Professional Documents

Culture Documents

Syllabus For Chemical Reaction Engineering Course

Uploaded by

Gwen Tennyson0 ratings0% found this document useful (0 votes)

161 views5 pagesIIT syllabus

Original Title

Syllabus for chemical reaction engineering course

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIIT syllabus

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

161 views5 pagesSyllabus For Chemical Reaction Engineering Course

Uploaded by

Gwen TennysonIIT syllabus

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

NPTEL Syllabus

Chemical Reaction Engineering 1

(Homogeneous Reactors) - Video

course

COURSE OUTLINE

NPTEL

In simple terms, Chemical Engineering deals with the

production of a variety of chemicals on large scale. Large scale

http://nptel.ac.in

production is associated with the engineering problems such

as fluid flow, heat and mass transfer, mixing and all types of unit

operations. These chemicals are produced through chemical

reactions in a vessel called Chemical Reactor. Chemical

Reactor is known as the heart of any chemical plant since the

new chemicals are produced only in this vessel and the

economics of the entire plant depends on the design of reactor.

Chemical Reaction Engineering (CRE) deals with the design of

Chemical Reactors to produce chemicals. The design of

Chemical Reactors is based on a few simple and useful Additional Reading:

concepts. Though the concepts are simple, it is not easy for the

students to develop a feeling for these concepts unless the

1. Fogler, H.S., 1999,

teacher explains by giving different day to day examples with

Elements of Chemical

which the students are familiar with.

Reaction Engineering,

This is what I tried to do in these courses, one on

3rd Ed., Prentice-Hall,

homogeneous reactions (some call this as Chemical Reaction

Englewood Cliffs.

Engineering I) and heterogeneous reactions (some call this is

2. Froment, G.B., and K.B.

as Chemical Reaction Engineering II).

Bischoff, 1990,

After understanding the concepts, if we look at the subject of

Chemical Reactor

Chemical Reaction Engineering, it will be full of simple to

Analysis and Design,

complex mathematics. But, without understanding the

2nd Ed., Wiley, New

concepts, the subject appears to be meaningless mathematical

York.

exercise and the student does not have a feel for the design of

3. C.G. Hill Jr., 1977, An

the reactor.

Introduction to Chemical

My experience at IIT Madras for the last 30+ years,

Engineering Kinetics

unfortunately, is that, even most of the PG students who come

and Reactor Design,

for their Masters and Doctorate degrees also do not have the

John Wiley & Sons,New

feel for the design of the reactor. I find that this is due to lack of

York.

conceptual understanding of fundamentals of Chemical

4. Carberry, J.J., 1976,

Reaction Engineering.

Chemical and Catalytic

With this in mind, I tried to spend more time in explaining the

Reaction Engineering,

concepts and physical understanding of the problems in CRE

McGraw-Hill, New York.

in terms of simple and familiar examples rather than spending

5. Smith, J.M., 1981,

a lot of time in solving a differential equation in the class. My

Chemical Engineering

belief is that once the student understands the concepts

Kinetics, 3rd Ed.,

thoroughly, he/she develops a passion for the subject. Once

McGraw-Hill, New York.

the student is passionate about any subject, using

6. Kunii, D & Levenspiel, O,

mathematics or any tool to solve the problems is part of that

Fluidization

unstoppable passion.

Engineering, 2nd Edn.

Chemical

Engineering

As all of us know, it is impossible to cover all aspects of CRE

even in these two courses and hence I tried to address some

important general aspects, where these general aspects can

be extended to specific cases. For example in heterogeneous

reactions, gas-liquid reactions will be part of gas-liquid-solid

reactions (slurry reactor) in simple analysis. I could not spend

time on gas-liquid and liquid-liquid reactions, but the

methodology used to analyze other reactions e.g. gas-solid

reactions, can be easily extended to these reactions.

To try put the students on the right track for learning, I was

telling in the lectures some morals, some anecdotes, stories

etc., whenever there is an opportunity. These may please be

taken in the right spirit since my intention was to make the

students learn as much as possible. I think that I have given

enough introductions to these courses and it is time for you to

explore. I always enjoyed teaching/explaining CRE and I hope

that you enjoy listening to CRE!!.

COURSE DETAIL

Lecture Lecture Topic

Number

1

Motivation & Introduction Part I

Motivation & Introduction Part II

What is Chemical Engg. Part I

What is Chemical Engg. Part II

What is Chemical Reaction Engg. Part I

What is Chemical Reaction Engg. Part II.

Homogeneous & Heterogeneous Reactions Part I

Homogeneous & Heterogeneous Reactions Part II

Basics of Kinetics and Contacting

10

Design of Batch reactors Part I

11

Design of Batch reactors Part II

12

Basics of Plug Flow Reactor Part I

Engineering, 2nd Edn.

B&H, Boston.

Coordinators:

Prof K. Krishnaiah

Department of Chemical

EngineeringIIT Madras

13

Basics of Plug Flow Reactor Part II

14

Design of Plug Flow Reactors Part I

15

Design of Plug Flow Reactors Part II

16

Basics of Mixed Flow Reactors

17

Design of Mixed Flow Reactors

18

Basics of Kinetics

19

Kinetics of Heterogeneous reactions Part I

20

Kinetics of Heterogeneous reactions Part II

21

Kinetics of Heterogeneous reactions Part III

22

Kinetics of Homogeneous reactions

23

Reaction rate for Homogeneous reactions

24

Gas Phase Homogeneous reactions

25

Contd. And later Reactor Design of PFR

26

Reactor Design for MFR and Combination of

reactors.

27

PFR and MFR in series.

28

Unsteady state MFR and PFR

29

Recycle Reactors

30

Recycle Reactors (Autocatalytic reactions) Part I

31

Recycle Reactors (Autocatalytic reactions) Part II

32

Multiple Reactions Part I

33

Multiple Reactions Part II

34

Multiple Reactions Part III

35

Multiple Reactions Part IV

36

Multiple Reactions Part V

37

Multiple Reactions Part VI

38

Non-Isothermal Reactors Part I

39

Non-Isothermal Reactors Part II

40

Non-Isothermal Reactors (Graphical Design)

41

Non-Isothermal Reactors contd. & Adiabatic

Reactors

42

Non-Isothermal Reactors (Graphical Design) Contd.

43

Non-Isothermal Batch Reactors

44

Non-isothermal Plug Flow Reactors Part I

45

Non-isothermal Plug Flow Reactors Part II

46

Adiabatic Plug Flow Reactors

47

Non-isothermal Mixed Flow Reactors

48

Non-isothermal Mixed Flow Reactors Contd.

(Multiple steady states) Part I

49

Non-isothermal Mixed Flow Reactors Contd.

(Multiple steady states) Part II

50

Non-Ideal Flow & Residence Time Distributions

50

Non-Ideal Flow & Residence Time Distributions

(RTD) basics Part I

51

Non-Ideal Flow & Residence Time Distributions

(RTD) basics Part II

52

RTD for various reactors contd. Part I

53

RTD for various reactors contd. Part II

54

Diagnosing the ills of equipments & Various RTD

Models

55

Dispersion Model

56

Dispersion with reaction Model and Tanks in Series

Model

57

Multi-parameter model (MFR with dead space and

bypass)

58

Direct use of RTD to predict conversion (Macro &

Micro-fluid as well as Macro & Micro-mixing

Concept) Part I

59

Direct use of RTD to predict conversion (Macro &

Micro-fluid as well as Macro & Micro-mixing

Concept) Part II

60

Direct use of RTD to predict conversion (Macro &

Micro-fluid as well as Macro & Micro-mixing

Concept) Part III

References:

O. Levenspiel, Chemical Reaction Engineering, 3rd Edn, Wiley

& Sons (1999).

A joint venture by IISc and IITs, funded by MHRD, Govt of India

http://nptel.ac.in

You might also like

- Operations Research by H.A TAHA Solution Manual (8th Edition)Document475 pagesOperations Research by H.A TAHA Solution Manual (8th Edition)Gwen Tennyson84% (180)

- Bernoulli Lab ReportDocument78 pagesBernoulli Lab ReportErraFatiha70% (23)

- Drywall Contracting AgreementDocument4 pagesDrywall Contracting AgreementBeenish YousafNo ratings yet

- Federal Lawsuit Against HinsdaleDocument15 pagesFederal Lawsuit Against HinsdaleDavid GiulianiNo ratings yet

- ms004 2004en F PDFDocument13 pagesms004 2004en F PDFDanielWildSheepZaninNo ratings yet

- The Handbook of Organic Compounds. NIR, IR, Raman, and UV-Vis Spectra Featuring Polymers and Surfactants (A 3-Volume Set) (PDFDrive)Document1,490 pagesThe Handbook of Organic Compounds. NIR, IR, Raman, and UV-Vis Spectra Featuring Polymers and Surfactants (A 3-Volume Set) (PDFDrive)Muhammad Jawad Ul RehmanNo ratings yet

- Sluice Gate Module-6Document4 pagesSluice Gate Module-6hemontoyNo ratings yet

- (1975 Berg) Capillary Pressures in Stratigraphic TrapsDocument18 pages(1975 Berg) Capillary Pressures in Stratigraphic TrapsAiwarikiaarNo ratings yet

- Past Final Papers 1Document21 pagesPast Final Papers 1Luqmanhakim XavNo ratings yet

- CH 5Document35 pagesCH 5AbrhaNo ratings yet

- Cet l3 Fall 21 Solar System DesignDocument155 pagesCet l3 Fall 21 Solar System DesignOwais JawaidNo ratings yet

- 50-State Survey - Bad Faith Standards Related To The Handling of Third-Party Liability ClaimsDocument16 pages50-State Survey - Bad Faith Standards Related To The Handling of Third-Party Liability ClaimslostvikingNo ratings yet

- Barry Shaffer v. State Farm Mutual Automobile I, 3rd Cir. (2016)Document9 pagesBarry Shaffer v. State Farm Mutual Automobile I, 3rd Cir. (2016)Scribd Government DocsNo ratings yet

- The Home Buying Process OverviewDocument2 pagesThe Home Buying Process OverviewJay VoglerNo ratings yet

- Gabapentin hydrochloride process under 38 charsDocument6 pagesGabapentin hydrochloride process under 38 chars13201940100% (1)

- 2 Dc-Motors-3Document69 pages2 Dc-Motors-3JheromeNo ratings yet

- Electric Service and Meter InstallationsDocument97 pagesElectric Service and Meter Installationsrajr1_rakshitNo ratings yet

- Types of Fuel CellsDocument8 pagesTypes of Fuel CellsNazim100% (3)

- Sales Contract TemplateDocument1 pageSales Contract TemplateLê HiếuNo ratings yet

- 10 Kinds of Drug AbuseDocument10 pages10 Kinds of Drug AbuseJennifer Piloton CañeteNo ratings yet

- Rental Agreement-Monthly PDFDocument4 pagesRental Agreement-Monthly PDFFraser FernandesNo ratings yet

- Well Permit GuideDocument20 pagesWell Permit GuidegarenthinoNo ratings yet

- MethDocument4 pagesMethapi-218061588No ratings yet

- 2016 Jayco Jay Feather Owners Manual PDFDocument152 pages2016 Jayco Jay Feather Owners Manual PDFChad BallNo ratings yet

- Judge Epstein Ruling 12.16.20Document42 pagesJudge Epstein Ruling 12.16.20Alex Koma100% (1)

- Illicit Drug LaboratoriesDocument9 pagesIllicit Drug LaboratoriesChris HowesNo ratings yet

- Save Energy and Money with Xcel Home Performance AuditDocument9 pagesSave Energy and Money with Xcel Home Performance AuditFarwa MalikNo ratings yet

- Synthetic Approaches To The 2002-2007 New DrugsDocument120 pagesSynthetic Approaches To The 2002-2007 New DrugsBen ZoeNo ratings yet

- Sally Solomon Et Al - Using Ice-Cooled Condensers in Chemistry LaboratoryDocument3 pagesSally Solomon Et Al - Using Ice-Cooled Condensers in Chemistry LaboratoryRoundSTICNo ratings yet

- Mediserve QLD Nurse Reg (Print)Document11 pagesMediserve QLD Nurse Reg (Print)Alex PiecesNo ratings yet

- Form SSA-3368-BKDocument14 pagesForm SSA-3368-BKMathis & MathisNo ratings yet

- Cert of InsuranceDocument1 pageCert of Insuranceapi-297993513No ratings yet

- Peroxide ProcessDocument10 pagesPeroxide ProcessAdrian Bermudez LoeraNo ratings yet

- The Scientific Method Gaining Results From Our Questions Stefanie Swanson National UniversityDocument5 pagesThe Scientific Method Gaining Results From Our Questions Stefanie Swanson National UniversityStefanie SNo ratings yet

- BeriberiDocument6 pagesBeriberistevenmattarunganNo ratings yet

- Employee Handbook Template 04Document9 pagesEmployee Handbook Template 04petebakarNo ratings yet

- Colleagues Excellence: Regenerative EndodonticsDocument8 pagesColleagues Excellence: Regenerative EndodonticsParamesh NdcNo ratings yet

- Why Hire Professional Drywall Installers and FinishersDocument3 pagesWhy Hire Professional Drywall Installers and FinishersBeenish YousafNo ratings yet

- YJ Oil and Gas Industry - ApexMinds - SynopsisDocument2 pagesYJ Oil and Gas Industry - ApexMinds - SynopsisSarahJTGNo ratings yet

- An Overview of Deconstruction With A Focus On: Community Development OpportunitiesDocument19 pagesAn Overview of Deconstruction With A Focus On: Community Development OpportunitiesNikolaNo ratings yet

- Exploring Tiny Homes As An Affordable Housing StraDocument22 pagesExploring Tiny Homes As An Affordable Housing StraKalyani sonekarNo ratings yet

- Guide To Services For People Who Are Homeless - 2011 - TorontoDocument77 pagesGuide To Services For People Who Are Homeless - 2011 - TorontoarthurmathieuNo ratings yet

- Your Information. Your Rights. Our ResponsibilitiesDocument6 pagesYour Information. Your Rights. Our ResponsibilitiesSoulMendNo ratings yet

- Rental Compliance InformationDocument3 pagesRental Compliance InformationClickon Detroit100% (1)

- School of Public Health Report Highlights Progress in Public Health Education and ResearchDocument76 pagesSchool of Public Health Report Highlights Progress in Public Health Education and ResearchatijalsNo ratings yet

- Card FAQ: The City Bank LTDDocument13 pagesCard FAQ: The City Bank LTDJisan ProdhanNo ratings yet

- Anti Theft System Using MemsDocument48 pagesAnti Theft System Using MemsSrinidhi A BelieverNo ratings yet

- SEC Enforcement Action Against Nicholas Louis Geranio, Kaleidoscope Real Estate & OthersDocument41 pagesSEC Enforcement Action Against Nicholas Louis Geranio, Kaleidoscope Real Estate & OthersRuss LatinoNo ratings yet

- Data Communication and Etworks: Prepared by Senait KDocument11 pagesData Communication and Etworks: Prepared by Senait KSenait Kiros100% (1)

- Criteria For Funding of ProjectsDocument2 pagesCriteria For Funding of ProjectsPraneet JaiswalNo ratings yet

- Website Coding BasicsDocument21 pagesWebsite Coding Basicstpo aecNo ratings yet

- Astoria Affordable Housing Study JULY, 2015Document52 pagesAstoria Affordable Housing Study JULY, 2015Rchie ZoneNo ratings yet

- Certify'em - Custom Templates PDFDocument5 pagesCertify'em - Custom Templates PDFMani Deepak ChoudhryNo ratings yet

- MethDocument2 pagesMethBrandon ZennerNo ratings yet

- Cultivation and Propagation Methods for Medicinal PlantsDocument8 pagesCultivation and Propagation Methods for Medicinal PlantsRita BhattaNo ratings yet

- (3-2) Super Handy Lawn Mower - Group A15Document160 pages(3-2) Super Handy Lawn Mower - Group A15Md Sabbir HossainNo ratings yet

- Seminar Topic: Drugs, Dealers, Users, MoneyDocument12 pagesSeminar Topic: Drugs, Dealers, Users, MoneyTeodora StevanovicNo ratings yet

- Business Plan Format Contents GuideDocument9 pagesBusiness Plan Format Contents GuideRaeden BeritanNo ratings yet

- Social Security Disability Exam InfoDocument19 pagesSocial Security Disability Exam InfoEA MorrNo ratings yet

- How To Outsmart Your Smart MeterDocument28 pagesHow To Outsmart Your Smart MeterAlienUFONo ratings yet

- HP Pavilion Notebook PC: Maintenance and Service GuideDocument100 pagesHP Pavilion Notebook PC: Maintenance and Service GuideMarius SpînuNo ratings yet

- Negotiating Government OrganizationsDocument56 pagesNegotiating Government Organizationspartha2479499No ratings yet

- Frustrated, Frazzled and Ready to Throw Up?: Guaranteed 7 Step SystemFrom EverandFrustrated, Frazzled and Ready to Throw Up?: Guaranteed 7 Step SystemRating: 3 out of 5 stars3/5 (1)

- 400 PuzzlesDocument194 pages400 PuzzlesGwen TennysonNo ratings yet

- Coke Reactivity IndexDocument1 pageCoke Reactivity IndexGwen TennysonNo ratings yet

- The Effect of Particle Resuspension During Walking Activity To PM10Document10 pagesThe Effect of Particle Resuspension During Walking Activity To PM10Gwen TennysonNo ratings yet

- Logarithmic flow curves large pipes and perspexDocument7 pagesLogarithmic flow curves large pipes and perspexGwen TennysonNo ratings yet

- Mass Fraction Vs Size After 15 Min: Diameter in MMDocument1 pageMass Fraction Vs Size After 15 Min: Diameter in MMGwen TennysonNo ratings yet

- Vocational Training: Project: Characterization of Coal Blend in Ten KG Coke OvenDocument2 pagesVocational Training: Project: Characterization of Coal Blend in Ten KG Coke OvenGwen TennysonNo ratings yet

- InlabDocument3 pagesInlabGwen TennysonNo ratings yet

- Arduino Based Mobile PhoneDocument1 pageArduino Based Mobile PhoneGwen TennysonNo ratings yet

- Comp TechDocument11 pagesComp TechGwen TennysonNo ratings yet

- Assignment Due On Mar 9 PDFDocument6 pagesAssignment Due On Mar 9 PDFGwen TennysonNo ratings yet

- Mass Fraction vs Particle Size after 5 MinutesDocument1 pageMass Fraction vs Particle Size after 5 MinutesGwen TennysonNo ratings yet

- Syllabus For Chemical Reaction Engineering CourseDocument5 pagesSyllabus For Chemical Reaction Engineering CourseGwen TennysonNo ratings yet

- Boundary LayerDocument1 pageBoundary LayerGwen TennysonNo ratings yet

- 2.4 Cooling Water Requirements: 2.4.1 Type of The System Closed SystemDocument9 pages2.4 Cooling Water Requirements: 2.4.1 Type of The System Closed SystemDu PhamtienNo ratings yet

- GDT - MEP Equipment WeightDocument10 pagesGDT - MEP Equipment WeightsovannchhoemNo ratings yet

- VentilationDocument28 pagesVentilationTannum Negi0% (1)

- Conduction Convection RadiationDocument32 pagesConduction Convection RadiationShalini Kulshrestha100% (2)

- Measurement of Thermal Conductivity: Engineering Properties of Biological Materials and Food Quality 3 (2+1)Document17 pagesMeasurement of Thermal Conductivity: Engineering Properties of Biological Materials and Food Quality 3 (2+1)Mel CapalunganNo ratings yet

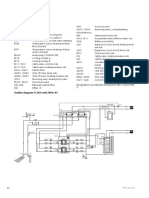

- Schema NIBE F1345 Cu HPAC45Document1 pageSchema NIBE F1345 Cu HPAC45Istvan MadacsyNo ratings yet

- Wallcon X-treme Installation and User ManualDocument44 pagesWallcon X-treme Installation and User Manualdimitri shalikianiNo ratings yet

- EIGA Doc 04 09 EDocument34 pagesEIGA Doc 04 09 EFernando VenceslauNo ratings yet

- KSB 9.0 - S.SFDocument9 pagesKSB 9.0 - S.SFSandesh KambleNo ratings yet

- Wavin PE Pressure Pipes Data SheetDocument2 pagesWavin PE Pressure Pipes Data SheetConspiracy_PTNo ratings yet

- New Microsoft Word DocumentDocument25 pagesNew Microsoft Word DocumentRathin KukrejaNo ratings yet

- Viscous Fluid Flow: Second EditionDocument4 pagesViscous Fluid Flow: Second EditionAnonymous ObsY3S7OtqNo ratings yet

- Supercritical Boiler: Higher Efficiency Through Advanced DesignDocument26 pagesSupercritical Boiler: Higher Efficiency Through Advanced DesignShaheena Khan100% (2)

- Lec 6 - Multiple ReactionsDocument37 pagesLec 6 - Multiple ReactionskaurNo ratings yet

- Catalyst Preparation Catalyst Preparation UnitDocument17 pagesCatalyst Preparation Catalyst Preparation UnitDivyansh Singh ChauhanNo ratings yet

- Unit Lightup Synchronisation & ShutdownDocument42 pagesUnit Lightup Synchronisation & ShutdownAshvani ShuklaNo ratings yet

- Unit Centrifugal Pumps: StructureDocument27 pagesUnit Centrifugal Pumps: StructureEfremWakjiraHodeNo ratings yet

- Optimized Design Method for Segmentally Baffled Shell-and-Tube Heat ExchangersDocument6 pagesOptimized Design Method for Segmentally Baffled Shell-and-Tube Heat ExchangersacckypenrynNo ratings yet

- 301-302 Flanged BAA SUCT DIFFUSER SDIDocument2 pages301-302 Flanged BAA SUCT DIFFUSER SDIIan OsorioNo ratings yet

- Dr. Nurul Nadia Adnan Abridged By: DR. AHMAD HASSANDocument27 pagesDr. Nurul Nadia Adnan Abridged By: DR. AHMAD HASSANThalagawali RajagopalNo ratings yet

- Water Distribution System Analysis and Design Using EpanetDocument126 pagesWater Distribution System Analysis and Design Using EpanetMelvin De VeraNo ratings yet

- Convection HMTDocument47 pagesConvection HMTbalakaleesNo ratings yet

- CFD Abl2Document38 pagesCFD Abl2Rahul ShuklaNo ratings yet

- Short Description of A Field-Testing Method With Cone Shaped Sounding ApparatusDocument4 pagesShort Description of A Field-Testing Method With Cone Shaped Sounding ApparatusAnonymous GnfGTwNo ratings yet

- Bulk Properties of PowdersDocument15 pagesBulk Properties of Powderslhphong021191No ratings yet

- Condensation in Automotive HeadlampDocument6 pagesCondensation in Automotive HeadlampArshad AliNo ratings yet