Professional Documents

Culture Documents

PLC-SPS Technical Handbook

Uploaded by

RodrigoCastilloAcostaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PLC-SPS Technical Handbook

Uploaded by

RodrigoCastilloAcostaCopyright:

Available Formats

9.3.

PROGRAMMABLE LOGIC CONTROLLER PLC

9.3.1 Programmable logic controller

PLC

This section applies to the RH 120 E

from serial no. 120 056

9.3.1.1

Introduction

This programmable logic controller (PLC) is capable of

- doing logical operations (AND, OR, ),

- saving/memorizing,

- forming lines,

- counting.

Specific modules for functions such as

- shift registers (16 bit),

- memories with dynamic inputs,

- "goto" instructions,

- comparators,

Basic functions of PLC:

Controls function:

-

Start+Stop engines

Idle Timer

Lamp test + cabinet fan

Lubrication

Lights (Ladder, cabine, maintenance)

Ultrasonic sound sensor

Monitoring:

-

Servo filter

Hydraulic tank lock-up valves

Lubrication initiators

lubrication pressure

Grease container filling level

Fuel gauges

are programmable.

You can program the this PLC from a personal computer (PC).

Thus, the following functions will be possible:

- setting outputs,

- checking input and output statuses,

- altering the programmed times and counts during

processing,

- diagnosis.

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

Page 9.3.1 - 1

9.3.1

9.3.1.2

PROGRAMMABLE LOGIC CONTROLLER PLC

Specifications

CAN/M4 basic unit

Supply voltage:

Power consumption:

CPU/RAM:

Cycle time:

Number of digital inputs:

Number of analog inputs:

Number of digital outputs:

Number of analog outputs:

24 V - (18 V 32 VDC)

approx. 5 8 W

512 kB RAM, 1 MB flash

typically 1.2 ms/kbyte command

32

(inputs for control functions not potential-isolated)

(green input status LED indicators)

(current consumption 7 mA per input)

8

(6 of them configured for 4 20 mA signal)

(2 of them configured for 0 10 VDC signal)

20

(transistor outputs)

(red output status LED indicators)

(max. load capacity 200 mA)

4

(output voltage 0 10 VDC, max. output current 10 mA)

Basic unit overview

Fig. 1

Page 9.3.1 - 2

640020

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

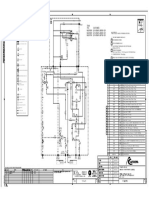

Terminal plan

Fig. 2

640020

Description of the terminals:

Top terminal strip

Terminal nos. 1-32

Terminal nos. 33-36

Terminal nos. 37-38

Digital inputs

Analog outputs

Digital outputs

Bottom terminal strip

Terminal nos. 39-56

Terminal nos. 57-72

Terminal nos. 73-74

Terminal nos. 75-76

Digital outputs

Analog inputs (2 x 0 10 VDC, 6 x 4 20 mA)

Power supply +24 VDC potential

Power supply GND potential

Front

RS232 port

CAN IN port

CAN OUT port

ON LED

BUS LED

RS232 input for programming this unit (for programming)

CAN IN input for integrating the PLC into the CAN bus system

CAN OUT output, for example, to connect a PC (for diagnosis)

LED to indicate whether the supply voltage is applied.

LED to indicate BUS communication.

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

Page 9.3.1 - 3

9.3.1

9.3.1.3

PROGRAMMABLE LOGIC CONTROLLER PLC

Maintenance

Installation

Install this control system into a cabinet where it is

protected from water. Ensure sufficient ventilation.

Removal

Changing the program

You can change the program of the PLC using a PC

with specific 'download software' and a download

cable, part no. 3685323 (serial 9-pin male 9-pin

female, 1:1).

Prior to changing the software, please consult the

Terex|O&KService Department to make sure that

the correct program version will be used.

To replace the basic unit proceed as follows:

1.

Set the key-operated switch on the control

panel in the operator's cab to "0" to cut off the

power supply of the control unit.

Software installation from a notebook

It can be possible that the control

unit is still energized via the timing

circuits of the "IDLE timer" or "ladder

light" functions, respectively.

Therefore, do not remove a control

unit before the ON LED is off, or

switch off the circuit breaker (F18).

2.

Renew any missing cable identifiers. Disconnect all wiring from the control unit.

3.

Remove the mounting screws from the sides

of the PLC and take out the control unit.

4.

If you wish to alter the control program please

refer to the "Changing the program" section.

To install the a new control unit proceed in the

reverse order.

Fig. 3

640021

When reconnecting the power supply, ensure correct polarity (24 VDC),

or the control unit will be destroyed.

Page 9.3.1 - 4

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Digital input ports

Input

Terminal

Description

Input 1

Input 2

Input 3

Servo filter

Input 4

Reset for truck counter

Input 5

Ignition

Input 6

Emergency stop

K24

Input 7

LH engine start

S5

Input 8

RH engine start

S6

Input 9

Stop LH engine

S90

10

Input 10

Stop RH engine

S92

11

Input 11

LH engine idle

S91

12

Input 12

RH engine idle

S93

13

Input 13

Hydraulic tank lock-up valve 1

S212

14

Input 14

Hydraulic tank lock-up valve 2

S212.1

15

Input 15

Hydraulic tank lock-up valve 3

S212.2

16

Input 16

Lubrication reset

S106

17

Input 17

LH PTG oil level

Not used

18

Input 18

RH PTG oil level

Not used

19

Input 19

Lubrication initiator 2

B336.1

20

Input 20

Lubrication initiator 1

B336

21

Input 21

Ladder light

S55

22

Input 22

Cabin light

S35.1

23

Input 23

Lube pump hydraulic oil filter

S257

24

Input 24

Maintenance light

25

Input 25

Not used

26

Input 26

Not used

27

Input 27

Not used

28

Input 28

Not used

29

Input 29

Not used

30

Input 30

Not used

31

Input 31

Not used

32

Input 32

Not used

Travel 2nd stage auto

Signal source

(refer to circuit diagram)

Not used

Not used

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

S250 & S250.1

S216.2

Ignition voltage 15

S41; S41.1; S42; S43

Page 9.3.1 - 5

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Analog output ports

Output

Output code

Description

Function enabled

33

Analog output 1

Not used

34

Analog output 2

Not used

35

Analog output 3

Not used

36

Analog output 4

Not used

Digital output ports

Output

Terminal

Description

37

Output 37

Ultrasonic sound sensor

38

Output 38

Terminal 30 (PLC self-holding)

39

Output 39

LH engine start

K2.3

40

Output 40

RH engine start

K3.3

41

Output 41

LH engine electronics

K7.1

42

Output 42

RH engine electronics

K7.2

43

Output 43

LH engine idle

K206

44

Output 44

RH engine idle

K207

45

Output 45

Lamp test

K36

46

Output 46

Cabinet fan

K28.1

47

Output 47

Lubrication ON

K200

48

Output 48

Lubrication bypass

K201

49

Output 49

Lubrication reversing valve

K202

50

Output 50

Speed reduction

51

Output 51

Undercarriage lubrication

K204

52

Output 52

Lock-up valves open

K158

53

Output 53

Grease container full

K205

54

Output 54

Ladder light

K22.1

55

Output 55

Cabin light

K199

56

Output 56

Maintenance light

K25.1

Page 9.3.1 - 6

Function enabled

(refer to circuit diagram)

H137.2; H137.3

Battery voltage 30

Not used

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Analog input ports

Input

Terminal

Description

Signal source

(refer to circuit diagram)

57

Analog input 57 1+ LH fuel gauge

B133

58

Analog input 58 1-

59

Analog input 59 2+ RH fuel gauge

60

Analog input 60 2-

61

Analog input 61 3+ Superstructure lubrication pressure

62

Analog input 62 3-

63

Analog input 63 4+ Undercarriage lubrication pressure

64

Analog input 64 4-

65

Analog input 65 5+ Grease container filling level

66

Analog input 66 5-

Not used

67

Analog input 67 6+

Not used

68

Analog input 68 6-

Not used

69

Analog input 69 7+

Not used

70

Analog input 70 7-

Not used

71

Analog input 71 8+

Not used

72

Analog input 72 8-

Not used

Not used

B134

Not used

B36

Not used

B127

Not used

B125

Power supply

73

Load voltage

X1/28

74

Voltage supply

X1/28

75

Ground

X1/8

76

Ground

X1/8

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

Page 9.3.1 - 7

9.3.1

9.3.1.4

PROGRAMMABLE LOGIC CONTROLLER PLC

Functional description

Greasing system with hydraulic pump

After the start of the diesel engines, the error message will be suppressed for 5 minutes to avoid the

occurrence of any possible faults (longer lubrication period due to cold oil or grease).

Start requirements:

At least one engine was started, the lubricant container is filled, and no error message is activated.

When the start requirement is met the PLC will

automatically start lubrication through line A.

(Outputs 47 and 48 active.)

Lubrication through line A will continue until initiator 1

changes over.

(Input 20 active.)

Now, the lubrication system will keep running for

another 22 seconds before it will change to line B

after a switch-over period of 4 sec. (output 47 will

be inactive during this period).

You can cancel the error message

with the "reset" pushbutton (input

16 active). (The "reset" pushbutton

is located on the control panel.)

If the lubricant container was empty

and has been refilled the error message will be automatically reset.

Now, lubrication through line B will start.

(Outputs 47, 48 and 49 active.)

Lubrication through line B will continue until initiator 2

changes over (input 19 active).

Now, the lubrication system will still keep running

for 22 sec. before it will stop.

(Outputs 47, 48 and 49 inactive.)

Now, the lubrication system will change to the pause

cycle which you can set in the BCS between 5 min.

and 40 min. (depending on the operating conditions).

The pause time will only be counted down if the

equipment is being moved.

Fault:

(Message in the BCS and system shut-off)

If a pressure in excess of 350 bar is built up,

or

after 2 minutes, in each case, if one of the two

initiators (input 19 or 20) does not switch over,

or

if the lubricant container is empty.

Fault:

(Message in the BCS without system shut-off)

If there is a cable break on the lubrication pressure

sensor,

or

in case of a cable break on the grease level sensor.

Error message suppression

Page 9.3.1 - 8

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Engines start

Requirements:

RH engine start:

The start command (input 8 active) immediately

switches on the starter (output 40 active) and

turns on the engine electronics (output 42 active).

No emergency stop switch has been actuated.

(Input 6 OFF.)

"Ignition ON" key-operated switch S4 is on.

(Input 5 active.)

The starter (output 40 active) will be activated

as long as the start command is active (input 8

active).

The engine was not stopped immediately before, so the starter interlock will be in effect for

a period of 10 sec.

Once the engine is running, this status will be

internally signalled via the CAN bus.

No "ENGINE STOP" command was/will be given

(input 9 or 10 inactive). This command has priority over the start command.

-

No attempt is made to start both engines at the

same time as this is interlocked.

The limit switches on the hydraulic tank lock-up

valves are closed (inputs 13, 14 and 15 active).

This will have an effect on two things:

1. The start command (input 8) will be disabled

(starter interlock). (Output 40) is switched off.

2. The fan for the cabinet in the platform compartment will be started by relay K28.1 (output 46

active).

Starter interlock

LH engine start:

The start command (input 7 active) immediately

switches on the starter (output 39 active) and

turns on the engine electronics (output 41 active).

The starter (output 39 active) will be activated

as long as the start command is active (input 7

active).

Once the engine is running, this status will be

internally signalled via the CAN bus.

This will have an effect on two things:

1. The start command (input 7) will be disabled

(starter interlock). (Output 39) is switched off.

2. The fan for the cabinet in the platform compartment will be started by relay K28.1 (output

46 active).

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

Each engine has a starter interlock.

The starter interlock prevents the starting of the

starters when the engines are already running, or

are running out. This would cause damage to the

pinions and starters. When the starter interlocks

are active, the start commands are disabled.

The starter interlocks will come into in effect when:

1. the engine is running, which will be internally

signalled via the CAN bus.

2. the engine was just stopped and is still running

out. In such case, the start command will be

disabled for 10 sec.

3. the engine has stalled without any stop command. In such case, the start command will be

disabled for 10 sec.

Page 9.3.1 - 9

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Engine stop by idle run timer

Explanation:

Both engines can be separately set to the idle

mode. This means that the diesel engine will still

keep running idle for a period of 5 min. after the

engine idle stop command was given.

Idle running can be started by operating S91 or

S93 at (input 11 active) or (input 12 active), respectively.

However, this will only be possible if the DSL (load

pressure switch) is not active (the load pressure

switch does no longer exist as a component but

will only be generated within the program).

The DSL will be inactive whenever no control commands are raised from the cabin through the manual levers and pedals.

To cancel the idle running mode you must either

actuate the control levers for at least 2 sec. or

press the engine stop pushbutton (input 9 active)

or (input 10 active), respectively.

If one of the lock-up valves on the

hydraulic tank (input 13 or input 14

or input 15) is closed while the

engines are running, the respective

engine will be stopped, restarting

being disabled.

Never close the lock-up valves

while the engine is running as

damage may be caused by the

idling down of the engine during

the stopping process.

When the fuel valves are locked at

their open positions, never close a

lock-up valve. In this case, the engines cannot be stopped by the electrical de-energising of the fuel valves.

The outputs (output 43 active) or (output 44 active), respectively, will signal readiness for the idle

running mode.

If the idle running time elapses without any interruption the relays for the engine electronics will be

de-energized via the outputs (output 41) or (output

42), respectively, and the motor will stop.

Even though the control voltage in key-operated

switch circuit # 15 ("ignition voltage") is turned off

after idle operation had already been initiated (output 43 active) or (output 44 active), respectively,

the control system will still be supplied through #

30 (battery voltage) for 5 min. (idle running time).

After this period, the control system will switch off

automatically. If one of the two emergency stop

pushbuttons (input 6 active) is actuated both diesel engines will be stopped immediately, no matter

whether "idle" has already been activated or not.

Page 9.3.1 - 10

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

9.3.1.5

PROGRAMMABLE LOGIC CONTROLLER PLC

LED indicators on the PLC

Fig. 4 shows the LED arrangement on the PLC.

Fig. 4

640022

As soon as the key-operated ignition switch is turned on in the operator's cabin, the green "ON" LED indicates that the control unit is supplied with 24 V. At the same time, the PLC undergoes an initialization run.

During this time, the "BUS" LED will be blinking several times. After successful initialization of the PLC, the

"ON" and the "BUS" LEDs will be lit.

Input and output status colour codes

The LED at the digital input/output is OFF.

The LED at the digital input is ON.

The LED at the digital output is ON.

Note: The statuses of the analog inputs and outputs as well as the power supply status are NOT indicated by LEDs.

On the following pages, the typical switching states of the PLC's inputs and outputs are listed in dependence

of the operating status of the excavator.

Figs. 5 to 12 show the LED codes for the PLC's inputs and outputs.

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

Page 9.3.1 - 11

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

9.3.1.6

LED codes for different scenarios

The supply voltage is on (the key-operated switch is ON).

Fig. 5

640023

Active input signals

Input 5

Input 13

Input 14

Input 15

Power supply (+15) has been turned on by key-operated switch.

Left lock-up valve on hydraulic tank OPEN.

Right lock-up valve on hydraulic tank OPEN.

Middle lock-up valve on hydraulic tank OPEN.

Active output signals

Output 38

Output 45

Page 9.3.1 - 12

PLC self-holding state.

Lamp test (ON for 5 seconds).

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Only LH drive engine being started

Fig. 6

640024

Constant LED indicators

Input 5

Input 13

Input 14

Input 15

Output 41

Output 38

Output 46

Power supply (+15) has been turned on by key-operated switch.

Left lock-up valve on hydraulic tank OPEN.

Right lock-up valve on hydraulic tank OPEN.

Middle lock-up valve on hydraulic tank OPEN.

LH engine electronics ON.

PLC self-holding state.

Cabinet fan.

Changing LED indicators

Input 7

Output 39

Input 19

Input 20

Output 47

Output 48

Output 49

LH engine ON start pushbutton.

LH engine ON starter relay as long as S5 (input 7) is engaged.

Lubrication initiator 2 (either input 19 or input 20, depending on lubrication system state).

Lubrication initiator 1.

Lubrication ON.

Lubrication bypass valve.

Lubrication reversing valve (only for line B lubrication).

Important: Input 6 (emergency stop) must be off to start the engines!

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

Page 9.3.1 - 13

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Only RH drive engine being started

Fig. 7

640025

Constant LED indicators

Input 5

Input 13

Input 14

Input 15

Output 42

Output 38

Output 46

Power supply (+15) has been turned on by key-operated switch.

Left lock-up valve on hydraulic tank OPEN.

Right lock-up valve on hydraulic tank OPEN.

Middle lock-up valve on hydraulic tank OPEN.

RH engine electronics ON.

PLC self-holding state.

Cabinet fan.

Changing LED indicators

Input 8

Output 40

Input 19

Input 20

Output 47

Output 48

Output 49

RH engine ON start pushbutton.

RH engine ON starter relay as long as S6 (input 8) is engaged.

Lubrication initiator 2 (either input 19 or input 20, depending on lubrication system state).

Lubrication initiator 1.

Lubrication ON.

Lubrication bypass valve.

Lubrication reversing valve (only for line B lubrication).

Important: Input 6 (emergency stop) must be off to start the engines!

Page 9.3.1 - 14

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

LH engine being stopped

Fig. 8

640026

Constant LED indicators

Input 5

Input 13

Input 14

Input 15

Output 38

Power supply (+15) has been turned on by key-operated switch.

Left lock-up valve on hydraulic tank OPEN.

Right lock-up valve on hydraulic tank OPEN.

Middle lock-up valve on hydraulic tank OPEN.

PLC self-holding state.

Changing LED indicators

Input 9

Input 19

Input 20

LH engine OFF stop pushbutton.

Lubrication initiator 2 (either input 19 or input 20, depending on lubrication system state).

Lubrication initiator 1.

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

Page 9.3.1 - 15

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

RH engine being stopped

Fig. 9

640027

Constant LED indicators

Input 5

Input 13

Input 14

Input 15

Output 38

Power supply (+15) has been turned on by key-operated switch.

Left lock-up valve on hydraulic tank OPEN.

Right lock-up valve on hydraulic tank OPEN.

Middle lock-up valve on hydraulic tank OPEN.

PLC self-holding state.

Changing LED indicators

Input 10

Input 19

Input 20

Page 9.3.1 - 16

RH engine OFF stop pushbutton.

Lubrication initiator 2 (either input 19 or input 20, depending on lubrication system state).

Lubrication initiator 1.

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Centralized lubrication system lubricating through line A

(Requirement: Both engines must be running.)

Fig. 10

640028

Constant LED indicators

Input 5

Input 13

Input 14

Input 15

Output 41

Output 42

Output 38

Output 46

Power supply (+15) has been turned on by key-operated switch.

Left lock-up valve on hydraulic tank OPEN.

Right lock-up valve on hydraulic tank OPEN.

Middle lock-up valve on hydraulic tank OPEN.

LH engine electronics ON.

RH engine electronics ON.

PLC self-holding state.

Cabinet fan.

Changing LED indicators

Input 19

Input 20

Output 47

Output 48

Lubrication initiator 2 (switching off when lubrication is being executed through line A).

Lubrication initiator 1 (switching on when lubrication is being executed through line A, and

lubrication pump still running for 22 sec.).

Lubrication ON.

Lubrication bypass valve.

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

Page 9.3.1 - 17

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Centralized lubrication system lubricating through line B

(Requirement: Both engines must be running.)

Fig. 11

640029

Constant LED indicators

Input 5

Input 13

Input 14

Input 15

Output 41

Output 42

Output 38

Output 46

Power supply (+15) has been turned on by key-operated switch.

Left lock-up valve on hydraulic tank OPEN.

Right lock-up valve on hydraulic tank OPEN.

Middle lock-up valve on hydraulic tank OPEN.

LH engine electronics ON.

RH engine electronics ON.

PLC self-holding state.

Cabinet fan.

Changing LED indicators

Input 20

Input 19

Output 47

Output 48

Output 49

Page 9.3.1 - 18

Lubrication initiator 1 (switching off when lubrication is being executed through line B).

Lubrication initiator 2 (switching on when lubrication is being executed through line B, and

lubrication pump still running for 22 sec.).

Lubrication ON.

Lubrication bypass valve.

Lubrication reversing valve.

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Lights: (Maintenance light, cabin light, ladder light)

(Requirement: Both engines are OFF.)

Fig. 12

640030

Constant LED indicators

Input 5

Input 13

Input 14

Input 15

Output 38

Output 56

Output 55

Output 54

Power supply (+15) has been turned on by key-operated switch.

Left lock-up valve on hydraulic tank OPEN.

Right lock-up valve on hydraulic tank OPEN.

Middle lock-up valve on hydraulic tank OPEN.

PLC self-holding state.

Maintenance light (set (light ON) and reset (light OFF) by input 24).

Cabin light (set (light ON) and reset (light OFF) by input 22).

Ladder light (set (light ON) by input 21 and automatically reset (light OFF) after 3 min.).

Changing LED indicators

Input 24

Input 22

Input 21

ON as long as one of the maintenance light pushbuttons is being pressed.

ON as long as one of the cabin light pushbuttons is being pressed.

ON as long as one of the ladder light pushbuttons is being pressed.

Important: You can also activate the maintenance and cabin lights when the ignition voltage is off. For this

purpose, just keep one of the light pushbuttons pressed for at least 3 seconds. The PLC will then change

into its self-holding state. To switch off the light press the same pushbutton again. The ladder light can also

be activated for 3 seconds if you press one of the ladder light pushbuttons. The self-holding state of the PLC

will be automatically reset after the 3 minutes have elapsed.

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

Page 9.3.1 - 19

9.3.1

9.3.1.7

PROGRAMMABLE LOGIC CONTROLLER PLC

Configuring the PLC and fault diagnosis by means of the PLC

There are two options to configure the PLC. The PLC can bee used for troubleshooting by sending status

requests.

Troubleshooting:

The BCS screen can be used for troubleshooting.

To enable status requests first call up the PLC menu from the BCS.

1. Press the "SERV" key (red arrow).

2. Select item 9, "Service Terex" (blue arrow).

3. Enter your PIN.

Fig. 13

Page 9.3.1 - 20

640039en

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

4. From the newly appearing "Service Terex" submenu, select item 10, "PLC" (red arrow).

Fig. 14

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

640040en

Page 9.3.1 - 21

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

5. Now, the status screen of the PLC will appear. To facilitate quick fault diagnosis you can read PLC error

and status messages on this screen.

In addition, if the lubrication system is in the pause cycle, you can read the remaining pause time.

Fig. 15

Page 9.3.1 - 22

640041en

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

6. Actuate the "DOWN" button to open the "PLC I/O Digital" screen. This screen displays the digital inputs

and outputs of the PLC module together with their associated functions. The example depicts the activity

of the lamp test output (red arrow).

Fig. 16

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

640042en

Page 9.3.1 - 23

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

7. Press the "DOWN" button again to open the "PLC I/O Analog" screen. This screen shows the analog

inputs and outputs of the PLC module. The example indicates analog input 57 (red arrow) which represents the voltage value of the left-hand diesel fuel tank filling level sensor.

Fig. 17

640043en

8. List of analog inputs:

Analog input 57: LH diesel fuel tank level sensor, 1.0 V = 0 % filling level, 10.0 V = 100 % filling level.

(Thus, a voltage below 1.0 V indicates a fault/cable break.)

Analog input 59: RH diesel fuel tank level sensor, 1.0 V = 0 % filling level, 10.0 V = 100 % filling level.

(Thus, a voltage below 1.0 V indicates a fault/cable break.)

Analog input 61: Superstructure lubrication pressure, 4.0 mA = 0 bar, 20 mA = 600 bar.

(Thus, a current below 4.0 mA indicates a fault/cable break.)

Analog input 63: Undercarriage lubrication pressure, 4.0 mA = 0 bar, 20 mA = 600 bar.

(Thus, a current below 4.0 mA indicates a fault/cable break.)

Analog input 65:

Page 9.3.1 - 24

Grease container level sensor, 4.0 mA = 0 % filling level, 20 mA = 100 % filling level.

(Thus, a current below 4.0 mA indicates a fault/cable break.)

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Option 1:

To configure the PLC open the "PLC Configuration" window at level 2.

1. Select item 11, "Configure Device" (red arrow) on the "SERVICE Terex" screen.

2. Enter your PIN.

Fig. 18

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

640044en

Page 9.3.1 - 25

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

3. Select item 8, "PLC Configuration".

Fig. 19

Page 9.3.1 - 26

640045en

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

This will open the configuration window where you can make the following settings:

Grease container level sensor

Lubrication undercarriage

Lubrication cycle time

Type of excavator

Type of engine

Yes/No

Yes/No

300 2400 s

RH 90/120/170/200/340

Cummins/Caterpillar

These settings are only made once at the factory and do not have to be changed later.

For testing and service purposes, it may, however, become necessary to use different configuration values.

Fig. 20

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

640046en

Page 9.3.1 - 27

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Option 2:

A second way how to configure the PLC or to perform fault diagnosis is offered by the optionally available

Electrical Diagnostic System (EDS).

In addition to a PC, the following will be required:

1.

2.

3.

EDS software (for Windows)

USB PC-CAN dongle

RS232 serial cable, 1:1

Fig. 21

Page 9.3.1 - 28

S/N: 2768865

S/N: 2482239

S/N: 3685323

640047

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

With help of the EDS, you can, in addition to the PLC data, read out of the CAN bus system other data of the

remaining electronic circuitry. Among other items, the program includes a BCS reader. This bilingual program can be switched from German to English or vice versa. The example below shows a shot of the PLC

DATA screen in the EDS.

Fig. 22

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

640048en

Page 9.3.1 - 29

9.3.1

PROGRAMMABLE LOGIC CONTROLLER PLC

Page 9.3.1 - 30

RH 120 E Diesel - 3668515en.doc - (01) - 01.06

You might also like

- PCCP - Simulator OperationDocument6 pagesPCCP - Simulator OperationnaveenNo ratings yet

- INLINE 5 Troubleshooting Guide PDFDocument5 pagesINLINE 5 Troubleshooting Guide PDFFernando BatistaNo ratings yet

- Rogrammabl e Ogic OntrollersDocument60 pagesRogrammabl e Ogic OntrollersSudarshan NavaleNo ratings yet

- Pib4169 Eam211 PDFDocument2 pagesPib4169 Eam211 PDFÁngelNo ratings yet

- Generator Set 3500Document13 pagesGenerator Set 3500Jhon Richard Chambi Paco100% (1)

- Dse Configuration Suite PC Software Installation Operation Manual Dse7310Document38 pagesDse Configuration Suite PC Software Installation Operation Manual Dse7310Irish ToleroNo ratings yet

- Electrical SchemaDocument9 pagesElectrical SchemaYacob PangihutanNo ratings yet

- Engine Reprogramming Tool Readme PDFDocument27 pagesEngine Reprogramming Tool Readme PDFMarcos Messias Valério100% (1)

- DCS Egypt PDFDocument94 pagesDCS Egypt PDFMiliani AhmedNo ratings yet

- Cat Elec Inst PanelDocument18 pagesCat Elec Inst PanelImad Hmd100% (1)

- CAT Diagnostic ECO Tools 11pgDocument11 pagesCAT Diagnostic ECO Tools 11pgRegulo TrujilloNo ratings yet

- RC12-10 30Document24 pagesRC12-10 30NikolayNo ratings yet

- Ge Mark VieDocument43 pagesGe Mark VieKevin Ngo100% (1)

- Main Valve Adjustment Procedure of Mark VIDocument19 pagesMain Valve Adjustment Procedure of Mark VImohamed abourayaNo ratings yet

- Configuratore - IA INTL 01 07 2019 - v1.00.00 PDFDocument406 pagesConfiguratore - IA INTL 01 07 2019 - v1.00.00 PDFDennys EstradaNo ratings yet

- CANopen User GuideDocument53 pagesCANopen User GuideDavid MacLean100% (2)

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerAndrei Bleoju100% (1)

- Answer Drives S.R.L. - Partially Owned by Ansaldo Sistemi Industriali - S.p.ADocument4 pagesAnswer Drives S.R.L. - Partially Owned by Ansaldo Sistemi Industriali - S.p.AMohamed AlkharashyNo ratings yet

- Emcp TrianingDocument31 pagesEmcp TrianingMr.Thawatchai hansuwan100% (1)

- Deep Sea Electronics: Model 5220 Installation and Configuration InstructionsDocument2 pagesDeep Sea Electronics: Model 5220 Installation and Configuration InstructionsNaing Min HtunNo ratings yet

- RENR8046 06 CAT C15 C18 Electric SchematicDocument2 pagesRENR8046 06 CAT C15 C18 Electric SchematicAE67% (3)

- SCADA Intouch ConnectionDocument19 pagesSCADA Intouch ConnectionAriel ViollaNo ratings yet

- Downloadable Version - Electronic H&S IdenitfierDocument13 pagesDownloadable Version - Electronic H&S IdenitfierasadiqbalansariNo ratings yet

- Operation Modes Easy Gen-3200Document34 pagesOperation Modes Easy Gen-3200Raul MontoyaNo ratings yet

- GE MARK VI CONTROL INTERFACE OPTIONSDocument8 pagesGE MARK VI CONTROL INTERFACE OPTIONStriplbingaziNo ratings yet

- Cimplicity HMI PDFDocument36 pagesCimplicity HMI PDFazizi reNo ratings yet

- Lincoln ManualDocument48 pagesLincoln ManualM RefaiNo ratings yet

- Special Instruction: Installation and Initial Start-Up Procedure For G3500 A3 EnginesDocument36 pagesSpecial Instruction: Installation and Initial Start-Up Procedure For G3500 A3 EnginesDjebali MouradNo ratings yet

- Detail Writeup of MarkvieDocument128 pagesDetail Writeup of MarkvieramkrishnaNo ratings yet

- SYMC Eu IV DTC Description V1 070307Document28 pagesSYMC Eu IV DTC Description V1 070307Sooziet RegmiNo ratings yet

- Volvo D12D500 Diesel Engine Specs and FeaturesDocument2 pagesVolvo D12D500 Diesel Engine Specs and Featuresmaxim ivanovNo ratings yet

- PCS7 Migration V6.1 to V8.0 with Batch Fox ControlDocument30 pagesPCS7 Migration V6.1 to V8.0 with Batch Fox Controlkrshna999100% (3)

- Garagekey Groove User Manual EnglishDocument10 pagesGaragekey Groove User Manual EnglishpazaNo ratings yet

- Kenr5934 02Document12 pagesKenr5934 02zeka100% (1)

- Gas Turbine 11 PDFDocument59 pagesGas Turbine 11 PDFajo zinzoNo ratings yet

- CAN Data Link Circuit - Test PDFDocument6 pagesCAN Data Link Circuit - Test PDFHafid AnwarNo ratings yet

- Gencomm Control KeysDocument4 pagesGencomm Control Keyskazishah100% (1)

- User's Guide: Group 5 ControllerDocument36 pagesUser's Guide: Group 5 Controllerlucien altidorNo ratings yet

- System Digital ControlDocument8 pagesSystem Digital ControlalfredohdnNo ratings yet

- System 57 5701 Control System ManualDocument213 pagesSystem 57 5701 Control System ManualRahul DevaNo ratings yet

- S digital+Governor+Ed1SIDocument8 pagesS digital+Governor+Ed1SIazeemmet9924No ratings yet

- Parts List - WWW - Powerplant.partsDocument44 pagesParts List - WWW - Powerplant.partsQuinhan Ltd100% (1)

- Test ECM Mode.Document10 pagesTest ECM Mode.Jorge EspinozaNo ratings yet

- A EG3200 Section 4 Config Toolkit (NXPowerLite)Document39 pagesA EG3200 Section 4 Config Toolkit (NXPowerLite)Halit Yalçınkaya100% (1)

- Schneider Altistart 48Document51 pagesSchneider Altistart 48Mas ChokyNo ratings yet

- 2301a A Setting ManualDocument40 pages2301a A Setting ManualRs Shetty100% (1)

- Murphy pv101C Users GuideDocument47 pagesMurphy pv101C Users GuideRafael StriederNo ratings yet

- EST To Flash A PowerWizardDocument2 pagesEST To Flash A PowerWizardmahmoud khtaNo ratings yet

- Cat Electronic Modular Control Panel (EMCP) 4.3 Upgrade KitDocument2 pagesCat Electronic Modular Control Panel (EMCP) 4.3 Upgrade KitKaung KharNo ratings yet

- c13 Cat Engine Brochure PDFDocument6 pagesc13 Cat Engine Brochure PDFJosè Manuel Coronado Saucedo100% (1)

- Conext CL Firmware 2.6.4 Upgrade ProcedureDocument15 pagesConext CL Firmware 2.6.4 Upgrade Proceduremumi87No ratings yet

- ECU List - 5.8 - New FeaturesDocument4 pagesECU List - 5.8 - New FeaturesMahesh MirajkarNo ratings yet

- DYNS 30000 CalibratorDocument4 pagesDYNS 30000 Calibratorgolu201100% (2)

- 09.1 PLC - Technical HandbookDocument30 pages09.1 PLC - Technical HandbookSandoval Ramos Eddy100% (1)

- GEMPAC Training: Terminations and Their FunctionsDocument25 pagesGEMPAC Training: Terminations and Their FunctionsjengandxbNo ratings yet

- Neuron II Elgi CompressorDocument42 pagesNeuron II Elgi CompressorOswaldo69% (16)

- Alpha Lubricator System Operation Manual MC EnginesDocument167 pagesAlpha Lubricator System Operation Manual MC EnginesHarpreet SinghNo ratings yet

- Bosch CC 100 MDocument213 pagesBosch CC 100 MMihaela Coada-GalbenaNo ratings yet

- ADEC Advanced Diesel Engine ControllerDocument49 pagesADEC Advanced Diesel Engine Controllerpevare100% (12)

- Casio FX-9700GH Calculator ManualDocument188 pagesCasio FX-9700GH Calculator ManualLuna StoneNo ratings yet

- Inspección de equipos de elevación y desplazamiento aéreoDocument3 pagesInspección de equipos de elevación y desplazamiento aéreoRodrigoCastilloAcostaNo ratings yet

- B0700ax BDocument38 pagesB0700ax BRodrigoCastilloAcostaNo ratings yet

- Sick 518Document1 pageSick 518RodrigoCastilloAcostaNo ratings yet

- B0700BG BDocument64 pagesB0700BG BRodrigoCastilloAcostaNo ratings yet

- Radio ControlDocument1 pageRadio ControlRodrigoCastilloAcostaNo ratings yet

- B0700ap ADocument76 pagesB0700ap ARodrigoCastilloAcostaNo ratings yet

- Parametros Nuevos Epm 7000Document3 pagesParametros Nuevos Epm 7000RodrigoCastilloAcostaNo ratings yet

- B0700ap ADocument76 pagesB0700ap ARodrigoCastilloAcostaNo ratings yet

- B0700ay BDocument44 pagesB0700ay BRodrigoCastilloAcostaNo ratings yet

- Sick ReflexDocument1 pageSick ReflexRodrigoCastilloAcostaNo ratings yet

- SRM 6000Document2 pagesSRM 6000RodrigoCastilloAcostaNo ratings yet

- Parametros Nuevos Epm 7000Document3 pagesParametros Nuevos Epm 7000RodrigoCastilloAcostaNo ratings yet

- HONEYWELLDocument1 pageHONEYWELLRodrigoCastilloAcostaNo ratings yet

- EnerVista UR Setup - Data Loggmotor2 Cv17Document33 pagesEnerVista UR Setup - Data Loggmotor2 Cv17RodrigoCastilloAcostaNo ratings yet

- FS8W CutsheetsDocument8 pagesFS8W CutsheetsRodrigoCastilloAcostaNo ratings yet

- Read MeDocument1 pageRead MeRodrigoCastilloAcostaNo ratings yet

- Compare HoperDocument1 pageCompare HoperRodrigoCastilloAcostaNo ratings yet

- ContentsDocument3 pagesContentsRodrigoCastilloAcostaNo ratings yet

- User Manual EN PDFDocument604 pagesUser Manual EN PDFAnonymous zQ8BonNo ratings yet

- 554-43-Hoja 1 de 2Document1 page554-43-Hoja 1 de 2RodrigoCastilloAcostaNo ratings yet

- Release NotesDocument13 pagesRelease NotesRodrigoCastilloAcostaNo ratings yet

- VFD and PLC Panel SchematicDocument1 pageVFD and PLC Panel SchematicRodrigoCastilloAcostaNo ratings yet

- LicenceDocument2 pagesLicenceRodrigoCastilloAcostaNo ratings yet

- 554-45-Hoja 1 de 2Document1 page554-45-Hoja 1 de 2RodrigoCastilloAcostaNo ratings yet

- Programacion Calentadores Programacion Calentadores Cleaver-Brooks Cleaver-BrooksDocument2 pagesProgramacion Calentadores Programacion Calentadores Cleaver-Brooks Cleaver-BrooksRodrigoCastilloAcostaNo ratings yet

- Tp0274 Mme 002 1 - Parte41 (Semaforos Descarga Chancador)Document2 pagesTp0274 Mme 002 1 - Parte41 (Semaforos Descarga Chancador)RodrigoCastilloAcostaNo ratings yet

- VFD and PLC Panel SchematicDocument1 pageVFD and PLC Panel SchematicRodrigoCastilloAcostaNo ratings yet

- 2 EquipmentList MV MCCDocument6 pages2 EquipmentList MV MCCRodrigoCastilloAcostaNo ratings yet

- March 17, 2016 Strathmore TimesDocument24 pagesMarch 17, 2016 Strathmore TimesStrathmore TimesNo ratings yet

- CalderaDocument56 pagesCalderaEsteban TapiaNo ratings yet

- Chapter 14 The Communist Manifesto As International Relations TheoryDocument12 pagesChapter 14 The Communist Manifesto As International Relations TheoryLaurindo Paulo Ribeiro TchinhamaNo ratings yet

- Sco 2Document15 pagesSco 2rkhandelwal9604No ratings yet

- The M.T Taco Food Truck Business Plan Project Business Plan DraftDocument23 pagesThe M.T Taco Food Truck Business Plan Project Business Plan DraftAbhishek Prasad RoyNo ratings yet

- FINS 2624 Quiz 2 Attempt 2 PDFDocument3 pagesFINS 2624 Quiz 2 Attempt 2 PDFsagarox7No ratings yet

- What Is RTN/Microwave TechnologyDocument27 pagesWhat Is RTN/Microwave TechnologyRavan AllahverdiyevNo ratings yet

- SIC CodeDocument424 pagesSIC CodeZohra MerchantNo ratings yet

- Koh Pich Construction Company Cambodia-China Polytechnic University Daily Activities ReportDocument7 pagesKoh Pich Construction Company Cambodia-China Polytechnic University Daily Activities ReportNhoek RenNo ratings yet

- The Hero of the Snore TangoDocument22 pagesThe Hero of the Snore TangoFlora Mae LacostalesNo ratings yet

- داينمك الملزمة كاملةDocument79 pagesداينمك الملزمة كاملةarno assassin33% (3)

- Balfour Relocation Feasibility StudyDocument176 pagesBalfour Relocation Feasibility Studygreg32777No ratings yet

- 2nd Semester All Courses-100Document194 pages2nd Semester All Courses-100Ejiade PeterNo ratings yet

- Spectrophotometric Determination of Triclosan Based On Diazotization Reaction: Response Surface Optimization Using Box - Behnken DesignDocument1 pageSpectrophotometric Determination of Triclosan Based On Diazotization Reaction: Response Surface Optimization Using Box - Behnken DesignFitra NugrahaNo ratings yet

- Pancreatic NekrosisDocument8 pagesPancreatic Nekrosisrisyda_mkhNo ratings yet

- AUS Triboard ManuaDocument112 pagesAUS Triboard ManuaWan RidsNo ratings yet

- General Guidelines For Design and Construction of Concrete Diaphram (Slurry) WallsDocument108 pagesGeneral Guidelines For Design and Construction of Concrete Diaphram (Slurry) WallsharleyNo ratings yet

- Christmas Around the WorldDocument16 pagesChristmas Around the WorldVioleta Veljanovska100% (1)

- Radiesse Pálpebras Gox-8-E2633Document7 pagesRadiesse Pálpebras Gox-8-E2633Camila CrosaraNo ratings yet

- 5-in-1 Document Provides Lessons on Trees and Environmental ConservationDocument45 pages5-in-1 Document Provides Lessons on Trees and Environmental ConservationPriya DharshiniNo ratings yet

- Water System BOQ 16.12.2023 R0Document144 pagesWater System BOQ 16.12.2023 R0moinu85No ratings yet

- RLCraft v2.9 ChangelogDocument28 pagesRLCraft v2.9 ChangelogSơn TrươngNo ratings yet

- The Role of Women in The Livelihood Strategies of The House Hold: Case of Geressie Woreda, Gamo Zone, EthiopiaDocument95 pagesThe Role of Women in The Livelihood Strategies of The House Hold: Case of Geressie Woreda, Gamo Zone, Ethiopiaermias eshetu100% (3)

- Tenofovir Disoproxil Fumarate: Riefing - Nfrared BsorptionDocument4 pagesTenofovir Disoproxil Fumarate: Riefing - Nfrared BsorptionMostofa RubalNo ratings yet

- Boston Acoustic PDFDocument12 pagesBoston Acoustic PDFAdam StarkNo ratings yet

- Din en 1320-1996Document18 pagesDin en 1320-1996edcam13No ratings yet

- JKF8 Intelligent Reactive Power Compensation ControllerDocument4 pagesJKF8 Intelligent Reactive Power Compensation ControllerGuillermo Morales HerreraNo ratings yet

- Msds PentaneDocument6 pagesMsds PentaneMuhammad FikriansyahNo ratings yet

- Guía Fallas para Ricoh Aficio 220Document31 pagesGuía Fallas para Ricoh Aficio 220desechableNo ratings yet

- M700-70 Series Programming Manual (M-Type) - IB1500072-F (ENG)Document601 pagesM700-70 Series Programming Manual (M-Type) - IB1500072-F (ENG)Mert SertNo ratings yet