds shall be visually examined from root side to

ensure that proper penetration & fusion have been achieved

C) Service & Category (Normal, D, M, Severe

Cycle) must be known

(Visual

Aceeptance Criteria given in ASME B 31.3Table 341.3.2 )

Butt welds in piping shall be RT'd as required below and:

A) If a weld falls under multiple classifications, the

most stringent requirement is applicable.

B) Minimum percent coverage of specified

NDT method may be increased (at any level up to 100%) if, in the

opinion of authorized SA inspector, welds are of questionable

workmanship or if NDT indicates an excessive number of defects.

C) Additional or

alternative NDT methods may be used at the discretion of the authorized

Saudi Aramco inspector in order to assist in determining the type or

extent of defects.

Page 3 of 17

SAES-W-011,

Para. 17.1.9 &

Para.

17.5.2 &

SAEP-324,

Para. 6.1.5

SAEP-324,

Para. 6.1.5

SAES-W-011,

Para. 17.5.2.1

SAES-W-011,

Para. 17.5.1

SAES-W-011,

Para. 17.5.2

31-Mar-13

DATE APPROVED

QR NUMBER

30-Apr-13

WELD-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2013)

Rev 7

SAUDI ARAMCO INSPECTION CHECKLIST

Selection of Welds for NDE (On-Plot Piping )

SAIC NUMBER

SAIC-W-2015

PROJECT TITLE

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

C4

For welds below 100% RT requirements, selection of welds is based on

the weekly weld production at a minimum. The detailed requirements of

SAEP-1160 apply. (Backlog basis = 7 days)

SAES-W-011,

Para. 17.5.2

C5

Weld joints selected due to progressive examination requirements (after

SAES-W-011,

weld defects are found) shall not count toward the required overall exam Para. 17.1.9

frequency (%).

C6

Onshore Piping RT & Offshore Piping RT Reqmts:

See Attachment 3 Tables & Notes.

C7

For on-shore piping, at least 10% of the each week's production weld

(circumferential girth welds), are radiographed for:

a. Carbon steel & low alloy steel for general & hydrocarbon Serv.

RT Exams

b. Firewater systems (Interpreted to "normal fluid service")

SAESc. Shop fabricated pipe matls for low temp service below -18C

W-011,

d. Shop fabricated alloy steel, Stainless steel nonferrous materials for all Para. 17.5.2.1

services except Category D fluids.

Shop is an indoor facility approved by SA Insection.

C8

For on-shore piping, 100% RT is performed on the following:

a. Field welds of piping in low temp service below -18C.

b. Shop fabricated alloy steel, P-No. 3, 4, and 5 materials.

c. For field & yard welds of all alloy steel materials (P4 & above),

stainless, & nonferrous matls for all services except Cat D fluids.

d. Hydrocarbon service at road crossings (carrier pipe only).

e. Piping with severe cyclic conditions (as defined in B31.3).

f. Category M fluid service (as defined in B31.3).

C9

For off-shore piping top side piping in Category D fluid service above

0C (includes all lines over water, over tidal flats, or within 30 m of the

shoreline), 10% of the weekly production welds are random selected for

radiography. These are:

a. Firewater systems

b. Raw water system

c. Pressure sewer system

d. All open non-pressure vents and drains

SAES-W-011,

Para. 17.5.2.2

C10

For off-shore top side piping (includes all lines over water, over tidal

flats, or within 30 m of the shoreline), 100% of the welds of piping

systems listed below are selected for radiography:

a. All services other than Category D fluids

b. Stainless steel in chlorinated sea water service.

SAES-W-011,

Para. 17.5.2.2

C11

Selection of welds for 10% RT is strictly controlled by procedure.

RT Process Control Procedure details all

aspects of Weld Selection for NDE.

SAIC-RT-2010

C12

Selection of welds for 10% RT includes welds completed by each welder.

{ASME B31.3, Para. 341.4.1 (b) (1)}

as referenced

C13

Weld joints completed by the welder each day are recorded per SAEP1160 requirements, Section 6.

SAES-W-011,

Para. 17.5.2.1

Page 4 of 17

RT Exams

SAESW-011,

Para. 17.5.2.1

SAEP-1160,

Section 6

31-Mar-13

DATE APPROVED

QR NUMBER

30-Apr-13

WELD-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2013)

Rev 7

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Selection of Welds for NDE (On-Plot Piping )

SAIC-W-2015

PROJECT TITLE

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

C14

Where multiple welders are used to weld a particular joint, daily weld

record shall indicate the weld area covered by each welder, ie: Root

weld, hot pass, capping etc.

SAES-W-011,

Para. 17.5.3

C16

Magnetic Particle Testing & Liquid Penetrant Testing

Magnetic particle testing (MT) for ferromagnetic materials.

Liquid penetrant testing (PT) for non-ferromagnetic materials.

Exception: PT shall be allowed for small

diameters where MT (yoke) is cumbersome & impractical. This includes

SW

C17

Pressure containing welds, other than butts, 100% MT/PT.

Includes Branch

Connections, Weldolets, Sockolets, & Welding Bosses ... Any other

Groove welded fittings.

SAES-W-011,

Para. 17.5.3.1

C18

All attachment welds on pressurized components that are not

hydrotested after making the attachment weld shall be 100% examined.

SAES-W-011,

Para. 17.5.3.2

D

D1

D2

E

E1

31-Mar-13

DATE APPROVED

QR NUMBER

30-Apr-13

WELD-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAEP-1160,

Section 6

WELD MODIFICATIONS AFTER FINAL ACCEPTANCE

Engineering Change Notice Procedure* covers such work.

ID, Numbering, NDE & Special Processes are

controlled.

NDE Process Control Procedure was followed. Database was used to

record NDE results. NDE sequence was followed relative to any special

process such as PWHT. SA Inspector witnessed the NDE.

Sch Q, Att. VI

Tables

Special

Process

AWS D1.1 Structural Steel Welding

Welding & Selection of NDE meets AWS D1.1 & 12-SAMSS-007

requirements:

Note: AWS D.1.1 shall be applied for Visual Examination & NDE

acceptance criteria

SAIC-M-2012

12SAMSS-007,

Para.

6.1.6 & 7.6

REMARKS:

NOTES: 1) Contractor's NDE Process Control Procedure shall cover elements of this checklist and provide clear direction for NDE Service Provider

Companies, along with close supervision.

Attachments:

Attachment 1 - SAEP-1160 DATABASE, PROCESS CONTROL TRACKING (By Weld)

Attachment 2 - ASME B31.3 Process Piping Welding Acceptance Criteria (Table 341.3.2)

Attachment 3 - SAES-W-011 Onshore & OffShore NDE Requirements

REFERENCE DOCUMENTS:

1. SAES-W-011, Welding Requirements for On-Plot Piping, 4 october 2009

2. SAEP-324, Certification Review and Registration of Project Welders and Brazers, (27 september 2009)

3. SAEP-1160, Tracking & Reporting of Welding, NDT and Pressure Testing for Capital Projects (10 July 2011)

4. 12-SAMSS-007, Fabrication of Structural and Miscellaneous Steel (17 May 2011)

5. American Welding Society (AWS) D1.1 Structural Steel Welding Code (2010 Edition)

6. ASME B31.3, Process Piping, (2010 Edition)

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

Name, Initials and Date:

QC Inspector

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

T&I Witnessed

Name, Organization,

Initials and Date:

Page 5 of 17

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2013)

Rev 7

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Selection of Welds for NDE (On-Plot Piping )

SAIC-W-2015

PROJECT TITLE

ITEM

No.

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

Quality Record Approved:

Name, Sign and Date:

REFERENCE

31-Mar-13

DATE APPROVED

QR NUMBER

30-Apr-13

WELD-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

Y = YES

N = NO F = FAILED

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Page 6 of 17

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2013)

SAUDI ARAMCO INSPECTION CHECKLIST

Selection of Welds for NDE (On-Plot Piping)

Rev 7

SAIC NUMBER

SAIC-W-2015

31-Mar-13

DATE APPROVED

QR NUMBER

30-Apr-13

WELD-

Attachment 1 - SAEP-1160 DATABASE, PROCESS CONTROL TRACKING (By Weld)

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2013)

SAUDI ARAMCO INSPECTION CHECKLIST

Selection of Welds for NDE (On-Plot Piping)

Rev 7

SAIC NUMBER

SAIC-W-2015

31-Mar-13

DATE APPROVED

QR NUMBER

30-Apr-13

WELD-

Attachment 2 - ASME B31.3 Process Piping Welding Acceptance Criteria (Table 341.3.2)

ASME B31.3 EQUAL LEG FILLET WELD (Fig 328.5.2A) - Acceptable Fillet Weld Shape & Contour

Note: Leg Size shall be determined by Fillet Gage* (Properly Used Depending upon the weld contour)

Attachment 2 - ASME B31.3 Process Piping Welding Acceptance Criteria (Table 341.3.2)

Attachment 2 - ASME B31.3 Process Piping Welding Acceptance Criteria (Table 341.3.2)

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2013)

SAUDI ARAMCO INSPECTION CHECKLIST

Selection of Welds for NDE (On-Plot Piping)

Rev 7

SAIC NUMBER

SAIC-W-2015

31-Mar-13

DATE APPROVED

QR NUMBER

30-Apr-13

WELD-

Attachment 3 - SAES-W-011 Onshore & OffShore NDE Requirements

NOTE TO INSPECTORS: Note 2 above (typo error) ... Should read P3, P4 and P5. No P6 applications at SA.

MT & PT REQUIREMENTS

You might also like

- Saic W 2003Document14 pagesSaic W 2003Mohammed IlliasuddinNo ratings yet

- Saudi Aramco Hardness Testing Procedure ReviewDocument3 pagesSaudi Aramco Hardness Testing Procedure ReviewphilipyapNo ratings yet

- Saudi Aramco Reinstatement Procedure ChecklistDocument5 pagesSaudi Aramco Reinstatement Procedure ChecklistpravinNo ratings yet

- Validate Welding Power SuppliesDocument4 pagesValidate Welding Power Suppliesfariboy123No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- SAUDI ARAMCO MPT INSPECTIONDocument6 pagesSAUDI ARAMCO MPT INSPECTIONphilipyapNo ratings yet

- SAIC-L-2014 Flange Joint Insp PDFDocument7 pagesSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNo ratings yet

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- SAUDICHECK - WELD TRACKING DATABASEDocument5 pagesSAUDICHECK - WELD TRACKING DATABASEManoj KumarNo ratings yet

- Saudi Aramco Pipe Inspection RequirementsDocument2 pagesSaudi Aramco Pipe Inspection RequirementsAbu Anas M.Salaheldin100% (1)

- Saep 321Document25 pagesSaep 321AbdullahNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- Saudi Aramco Storage ChecklistDocument4 pagesSaudi Aramco Storage Checklistரமேஷ் பாலக்காடுNo ratings yet

- Inspection Procedure EDRDocument8 pagesInspection Procedure EDRaamirtec301No ratings yet

- Saudi Aramco Inspection ChecklistDocument23 pagesSaudi Aramco Inspection ChecklistjahaanNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinNo ratings yet

- III. Applicable Codes & Standards for Aramco ProjectsDocument5 pagesIII. Applicable Codes & Standards for Aramco ProjectsZain Ali KidwaiNo ratings yet

- SATR-L-2001 Rev. 5Document10 pagesSATR-L-2001 Rev. 5Neelam AhmadNo ratings yet

- SAIC-G-2022 Rev 2Document25 pagesSAIC-G-2022 Rev 2faisal hussainNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System Specificationimranb_001100% (1)

- TK®-236 Physical Properties: 1. HardnessDocument2 pagesTK®-236 Physical Properties: 1. HardnessSaradhi MedapureddyNo ratings yet

- PIPELINE WELD NUMBERING SYSTEMDocument9 pagesPIPELINE WELD NUMBERING SYSTEMgst ajah100% (2)

- Saudi Aramco flange inspection procedureDocument13 pagesSaudi Aramco flange inspection procedurebiplabpal2009No ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Saudi Aramco System Lay-up ReportDocument2 pagesSaudi Aramco System Lay-up Reportdeepa narayan100% (1)

- Shrikant B. Moje CVDocument6 pagesShrikant B. Moje CVPaul PhiliphsNo ratings yet

- Galvanic CP test stationsDocument4 pagesGalvanic CP test stationsImran khanNo ratings yet

- Saudi Aramco Air Cooled Heat Exchanger Inspection PlanDocument2 pagesSaudi Aramco Air Cooled Heat Exchanger Inspection PlanAnonymous S9qBDVkyNo ratings yet

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- PQR use for welding different material gradesDocument1 pagePQR use for welding different material gradeslaz_kNo ratings yet

- Weld Mech. QuestionsDocument4 pagesWeld Mech. QuestionservkslmNo ratings yet

- Saudi Aramco welding inspection planDocument12 pagesSaudi Aramco welding inspection planspravin231No ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- QIR-118-Piping Pressure Test ReportDocument1 pageQIR-118-Piping Pressure Test ReportSamer BayatiNo ratings yet

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- Welder Wise Repair PercentageDocument135 pagesWelder Wise Repair PercentageaakashNo ratings yet

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- Saudi Aramco welding checklistDocument13 pagesSaudi Aramco welding checklistAnonymous S9qBDVky100% (1)

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Alert 01 002Document2 pagesAlert 01 002SUKhanNo ratings yet

- 175 010300 PDFDocument2 pages175 010300 PDFAbu Anas M.SalaheldinNo ratings yet

- SAESL350Document14 pagesSAESL350Lester Dechavez100% (1)

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Qcf301 Tp05 Pressure Test ChecklistDocument1 pageQcf301 Tp05 Pressure Test ChecklistminhnnNo ratings yet

- Saep 351Document24 pagesSaep 351Raj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14Document10 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14pravinNo ratings yet

- Weekly Welder ReportDocument2 pagesWeekly Welder Reportkarthi51289No ratings yet

- SAIC-D-2022 Rev 2Document5 pagesSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-W-2015 Select Welds For NDE (On-Plot)Document3 pagesSAIC-W-2015 Select Welds For NDE (On-Plot)KirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Coordinating and Subordinating ConjunctionsDocument2 pagesCoordinating and Subordinating ConjunctionsvijayachiduNo ratings yet

- Astm A47 A47m (1999)Document5 pagesAstm A47 A47m (1999)Narendrasinh JadejaNo ratings yet

- Saudi Aramco Inspection Checklist 6232Document19 pagesSaudi Aramco Inspection Checklist 6232Munir Choudary100% (1)

- Conjunction S CombinedDocument6 pagesConjunction S CombinedvijayachiduNo ratings yet

- Pages From DGS-6300-001 Red Marked PDFDocument1 pagePages From DGS-6300-001 Red Marked PDFvijayachiduNo ratings yet

- Qa Activities (C.V.)Document2 pagesQa Activities (C.V.)vijayachiduNo ratings yet

- Api 1104Document7 pagesApi 1104vijayachiduNo ratings yet

- Bonney Forge BrochureDocument22 pagesBonney Forge BrochureAnonymous dvrhf5No ratings yet

- 1Document2 pages1vijayachiduNo ratings yet

- rt.5 Torque Chart With Quick Setup PDFDocument2 pagesrt.5 Torque Chart With Quick Setup PDFardi_a0uNo ratings yet

- PIPE SUPPORT SATR-W-2007 2rev 7Document65 pagesPIPE SUPPORT SATR-W-2007 2rev 7vijayachiduNo ratings yet

- Fluid Service Code PDFDocument1 pageFluid Service Code PDFvijayachidu100% (1)

- SAIC-M-2012 Rev 7supportsDocument33 pagesSAIC-M-2012 Rev 7supportsvijayachiduNo ratings yet

- Electrode Baking Record: Prepared /checked by Reviwed by CompanyDocument2 pagesElectrode Baking Record: Prepared /checked by Reviwed by CompanyvijayachiduNo ratings yet

- Astm A48Document5 pagesAstm A48jemorpeNo ratings yet

- Saes A 004Document22 pagesSaes A 004Branko_62100% (1)

- A00-Ga-E-0060011 - 00 (01 01) 00080 PDFDocument2 pagesA00-Ga-E-0060011 - 00 (01 01) 00080 PDFvijayachiduNo ratings yet

- Major Differences Between API 5L PSL 1 & PSL 2 PipesDocument1 pageMajor Differences Between API 5L PSL 1 & PSL 2 PipesvijayachiduNo ratings yet

- Ibps Po Prelim. Set 1 Bank PoDocument23 pagesIbps Po Prelim. Set 1 Bank PoAkanksha SrivastavaNo ratings yet

- PDFDocument9 pagesPDFvijayachiduNo ratings yet

- A5 5-A5 5M-2006PVDocument5 pagesA5 5-A5 5M-2006PVanonimous2516No ratings yet

- PWHT Reduces Welding Residual StressesDocument1 pagePWHT Reduces Welding Residual StressesvijayachiduNo ratings yet

- Vi R0 PDFDocument28 pagesVi R0 PDFvijayachiduNo ratings yet

- Nominal Pipe Size ChartDocument1 pageNominal Pipe Size ChartvijayachiduNo ratings yet

- Preparation and Study MaterialsDocument1 pagePreparation and Study MaterialsvijayachiduNo ratings yet

- Piping Guide Very ImportantDocument19 pagesPiping Guide Very ImportantvijayachiduNo ratings yet

- NCR FormDocument4 pagesNCR FormvijayachiduNo ratings yet

- Interview Questions For QAQC MechanicalDocument33 pagesInterview Questions For QAQC MechanicalBalakumar95% (351)

- Geberit Gulf Siphonic Rainwater Systems Techtalk February 2021Document41 pagesGeberit Gulf Siphonic Rainwater Systems Techtalk February 2021Kim Duy DoanNo ratings yet

- Astm F714 PDFDocument10 pagesAstm F714 PDFIván López PavezNo ratings yet

- Technical Guidelines For Connection To District Cooling SystemDocument30 pagesTechnical Guidelines For Connection To District Cooling Systemrizkboss8312No ratings yet

- Subject: Reply of Observations On Thrust Blocks. Ref.: EE/WR/Baran/Par-II/Tech.-72/4726 Dated 18.11.2021Document2 pagesSubject: Reply of Observations On Thrust Blocks. Ref.: EE/WR/Baran/Par-II/Tech.-72/4726 Dated 18.11.2021Rajendra MittalNo ratings yet

- Saudi Aramco CBT Body of KnowledgeDocument6 pagesSaudi Aramco CBT Body of KnowledgeRajesh Kumar RaviNo ratings yet

- 310-00C Fuel System - General Information - 5.0L 32V Ti-VCT/5.0L Ti-VCT V8 (308kW/418PS) 2016 MustangDocument30 pages310-00C Fuel System - General Information - 5.0L 32V Ti-VCT/5.0L Ti-VCT V8 (308kW/418PS) 2016 MustangJaciel LMNo ratings yet

- MSIG Volume III - Sewer Networks and Pump StationsDocument177 pagesMSIG Volume III - Sewer Networks and Pump StationsBFang Ku100% (8)

- DIYAB GAS EXPORT PILOT PROJECT CORROSION INHIBITOR INJECTION PACKAGE MATERIAL REQUISITIONDocument29 pagesDIYAB GAS EXPORT PILOT PROJECT CORROSION INHIBITOR INJECTION PACKAGE MATERIAL REQUISITIONTalha Ahmad100% (3)

- NR-13 (English 2014)Document21 pagesNR-13 (English 2014)Ruano Andreola StumpfNo ratings yet

- PIPE-FLO Professional Release NotesDocument3 pagesPIPE-FLO Professional Release Notesbrujula27100% (1)

- Lesson 1 - Plumbing MaterialsDocument18 pagesLesson 1 - Plumbing MaterialsNicholas Bonn SingNo ratings yet

- BSD Aluminum Doors and FramesDocument4 pagesBSD Aluminum Doors and FramesBinh Hung OngNo ratings yet

- Essential plumbing fittings and valves guideDocument57 pagesEssential plumbing fittings and valves guideJonathan Delos SantosNo ratings yet

- Ga 201Document31 pagesGa 201JJ WeldingNo ratings yet

- Regulating ValveDocument18 pagesRegulating ValveMohammed Hassan B KorainaNo ratings yet

- Fired HeatersDocument24 pagesFired HeatersCynthia Magali Márquez Ramírez100% (1)

- Hot Tapping CalculationsDocument19 pagesHot Tapping Calculationsna270791dia100% (1)

- Promag 53Document162 pagesPromag 53Vicho TronicoNo ratings yet

- 3300 Ceramic Capped Probe Datasheet - 172932Document11 pages3300 Ceramic Capped Probe Datasheet - 172932SPIC UreaNo ratings yet

- Field Inspection Report SummaryDocument3 pagesField Inspection Report Summarykbpatel123No ratings yet

- A Technical Analysis:: The Use and Maintenance of Dry Type SprinklersDocument16 pagesA Technical Analysis:: The Use and Maintenance of Dry Type SprinklersNikhil RajanNo ratings yet

- Circuit SetterDocument4 pagesCircuit SetterHVACRNIC2005No ratings yet

- Estimate FenceDocument45 pagesEstimate FenceMsonnnNo ratings yet

- CAT MANUAL-VALVES PVC-U EN ElrDocument362 pagesCAT MANUAL-VALVES PVC-U EN ElrBruno ManestarNo ratings yet

- End Caps ANSI B16.9Document1 pageEnd Caps ANSI B16.9Thappatla IndurNo ratings yet

- Flexible Pipe BrochureDocument12 pagesFlexible Pipe BrochureaishahNo ratings yet

- Production Process Flow ChartDocument5 pagesProduction Process Flow ChartKenny RojasNo ratings yet

- FLS304 Water Flow Switch for Pipes 1" to 8Document2 pagesFLS304 Water Flow Switch for Pipes 1" to 8ckyee88No ratings yet

- Modeling Pressure Balance Expansion BellowsDocument4 pagesModeling Pressure Balance Expansion Bellowsbrunomorena50% (2)

- Building Utilities & Building Technology - Compiled ReviewersDocument35 pagesBuilding Utilities & Building Technology - Compiled Reviewersnimha0% (1)